27 min read

Practical AI Applications and Use Cases in Procurement: A Complete Guide

AI transforms procurement with smart contracts, risk monitoring, and demand forecasting. Explore practical AI applications for simpler operations.

Procurement is no longer just about buying. Teams strive to make faster and more strategic decisions that improve efficiency and strengthen the bottom line. But with mountains of data, countless suppliers, and complex contracts, staying ahead can feel impossible.

That’s where Artificial Intelligence (AI) comes in. By combining machine learning, natural language processing, and predictive analytics, AI uncovers insights, predicts risks, and transforms how teams manage spending.

In this guide, we’ll explore the practical AI applications that are revolutionizing procurement operations today.

What is AI in procurement and why does it matter?

What are the main benefits of implementing AI in procurement?

What are the top AI use cases in procurement?

How is AI revolutionizing contract management?

What practical applications does AI have in purchase order processing?

What is AI‑powered OCR and how does it streamline procurement?

How does AI reduce Accounts Payable Days (DPO)?

How can AI improve supplier risk management?

What role does AI play in demand forecasting and planning?

How does generative AI enhance procurement communications and documentation?

Frequently asked questions

What is AI in procurement and why does it matter?

The primary purpose of artificial intelligence in procurement is to transform the way businesses manage their purchasing processes, supplier relationships, and spending decisions. The technology in question combines machine learning (ML) algorithms, natural language processing (NLP), and predictive analytics to automate routine tasks while extracting insights from procurement data.

AI in procurement analyzes patterns across a wide range of transactions to help procurement teams identify cost-saving opportunities, detect fraud, and even optimize supplier selection.

Traditional procurement systems are incapable of processing the sheer volume and complexity of information that a single modern supply chain produces. AI capabilities are supposed to become a helping hand in scenarios such as these to provide real-time visibility into a company’s spending patterns, supplier performance, and contract compliance. It’s a fundamental shift from manual and reactive operations to decision-making sequences that are much more predictive and automated.

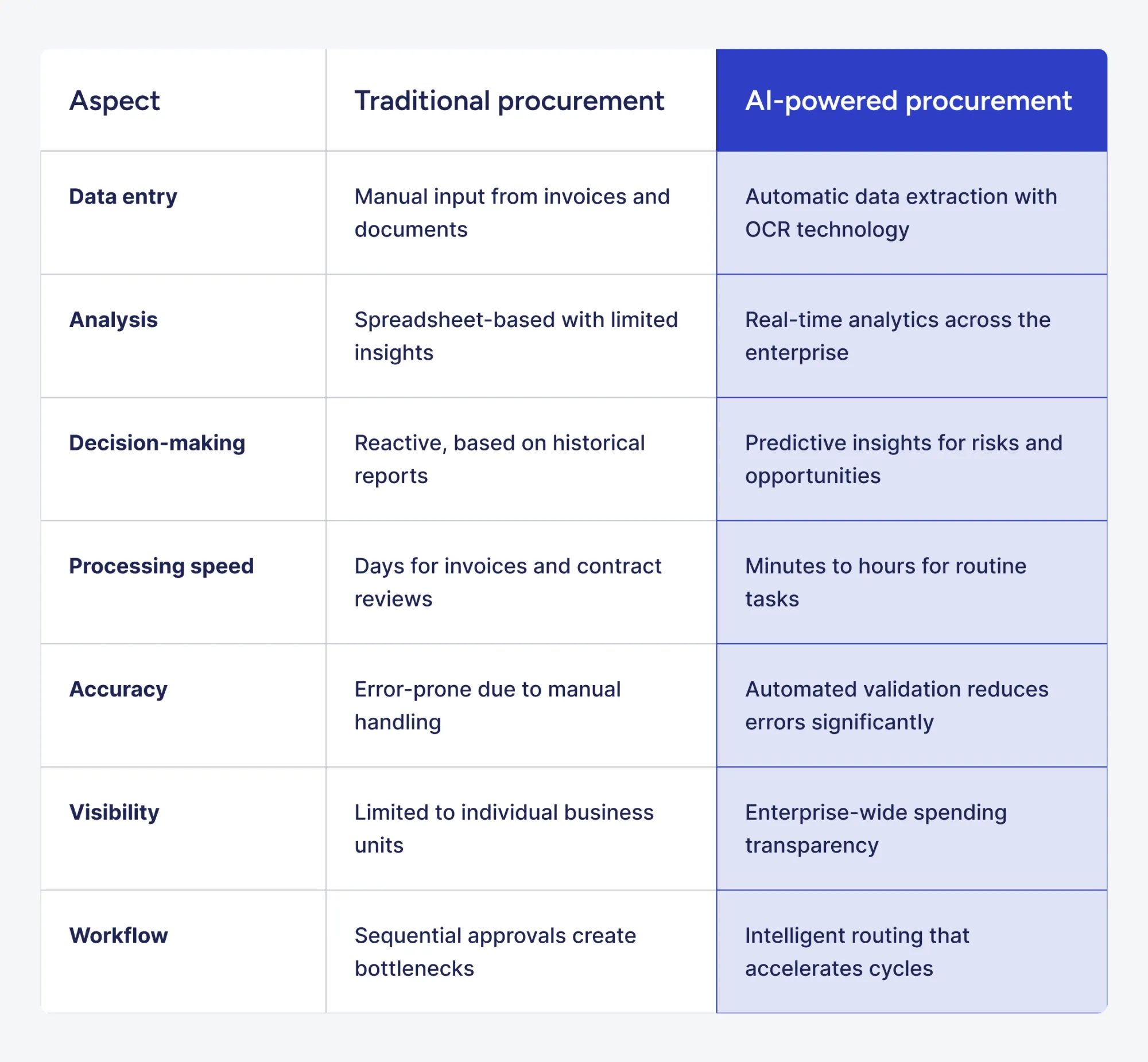

What are the key differences between traditional and AI-powered procurement?

The fundamental differences between traditional and AI-powered procurement are all about efficiency, accuracy, and strategic value. The following table offers a general overview of the most notable differences between the two approaches:

Organizations that implement AI-powered procurement capabilities can redirect their teams from routine administrative tasks to important strategic initiatives like supplier relationship management or cost efficiency.

What are the main benefits of implementing AI in procurement?

AI in procurement can offer genuine improvements when it comes to factors such as cost reduction, supplier management, risk mitigation, and spending control. Businesses that implement AI technology commonly report faster processing cycles, better accuracy, and improved visibility into procurement operations as a whole.

These benefits also extend beyond simple automation, transforming the way procurement teams manage relationships, make decisions, and respond to risks. With these benefits, procurement shifts from a purely administrative task to a strategic function that drives real business value.

How much can AI reduce procurement costs and cycle times?

AI manages to reduce procurement costs using a number of mechanisms to address labor expenses, operational inefficiencies, and error correction. The ability to automate certain repetitive tasks (data entry, purchase order matching, invoice processing) allows businesses to reallocate their resources toward more high-value activities.

Manual invoice processing tends to take days and multiple touchpoints, while AI-powered environments can do the same tasks in a matter of minutes with barely any human participation. Such time savings are compounded across thousands of transactions, showcasing massive improvements in terms of efficiency.

The results of cycle time reductions appear throughout the entire procurement process. Contract reviews that required days of manual work can now be completed in hours, with AI handling term extraction and issue detection.

Purchase requisitions also move through approval workflows much faster with an intelligent routing system. As a result, procurement teams respond more quickly to business needs and improve service delivery for internal stakeholders.

AI also helps reduce costs by improving accuracy. It minimizes errors in areas like data entry, duplicate payments, and invoice discrepancies. The technology uncovers savings opportunities, like favorable payment terms or volume discounts, that manual reviews might overlook. Teams can redirect time from error correction to strategic activities such as supplier negotiations and category management.

Can AI improve supplier relationship management and decision-making?

AI provides full visibility into supplier performance to enable data-driven decisions and transform supplier relationship management.

Traditional SRM tools depend on periodic reviews and limited metrics, leaving blind spots around supplier capabilities and risks. In contrast, AI-powered systems continuously monitor suppliers across multiple factors, helping procurement teams spot issues early and recognize high-performing partners.

The technology supports several major decision types that improve supplier relationships:

- Supplier consolidation: Analyzing spend patterns to determine optimal supplier counts.

- Negotiation timing: Identifying the favorable moment to renegotiate.

- Sourcing strategy: Determining the best mix of suppliers based on performance data.

- Supplier switching: Recognizing when performance or risk indicators warrant changes.

AI creates a complete 360-degree view of each supplier by consolidating data from procurement transactions, quality metrics, delivery performance, financial health, and external risk signals.

A comprehensive perspective makes vendor relations management far more nuanced than traditional approaches, which often focus only on price and delivery times. By now, 58% of AI implementations in supplier risk assessment or monitoring are already in production, showcasing the maturity of these capabilities in an enterprise environment.

Machine learning systems can recognize seasonal demand fluctuations, predict potential supply disruptions, and even suggest alternative suppliers whenever risks appear on the horizon. Such extensive predictive capability makes it possible to switch supplier relationship management from reactive problem-solving to proactive partnership development.

What role does AI play in risk mitigation and compliance?

AI improves both compliance and risk mitigation efforts by implementing continuous monitoring, pattern recognition, and automated validation for all procurement tasks. The technology works with many risk categories that could be a threat to organizational integrity or procurement effectiveness.

The most important risk categories AI solutions have to monitor are:

- Fraud risk: Duplicate invoices, fictitious vendors, and payment manipulation schemes.

- Financial risk: Supplier insolvency, credit issues, and payment default potential.

- Operational risk: Delivery failures, quality problems, and capacity constraints.

- Compliance risk: Regulatory violations, contract breaches, and policy deviations.

- Geopolitical risk: Trade restrictions, regional instability, and supply chain disruptions.

There is plenty of research highlighting the fact that organizations report reductions of 30-40% in fraud-related losses after implementing AI-powered fraud detection. AI can detect anomalies that manual reviews often miss, such as invoice patterns that suggest collusion or pricing discrepancies that may indicate overbilling. With companies losing around 5% of annual revenue to fraud (as of 2022), AI-powered detection and prevention become high-priority use cases.

Compliance monitoring also improves with AI through features like automated policy enforcement and deviation detection. These systems flag transactions that violate contract terms, regulatory requirements, or internal policies. This proactive approach helps prevent compliance issues instead of addressing them only after audits. AI also makes it easier to maintain comprehensive audit trails by documenting decision paths and approval chains to support regulatory reporting and internal controls.

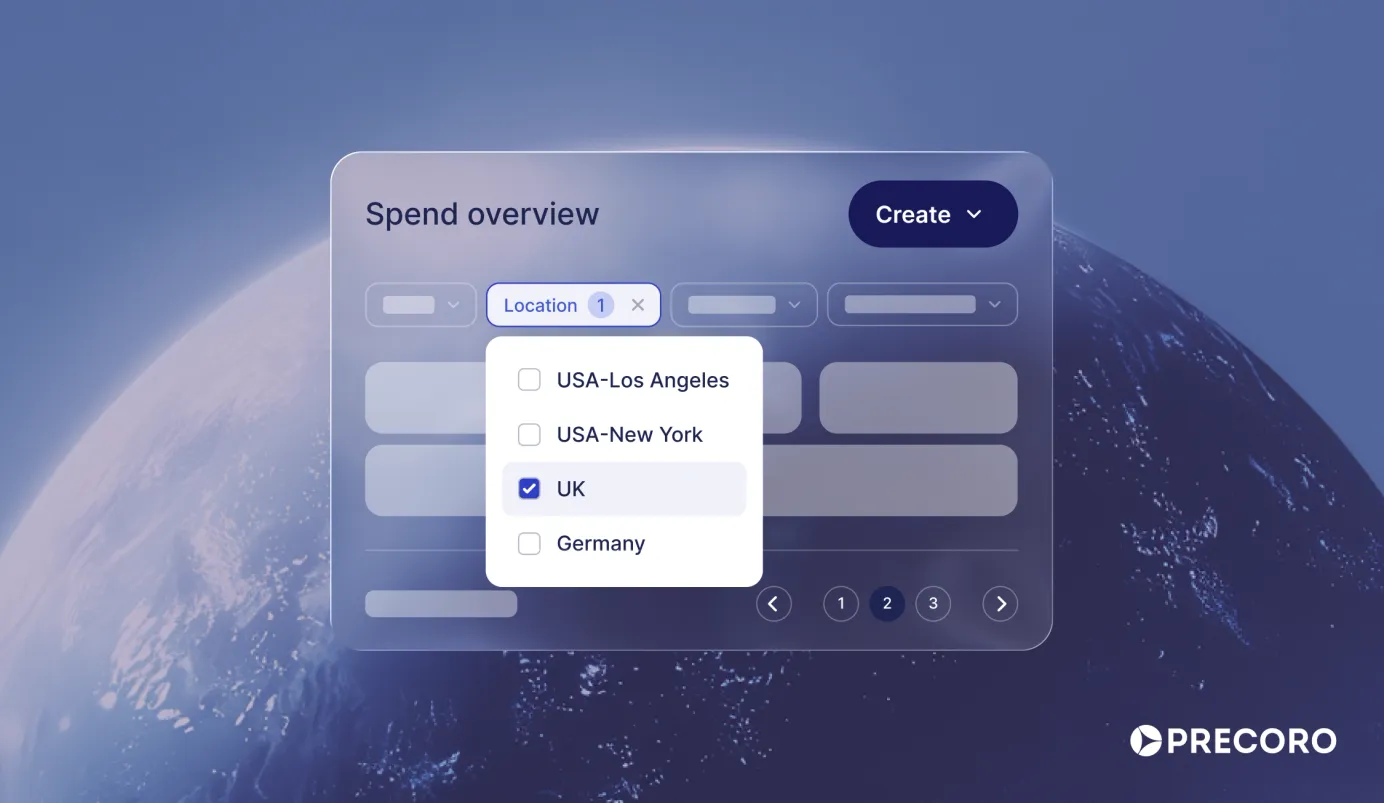

How does AI enhance spend visibility and control?

AI provides real-time visibility into procurement spending through advanced analytics and intelligent categorization across the organization. Traditional systems struggle to analyze spending patterns and often require manual data extraction and consolidation from multiple sources. AI-powered procurement platforms automate these steps and present actionable insights through dashboards and reports, enabling more informed decisions at every level of the organization.

The technology enhances spend visibility through several mechanisms:

- Real-time budget tracking shows remaining budgets by department, project, or category, helping prevent overspending and enabling proactive resource management.

- Intelligent spend classification categorizes purchases automatically and identifies patterns that manual review would miss.

- Excessive spending detection locates situations where purchases bypass approved channels or suppliers, allowing procurement teams to enforce compliance and capture volume discounts through preferred vendors.

Anomaly detection capabilities flag unusual spending patterns that may indicate fraud, errors, or policy violations. AI identifies transactions that deviate from historical norms, such as sudden price increases from established suppliers or purchases that exceed typical ranges for specific categories. The early warning enables procurement teams to investigate issues before they escalate into significant problems.

Spend visibility extends beyond transaction-level detail to strategic insights about supplier concentration, category performance, and cost-saving opportunities. Organizations gain clarity on which suppliers receive the most spend, where spending growth occurs, and how procurement performance compares across business units. This comprehensive visibility transforms procurement from a reactive ordering function to a strategic partner that drives cost optimization and supports business objectives.

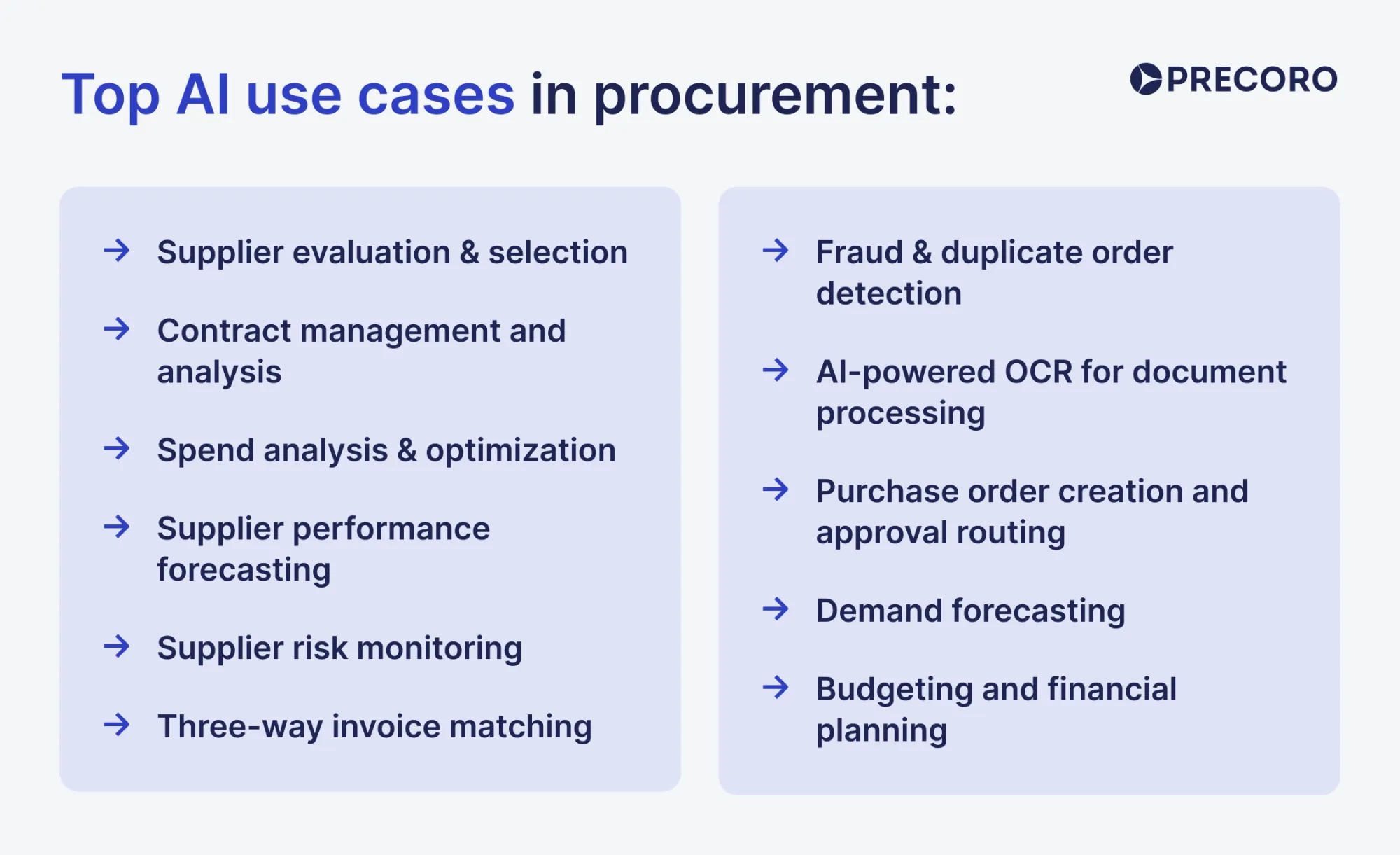

What are the top AI use cases in procurement?

AI applications in procurement range from supplier evaluation to spending optimization. The most common use cases address supplier selection, spend visibility, performance forecasting, and sourcing decisions. These applications deliver immediate value by automating complex analyses that traditional methods cannot perform at scale.

How can AI identify and qualify the best suppliers automatically?

AI evaluates potential suppliers and vendors using multiple criteria that extend beyond price comparisons. The systems analyze comprehensive data to create supplier profiles, including:

- Financial stability: Credit ratings, payment histories, and fiscal health indicators.

- Delivery performance: On-time delivery rates, lead time consistency, and fulfillment accuracy.

- Quality certifications: Industry standards, compliance credentials, and audit results.

- Production capacity: Manufacturing capabilities, scalability, and volume handling ability.

- Risk factors: Geographic concentration, single-source dependencies, and business continuity plans.

This multidimensional assessment enables procurement teams to identify qualified vendors quickly.

Automated scoring systems rank suppliers based on organizational goals. A company prioritizing sustainability might weigh environmental certifications heavily, while another focused on risk mitigation emphasizes financial health metrics. The scoring adapts to different procurement categories, which ensures relevant evaluation criteria for each purchasing need.

The qualification process happens continuously rather than during periodic reviews. AI monitors supplier data streams for changes in financial status, certifications, or performance indicators. When a potential supplier meets threshold requirements, the system flags them for procurement consideration. This proactive approach builds a pipeline of pre-qualified vendors ready for engagement.

The technology also identifies red flags that disqualify suppliers. Late payment histories, expired certifications, or inadequate capacity trigger automatic exclusions. Procurement teams receive filtered candidate lists rather than raw supplier databases, which accelerates the sourcing process and reduces vetting time.

What is AI-powered spend analysis and how does it work?

AI-powered spend analysis automatically categorizes and analyzes procurement transactions across the organization. Traditional spend analysis requires manual data extraction, cleaning, and classification, which consumes weeks of effort. AI systems process invoices, purchase orders, and payment records in hours, applying intelligent classification that recognizes spending patterns.

The technology identifies cost-saving opportunities through several mechanisms:

- Volume consolidation: Detecting multiple departments purchasing similar items from different suppliers.

- Price variance analysis: Highlighting identical products carrying different costs across business units.

- Contract compliance: Ensuring purchases follow negotiated terms and preferred supplier agreements.

- Tail spend optimization: Identifying low-value, high-frequency purchases that often go unnoticed.

Excessive spending becomes immediately visible when purchases bypass approved suppliers or contract terms. The system flags these transactions and quantifies the cost impact of non-compliance. Organizations recover savings by redirecting spending to contracted suppliers with negotiated rates.

Category-level insights reveal spending trends over time. Procurement teams see which categories experience cost increases, where spending concentrates, and which suppliers capture the most spend. The visibility supports strategic decisions about contract renewals, supplier consolidation, and category management priorities.

Modern procurement platforms integrate spend analysis with supplier performance data and market intelligence to provide comprehensive insights. The combination enables procurement teams to evaluate spending effectiveness alongside supplier relationship quality.

Can AI predict supplier performance and reliability?

AI predicts supplier performance by analyzing historical delivery data, quality metrics, and responsiveness patterns. The systems identify trends that indicate improving or declining performance before issues become critical:

- Delivery reliability: On-time performance trends, lead time consistency, and fulfillment accuracy.

- Quality metrics: Defect rates, return frequencies, and customer complaint patterns.

- Financial health: Payment behaviors, credit ratings, and financial statement trends.

- Responsiveness: Communication speed, issue resolution times, and adaptation to changes.

Early detection enables procurement teams to address problems proactively or shift volume to more reliable suppliers.

The predictions become more accurate as systems process additional data. Organizations implementing these capabilities report improved supplier relationship management and reduced supply disruptions. The technology shifts supplier management from reactive firefighting to strategic partnership development.

How does machine learning optimize sourcing strategies?

Machine learning evaluates multiple factors simultaneously to recommend optimal sourcing strategies. The analysis considers cost, risk, capacity, quality, and delivery performance across potential supplier combinations. This multi-factor optimization identifies sourcing approaches that balance competing priorities rather than optimizing single variables.

Scenario modeling tests different sourcing strategies against various conditions. Organizations see projected outcomes for single-source versus multi-source approaches, regional concentration versus geographic diversification, or incumbent versus new supplier selection. The modeling quantifies trade-offs between cost savings and risk exposure.

Recommendation engines suggest supplier portfolios that meet organizational objectives. A company prioritizing cost reduction receives different recommendations than one emphasizing supply security or sustainability. The systems adjust recommendations as business priorities change or market conditions shift.

The technology also identifies optimal order quantities and timing based on demand forecasts, supplier capacity, and pricing patterns. Organizations avoid both stockouts and excess inventory by aligning purchasing decisions with predicted needs. This demand-supply matching improves working capital efficiency and reduces waste.

Real-time optimization responds to changing conditions faster than manual planning processes. When disruptions occur or opportunities emerge, the systems recalculate optimal sourcing strategies and present updated recommendations. This agility enables procurement teams to maintain effectiveness despite volatility.

How is AI revolutionizing contract management?

Contract management represents one of the most impactful applications for AI in procurement. The technology addresses long-standing challenges in contract visibility, compliance monitoring, and risk identification. Organizations gain control over contract portfolios that previously existed across scattered systems and file repositories.

What is intelligent contract analysis and what problems does it solve?

Intelligent contract analysis solves six critical problems that plague traditional contract management:

- Missed renewals

- Unfavorable terms

- Compliance gaps

- Manual review bottlenecks

- Lost contract value

- Scattered contract data

Missed renewals and auto-renewals create financial exposure when organizations lose negotiation leverage. According to Deloitte research, 62% of companies have difficulty locating previously approved agreements. Missing an opt-out date can lead to unwanted contract extensions on poor terms. AI tracks renewal dates automatically and sends alerts before critical deadlines pass.

Unfavorable terms are often buried in dense legal language that manual reviews can miss. Auto-renewal clauses, penalty provisions, unlimited liability terms, and vague service warranties create risks that typically appear only during disputes. AI can extract these clauses during contract intake and flag problematic language before agreements are signed.

Compliance gaps appear when contracts lack required protections. Absent data protection clauses, incomplete confidentiality terms, and missing termination rights expose organizations to regulatory violations. The technology performs gap analysis against standard templates and suggests language to address deficiencies.

Manual review bottlenecks slow procurement cycles and consume legal resources. The abovementioned report from Deloitte also states that contracting inefficiencies cost organizations an average of $1.5 million in revenue annually. One organization reduced contract review time from 2-3 days to 1-2 hours by implementing AI-assisted analysis.

Lost contract value occurs when organizations fail to claim discounts, rebates, or service credits. Manual tracking can overlook recoverable entitlements and escalation clauses, but AI identifies them systematically.

Scattered contract data prevents centralized visibility when agreements exist in emails, shared drives, and legacy systems. Teams risk operating under outdated terms or duplicating negotiations. AI creates unified repositories with intelligent search capabilities that locate relevant contracts in seconds.

How can AI automate contract review and approval workflows?

AI automates contract workflows by extracting key information, routing documents intelligently, and flagging issues that require attention.

Clause extraction identifies critical contract elements automatically. The systems recognize payment terms, renewal conditions, liability provisions, and confidentiality requirements without manual reading. Extracted data populates structured fields that enable analysis across contract portfolios.

Risk scoring evaluates contract language against organizational standards and legal requirements. Deviations from approved templates receive risk ratings that prioritize legal review. High-risk contracts move to specialized reviewers while standard agreements flow through automated approvals.

Version comparison tracks changes between contract drafts and highlights modifications. Procurement teams see exactly what suppliers altered in redlined documents. This feature prevents subtle language changes from introducing unfavorable terms into agreements.

Intelligent routing directs contracts to appropriate approvers based on value thresholds, risk levels, and contract types. The system removes the need for manual forwarding and shortens approval cycles. Automated reminders keep contracts from getting stuck in approval queues.

Workflow automation maintains audit trails that document every review step and approval decision. Organizations demonstrate compliance with internal controls and regulatory requirements through complete transaction histories. The transparency supports both internal audits and external examinations.

Can AI predict contract risks and renewal opportunities?

AI predicts contract risks by monitoring obligations, analyzing compliance patterns, and tracking performance against terms.

Expiration tracking notifies teams of contracts approaching renewal dates before they become urgent. The systems calculate optimal renegotiation windows based on notice periods and market conditions. Procurement teams receive advance warning that enables strategic planning rather than emergency renewals.

Risk indicator detection flags clauses that create potential exposure, including:

- Automatic renewal provisions without opt-out windows

- Penalty terms exceeding industry standards

- Payment conditions that favor suppliers disproportionately

- Indemnification clauses creating unlimited liability

- Service level agreements lacking enforcement mechanisms

Value opportunity identification reveals renewal leverage points. The technology analyzes usage patterns, spending levels, and supplier performance to recommend renegotiation strategies. Organizations approach renewals armed with data about actual contract utilization and vendor compliance.

Obligation monitoring tracks deliverables, milestones, and commitments that both parties must fulfill. Alerts trigger when obligations approach due dates or when compliance issues emerge. This proactive management prevents breaches and maintains relationship quality.

Gartner predicts that 50% of organizations will use AI tools to support supplier contract negotiations by 2027. The adoption reflects growing recognition that contract intelligence provides a competitive advantage in supplier relationships.

What are the benefits of AI-driven contract compliance monitoring?

AI-driven compliance monitoring transforms contract management from periodic audits to continuous oversight. The technology provides several key benefits:

- Real-time obligation tracking: Automated monitoring systems replace manual spreadsheets by extracting commitments and creating tracking schedules.

- Policy enforcement: Systems flag purchases that violate spending limits, bypass preferred suppliers, or deviate from standard terms.

- Audit trail generation: Every contract interaction, from initial request to final execution, is fully documented.

- Performance measurement: The system compares actual supplier delivery against contracted commitments to identify service failures.

- Exception management: Unusual contract terms that require legal review are highlighted, allowing teams to focus on genuine risks.

Contract compliance monitoring reduces the risk of costly violations and strengthens negotiating positions through detailed performance documentation. Organizations using advanced AI contract storage systems are nearly 70% more likely to surpass their contract and risk management targets.

What practical applications does AI have in purchase order processing?

Purchase order processing contains numerous manual steps that AI automates for faster, more accurate procurement operations. This technology handles PO creation, approval routing, fraud detection, and invoice matching without human intervention for routine transactions.

How does AI automate purchase order creation and approval?

AI automates purchase order creation by extracting information from requisitions and populating PO fields automatically. The systems recognize product descriptions, quantities, and pricing from internal requests or supplier catalogs. Standard purchases no longer require manual data entry, which speeds up processing and prevents transcription errors.

Budgets are automatically checked before a purchase order is finalized. The technology verifies available budgets by department, project, or cost center and prevents orders that exceed allocations. Organizations maintain spending control without requiring manual budget reviews for every transaction.

Intelligent routing directs purchase orders to appropriate approvers based on configurable rules:

- Value thresholds: Orders above specified amounts route to senior approvers.

- Category requirements: Certain purchase types require specialized approval chains.

- Departmental authority: Approvers receive only requests within their responsibility areas.

- Emergency protocols: Urgent purchases follow expedited approval paths.

The systems track approval status in real time and send automated reminders when POs await action. Bottlenecks become visible immediately, which enables managers to address delays before they impact operations.

Approval workflows maintain complete audit trails documenting who approved each PO and when decisions occurred. The transparency supports compliance requirements and provides accountability for purchasing decisions.

Can AI detect fraudulent or duplicate orders?

AI detects fraudulent and duplicate orders through pattern analysis, anomaly detection, and automated validation. Organizations implementing AI fraud detection report reductions of 30-40% in fraud-related losses, which makes this capability a high priority for procurement teams.

Duplicate invoice detection identifies orders submitted multiple times through various schemes. The technology recognizes exact duplicates as well as strategic near-matches where fraudsters modify small details to bypass manual review. Warning signs include identical amounts appearing on consecutive days, purchase order numbers differing by a single character, or the same invoice submitted through different channels.

AI flags several fraud patterns that manual processes tend to miss:

- Ghost vendors: Fictitious supplier entities created to divert payments without delivering goods or services.

- Overbilling schemes: Inflated unit costs, padded hours, or phantom quantities hidden within legitimate invoices.

- Split orders: Purchases artificially divided to stay below approval thresholds and avoid scrutiny.

- Payment diversion: Altered bank details that redirect payments to fraudulent accounts.

- Kickback arrangements: Vague invoice descriptors and round-number charges suggesting insider collusion.

The systems establish baseline behavior patterns for each vendor and flag deviations that indicate potential fraud. A supplier who suddenly submits invoices more frequently, requests unusual payment terms, or raises prices without market justification will trigger an investigation. Companies lose approximately 5% of annual revenue to fraud, highlighting the cost of weak detection systems.

Validation processes compare purchase orders against vendor records, historical pricing, and contract terms. The technology identifies invoices for goods never ordered, prices exceeding negotiated rates, or vendors lacking proper registration. Organizations prevent fraudulent payments before they affect the books rather than discovering losses during post-payment audits.

What is touchless PO processing and how does it work?

Touchless PO processing cuts manual intervention for routine purchase orders by automating data extraction, validation, and approval steps. The technology processes standard orders from request through payment without human touchpoints, which dramatically reduces processing time and labor requirements.

Optical character recognition is the foundation of touchless processing. AI-powered OCR extracts data from purchase requisitions, supplier quotes, and invoices regardless of format. The systems handle scanned PDFs, images, email attachments, and digital documents with high accuracy. Modern OCR solutions are extremely accurate when it comes to data extraction, so only minor corrections may be needed.

The workflow operates using several automated steps:

- Document intake: Requisitions and invoices arrive through email, portal uploads, or system integrations.

- Data extraction: OCR technology identifies vendor names, amounts, line items, dates, and payment terms.

- Validation: Systems verify data against purchase orders, contracts, and vendor records.

- Matching: Invoices automatically match to corresponding POs and receipts for three-way validation.

- Approval routing: Documents meeting criteria flow through automated approval or flag for review.

Organizations implementing touchless processing report significant efficiency gains. Processing time drops from days to minutes for routine transactions. An implementation guide from Precoro notes that companies can achieve 80% reductions in accounts payable workload by automating invoice handling, which allows AP teams to focus on exceptions and strategic activities.

The technology learns and improves through continued use. Machine learning models recognize new document formats, adapt to supplier variations, and reduce error rates over time. Organizations processing high transaction volumes see accuracy improvements within weeks of implementation.

How can AI match invoices to purchase orders automatically?

AI matches invoices to purchase orders through automated validation that compares multiple data points across documents. The technology performs three-way matching between purchase orders, invoices, and receipt records to verify accuracy before payment processing occurs.

Matching algorithms compare critical fields automatically:

- Purchase order numbers: Verify that an invoice references valid, active POs.

- Vendor information: Confirm that supplier names and payment details match records.

- Line item details: Ensure product descriptions, SKUs, and quantities align across documents.

- Pricing accuracy: Check that unit prices and total amounts match negotiated rates.

- Date validation: Confirm that delivery dates, invoice dates, and payment terms are consistent.

The systems identify discrepancies that require attention before payment authorization. Quantity mismatches appear when delivered amounts differ from ordered volumes. Price variances trigger alerts when invoice amounts exceed purchase order rates. Missing items become visible when invoices include charges for products not listed on the original PO.

Exception handling routes problematic invoices to appropriate reviewers rather than blocking entire payment cycles. Minor discrepancies below tolerance thresholds may auto-approve when properly documented, while significant variances require manual investigation. The intelligent routing prevents payment delays for valid invoices while protecting against errors and fraud.

Automated matching prevents duplicate payments by tracking invoice numbers and comparing them against payment histories. The technology flags invoices submitted multiple times or payments already processed for the same goods. As a result, organizations no longer rely on manual spreadsheets to track and catch duplicate submissions.

The validation process keeps full audit trails of match results, approval decisions, and exception resolutions. Compliance teams can access detailed records explaining why payments were approved or flagged for further review.

What is AI‑powered OCR and how does it streamline procurement?

Procurement becomes faster and more accurate with AI-powered OCR, which automatically extracts and validates data from key documents. The technology combines optical character recognition with machine learning to understand document context, not just read text.

Traditional OCR systems simply digitize text, while AI-enhanced OCR interprets layouts, recognizes fields, and validates information against existing procurement records. The system processes documents that arrive in various formats across procurement workflows.

Paper invoices, scanned contracts, and emailed purchase orders all require manual data entry in traditional procurement operations. AI-powered OCR prevents this bottleneck by reading supplier invoices, extracting line items, tax amounts, and payment terms, then routing the data directly into procurement systems. The technology handles poor scan quality, handwritten notes, and inconsistent formatting, which previously required human review.

Common applications of AI-powered OCR in procurement include:

- Invoice processing: Captures invoice numbers, dates, amounts, and vendor details in 1-2 seconds versus 10-30 minutes manually.

- Contract data extraction: Pulls key terms, renewal dates, pricing clauses, and compliance requirements from multi-page agreements.

- Purchase order matching: Automatically captures supplier confirmations and matches them against internal PO records.

- Three-way matching: Compares invoice data against purchase orders and receiving records, flagging discrepancies instantly.

Contract management benefits significantly from this technology. Procurement teams can search across thousands of contracts for specific clauses or obligations without manual review. AI-powered OCR creates searchable, structured data from static documents, enabling better contract compliance and risk management.

The technology also reduces errors that lead to payment disputes and delayed shipments by automatically validating extracted data against existing procurement records.

How does AI reduce Accounts Payable Days (DPO)?

AI reduces days payable outstanding by automating approval workflows and preventing manual bottlenecks in the payment cycle. The technology accelerates invoice processing from receipt to payment, allowing organizations to optimize cash flow while maintaining strong supplier relationships.

Traditional accounts payable processes involve multiple manual touchpoints. Invoice receipt, data entry, three-way matching, approval routing, and payment authorization each introduce delays that extend DPO.

AI-powered procurement systems compress these steps into automated workflows that run continuously without human intervention. The technology automatically matches incoming invoices against purchase orders and receiving records in seconds rather than days.

Automated three-way matching removes the manual reconciliation that usually takes 45–60 minutes per transaction. Discrepancies are immediately flagged to the right stakeholders, so invoices don’t stall in approval queues.

AI also optimizes approval routing by analyzing invoice characteristics and directing them to appropriate approvers based on amount thresholds, cost centers, and organizational hierarchies. The system learns from historical approval patterns to predict which invoices require additional scrutiny and which can be processed through standard workflows.

Organizations benefit from faster payment cycles in several ways:

- Early payment discounts: Capturing 2/10 net 30 terms (2% discount for payment within 10 days), which were previously missed due to processing delays.

- Improved supplier relationships: Consistent on-time payments strengthen negotiating position for better terms.

- Reduced late payment penalties: Automated reminders and scheduled payments prevent fees from missed deadlines.

- Better cash flow visibility: Real-time processing provides accurate forecasts of upcoming payment obligations.

Payments move faster with AI, but financial control and audit compliance remain intact, allowing procurement teams to balance spend management strategy with supplier satisfaction.

How can AI improve supplier risk management?

AI transforms supplier risk management by continuously monitoring thousands of data sources to identify threats before they disrupt operations. The technology analyzes financial indicators, geopolitical events, regulatory changes, and operational patterns that traditional manual reviews cannot process at scale. Organizations using AI-powered risk management systems gain early visibility into supplier vulnerabilities across their entire supply network.

Traditional supplier risk assessment relies on periodic audits, financial statements, and manual reviews that only capture snapshots of the current moment in time. AI-powered systems operate continuously, processing real-time data from news feeds, trade databases, shipping records, and regulatory filings. The technology identifies emerging risks weeks or months before they materialize into operational problems.

What types of supplier risks can AI identify and predict?

AI systems detect multiple categories of supplier risk by analyzing diverse data streams. Financial distress indicators include declining credit scores, delayed payments to other vendors, and deteriorating cash flow ratios, which signal potential bankruptcy or operational failures. The technology also monitors compliance risks, such as regulatory violations, labor disputes, and quality control issues that may impact supplier reliability.

Operational risks represent another critical category. AI tracks production capacity changes, facility closures, key personnel departures, and supply allocation shifts that affect a supplier's ability to fulfill commitments. By mapping supply network dependencies, the systems reveal concentration risks, such as multiple suppliers depending on the same sub-tier vendors or regions.

Geopolitical risks have become increasingly important for supply chain management. According to the research from interos.ai, political unrest in Eastern Europe, the South China Sea, and the Red Sea could result in up to $1 trillion in total economic damages, with 481 companies in the S&P 500 having their direct suppliers in high-risk regions. Organizations in agriculture, building and civil engineering, retail, and computer manufacturing face particularly high exposure to this issue.

How does AI monitor supplier financial health in real-time?

AI-powered financial monitoring analyzes credit reports, payment histories, bankruptcy filings, and market indicators to assess supplier stability. The technology processes these data points continuously instead of waiting for quarterly financial statements. Machine learning models can even identify patterns that act as precursors to financial distress, such as extending payment terms to their own suppliers, reducing inventory levels, or shifting to higher-cost financing.

The systems also monitor indirect financial indicators. Changes in shipping volumes, employee headcount reductions, facility consolidations, and decreased marketing activity can all be considered early warning signals. AI correlates these operational changes with financial metrics to calculate risk scores, which update in real time as new information becomes available.

Despite the critical importance of financial monitoring, McKinsey research reveals that 90% of supply chain leaders faced resilience challenges in 2024, yet visibility remains limited. More than 40% of organizations report having limited or no visibility into even their tier-one supplier performance, creating blind spots that leave companies vulnerable to supplier financial failures.

Integration with credit bureaus, trade databases, and public filings enables automated alerts when suppliers exhibit concerning financial patterns. Procurement teams receive notifications about specific risk factors without the need to review raw financial data by hand. This automation allows organizations to monitor hundreds or thousands of suppliers simultaneously without proportional increases in staff.

What are AI-powered early warning systems for supplier issues?

AI systems track geopolitical developments and their potential impact on supply chains by processing news sources, government announcements, trade restrictions, and regional conflict data. The technology maps supplier locations against geopolitical risk zones to identify exposure to specific threats.

The technology analyzes specific disruption impacts that affect procurement decisions. For example, the crisis in the Red Sea has forced many carriers to avoid the Suez Canal, rerouting ships around the Cape of Good Hope, which increased delivery times by 10 days or more on average.

Taiwan's dominance in semiconductor production represents another critical vulnerability, with the island producing over 90% of the world's advanced semiconductors. AI systems quantify these geographic concentration risks, creating and providing models for alternative sourcing scenarios.

According to McKinsey's supply chain research, disruptions lasting longer than one month occur every 3.7 years on average and can cost businesses up to 45% of annual profit over a decade.

The technology monitors regulatory changes, including export controls, sanctions lists, and tariff updates. AI tracks when suppliers or their sub-tier vendors appear on restricted entity lists, alerting procurement teams to compliance risks before they cause shipment delays or regulatory violations.

What role does AI play in demand forecasting and planning?

AI revolutionizes demand forecasting by analyzing vast datasets that traditional statistical methods cannot process effectively. The technology identifies complex patterns across sales history, market trends, economic indicators, and external factors to generate predictions with significantly higher accuracy. Organizations using AI-driven forecasting reduce stockouts, minimize excess inventory, and align procurement spending with actual demand patterns.

Traditional forecasting uses historical averages, seasonal trends, and linear regression models, which assume stable relationships between variables. In contrast, AI-powered systems continuously adapt to changing market conditions, learning from past forecast errors to improve future predictions.

AI processes unstructured data sources such as social media trends, weather patterns, promotional schedules, and competitor activity, capturing demand signals that traditional forecasting models often miss.

How accurate is AI-driven demand forecasting compared to traditional methods?

According to McKinsey research, AI-driven forecasting can reduce errors by 20-50% in supply chain networks. This improvement translates into tangible business benefits: up to 65% reduction in lost sales due to stockouts, 5-10% lower warehousing costs, and 25-40% improvement in administration costs.

Machine learning models can capture complex, non-linear relationships and interactions that simple time-series analysis often misses. These systems show how variables like weather or promotional timing work together to impact demand.

Key accuracy improvements include:

- Volatility handling: Products with irregular purchase patterns, long lead times, or seasonal variations benefit substantially from AI forecasting.

- Real-time adaptation: Neural networks detect subtle signals in noisy data, which indicate emerging demand shifts before they appear in aggregate sales.

- New product forecasting: Transfer learning techniques allow models trained on established products to inform predictions for new launches with limited historical data.

Forecast accuracy translates directly into procurement performance. Better predictions allow procurement teams to negotiate more favorable terms with suppliers by providing advance visibility into order volumes and timing.

Can AI predict seasonal fluctuations and market trends?

AI systems detect seasonal patterns across multiple timescales at once, from daily fluctuations to annual cycles. The system identifies seasonal patterns, single occurrences, and emerging trend shifts, which traditional approaches often confuse.

Seasonal pattern analysis: Machine learning models track how seasonal patterns change over time instead of assuming they repeat in a fixed way. The systems consider external factors that affect seasonal demand—such as weather, holiday schedules, economic conditions, and competitor activity. AI uses this context to adjust seasonal forecasts dynamically, rather than relying on static seasonal indices.

Trend detection capabilities: AI identifies inflection points where demand trajectories shift due to market saturation, competitive entry, technological change, or evolving consumer preferences. The technology monitors leading indicators, which signal trend changes before they appear in sales data, allowing procurement teams to adjust sourcing strategies proactively.

Market trend analysis extends beyond individual products to category-level shifts. AI detects when demand migrates between product segments, when new categories emerge, or when established categories decline. These insights inform strategic procurement decisions about supplier relationships, contract terms, and inventory allocation across product portfolios.

How does machine learning optimize inventory levels?

Machine learning optimizes inventory by balancing carrying costs against stockout risks across thousands of SKUs simultaneously. The technology optimizes reorder points and order quantities to lower costs without compromising service levels.

The systems account for variability in both demand and supply. Traditional inventory models use fixed safety stock calculations based on average lead times and demand volatility. Machine learning models recognize that lead time variability, supplier reliability, and demand uncertainty interact in complex ways, which require dynamic optimization.

Advanced applications include:

- Multi-echelon optimization: Determining optimal inventory positioning across distribution networks, warehouse locations, and retail stores.

- Dynamic parameter adjustment: Continuously updating reorder points and order quantities as demand patterns, lead times, and cost structures change.

- Seasonal inventory planning: Balancing the costs of holding seasonal inventory against markdown losses from excess stock and lost sales from insufficient inventory.

- Network-wide cost minimization: Considering transportation costs, storage capacity constraints, and service level requirements at each location.

What impact does AI forecasting have on procurement budgeting?

AI forecasting provides procurement teams with more accurate budget projections by predicting both demand volumes and pricing trends. The technology analyzes commodity price movements, currency fluctuations, supplier capacity constraints, and market dynamics that affect procurement costs.

Budget precision improvements: Organizations can budget with greater precision, reducing the need for large contingency reserves that tie up working capital. The systems enable scenario planning for budget development, allowing procurement teams to model how different demand scenarios, supplier disruptions, or market conditions would impact spending requirements.

AI quantifies the probability and financial impact of various scenarios, supporting risk-adjusted budget planning rather than single-point estimates. Rolling forecasts replace static annual budgets in organizations with mature AI forecasting capabilities. The technology updates spending projections continuously as actual results emerge and market conditions evolve.

Procurement negotiation advantages: Supplier negotiations benefit from improved demand forecasts. Procurement teams can commit to volume-based pricing with greater confidence when AI forecasts provide reliable demand predictions. By accurately forecasting total category demand across business units or product lines, the technology reveals opportunities to reduce the number of suppliers.

How does generative AI enhance procurement communications and documentation?

Generative AI can automatically draft requests for proposals, supplier emails, contract summaries, and internal documentation. It analyzes context from previous communications, contract terms, and organizational requirements to generate professional correspondence in seconds. Procurement teams reduce time spent on routine writing tasks while maintaining consistency and accuracy across all supplier interactions.

There are many specific examples to mention here regarding:

- RFPs

- Contracts

- Supplier communication

- Internal documentation

- Cross-language capabilities

RFP creation and customization: Generative AI generates comprehensive RFPs by pulling relevant specifications from product requirements, compliance standards, and historical procurement documents. The systems customize language for different supplier types, industries, and contract values while ensuring all necessary terms and conditions appear in each document. What previously required hours of manual drafting now completes in minutes.

Contract analysis and summarization: The technology reviews multi-page supplier agreements and produces concise summaries, which highlight key terms, obligations, pricing structures, and renewal conditions. Procurement professionals can quickly understand contract essentials without reading entire documents, accelerating review and approval processes.

Supplier communication automation: Generative AI drafts follow-up emails, clarification requests, negotiation counterproposals, and performance feedback messages based on procurement team inputs. The systems maintain appropriate tone and formality levels for different communication contexts, from routine order confirmations to sensitive contract negotiations. Standardized messaging reduces miscommunication and ensures consistent supplier relationship management.

Internal documentation efficiency: The technology creates procurement policy documents, process guides, training materials, and executive summaries from raw data and requirements. The system automatically creates meeting notes and action items from procurement discussions, highlighting key decisions, pending questions, and next steps.

Cross-language capabilities: Translation features enable global procurement teams to communicate effectively across language barriers. Generative AI translates contracts, emails, and specifications correctly, so teams can safely collaborate with suppliers beyond their own country.

Frequently asked questions

Agentic AI refers to autonomous systems that can execute complex procurement tasks independently, making decisions and taking actions without constant human oversight. Traditional AI in procurement assists with specific functions like data analysis or pattern recognition, while agentic AI can manage entire workflows, such as supplier selection, contract negotiation, and purchase order processing from start to finish. This autonomy allows procurement teams to focus on strategic decisions while AI agents handle routine transactions and operational tasks.

AI procurement solutions generally take three to twelve months to implement, depending on complexity, data quality, and company size. Companies with well-organized data can deploy AI tools for specific tasks like invoice processing or spend analysis in just 8–12 weeks. Full enterprise-wide deployments usually take 6–12 months for data prep, integration, and change management. Rolling out AI in phases with high-impact use cases typically delivers faster results than a full-scale launch.

AI systems can automatically collect and analyze demographic data, ownership structures, and certification statuses across the supplier base. The technology tracks ethical sourcing compliance by scanning news sources, regulatory databases, audit reports, and third-party certifications to identify potential labor violations, environmental concerns, or human rights issues within supply chains. Automated monitoring and reporting help procurement teams maintain diversity targets and ethical standards without manual data collection across thousands of suppliers.

See how AI can work for your procurement team in practice.

Book a demo of Precoro today.