26 min read

The Procurement Process Explained: 7 Steps and Cycle Stages

Explore the 7-step procurement process that guides companies from need identification through payment, and learn how strategic sourcing adds value.

Every successful purchase starts with a smart procurement process that helps businesses get the right goods and services on time and within budget.

This article walks you through the process and shows how to make it work in practice.

Scroll down to find out:

Overview of the procurement process

Procurement process flow

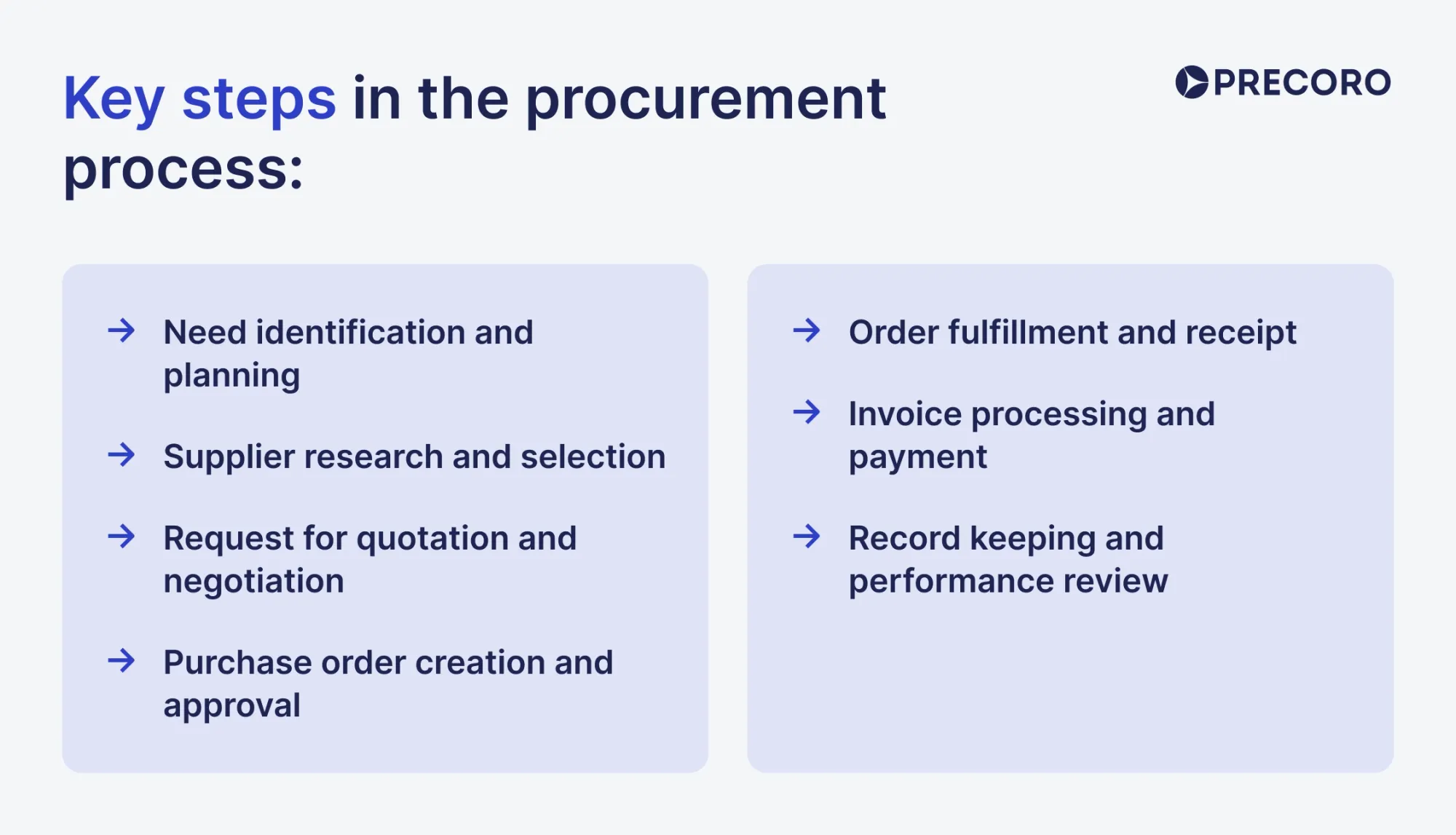

Key steps in the procurement process

Stages of the procurement cycle

Strategic sourcing: The 7-step model

Key takeaways

Frequently asked questions

Overview of the procurement process

The procurement process is a systematic approach that businesses rely on to acquire goods or services. Organizations use a certain sequence of procurement process steps to ensure efficiency in vendor management and spend control.

The procurement process consists of several stages, and understanding them helps businesses optimize their purchasing activities while maintaining better supplier relationships.

Purpose of a procurement framework

A procurement framework forms the structure that is used to guide purchasing activities within an organization. It defines a combination of procedures, policies, and controls that govern the way teams are supposed to acquire goods or services. Procurement frameworks are implemented in organizations as the means of achieving certain critical objectives in support of operational efficiency.

A procurement framework brings consistency to every purchasing activity. By standardizing how teams define needs, choose suppliers, and handle payments, it minimizes mistakes and keeps everyone accountable. Alternatively, organizations that do not rely on structured frameworks tend to experience duplicated efforts, maverick spending, and even compliance issues.

Key benefits of implementing a procurement framework include:

- Reduced purchasing costs through standardized vendor selection

- Improved compliance with regulatory requirements and internal policies

- Enhanced visibility into spending patterns across departments

- Stronger supplier relationships through consistent communication protocols

- Better risk management through established evaluation criteria

The framework also supports strategic decision-making by providing information about procurement activities. With it, teams can analyze spending patterns, identify opportunities for cost savings, and attempt to negotiate better terms with suppliers. A well-designed framework contributes greatly to the alignment of procurement activities with broader business goals and financial objectives.

Key stakeholders and responsibilities

Multiple stakeholders participate in the procurement process, and each of them contributes their own specific expertise and oversight. Different procurement stages require coordination efforts between requesters, buyers, approvers, and finance teams. Knowing the responsibilities of each stakeholder ensures the procurement process runs efficiently, with no delays or miscommunication.

Procurement requesters initiate the process through the identification of needs and purchase requisition submissions. These stakeholders (department managers or project leads in most cases) define specifications and justify the business need for new purchases. The requester also bears responsibility for making sure that the items in question align with both project requirements and budget constraints.

Procurement specialists are the ones who manage the sourcing activities and vendor relationships. They are professionals in their field who conduct market research, evaluate supplier proposals, and negotiate contract terms. The procurement team is tasked with ensuring that the chosen suppliers meet the necessary quality standards while optimizing costs and delivery timelines.

Approval authorities review purchase orders and requisitions while keeping the spending thresholds in mind. Finance directors, department heads, and executive leadership are the ones providing approvals in accordance with budget availability and overall strategic alignment. The approval process establishes financial controls that prevent unauthorized spending.

Accounts payable (AP) teams handle vendor payments and invoices during the final stages of the procurement cycle. They verify that invoices match purchase orders or delivery receipts before confirming the release of each payment. Accurate financial records and positive vendor relationships via timely payments are part of their responsibilities.

Procurement process flow

Procurement process flow maps the sequence of activities from the identification of initial needs up to the final payment. This flow is supposed to create a standardized path for purchasing requests to follow within an organization. Businesses typically use the procurement process flow as a way to maintain control over spending while ensuring compliance with all kinds of internal policies.

From requisition to payment

The procurement cycle stages begin with an employee or a department identifying a need for some sort of product or service. Each stage is closely connected to the next, forming a continuous flow that organizations follow in order to successfully complete purchases. These procurement process steps ensure that all spending decisions are properly authorized before any purchase is finalized.

The procurement process flow consists of the following sequential stages:

- Need identification and requisition submission

An employee documents the required items, quantities, specifications, and business justification in a purchase requisition. The requisition enters an approval workflow based on spending thresholds and departmental budgets. - Approval and authorization

Designated authorities review the requisition to verify budget availability and business necessity. The approval process creates a checkpoint, which prevents unauthorized or unnecessary spending. - Vendor selection and sourcing

The procurement team evaluates potential suppliers based on price, quality, delivery capabilities, and past performance. This evaluation ensures that the organization selects vendors who can meet requirements reliably. - Purchase order creation

The procurement team issues a purchase order, which serves as a legally binding commitment. The vendor receives this document and agrees to the terms, specifications, and delivery schedule. - Order fulfillment and receipt

The vendor delivers goods or completes services according to the purchase order. The receiving department inspects deliveries and verifies that they match order specifications and quality standards. - Invoice processing and verification

The vendor submits an invoice for payment. The accounts payable team matches this invoice against the purchase order and receiving documentation to ensure accuracy. - Payment execution

Once verification is complete, the accounts payable team processes payment according to agreed terms. This final step closes the transaction and updates records for the financial audit.

The complexity of a procurement process flow varies depending on the purchase value and organizational policies, among other factors. High-value purchases often require additional approval levels, as well as a more rigorous vendor evaluation. In contrast, low-value purchases use much more expedited paths with no need for excessive approval.

Visualizing the procurement cycle

Visual representations of the procurement process and its numerous steps help teams with identifying both bottlenecks and potential improvement opportunities. Flowcharts commonly display each separate stage as its own box or node that is connected with others with arrows. Diagrams like these help illustrate decision points, approval gates, handoff rules between departments, and more.

Different procurement activities also require specific levels of detail when it comes to visualization efforts. Simple purchases might consist of as few as three steps in a procurement process flow, while complex procurements covering multiple vendors or long-term contracts would have to be a lot more detailed in comparison. The exact phases of procurement become clearer once teams can visualize how exactly different activities connect to each other and where potential delays might happen.

A comprehensive procurement flowchart includes:

- Requisition submission and routing paths

- Approval hierarchies based on spending limits

- Vendor selection and evaluation criteria

- Purchase order generation and distribution

- Goods receipt and quality inspection checkpoints

- Invoice reconciliation and payment authorization

- Record retention and audit trail documentation

Some organizations even color-code their charts in order to show which department handles which step. It’s a simple visual technique that clarifies responsibilities and helps newer employees understand the procurement process flow within the organization.

Additionally, modern digital procurement systems often incorporate visualizations directly into their interfaces, enabling real-time status updates as purchases move through each stage.

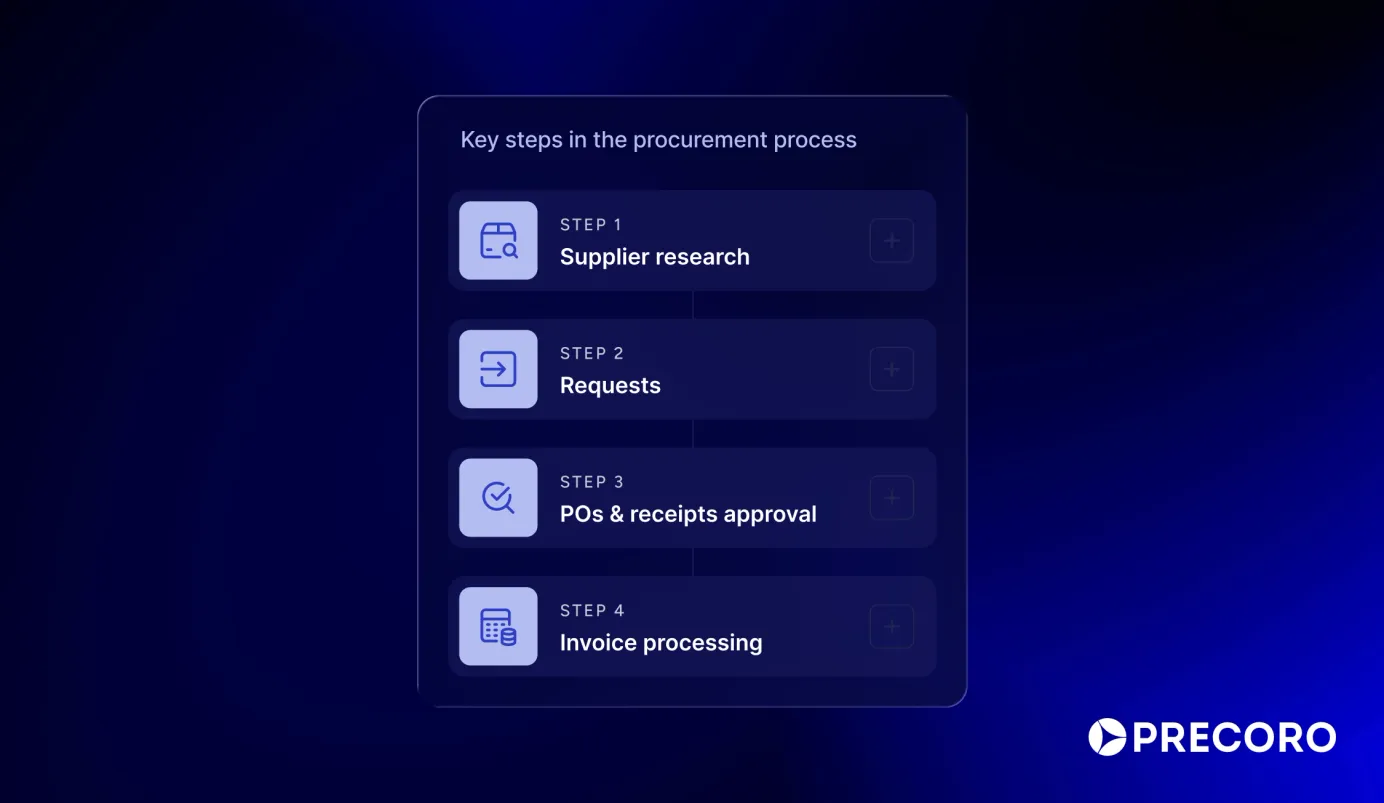

Key steps in the procurement process

It’s common for organizations to break down their procurement activities into many distinct steps that act as the framework for team guidance. Each step has its own purpose in a broader procurement cycle, contributing to successful purchasing outcomes in its own way.

Need identification and planning

The procurement process begins when departments recognize a need for goods or services. This recognition may stem from depleted inventory, new project demands, operational improvements, or equipment replacements. Teams must document the specific requirements, including detailed specifications, quantities, quality standards, and delivery timelines that are aligned with project schedules.

Effective planning during this initial stage prevents costly mistakes later in the procurement cycle stages.

The requesting department conducts an internal assessment in order to determine whether the need can be met through existing inventory, current contracts, or alternative solutions.

This assessment also considers factors such as budget constraints, alignment with organizational priorities, and potential impacts on other departments or projects. Rushed or poorly planned requisitions might result in incorrect specifications and lead to delays, additional costs, and strained supplier relationships.

The planning phase is where the success criteria for the purchase are established. Teams define quality standards, performance metrics, acceptable price ranges, and delivery expectations. These criteria guide vendor selection and provide benchmarks for evaluating delivered goods or services.

Organizations that invest time in thorough planning typically achieve better outcomes, negotiate more favorable terms, and experience fewer procurement disputes. Documentation created during this phase becomes the foundation for all subsequent procurement process steps.

Supplier research and selection

Supplier research identifies potential vendors who can meet the organization's requirements at competitive prices. The procurement team gathers information about supplier capabilities, pricing structures, delivery performance, financial stability, and industry reputation. This research phase is a critical component of the procurement process steps because supplier quality directly impacts purchase outcomes and long-term operational success.

Key factors in supplier evaluation include:

- Technical capability to meet product or service specifications

- Financial health and business continuity indicators

- Past performance records and verifiable client references

- Pricing competitiveness relative to current market rates

- Geographic location and logistics capabilities

- Compliance with industry standards and required certifications

Organizations evaluate suppliers across these dimensions to build a qualified vendor pool that can reliably deliver value.

The selection process narrows the supplier pool to candidates who meet minimum qualification criteria. Procurement teams may issue requests for information to gather preliminary data about supplier capabilities, capacity, and experience with similar projects. Organizations then conduct deeper due diligence on shortlisted vendors, which may include site visits, reference checks, financial reviews, and capability assessments.

Supplier diversity considerations also factor into selection decisions. Many organizations maintain programs that encourage procurement from minority-owned, women-owned, veteran-owned, or small businesses. These programs support broader corporate social responsibility goals while expanding the supplier base and fostering innovation. The final supplier selection balances multiple factors to identify the vendor that offers the best overall value proposition rather than simply the lowest price.

Request for quotation and negotiation

The request for quotation (RFQ) process formalizes pricing inquiries with qualified suppliers. Organizations distribute detailed specifications, requirements, delivery schedules, and evaluation criteria to selected vendors, requesting formal price quotes. This step in the procurement process flow creates competition among suppliers, which typically results in more favorable pricing, better terms, and improved service commitments.

Suppliers respond with proposals that outline their pricing, delivery schedules, payment terms, warranty provisions, and any additional conditions or value-added services. The procurement team evaluates these responses against predefined criteria. Price is an important factor, but organizations also consider the total cost of ownership, which includes maintenance expenses, training requirements, support costs, and potential downtime.

RFQ evaluation and negotiation stages:

- Initial review – Screen proposals for completeness and compliance with requirements.

- Technical evaluation – Assess capability to meet specifications and quality standards.

- Financial analysis – Compare pricing and calculate the total cost of ownership.

- Negotiation preparation – Identify leverage points and alternative options.

- Active negotiation – Discuss pricing, terms, service levels, and contract provisions.

- Final agreement – Document all terms and obtain signatures from both parties.

Experienced negotiators obtain concessions that raise value and still maintain product quality and service reliability.

Negotiation begins after the procurement team identifies preferred suppliers based on evaluation scores. The negotiation phase addresses pricing adjustments, payment terms, delivery schedules, warranty provisions, service level agreements, and performance penalties.

Both parties must agree on performance standards, liability provisions, change order procedures, and dispute resolution mechanisms. The negotiation process concludes when all terms are documented in a formal agreement that both parties sign, which becomes the foundation for the ongoing supplier relationship.

Purchase order creation and approval

Purchase order creation translates negotiated agreements into actionable documents that initiate supplier obligations. For standard, low-risk, or one-off purchases, the PO itself acts as a contract once accepted by the supplier. When there is a signed formal agreement in place, the PO formalizes the purchase under the terms of that contract, creating enforceable obligations for both parties.

The purchase order includes reference numbers that link back to the original requisition, approved budget, and any related contracts. Line items detail each product or service with corresponding unit prices, quantities, and extended totals. Special instructions regarding packaging, labeling, delivery procedures, or quality requirements appear in designated fields. The purchase order also specifies payment terms, which define when and how the supplier will receive compensation.

Modern procurement platforms send orders electronically, which dramatically accelerates processing while reducing errors.

Organizations implement approval workflows based on purchase value and organizational hierarchy. Small purchases below certain thresholds may require only departmental manager approval, while medium-value expenditures need director-level authorization, and large purchases demand executive review. The approval process verifies that the purchase order matches the approved requisition, falls within budget constraints, and complies with procurement policies.

Multiple approvers may review the document sequentially or simultaneously, with each level checking different aspects of the purchase. Finance reviews budget availability, department heads confirm business necessity, and compliance teams verify policy adherence.

Once all required approvals are obtained, the procurement system sends the purchase order to the supplier through electronic data interchange, a supplier portal, or email. The supplier acknowledges receipt and confirms the ability to fulfill the order according to specifications, which activates their obligation to perform.

Order fulfillment and receipt

Order fulfillment begins when the supplier processes the purchase order and prepares goods for shipment or schedules service delivery. The supplier allocates inventory, manufactures custom items according to specifications, or coordinates service resources to meet agreed timelines. Communication between the supplier and procurement team during this phase ensures that any production issues, delivery delays, or specification questions are identified and resolved quickly.

Proactive suppliers provide status updates at key milestones to help procurement teams manage internal expectations and coordinate receiving activities.

The receiving process activates when shipments arrive at the designated facility or delivery location. Receiving personnel verify that delivered quantities match the purchase order and inspect goods for visible damage, defects, or specification deviations. This inspection represents a critical control point in the procurement process steps because it prevents payment for unsatisfactory deliveries and protects the organization from accepting defective goods.

Standard receiving procedures include:

- Physical count of delivered items against packing slips and purchase orders

- Visual inspection for obvious damage, defects, or quality issues

- Verification of product specifications, model numbers, and serial numbers

- Documentation of receipt date and condition in the procurement system

- Routing of accepted goods to the requesting departments or the inventory storage

- Immediate notification to suppliers regarding rejected or damaged items

Discrepancies between ordered and delivered items require immediate resolution. The receiving team contacts the supplier to report shortages, damage, incorrect items, or specification deviations.

The procurement process flow may be temporarily on hold while suppliers ship replacements, issue credits for missing quantities, or provide documentation to resolve disputes. Organizations maintain detailed receiving records, including photographs of damage and signed delivery receipts, to support dispute resolution and provide audit trails for financial compliance purposes.

Invoice processing and payment

Invoice processing begins when suppliers submit payment requests for delivered goods or completed services. Suppliers typically send invoices electronically through procurement portals or via email, though some organizations still receive paper invoices through traditional mail channels. The accounts payable team receives these invoices and initiates a verification process known as three-way matching.

Three-way matching compares the invoice against the purchase order and receiving documentation to ensure accuracy before payment.

This comparison ensures that the invoiced amount matches the agreed price, the quantities match what was actually received, and the terms align with the contract. Line-by-line verification checks unit prices, extended totals, applicable taxes, and any agreed discounts or adjustments.

Discrepancies trigger investigation and resolution before payment processing continues. Common discrepancies include pricing errors, quantity mismatches, duplicate invoices, or charges for items not received. Organizations use this control mechanism to prevent overpayment and detect potential invoice fraud.

Payment terms negotiated during the procurement stages determine when payment is due. Common terms include net 30 or net 60, which are payments due within 30 or 60 days of the invoice date. Some suppliers offer early payment discounts, such as 2/10 net 30, which gives a 2% discount if the invoice is paid within 10 days. Organizations evaluate whether taking these discounts provides better value than retaining cash for other purposes or investment opportunities.

The payment execution process varies based on organizational preferences, supplier requirements, and transaction volumes. Most businesses now pay electronically using ACH transfers, which reduce costs, provide faster payment, and create automatic audit trails.

International payments may require wire transfers or letters of credit, depending on supplier location and risk factors. The accounts payable team schedules payments to meet due dates, manage cash flow efficiently, and maintain strong relationships with suppliers.

Record keeping and performance review

Record keeping throughout the procurement process creates documentation that supports multiple organizational needs and regulatory requirements. Complete records enable financial audits, support dispute resolution, provide data for strategic analysis, and demonstrate compliance with internal policies and external regulations. Organizations maintain purchase orders, invoices, receipts, contracts, correspondence, and approval records in organized filing systems.

Digital procurement systems automatically capture transaction data at each stage, creating comprehensive audit trails that show authorization paths and approval timelines.

These systems record who authorized purchases, when approvals were granted, how transactions progressed through each stage, and what communications occurred between parties. Organizations typically need to keep procurement records for three to seven years to meet regulatory and policy requirements. Digital record systems simplify compliance with automated retention and easy access for audits.

Performance review analyzes procurement outcomes to identify improvement opportunities and inform future decisions. The procurement team evaluates supplier performance against agreed service levels, quality standards, and contractual commitments. Metrics such as on-time delivery rates, defect percentages, order accuracy, and responsiveness to issues provide objective measures of supplier reliability and value.

Comprehensive performance review includes:

- Supplier scorecards – Track delivery performance, quality metrics, responsiveness, and innovation contributions.

- Cycle time analysis – Assess the time span from requisition to delivery across purchase categories.

- Cost analysis – Compare actual spending against budgets and identify savings opportunities.

- Exception reporting – Identify transactions that required special handling or experienced problems.

- Process optimization – Use insights to eliminate bottlenecks, reduce costs, and accelerate procurement activities.

Organizations also review internal procurement process steps to identify bottlenecks, inefficiencies, and opportunities for automation. Procurement analysis may reveal that certain approval levels cause unnecessary delays, specific suppliers consistently underperform, or particular product categories generate frequent disputes.

These insights drive process improvements, supplier relationship adjustments, and policy updates. Continuous review ensures that procurement practices evolve to meet changing organizational needs, adapt to market conditions, and incorporate emerging technologies or methodologies.

Stages of the procurement cycle

The procurement cycle stages represent broader phases that encompass multiple activities and decisions. While the procurement process steps focus on individual tasks, the stages of the procurement process provide a macro view of how organizations move from planning through completion. They help leadership understand resource allocation, timeline expectations, and strategic considerations at each phase.

Planning and sourcing stage

The planning and sourcing stage establishes the foundation for successful procurement outcomes. Organizations conduct spend analysis to understand current purchasing patterns, identify consolidation opportunities, and forecast future needs. This analysis reveals which categories consume the most resources and where strategic sourcing initiatives can deliver the greatest value.

Market research during this stage examines supplier landscapes, pricing trends, and emerging alternatives that could improve quality or reduce costs. Teams develop sourcing strategies that align with organizational objectives and risk tolerance. These strategies define whether the organization will pursue single sourcing, dual sourcing, global sourcing, or multiple supplier approaches for different categories.

Common sourcing approaches and their applications:

The sourcing decision depends on factors such as supply risk, volume requirements, quality criticality, and market conditions. Organizations also determine whether to use competitive bidding, negotiations, or collaborative partnerships as their primary sourcing mechanism.

Stakeholder engagement occurs throughout the planning and sourcing stage. Procurement teams collaborate with end users to understand requirements, with finance teams to establish budgets, and with legal teams to identify contractual needs.

This collaboration ensures that sourcing decisions reflect operational realities rather than purely theoretical considerations. The planning and sourcing stage concludes when organizations have identified qualified suppliers and established the framework for moving forward with specific purchases.

Contract negotiation stage

The contract negotiation stage transforms sourcing decisions into binding agreements that govern supplier relationships. Organizations enter this stage with shortlisted suppliers who have demonstrated capability and competitive pricing. The negotiation process addresses not only price but also payment terms, delivery schedules, quality standards, warranty provisions, and liability allocations.

Successful negotiations create agreements where both parties understand obligations and feel the terms are equitable.

To prepare for negotiations, procurement teams establish walk-away points, identify must-have terms, and explore alternatives if negotiations fail. This preparation covers research on market conditions, analysis of supplier financial health, and consultation with internal stakeholders about acceptable trade-offs. Teams also identify leverage points, such as volume commitments, longer contract terms, or payment timing, that can be used to secure better terms.

Contract terms extend beyond basic commercial provisions to address operational details. Service level agreements define performance expectations and measurement methods. Change order procedures specify how modifications to the scope or specifications will be handled. Dispute resolution mechanisms establish processes for addressing disagreements without litigation. Intellectual property provisions clarify ownership of designs, specifications, or innovations that emerge during the relationship.

The negotiation stage sometimes needs multiple rounds of discussion as parties refine language and reach consensus on contentious points. Legal review ensures that contract terms protect organizational interests and comply with applicable regulations.

Once both parties agree to all terms, authorized signatories execute the contract, which advances the procurement cycle stages to the execution phase. The signed contract becomes the governing document for the supplier relationship and provides the foundation for performance management.

Execution and delivery stage

The execution and delivery stage activates when organizations issue purchase orders under negotiated contracts. Suppliers begin fulfilling orders according to agreed specifications, timelines, and quality standards. This stage represents the operational phase where theoretical agreements translate into physical goods or completed services.

Order management during this stage requires coordination between procurement teams, suppliers, and receiving departments. Suppliers provide production updates, shipping notifications, and delivery confirmations. Procurement teams monitor progress against schedules and intervene when delays or issues emerge.

During execution, procurement teams must actively monitor progress rather than simply wait for deliveries. Quality assurance activities also intensify during the execution and delivery stage in order to ensure that all received goods meet specifications.

Receiving departments inspect deliveries using criteria established during the planning stage. This inspection may involve (depending on the product category):

- Visual examination

- Dimensional verification

- Functional testing

- Laboratory analysis

Documentation of inspection results creates records to support payment processing and provide evidence for resolving disputes. Organizations reject deliveries that fail to meet specifications and work with suppliers to obtain conforming replacements.

The execution and delivery stage also involves managing exceptions, where the process does not go as planned. These include expedited orders, partial shipments, backorders, and specification changes, all of which require special handling.

Procurement teams are required to document these exceptions and ensure that systems reflect actual transaction details rather than original plans. Effective management during this stage prevents disruptions to operations and maintains productive supplier relationships despite inevitable complications.

Payment and closure stage

The payment and closure stage completes individual transactions and supports performance assessment. This stage begins when organizations receive invoices for delivered goods or completed services.

The accounts payable team verifies invoice accuracy through three-way matching before authorizing payment. Timely payment maintains positive supplier relationships and may secure early payment discounts that improve overall procurement value.

Payment timing affects both supplier relationships and organizational cash flow, requiring a careful balance between competing priorities.

Organizations close purchase orders once all deliveries are complete, invoices are paid, and no outstanding issues remain. This closure updates procurement systems to reflect transaction completion and prevents additional charges against closed orders.

Financial systems record final costs and update budget consumption figures. The closure process also triggers retention schedule rules, which determine how long transaction records must be maintained.

Performance assessment provides valuable input for any future sourcing decisions. Procurement teams evaluate whether suppliers met delivery schedules, quality standards, and service commitments. This assessment considers both quantitative metrics and qualitative factors such as communication quality, problem-solving ability, and willingness to accommodate reasonable requests. Organizations document performance in supplier scorecards that inform future supplier selection and contract renewal decisions.

The payment and closure stage also includes lessons learned review for complex or strategic procurement activities. Teams identify what worked well, what challenges emerged, and how future similar procurements could be improved.

This organizational learning ensures that the procurement cycle stages continuously improve over time. The insights gained during closure feed back into the planning and sourcing stage for subsequent procurement cycles, creating a continuous improvement loop.

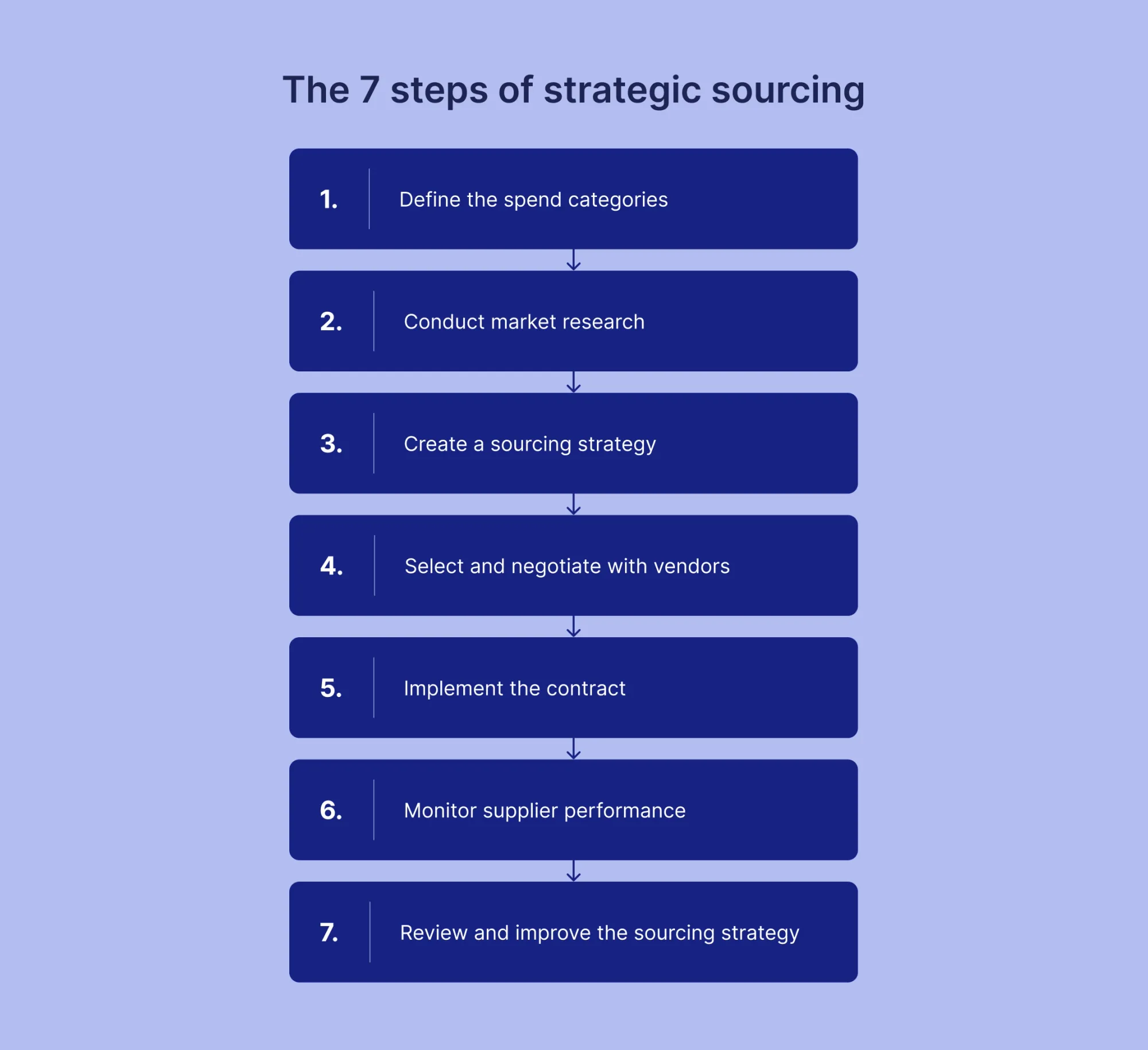

Strategic sourcing: The 7-step model

While the procurement cycle stages focus on carrying out individual purchases, strategic sourcing takes a broader, more analytical view. It complements procurement by shaping supplier selection, managing costs, and driving long-term value.

Organizations use the 7 steps of strategic sourcing to analyze spending categories and build sourcing strategies that drive long-term improvements, not just one-time cost reductions.

1. Define the spend categories

Defining the spend category establishes the scope and boundaries for strategic sourcing analysis. Organizations group related purchases into categories based on common characteristics, supplier markets, or business functions. This categorization allows procurement teams to analyze spending patterns, identify consolidation opportunities, and develop specialized strategies for each category.

The category definition process examines historical spending data to understand purchase volumes, frequency, and distribution across suppliers. Organizations extract this data from procurement systems, accounts payable records, and purchasing card transactions. The analysis reveals which suppliers currently serve the category, what price variations exist, and whether spending is concentrated or fragmented across multiple vendors.

Category boundaries must be drawn carefully to ensure meaningful analysis. Categories that are too broad make it difficult to develop actionable strategies because supplier markets and requirements vary significantly. Categories that are too narrow miss opportunities for volume consolidation and strategic supplier relationships.

Organizations assess category characteristics that influence sourcing strategy:

- Spend magnitude and business criticality

- Supply market complexity and supplier concentration

- Standardization potential versus customization requirements

- Current supplier performance and relationship quality

This assessment helps prioritize which categories require immediate strategic sourcing focus. High-spend categories with fragmented supplier bases typically receive immediate attention. The category definition phase concludes when teams have documented scope, gathered baseline data, and established clear objectives for the strategic sourcing initiative.

2. Conduct market research

Market research provides critical intelligence about supplier capabilities, pricing dynamics, and industry trends within the defined spend category. Organizations gather information from multiple sources to understand the competitive landscape and identify potential sourcing opportunities. This research phase informs strategy development and ensures that sourcing decisions reflect current market realities rather than outdated assumptions.

The research process examines supplier market structure, including the number of viable suppliers, their geographic distribution, and relative market shares. Organizations analyze whether the market is highly concentrated with few dominant suppliers or fragmented with numerous smaller players. Concentrated markets may require collaborative partnerships, while fragmented markets enable competitive bidding approaches.

Key market research activities include:

- Identifying qualified suppliers and assessing their capabilities

- Analyzing pricing trends and cost drivers within the category

- Evaluating technological innovations or alternative solutions

- Understanding supplier financial health and business stability

- Reviewing regulatory changes or industry disruptions

Organizations also benchmark their current spending against market rates to identify cost-saving opportunities. This benchmarking reveals whether the organization pays premium prices or achieves competitive rates. The research may uncover emerging suppliers, alternative materials, or new delivery models that were not previously considered.

Market research findings feed directly into strategy development during the subsequent steps of strategic sourcing. The insights gained during this phase help procurement teams set realistic targets, identify negotiation opportunities, and avoid strategies that market conditions cannot support.

3. Create a sourcing strategy

Creating a sourcing strategy translates market research insights into actionable plans for category management. The strategy defines how the organization will approach suppliers, structure relationships, and achieve cost and performance objectives. It represents the transition from analysis to decision-making within the 7 steps of strategic sourcing.

The strategy addresses several fundamental decisions that shape the procurement approach. Organizations determine whether to consolidate spending with fewer suppliers or maintain a diversified supplier base. This decision balances volume leverage against supply risk and competitive pressure. The strategy also defines relationship models, ranging from transactional spot purchases to long-term strategic partnerships.

Core elements of a sourcing strategy include:

- Supplier selection criteria and evaluation methodology

- Contract structure and duration preferences

- Pricing mechanisms (fixed, indexed, cost-plus arrangements)

- Risk mitigation approaches and contingency plans

- Implementation timeline and resource requirements

The strategy considers both short-term cost reduction targets and long-term value creation opportunities. Organizations may prioritize immediate savings through competitive bidding or invest in supplier development programs that deliver sustained improvements. The chosen approach must align with organizational priorities, risk tolerance, and available resources.

Stakeholder input ensures that the sourcing strategy reflects operational requirements and constraints. Procurement teams present strategy recommendations to leadership for approval before proceeding to implementation. This approval authorizes resource allocation and establishes accountability for achieving stated objectives within the procurement process steps.

4. Select and negotiate with vendors

Vendor selection and negotiation execute the sourcing strategy developed in the previous phase. Organizations issue requests for proposals or requests for quotations to qualified suppliers identified during market research. These formal solicitations communicate requirements, evaluation criteria, and selection timelines to ensure transparent and competitive processes.

Supplier proposals undergo systematic evaluation against predefined criteria. Evaluation teams assess technical capability, pricing competitiveness, delivery reliability, and financial stability. Organizations may conduct site visits, request references, or perform capability assessments to verify supplier claims. This thorough evaluation reduces the risk of selecting suppliers who cannot meet performance expectations.

Negotiation begins after identifying preferred suppliers based on evaluation scores. The negotiation process addresses pricing, payment terms, delivery schedules, quality standards, and performance guarantees. Procurement teams leverage competitive pressure and market insights to secure favorable terms. The phases of procurement that involve negotiation require preparation and a clear understanding of acceptable outcomes.

Successful vendor selection and negotiation achieve:

- Competitive pricing aligned with market rates

- Clear performance expectations and measurement methods

- Favorable payment terms and contract flexibility

- Risk allocation appropriate to both parties

- Long-term value commitments beyond initial pricing

Contract finalization documents all negotiated terms in formal agreements. Both parties review legal language, clarify ambiguous provisions, and resolve outstanding concerns before signing. The signed contracts establish the foundation for implementation and ongoing supplier management within the strategic sourcing framework.

5. Implement contracts

Contract implementation activates the negotiated agreements and transitions the sourcing strategy into operational reality. Organizations communicate new contract terms to internal stakeholders, update procurement systems, and establish processes for ordering under the new arrangements. This implementation phase requires coordination across procurement, finance, operations, and end-user departments to ensure smooth transitions.

System configuration represents a critical implementation activity. Procurement platforms must reflect new suppliers, updated pricing, approved item catalogs, and contract terms. Organizations establish purchase order routing rules, approval workflows, and spending controls that align with contract provisions. Proper system setup increases spend under management and ensures that stakeholders order from approved suppliers at negotiated rates.

Key implementation activities include:

- Stakeholder communication and training on new suppliers and processes

- System updates to reflect contract terms and pricing

- Transition planning for switching from incumbent to new suppliers

- Order placement procedures and contact information distribution

- Performance tracking mechanisms and reporting requirements

Supplier onboarding ensures that new vendors understand organizational requirements and procedures. Organizations provide suppliers with technical specifications, quality standards, delivery instructions, and invoice submission protocols. This onboarding reduces errors and establishes clear expectations from the start of the relationship.

Transition management addresses the changeover from previous suppliers to newly selected vendors. Organizations may phase implementations to minimize disruption, maintain backup suppliers during transition periods, or overlap old and new contracts briefly. Careful transition planning prevents supply interruptions that could impact operations during the procurement cycle stages.

6. Monitor supplier performance

Monitoring supplier performance ensures that contracted commitments translate into actual results. Organizations establish measurement systems that track delivery performance, quality levels, responsiveness, and cost compliance. This ongoing monitoring represents a critical component of the 7 steps of strategic sourcing because it validates strategy effectiveness and identifies improvement opportunities.

Performance metrics align with the criteria established during contract negotiation. Common metrics include on-time delivery rates, order accuracy percentages, defect rates, and invoice accuracy. Organizations collect this data through procurement systems, receiving records, quality inspection reports, and user feedback. Automated tracking reduces administrative burden while providing real-time visibility into supplier performance.

Effective performance monitoring includes:

- Regular scorecard reviews with quantitative metrics

- Periodic business reviews with suppliers to discuss performance trends

- Issue escalation procedures for addressing problems quickly

- Recognition programs for suppliers exceeding expectations

- Corrective action plans for persistent performance gaps

Supplier scorecards provide standardized formats for documenting performance across multiple dimensions. These scorecards facilitate objective comparisons between suppliers and track performance trends over time. Organizations often share scorecards with suppliers to maintain transparency and focus improvement efforts on specific weaknesses.

Performance data informs ongoing relationship management and future sourcing decisions. Consistently high-performing suppliers may receive expanded business or longer contract terms. Suppliers with recurring performance issues face corrective action requirements or contract termination. This performance-based approach maintains accountability and drives continuous improvement within the procurement process flow.

7. Review and improve sourcing strategy

Strategy review completes the strategic sourcing cycle and prepares organizations for the next iteration. This final step evaluates whether sourcing objectives were achieved, identifies lessons learned, and determines necessary adjustments for future cycles. Regular review ensures that sourcing strategies remain aligned with changing business needs and market conditions.

The review process compares actual results with the targets set during strategy creation. Organizations compare actual cost savings to projected savings, evaluate supplier performance against expectations, and measure operational improvements.

This assessment identifies which strategy elements delivered value and which fell short of objectives. Honest evaluation supports continuous improvement and prevents repetition of unsuccessful approaches.

Comprehensive strategy review examines:

- Cost savings achieved versus targets

- Supplier performance and relationship quality

- Process efficiency improvements and cycle time reductions

- Risk mitigation effectiveness and supply continuity

- Stakeholder satisfaction with outcomes

Organizations also monitor external factors that may require strategy modifications. Market changes, new regulations, emerging technologies, or shifts in organizational priorities may require adjustments to the sourcing strategy. The procurement process steps must adapt to these evolving conditions rather than rigidly following outdated plans.

The review phase feeds insights back into category definition for the next sourcing cycle. High-performing categories may require only minor refinements, while underperforming categories need a comprehensive strategy redesign. This continuous improvement loop ensures that the 7 steps of strategic sourcing deliver sustained value rather than one-time gains. Organizations that commit to regular review and adaptation achieve superior procurement outcomes over time.

Key takeaways

- The procurement process steps guide organizations from need identification through payment, creating standardized workflows that improve spending control and supplier management.

- Procurement cycle stages provide a macro view of purchasing activities, encompassing planning and sourcing, contract negotiation, execution and delivery, and payment and closure phases.

- Effective procurement requires coordination between multiple stakeholders, including requesters, procurement specialists, approval authorities, and accounts payable teams.

- Strategic sourcing complements transactional procurement by taking a category-level approach focused on supplier selection, cost optimization, and long-term value creation.

- The 7 steps of strategic sourcing provide a systematic framework to analyze spending patterns, research markets, develop strategies, and continuously improve sourcing outcomes.

- Performance monitoring and regular review ensure that procurement processes and sourcing strategies adapt to changing business needs and market conditions.

Frequently asked questions

Start by identifying all steps in your procurement cycle from requisition submission through payment completion. Map each step sequentially using boxes or nodes connected by arrows, and include decision points, approval gates, and departmental handoffs. Use flowchart software or diagramming tools to create visual representations that clearly show how purchases move through each stage and which stakeholders handle specific activities.

Supplier selection and negotiation typically consume the most time within the procurement process steps, often requiring several weeks for complex purchases. Organizations can streamline this phase by maintaining pre-qualified supplier lists, using standardized evaluation criteria, and implementing electronic RFQ platforms that accelerate response collection and comparison. Establishing framework agreements for frequently purchased categories also reduces repetitive sourcing activities and accelerates individual purchase cycles.

Strategic sourcing operates at a category level to develop long-term sourcing strategies, while procurement executes individual transactions within those strategies. The 7 steps of strategic sourcing establish supplier relationships, set up master agreements, and define purchasing approaches that guide subsequent procurement activities. Organizations use strategic sourcing periodically to optimize categories, then rely on standard procurement processes to execute purchases under established contracts and frameworks.

Common mistakes include inadequate planning that results in rushed purchases, insufficient supplier research leading to poor vendor selection, and weak contract terms that fail to protect organizational interests. To avoid these mistakes, organizations invest time in thorough needs assessment, conduct comprehensive market research before sourcing decisions, and involve legal and finance teams in contract review. Regular process audits and performance reviews also identify recurring problems and drive continuous improvement across the procurement cycle stages.

Manage approvals, budgets, and suppliers across the entire procurement cycle. Explore Precoro.