22 min read

Procurement Analysis: A Game Changer for Strategic Purchasing

Explore what procurement analysis is, why it’s so important, and how it can benefit your business.

With global markets expanding and supply chains growing more complex, the role of procurement leaders has shifted from tactical to strategic. Thus, procurement analysis has become an essential tool in their arsenal.

According to Procurement Tactics, procurement teams are now more involved in shaping business strategies, stepping in conversations from the start rather than when problems come up. However, the success of any strategy hinges on the quality of the data it’s built on. With procurement data analysis, companies can create well-informed plans that drive real, measurable outcomes.

Keep reading to learn more about procurement analytics principles and how they can benefit your business:

What is Procurement Analysis?

Types of Procurement Analytics

Procurement Analysis Steps

Procurement Analytics Benefits and Use Cases

How to Overcome the Challenges of Procurement Analysis

Benefits of Using Software for Procurement Analytics

How to Choose the Right Software

Frequently Asked Questions

What is Procurement Analysis?

Procurement analysis (also known as purchasing analysis) is the process of gathering, reviewing, and interpreting procurement-related data to evaluate past performance, understand the current situation, and inform decision-making. Procurement analytics is the closest related concept. It covers tools, technologies, and methods (such as dashboards, software, and data models) used to collect, process, and analyze this data effectively.

By conducting purchasing analysis, procurement teams can answer the following questions for their companies:

- What are we buying?

- From whom are we buying?

- In what quantities are we buying?

- How much are we spending?

- How often do purchases happen?

- How do we categorize purchases? Which category represents the largest spend?

- What are the average market prices, and what are we paying?

- Are our payment and delivery terms fair?

- Are our business needs met?

- Is it possible to reduce costs? By how much?

- How efficient are our internal workflows, sourcing, and procure-to-pay cycles?

For solid procurement analytics, companies often rely on procurement software that’s built for the job. They also bring in data experts who can quickly sort through and organize vast amounts of information with precision. This mix of the right tools and skilled people helps businesses make sense of the numbers and get the insights they need to move forward.

Types of Procurement Analytics

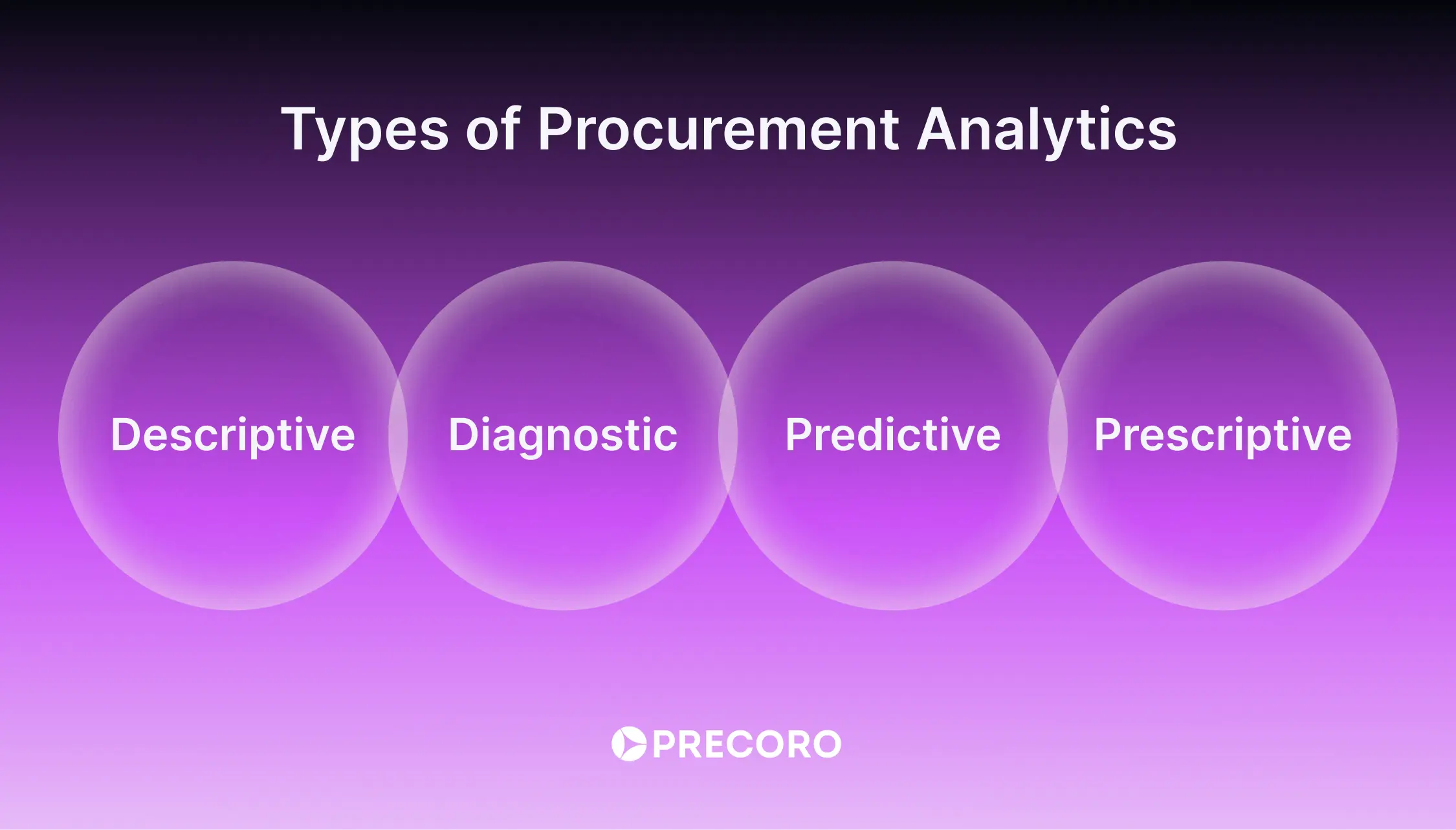

There are numerous ways to use data, and the type of procurement analysis you conduct depends on your goals: whether you want to describe past events, diagnose issues, predict trends, or prescribe actions.

- Descriptive purchasing analytics focuses on understanding what happened in the past. For example, reviewing past purchase orders can uncover patterns like frequent price fluctuations in certain categories of goods. Additionally, it could highlight the most frequently selected vendors over the last quarter and how their performance impacted the company’s overall procurement costs.

- Diagnostic purchasing analytics helps uncover the reasons behind past outcomes. For example, a procurement manager may investigate why a supplier consistently failed to meet delivery deadlines by looking into factors like production delays, logistics issues, or communication breakdowns.

- Predictive purchasing analytics looks ahead, identifying trends and potential future outcomes. For example, procurement managers could use historical spend data to predict future procurement needs, such as forecasting an increase in the purchase of raw materials during peak production seasons. Predictive models could also help anticipate price hikes based on historical trends or global commodity price shifts.

- Prescriptive purchasing analytics helps companies determine the best course of action for a given challenge. Let’s say that predictive analytics warns of a supply chain risk due to geopolitical issues. Then, prescriptive analytics might recommend diversifying suppliers or adjusting inventory to reduce impact.

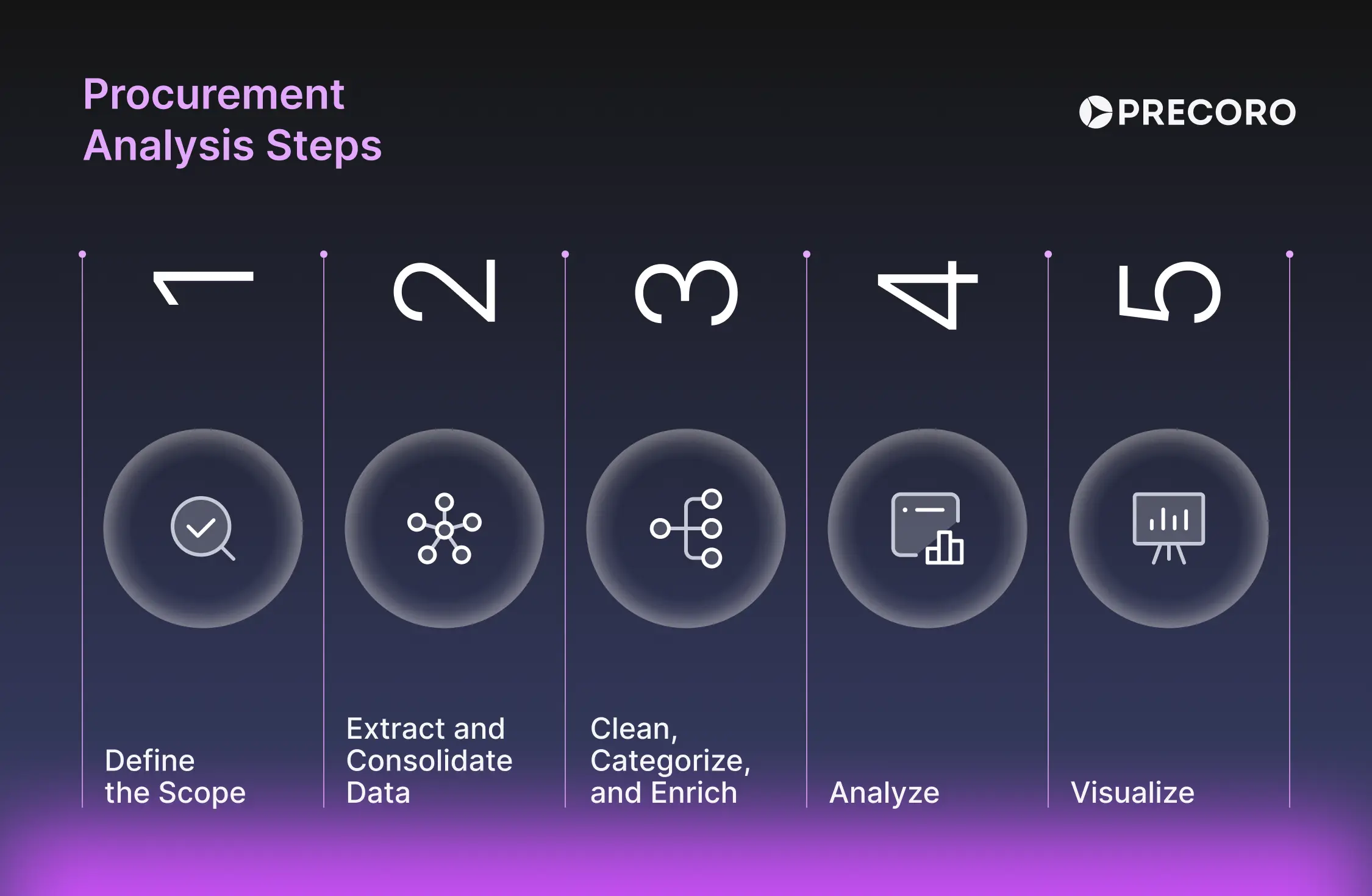

Procurement Analysis Steps

They say data is king these days, and it’s everywhere — from spreadsheets and software to emails and beyond. It’s constantly flowing, but turning that flood of information into something useful is another challenge.

The trick is knowing what matters and figuring out how to pull it from the sea of data. This takes a mix of market know-how, the right tools, and a deep understanding of the processes.

Now, let’s break down the key steps for procurement data analysis.

Step 1: Define the Scope

Before undertaking the analysis, it’s important to determine its scope. This means clearly defining objectives, key performance indicators (KPIs), and the necessary resources to ensure that procurement analysis is both purposeful and focused. The scope will determine what data you need and how to process it.

Goals can be focused on a variety of aspects, such as reducing procurement costs or minimizing supply chain disruptions. Based on the determined goal, decide whether you need a broad procurement data analysis (company-wide, across multiple categories) or a narrow one (focusing on specific suppliers or categories). The larger the scope, the more time the analysis would require.

Next, think about relevant KPIs that would reflect your goals and guide the analysis. Some examples of the relevant metrics include:

- For Cost Reduction: Total spend per supplier, cost savings percentage, the average cost per unit, and spend under management.

- For Supplier Performance: On-time delivery rate, defect rate, supplier lead times, and supplier compliance rate.

- For Risk Mitigation: Supplier risk score, supply chain disruption frequency, and critical supplier dependency ratio.

Step 2: Extract and Consolidate Data

The next step of the procurement analysis process is to fetch the required data from every possible source and gather it in a single centralized database. Begin with compiling a list of internal and external sources.

Internal data sources are corporate applications and other documentation, such as:

- End-to-end procurement management software, ERP tools, or other solutions (for example, warehouse or inventory management software)

- Accounting system

- Excel spreadsheets

- Emails

- Paper documents

External data sources are found outside of the company’s systems and databases:

- Suppliers

- Market reports

- Industry benchmarks

- Bank information

- Public financial statements

- External analytics databases

Data extraction is complex, even from well-known and easily accessed internal sources. It requires time, effort, and often financial investments. Depending on their size and industry, some businesses may need to hire dedicated professionals. For instance, a data scientist can design workflows for how data should be processed, while a data engineer can build and automate the systems that integrate data from various sources.

Remember, not all data holds equal value for the specific purchase analysis. First of all, focus on the information directly tied to your objectives. For example, to identify cost reduction opportunities, key data points include maverick spend, supplier pricing trends, contract terms, and volume discounts. On the other hand, to improve supplier performance, relevant data would focus on delivery times, defect rates, and compliance records.

A good idea is to structure data into categories:

- Must-have data is the critical information needed to address your primary objectives and measure progress toward your goals. Usually, it’s from internal sources, like purchase order history or contract terms.

- Nice-to-have data provides additional context that may improve decision-making but can be skipped if resources are limited. It may include external sources, like industry benchmarks or competitor insights.

- Irrelevant data doesn’t contribute to achieving the specific goals of your analysis. This data often comes from non-procurement sources, like HR or unrelated operational records.

In the beginning, extracted data might be messy and hard to understand, but that’s why the following steps of purchasing analysis exist.

Step 3: Clean, Categorize, and Enrich

Start by evaluating the quality of the data to see if it requires cleaning or reformatting. For instance, you may need to standardize the currencies or adjust date formats to ensure uniformity across the documents. Cleaning the data involves eliminating any errors or inconsistencies that could distort the results of the procurement data analysis.

The next step is categorization. Organizing the data into a logical structure simplifies the analysis and helps uncover valuable insights. This process ensures that all information is coherent and consistent, whether it’s classifying suppliers, product categories, or types of spending.

Once the data is cleaned and categorized, enrich it by adding relevant context or extra attributes. For example, in procurement opportunity analysis, you might include market trends or supplier performance data. Or, in procurement cost analysis, incorporating details like contract terms or total cost of ownership can highlight potential savings.

Step 4: Analyze

The next step is to analyze the collected and enriched data using various methods and tools to extract meaningful insights. Here are some techniques procurement managers can apply in their purchasing analysis:

Review historical data

Analyze past purchase orders, invoices, and supplier performance records to identify trends and patterns. For example, historical data in sourcing analytics might highlight consistent price increases from a supplier or frequent delivery delays, which can guide future negotiations or sourcing strategies.

Identify patterns and anomalies

Look for recurring trends (like seasonal spikes in demand) or anomalies (for example, sudden cost increases in a specific category) to pinpoint inefficiencies or risks in the procurement process.

Cross-reference data sets

Compare internal procurement data with external market data to uncover correlations. For instance, linking supplier price trends with raw material cost fluctuations can help verify if suppliers’ price increases are justified.

Use scenario modeling and simulations

Run “what-if” scenarios as part of procurement opportunity analysis to evaluate the potential impact of decisions. For example, simulate the effect of increasing order volumes to leverage volume discounts, exploring alternative suppliers for cost savings, or consolidating purchases across departments.

Optimization algorithms

Use mathematical models and algorithms to process large amounts of data and identify the best decisions. For example, the algorithms can help determine the most optimal stock at the right time, balancing storage costs with the risk of stockouts.

Step 5: Visualize

In the end, a large data pool can be effectively summarized and communicated through diagrams and charts. Data visualization is especially useful when managers need to share the outcomes of procurement analysis with non-technical audiences, such as executives or cross-functional teams. That way, the hard work of the analyst can really be put into action.

Each chart or graph should directly address a key question or objective. For example, a bar chart showing spend by category can answer: “Which categories consume the most budget?” while a scatter plot of supplier lead times versus quality scores can reveal: “Which suppliers are underperforming?”

Another tip is to match the visual to the data type:

- Use line charts to show trends over time (for example, monthly spend fluctuations).

- Apply pie charts for proportion comparisons (for instance, spend distribution across suppliers).

- Leverage heatmaps to highlight areas of high spend or risk (for example, identifying regions with frequent supply chain disruptions).

Procurement Analytics Benefits and Use Cases

Procurement analysis goes beyond reviewing numbers; it’s about creating a roadmap to meet business goals and stay ahead of the competition. By relying on the insights from the analysis, procurement managers can take control of costs, handle risks, and improve supplier performance.

Additionally, purchasing analytics enables teams to identify spending trends, uncover inefficiencies, and spot opportunities for better negotiations and process improvements. Beyond this, it ensures that strategies align with broader business objectives, transforming decisions from guesswork into data-backed actions.

In challenging situations (like navigating supply chain disruptions or adapting to market instability) procurement analysis is invaluable. It helps companies design responsive, data-driven plans, diversify suppliers, and ensure long-term stability.

Here are specific examples of how procurement analysis can make a significant impact.

Procure-to-Pay Cycle

The procure-to-pay (P2P) cycle covers the entire process of acquiring goods or services, from initial requisition to final payment. It’s a complex process, and without the right knowledge, it can become a maze of approvals, invoices, and potential complications. Here are some examples of how analytics can help procurement managers improve the P2P cycle:

- Procurement analysis can help procurement managers track how long it takes to approve purchase requisitions and pinpoint where delays happen and why (whether it’s a specific department holding up approvals, an overly complex multi-level approval process, or outdated manual workflows).

- In the P2P cycle, purchase analysis can identify trends in mismatched or disputed invoices across suppliers and transactions (for instance, if a particular supplier frequently submits invoices that don’t align with agreed-upon terms or delivery records).

- Procurement analysis helps highlight potential compliance issues within the P2P cycle, such as duplicate invoices or unauthorized spending. Finding anomalies helps businesses identify risks and fix their causes.

- Through purchasing analytics, organizations can measure the overall efficiency of the P2P cycle by analyzing cycle times, error rates, and cost trends. These insights help identify areas for automation, process reengineering, or strategic improvements.

Category Management

Procurement analytics simplifies category management. It helps businesses tailor strategies for specific goods or services by looking at details like supplier reliability, market pricing trends, and a company’s spending patterns. For example, analytics might find price volatility in the raw materials category. This might prompt procurement to lock in long-term contracts with stable suppliers and avoid cost fluctuations.

In office supplies, purchasing analytics could find frequent, low-value purchases that fall under tail spend. It could suggest consolidating orders or switching to preferred suppliers for bulk discounts. For transportation and logistics services, analytics may identify seasonal demand spikes. This insight can prompt companies to secure supplier agreements, ensuring sufficient capacity during peak periods.

Sourcing

Sourcing analytics provides a comprehensive view of the supplier landscape, uncovering the number of potential suppliers, their regional availability, and pricing trends. This information lays the groundwork for a more thorough evaluation of potential suppliers.

Data-driven analysis can help procurement managers answer critical questions like:

- How many suppliers provide similar goods and services?

- Who offers the most favorable payment and delivery terms?

- Should the contract be awarded to existing suppliers or new ones with better potential?

Using procurement analytics ensures that sourcing decisions are informed, strategic, and aligned with organizational goals.

Supplier Management

Managing supplier relationships is crucial for any business, as suppliers and vendors form the backbone of the supply chain. Procurement analysis plays a vital role in monitoring supplier KPIs and assessing their performance and reliability. Key questions that procurement managers can answer with analytics include:

- How are suppliers performing overall?

- Can they consistently provide the requested goods or services?

- Do they frequently adjust prices?

- Are their payment options flexible enough to suit business needs?

- Can they ensure timely delivery?

As the number of contracts grows, organizations need to segment their suppliers. Procurement managers can do that based on criteria such as supplier size, order frequency, or the value of purchased items. Segmenting suppliers in this way provides a clearer picture of their roles and performance levels, allowing for more accurate analysis.

Procurement teams can use supplier segmentation in their procurement opportunity analysis. This approach helps identify areas where renegotiation, bulk purchasing, or switching to alternative suppliers could result in cost savings or improved service levels.

Contract Management

Procurement analysis is useful to procurement teams at every stage of the contract lifecycle. During negotiations, data provides valuable insights into spending patterns, predicted purchase volumes, and market benchmarks. For example, comparing supplier pricing to market rates can help identify opportunities to secure more competitive offers before finalizing the agreement.

After signing the contract, analysis becomes even more critical as the procurement team should track key metrics, such as agreed prices, delivery schedules, payment terms, and other conditions. Procurement analytics helps identify trends and anomalies, such as suppliers consistently charging above agreed prices or missing delivery deadlines.

Additionally, procurement cost analysis can detect unapproved or maverick spending, where purchases are made outside the contract or from unauthorized suppliers. It can help procurement managers ensure that all procurement activities stay aligned with company policies, mitigating the risk of non-compliance or contract violations.

Furthermore, analytics can also help with contract renewal and preparation. By tracking contract timelines and renewal periods, businesses can proactively prepare for renegotiations or competitive bids, ensuring no gaps in supplier agreements. Data-driven contract management not only reduces risks but also maximizes the value of supplier partnerships.

Procurement Documents

A company can analyze the efficiency of the procurement process by looking into key documents, like purchase requisitions, purchase orders, and invoices. Additionally, teams can pinpoint delays by calculating cycle time (how much time it takes to approve purchase requests, process orders, and complete payments).

Procurement opportunity analysis based on documents could highlight areas where automation is lacking or where manual processes are slowing down the overall workflow. For example, long approval times for purchase requisitions could suggest an overcomplicated approval chain, a lack of requisition numbering system, or a lack of digital tools to speed up the process.

Furthermore, businesses can identify if the money is spent as planned by comparing approved purchase requests with actual payments. If a company regularly finds that payments don’t align with the original requests or purchase orders, it indicates reconciliation issues or maverick spending.

Procurement analysis can uncover patterns in overpayments, incorrect invoicing, or unnecessary purchases. This enables businesses to quickly tackle wasteful spending and improve budget alignment.

Risk Management

Data from procurement analytics can highlight weak spots in supplier relationships, such as poor delivery reliability, inconsistent quality, or contractual non-compliance. For example, if a supplier delivers late or fails to meet quality standards, analytics can highlight this risk. Then, businesses can take corrective actions, such as negotiating stricter terms, diversifying their supplier base, or even replacing unreliable vendors.

Procurement analytics can also provide early warnings about potential disruptions during supply chain planning. For example, data might reveal over-reliance on a single supplier in a region prone to geopolitical instability or natural disasters. Armed with this insight, businesses can implement risk-reduction measures, such as sourcing from multiple suppliers, building inventory buffers, or reconfiguring the supply chain to minimize exposure to vulnerable areas.

Once risks are identified, procurement teams can prioritize them based on their potential impact and likelihood. Procurement analytics enables the creation of risk dashboards or reports that provide a clear overview of critical issues, allowing businesses to allocate resources effectively. Additionally, advanced analytics tools can simulate scenarios, such as a supplier default or a spike in material costs, helping organizations prepare contingency plans and strengthen their risk management strategies.

Expense Control

Effective expense control begins with evaluating two key types of spending in procurement cost analysis: direct and indirect.

Direct spending refers to purchases directly tied to the production of goods or services, such as raw materials, manufacturing components, or specialized equipment. Procurement analysis helps businesses not only monitor direct spend but also identify cost-saving opportunities. For example, it can reveal that certain raw materials are consistently more affordable when purchased in bulk or during specific periods.

Indirect spending covers expenses not directly linked to production but necessary for running the business, such as office supplies, utilities, marketing expenses, IT services, and travel costs. Unlike direct spending, indirect costs are often dispersed across departments and harder to monitor, leading to potential overspending. Purchase analysis can help companies address these challenges by highlighting where expenses can be categorized and consolidated and spotting unnecessary overspending on some supplies or software subscriptions.

Demand Forecasting

Demand forecasting helps businesses predict what goods or services they’ll need, in what quantities, and when. By analyzing historical data, market trends, and customer behavior, procurement teams can prepare for the future with confidence.

Why does this matter? Because without forecasting, companies are walking a tightrope between two extremes: running out of stock or drowning in it. Imagine promising a customer their order, only to realize you’re out of supplies. On the flip side, overordering means you’re stuck paying for storage and watching inventory collect dust.

With procurement analysis, companies can spot seasonal trends, anticipate demand spikes, and avoid those last-minute “we’ll pay anything” purchases. By relying on data, a retailer can stock up on the right products before the holiday rush. Meanwhile, a manufacturer can align raw material orders with production schedules to cut costs.

Price Change Forecasting

Prices are constantly shifting due to factors like supply chain issues, inflation, or new trends. In such a volatile environment, procurement analysis can make a real difference. With the right data at their fingertips, procurement managers can stock up on critical items at the best price and keep their budgets in check even when prices seem anything but predictable.

Businesses can predict price movements with surprising accuracy by looking at historical data, tracking market trends, and keeping an eye on external factors like exchange rates or global events. For example, if past data shows that materials are consistently cheaper during off-peak season, a company can plan its purchases accordingly and avoid paying more later. Or, if a key supplier is likely to raise prices due to market trends, the business can lock in better deals ahead of time.

Overcoming the Challenges of Procurement Analysis

Data used to be a byproduct of purchasing operations rather than an integral part of the procurement strategy. Therefore, it’s not surprising that many organizations don’t have the necessary infrastructure to gather and process the vast amounts of information available today.

When the stakeholders and executives decide to bring data into the spotlight, they often run into the same set of hurdles.

Unstructured Data

At the start of your procurement analysis journey, expect the existing data to be a bit of a mess (to say the least). If procurement operations have been managed manually or siloed across different departments and tools, the data will likely be inconsistent, fragmented, and difficult to interpret. For example, purchase orders, invoices, and supplier records might be stored in various formats, making it a challenge to get a clear view of the data.

To tackle this, organizations can implement standardized templates and define clear workflows for data entry and extraction. Training employees on best practices for data handling and ensuring consistency across departments is another key to improvement. Over time, incorporating regular data reviews and audits will help clean up the data and improve its readability for purchase analysis.

Unaligned Team

It’s not enough for successful procurement analysis to have one person on board; it requires full alignment across teams. Procurement managers can champion the cause, but without the support of executives and a collaborative team effort, it will likely become a challenge.

For insightful procurement analytics, stakeholders need to invest in the right infrastructure — whether that’s software, training, or skilled personnel (most likely all three). This investment must be matched with a commitment from procurement officers and financial specialists to learn and apply new tools and techniques.

It’s important to acknowledge that the results from analytics won’t be instant. Gathering and processing meaningful data takes time, and the early stages may feel like slow progress. That’s why motivating the team to stay focused, patient, and goal-driven is highly important. With the right alignment and persistence, the payoff from analytics for procurement can be game-changing.

Outdated Tools

Procurement teams have long relied on Excel spreadsheets for purchase analysis, but nowadays, more organizations are switching to specialized software solutions. While this transition requires upfront investment, it typically pays off quickly.

Managing procurement tasks manually results in data inconsistency and limited accountability for the errors. When procurement documents are tracked in shared spreadsheets, it’s often unclear who’s responsible for changes, making errors harder to catch. Additionally, requesting supplier information via email is not only time-consuming but also opens the door for human error and miscommunication.

Spreadsheets are useful for basic data organization, but they start to fall short when dealing with large volumes of data and the need for speed. Conducting procurement analysis manually can be overwhelming, as it involves juggling multiple data sources and constantly recalculating KPIs. Plus, this type of work is prone to human error, especially when done frequently.

This is where software really shines. A 2023 Deloitte survey found that 42% of high-performing procurement organizations prioritize digital transformation to drive more value. This digital shift isn’t just a passing trend. It’s becoming a must-have to keep procurement operations competitive and efficient.

Benefits of Using Software for Procurement Analytics

Let’s see how exactly specialized software for purchasing analytics can benefit companies.

Faster Processing

With a comprehensive procurement platform, companies can manage all their procurement operations in one place, ensuring that all relevant data is centralized. This creates a single source of truth for procurement, making it easier to generate reports and gain insights.

When your procurement platform integrates with accounting or ERP systems, it can also pull in the necessary data from those tools, providing a complete picture for decision-making. This cuts down on errors and ensures that your team can access up-to-date, accurate information for procurement analysis.

Clean Data

Companies can easily maintain clean data for purchasing analytics by setting up controls during data entry. Procurement software ensures consistency by restricting data entry formats, such as date fields with specific formats or dropdown menus for categories. Thus, companies can prevent incorrect or inconsistent entries from the start.

Additionally, procurement managers can set up mandatory fields in documents within the platform to ensure that crucial information isn’t missed. For example, when a user creates a purchase order, the software can require fields like item description, quantity, price, and supplier contact info before it allows submission. This ensures that critical data isn’t overlooked or skipped, eliminating gaps in procurement records.

High-Level Security

Security is a top priority for modern procurement analytics solutions. These platforms typically store data securely in the cloud, with automatic backups and encryption, ensuring that sensitive information is well-protected. This significantly reduces the risk of data breaches compared to older, more vulnerable methods, like emailing confidential details or saving them in spreadsheets.

Customer Support

When using procurement software, organizations get access to a dedicated support team that can assist in resolving any issues that may arise. The support team knows how to troubleshoot the problems that commonly occur, like network instability, incomplete data extraction, or data discrepancies.

In addition, the team can assist in the interpretation of complex procurement data or fixing exceptions, so that procurement managers can focus on making decisions without being bogged down by technical difficulties. This support also includes data integrations with ERP systems and other business tools to make sure that all the needed information can be properly processed in procurement analytics.

How to Choose the Right Software

Choosing the right procurement platform with purchasing analytics capabilities is a decision that your team will grapple with for years to come. It’s not just a matter of picking the cheapest option. Instead, approach it as a smart investment that should align with your long-term goals. To begin this strategic process, a comprehensive software directory can serve as an invaluable resource for shortlisting potential solutions. When evaluating software solutions, procurement professionals and other stakeholders should consider several key factors:

Cost of Acquiring, Support, and Development

While the upfront cost is an obvious consideration, the total cost of ownership is just as important. Consider long-term expenses like support, training, customizations, and future updates. Some procurement analytics solutions might seem cheaper upfront but can rack up costs over time in maintenance or additional features.

Ask yourself:

- Can the software provider offer training sessions for the team?

- Does the software offer dedicated, ongoing support, or is it limited to case-by-case troubleshooting?

- Will you need to pay extra for future updates or software enhancements?

- How flexible is the system in terms of customization to meet your evolving needs?

Functionality and User-Friendliness

The software you choose must strike the right balance between powerful functionality and user-friendliness. On one hand, it must be comprehensive enough to handle the entire procurement process. On the other hand, it should be easy enough for both new users and experienced procurement professionals to navigate without extensive training.

A procurement software solution designed for long-term use should support the entire procurement lifecycle with features that simplify every step. This includes:

- Supplier management: The ability to store supplier data and track the suppliers’ performance.

- Sourcing & RFQs: Tools for creating, managing, and analyzing requests for proposals (RFPs) and bids.

- Intake management: Streamlined requesting with item and supplier catalogs, custom fields, and dynamic forms to create documents tailored to your needs.

- Purchase order (PO) management: Customizable templates for POs, the ability to set up extensive approval workflows, and tracking capabilities.

- Invoice reconciliation: Automated three-way match (reconciling the purchase order, invoice, and receipt) to ensure that the company only pays for what’s been delivered, reducing maverick spending and fraud risks.

- Contract management: Features for storing, monitoring, and tracking contracts to ensure compliance, with automated reminders for expiration dates.

Make sure that a solution is suitable for your region, whether in the USA, the UK, Australia, or South Africa. For multi-entity companies, especially those that operate across multiple regions, the software must offer scalability and flexibility. It should allow centralized control while providing the ability to tailor processes and reporting to each entity’s specific needs.

For example, if a company has branches in the U.S., Europe, and Asia, the software must handle multiple currencies, tax rules, and procurement policies. Moreover, the system should ensure consistent reporting and visibility across all entities.

Data quality and integrations

For procurement software to truly shine, it must not only guarantee the security of your data but also enable seamless integrations with other tools. Otherwise, the procurement team will be forced to make manual transfers to procurement analysis platforms — essentially coming back to square one.

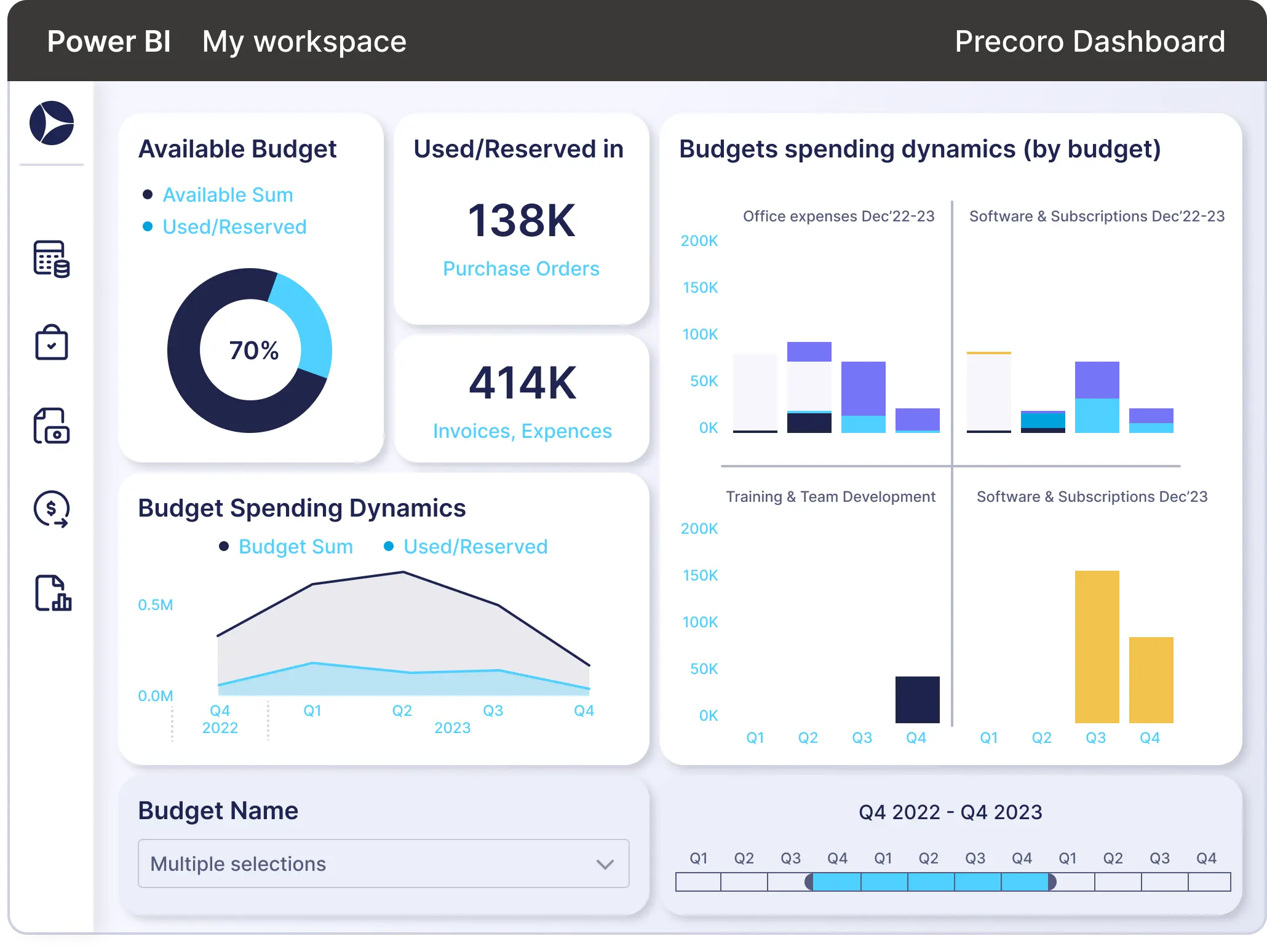

Let’s look at how important integrations are, using Precoro and Power BI as an example. Power BI is a popular suite of business intelligence tools used by many organizations to generate visual and interactive reports from nearly any imported data.

Precoro, a platform for procurement centralization and automation, is a workplace for intake management, purchasing, invoice processing, and supplier management. Its Reports Module allows users to create unlimited preset or custom reports based on any procurement data. Moreover, thanks to Precoro’s integration with Power BI, users can:

- Easily sync all the data from Precoro (like budgets, inventory, invoices, POs, receipts, RFPs, suppliers, and more) to their Power BI account with just one click.

- Create multiple analysis pages (for example, budgets, POs, invoices) on their Precoro dashboard in Power BI and organize all metrics into meaningful categories for clearer insights.

- Set up automated updates for their reports, customizing the refresh frequency and parameters (such as time, categories, and more) to ensure they always have the latest data without manual input.

Frequently Asked Questions

Data in procurement serves as a foundation for informed decision-making. Procurement professionals use it in their analysis to spot purchasing patterns, monitor supplier performance, identify cost-saving opportunities, and forecast demand.

Procurement analysis is the process of collecting, organizing, and reviewing procurement data to make fact-based decisions. This type of analysis enables procurement teams to review past performance, assess existing processes, and anticipate potential risks and opportunities in the future.

Procurement teams follow a set process for purchasing analysis. They begin by defining the scope of analysis, then extract, consolidate, clean, categorize, and enrich the data. The final steps involve analyzing the information and visualizing the insights.

A procurement analyst evaluates purchasing data and processes. They prepare reports for stakeholders where they analyze spending patterns, assess supplier performance, forecast future needs, or identify opportunities for cost savings.

Analytics for Procurement in a Nutshell

The purpose of procurement analysis isn’t to crunch numbers but to help the procurement department make informed decisions that influence the bottom line of the entire company. By collecting and analyzing data from sources like purchase orders, supplier invoices, and contracts, teams can do the following:

- Spot trends, such as relying too much on high-cost suppliers, and take action to negotiate better deals.

- Predict potential supply chain disruptions or spot poor supplier performance early, allowing proactive interventions.

- Optimize supply chain inventory to avoid overstock or shortages and identify bottlenecks in the approval process.

Executives also rely on procurement analytics to align purchasing strategies with broader business goals. Whether it’s reducing overall costs, ensuring compliance, or supporting sustainability initiatives, analytics turns data into actionable insights.

To stay competitive, companies increasingly invest in procurement platforms with reporting capabilities, dashboards, and integrations to various business tools. All to ensure that data flows freely and in real time. With the right tools in place, procurement analytics becomes less of a chore and more of an easily achievable foundation for great decisions.