18 min read

Procurement Strategy: Your Action Plan for Proactive Purchases

Move from reactive buying to strategic procurement. With a procurement strategy, every purchase contributes to your business goals.

Without a well-defined procurement strategy, your purchasing is just that—a routine set of steps your team follows without any sense of direction. The system might work, but it won’t bring any worthwhile results. And businesses know how important the strategy is: only 6% operate without one. However, most still struggle with execution and performance tracking.

This guide will go over the basics of strategic procurement, its key objectives, and how to develop a strategy that perfectly fits your company’s needs.

Ready to move your strategy to the next level? Read on to learn:

What is a procurement strategy?

What is strategic procurement?

Differences between tactical, operational, and strategic procurement

Key strategic procurement objectives

How to build an effective strategic procurement process

What a procurement strategy should include: A practical template

Frequently asked questions about procurement strategy

What is a procurement strategy?

A procurement strategy is the company’s long-term plan for purchasing high-quality goods and services, within budget, and on time. It sets clear priorities, like what to buy, from whom, when, and under what terms, so every purchase supports business goals. It also defines the criteria for making those decisions, such as supplier qualifications, budget limitations, and procurement compliance requirements.

Internal company data and external market procurement intelligence shape the direction of the strategy. Procurement professionals usually consider supplier data, market trends, price fluctuations, legal and compliance demands, and other industry-relevant factors.

A procurement strategy shows how a company plans to buy what it needs in a way that supports its overall goals. It sets the standards for how to choose suppliers, control costs, and get the right quality at the right time.

Watch this video to learn more about procurement strategies:

What is strategic procurement?

Once you’ve defined your strategy, strategic procurement is how you put it into action. It focuses on making purchases that meet immediate needs and support business growth. Strategic procurement prioritizes total value over lowest price and helps ensure that every order is delivered on time, within budget, and in line with the broader company goals.

It’s a proactive, forward-looking approach to purchasing. Instead of simply asking, “What do we need right now?”, your team is thinking, “What will we need next quarter? Is there a better time to purchase this? Can we get more out of this contract?”

Differences between tactical, operational, and strategic procurement

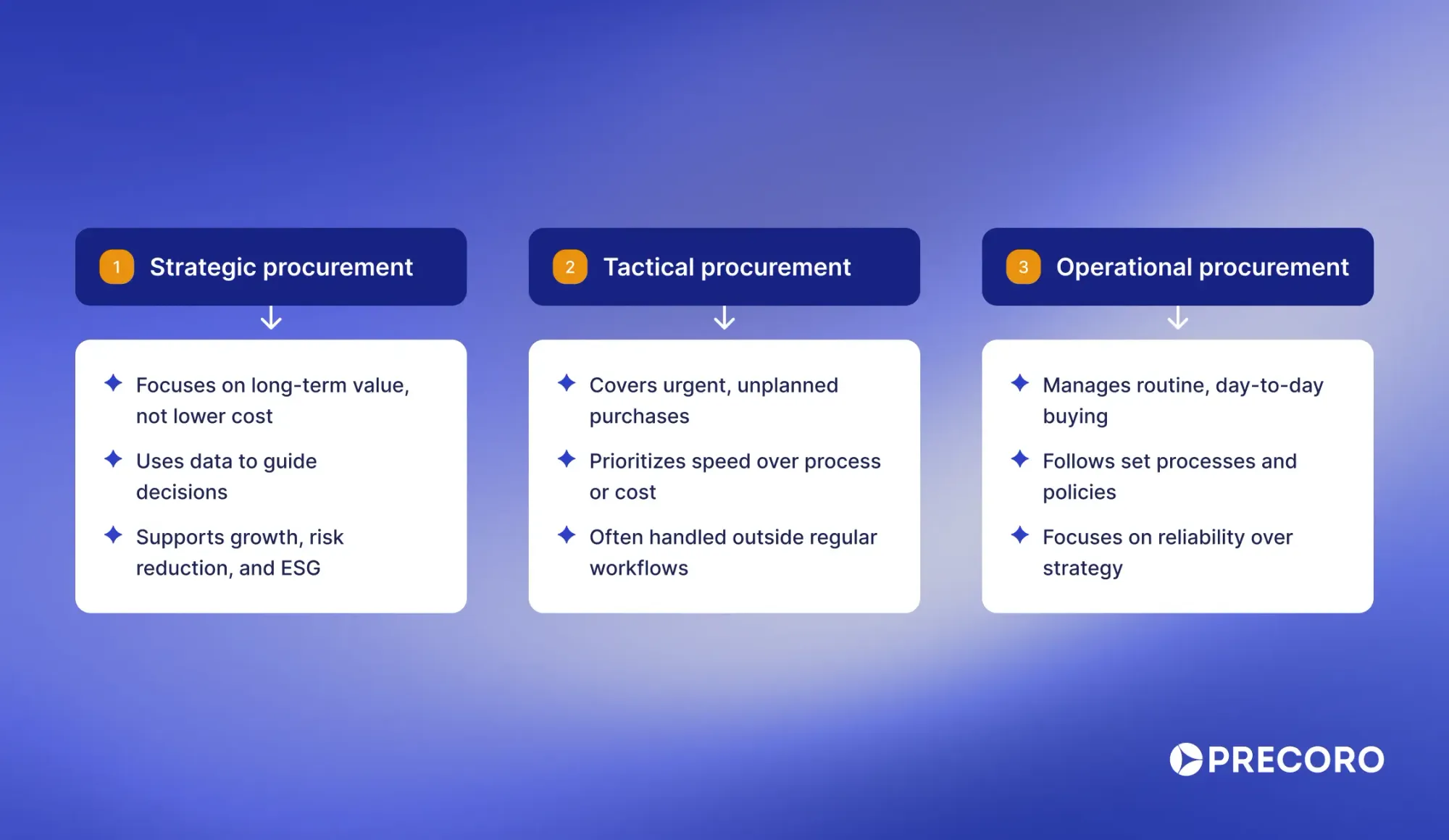

Strategic procurement isn’t the only way companies can implement their strategy, and it shouldn’t be. Not every purchase needs long-term planning or stakeholder buy-in. Different situations call for different measures, tactical and operational being some of them.

Let’s take one of the procurement strategy examples: if production equipment suddenly broke down one day, you wouldn’t gather all stakeholders to discuss the next steps. You’d probably do everything to get things up and running again: you’d either contact maintenance or order a replacement from another vendor.

Yes, you’d have to pay more now and compromise for this expense in other ways, but the costs you’d suffer for stalled production would be much bigger. That’s known as tactical procurement, a reactive approach to purchasing.

In contrast, operational procurement handles the routine purchases that keep the business going. For example, your company probably has software subscriptions for cloud storage or antivirus purposes, all of which renew every year.

That’s operational: renewal is automatic, pricing is fixed in your contract, and the payment dates are non-negotiable. Switching to another vendor on a whim isn’t an option since you need these services to keep the operation running.

Let’s dive deeper into how each approach stacks up against the other:

- Strategic procurement looks at the bigger picture. It’s long-term, data-driven, proactive, and designed to align procurement with the company’s core objectives. Being strategic often means negotiating bulk orders through long-term contracts, sourcing from more sustainable vendors, or consolidating purchases into spend categories.

- Tactical procurement is short-term and reactive. It’s focused on meeting immediate needs, like buying something quickly to keep a project moving or to replace a missing item.

- Operational procurement handles the day-to-day purchasing that supports the business operations. It’s managed through a set of standard processes and policies. The goal is to keep everything running steadily and without any hiccups.

Key strategic procurement objectives

When you create a procurement strategy, your goal isn’t only to reduce costs. The potential outcomes are much bigger and impact operations on a deeper level than you’d ever achieve with on-the-spot decisions. Here, you’re not just trying to keep the process going; you’re aiming to make it better.

There are no two identical procurement strategies. Every business has its own unique objectives, shaped by internal and external factors. However, each plan has a starting point that you build around and expand depending on what you want to achieve. Here are the strategic procurement objectives that companies focus on first.

Cost optimization

Cost reduction is and should be the focus, but the goal of strategic procurement is to make these cuts scalable and sustainable, not just one-off occasions. Instead of quick fixes like employee layoffs or a switch to a cheaper vendor, a good strategy improves how money is spent over time.

Strategic procurement aims to save money by lowering the total cost of ownership (TCO). Before buying, you factor in all the supporting costs, like maintenance, shipping, and upgrades. For companies with a tight budget, paying more upfront but less in the long run could completely change the profit picture.

Besides focusing on TCO, you can work on your cost control in a number of ways:

- Negotiate vendor contracts. Review volumes, delivery schedules, and payment terms before renewal. Use your purchase data to lock in better pricing, secure volume discounts, and add service-level guarantees.

- Automate routine steps. Manual work adds hidden costs. Automating purchase requests, approvals, and 3-way matching helps your team spot gaps in existing workflows and focus on the supply chain optimization strategy itself.

- Look at outsourcing options. Not everything needs to be handled in-house. Outsourcing time-consuming tasks, like accounts payable, can free up internal resources, especially with the right partners.

- Divide spend into categories. Category management helps identify where the money is going, where you can consolidate orders, and where specific procurement strategies will have the most impact. Instead of a single, company-wide savings target, you can set specific ones that together contribute to the bigger goal.

Risk mitigation

If you only focus on short-term outcomes, risks often go unnoticed until they disrupt your operations. A risk management strategy helps predict supply chain disruptions ahead of time and minimize the potential damage. When you analyze the state of the market, internal conditions, and general geopolitical picture, you’re not only aware of the risks, but you can develop ways to stop them before they hit the business.

If risk mitigation is one of the objectives in your procurement strategy, here’s a core set of steps you can take:

- Identify what could go wrong and why.

- Analyze the root cause of the risks, what they are, and how badly they could affect the business.

- Prioritize the risks based on how serious the impact could be.

- Monitor for early warning signs to spot risks in time.

- Communicate your plan of action to the teams involved in procurement.

- Take preventive measures before the disruption happens or react quickly to minimize the damage.

Let’s take a real-life scenario of how risk mitigation works in practice. A vendor you’ve been sourcing from for years suddenly filed for bankruptcy without notice and left you stranded without the materials you need. Nothing seemed wrong: the last delivery arrived on time, the payment went through, and communication was crystal clear up until that point.

If your strategy didn’t include a plan for such cases, you’d have been left without supplies and scrambling to find a new supplier. If you approached sourcing strategically, you’d have a secondary supplier on hand. You could renegotiate the terms and adjust the order volume to cover what the previous vendor supplied.

Strategic supplier management

Any procurement strategy worth its salt focuses on turning critical suppliers into partners that can help you achieve business goals. Sourcing teams research and vet potential vendors and select the ones that offer the best price-to-quality ratio. The procurement team then sets up clear communication channels and workflows to build long-term, sustainable vendor relationships.

Suppliers that play a critical role in your operations are worth the extra investment. Instead of keeping the relationship strictly transactional, work with them to renegotiate contracts, improve services, or even co-develop products. These partnerships can benefit both sides. You get a fresh perspective on what you’re offering to consumers and favorable terms. The supplier, on the other hand, gets a steady flow of orders and future collaboration opportunities.

Of course, not every supplier has to (or wants to) be involved in strategic procurement management. These efforts usually focus on a small number of vendors that provide essential or niche goods.

Global sourcing

Even with tariffs and trade tensions, most businesses still source globally, with only 13% planning to reshore (bring sourcing back to the company’s home country). US-based organizations indicate a desire to nearshore (purchase from neighboring regions). These numbers indicate only one thing: the benefits of global sourcing still outweigh its risks.

The goal of strategic procurement? Services or goods that cost more locally can be sourced at better prices in international markets. Working with global suppliers also gives you access to expertise, materials, or technologies that may not exist in your home country.

However, before you shift the focus of your procurement strategy to global sourcing, consider the challenges it brings:

- Communication barriers that can affect quality and cost: Misunderstandings can lead to delays, unexpected expenses, or quality issues.

- Complex supply chains: The more suppliers you rely on, the harder it is to spot supply chain risks, especially if supplier management is entirely manual.

- Long delivery times: Shipping from abroad can take weeks. If the order wasn’t delivered in full, you have to wait even longer for the vendor to correct the mistake.

- Strict regulations and compliance demands: 1 in 4 businesses struggle to keep up with the overwhelming number of rules and laws.

- Increased carbon footprint: Longer transportation isn’t typically environmentally friendly.

- Hidden costs: Unexpected customs fees, tariffs, and exchange rates can slowly drain your budget.

Sustainability and Corporate Social Responsibility (CSR)

With ESG and CSRD regulations, companies turn to green purchasing: a conscious effort to source in a way that lowers negative effects on the environment and human health. They prioritize purchases from suppliers that follow sustainable procurement procedures and offer goods produced with minimal environmental impact.

To do this, companies either select suppliers with a green company philosophy (70% of businesses consider at least one ESG factor during vendor selection) or encourage their existing network to adopt a more sustainable approach. As part of CSR practices, procurement teams audit suppliers to check how they source raw materials, produce goods, treat their employees, and handle shipping.

Total Quality Management (TQM)

Total Quality Management (TQM) is a comprehensive approach that aims to improve the quality of services or goods the company delivers through better procurement practices. This approach doesn’t just focus on a single objective; it aims to make purchasing better across the entire supplier lifecycle, from vendor selection to final payment. The goal is to create a high-quality product for the end customer in the most efficient way possible.

Quality becomes a shared responsibility in TQM as all involved parties are held accountable for their performance and results. To integrate TQM into your procurement, do the following:

- Choose suppliers who can consistently meet quality standards;

- Work closely with vendors to improve their performance over time;

- Align strategic purchasing decisions with broader company goals for product and service quality;

- Use feedback and data to drive long-term improvements; and

- Implement quality control and quality assurance practices throughout procurement.

As part of this strategy, you look for areas that need improvement, automate workflows for sourcing and purchasing processes, and continuously train employees. Tools like Precoro help put these changes into action. It lets you standardize requests, so no information is left out, automate approvals with custom workflows, and hand over invoice capture and expense reporting to AI.

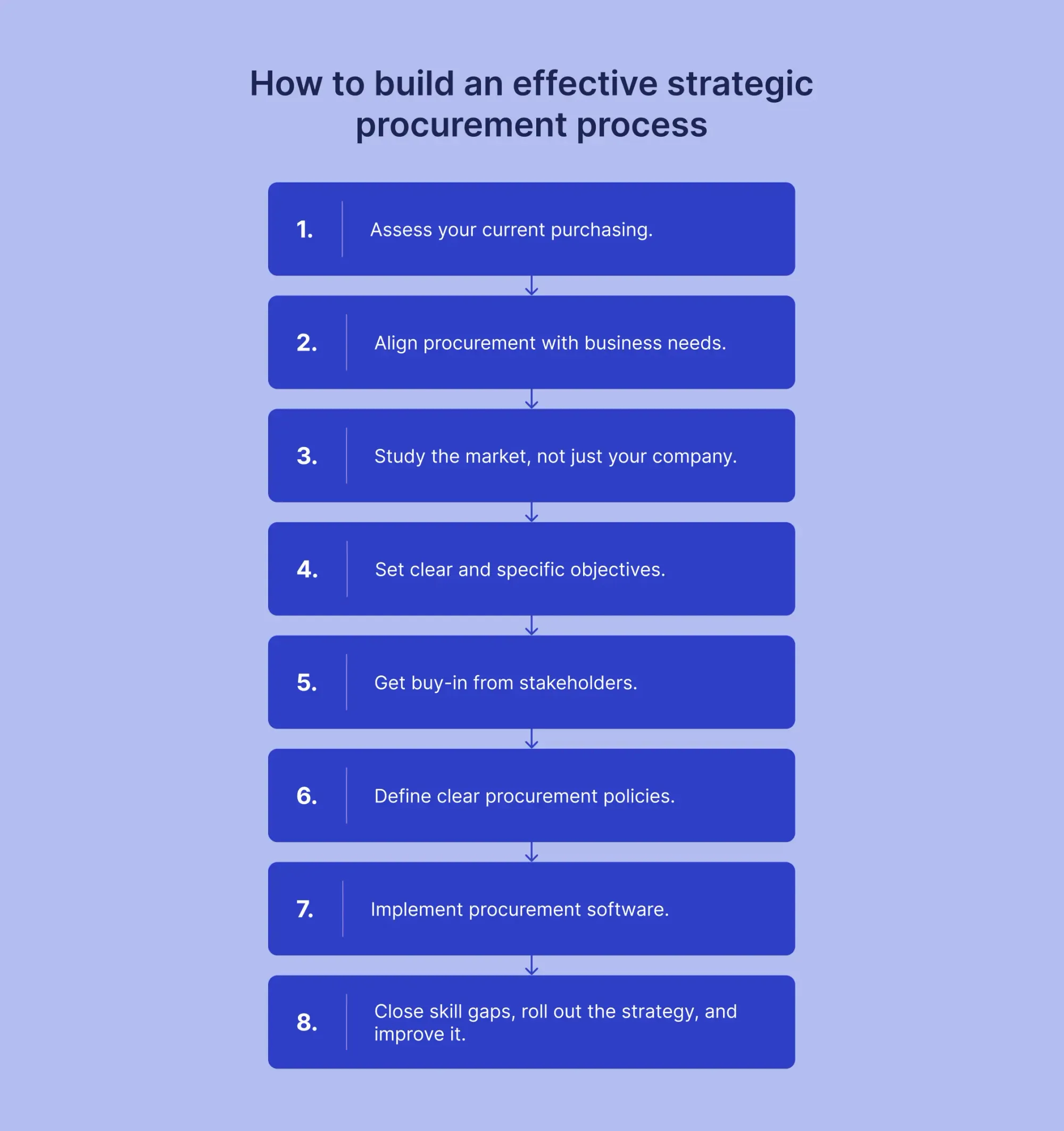

How to build an effective strategic procurement process

An effective procurement strategy example is result-oriented and sets ground rules that your team can follow instead of simply guessing. The present isn’t the only factor in the picture—such strategies account for how unpredictable and complex the market environment can be. They also have enough space to evolve and include digital solutions to improve routine tasks.

Still not sure where to start? The Kraljic matrix helps you understand where each of your company’s purchases sits in the overall strategy. Analyze your purchasing portfolio based on two key criteria:

- Profit impact: How much does the purchase contribute to the company’s profitability? Does it directly affect customer satisfaction or product quality? Is there an opportunity to save?

- Supply risk: How complex and competitive is the supply market? Are there any risks that could disrupt the supply chain? Is the material widely available or highly specialized?

We’ve covered in detail how to apply the Kraljic matrix to your existing supplier network in our article about vendor relations (see: Tools to manage vendor relationships: Kraljic matrix).

Let’s go through a set of steps you need to take for a well-rounded procurement strategy development.

1. Assess your current purchasing.

Start by analyzing the company's current spending culture. Identify what exactly it buys and how it spends. Then, pinpoint different business units and departments involved in the strategic procurement process and review their processes to identify inefficiencies.

If you already have a strategy, assess whether it still meets your current needs and can support the plans for the company's growth. Flag any roadblocks and missed opportunities, so you can address them over time.

2. Align procurement with business needs.

Through current state analysis, you’ve determined how your company purchases today. Now, take a hard look at how you think the company should purchase. Do you want more cost savings in your procurement strategy? Planning to expand to a different market in the next five years? Review the contract terms and spot where you could negotiate deals or discounts.

Talk to stakeholders and consultants from procurement strategy services. They might offer a fresh perspective on what the business actually needs and whether its purchasing practices contribute to it or hold it back.

3. Study the market, not just your company.

Once your internal goals are clear, it’s time to zoom out and look outward. A realistic procurement strategy should focus both on the external risks you’re not prepared for and hidden opportunities.

Use these tools to structure your findings:

- Porter's Five Forces model analyzes how competitive the market is. It focuses on five factors affecting the market: competitor rivalry, the threat of new market entrants, the bargaining power of suppliers, the bargaining power of buyers, and the threat of substitute products or services.

- PESTEL analysis helps track the external forces that can affect your company: Political, Economic, Social, Technological, Environmental, and Legal factors.

- SWOT analysis is used to identify Strengths, Weaknesses, Opportunities, and Threats that the procurement team might face.

In your market analysis, make sure to include all the key players of the procurement process, not just the designated team. List suppliers, distributors, competitors, partners, and, most importantly, end customers. Markets are notoriously ever-changing, so update the analysis as often as you can to make sure the strategy stays relevant.

4. Set clear and specific objectives.

To define strategic procurement objectives, balance what you want to achieve and what resources you have on hand. These objectives should guide all the teams involved in purchasing and supply decisions, not just procurement.

Prioritize key points based on their impact on the company’s bottom line. Make objectives specific and measurable—that way, you’re not just promising to spend less but have a realistic target you can track. Instead of saying, “The company will save more,” define the goal like this: “The company will reduce indirect spend by 10% in Q2 and Q3 by renegotiating contracts with the top 5 suppliers and consolidating orders.”

Use the SMART framework to keep each goal:

- Specific: Specify and align the goal with a defined need or objective.

- Measurable: Set a clear metric to measure the goal’s progress and change the course of action if needed.

- Assignable: Define who can be held accountable for the execution and the final outcome.

- Realistic: Ensure the goal can be achieved with the available resources (budget, time, human capacity, etc).

- Time-bound: Set a clear timeline for each goal, with the start date, checkpoints, and end date.

5. Get buy-in from stakeholders.

During procurement strategy development, you’ll need input from the company’s stakeholders and partners. Stakeholders are the people interested in the company’s success, such as investors, procurement managers, employees, suppliers, and customers.

All your stakeholders involved in the procurement process should be on board with creating or revising the procurement strategy and should know exactly how they’re expected to contribute.

6. Define clear procurement policies.

Outline who approves what, what types of purchases each department can make, which suppliers to use, and any exceptions to the rule. You don’t need to start from scratch. Review your existing procurement guidelines and adjust them to fit your current goals, tools, and team structure. It’s faster and helps make sure nothing important gets missed.

Remember to also engage stakeholders during this step. Simply creating policies at one person’s wish might result in resentment and disagreements down the line. Make these policies easily accessible to everyone involved. Update them once something changes. If a specific issue comes up several times, write down the solution, so your team has a clear path of action to follow.

7. Implement procurement software.

The procurement process involves a lot of moving parts that can skew the entire system if not handled carefully. Think about which tasks in strategic purchasing you still manage manually. Is your team wasting hours entering invoices into the in-house system? Do you have to deal with duplicate invoices? Are the documents scattered between spreadsheets and email inboxes? Then, using technology is no longer optional.

Platforms like Precoro give your team control over every step of the process. They centralize requests, approvals, POs, invoices, and budgets in one system, so you don’t need to search for emails or update spreadsheets. You can set up approval workflows for each type of document, auto-generate POs from approved requests, and perform 3-way matching in just 30 seconds.

8. Close skill gaps.

Before rolling out a strategy, make sure your team understands what you’re trying to achieve and how procurement fits into the bigger picture. It’s always a good idea to have an open-minded and honest conversation with the team and offer everyone a safe space to express any concerns, offer feedback, or ask questions. If needed, bring in an external consultant who’s offering procurement strategy services to address the team’s worries.

Keep employees aligned with the strategy’s key objectives, and make sure they know what’s expected of them at each stage. If you're introducing new tools like procurement software or shifting from tactical to strategic purchasing, set aside time for your team to get used to the new systems and processes.

9. Roll out and improve the strategy.

Once you've outlined your procurement strategy on paper, it’s time to put it into action. This process requires you to monitor and analyze what works and what doesn’t. Unfortunately, only 41% of businesses regularly track their strategy’s execution, meaning they lose out on savings and other opportunities. Define what a successful outcome looks like from the start and set key performance indicators (KPIs) to monitor the results:

- Cost savings: Is the company spending less per category?

- Spend under management: How much spend is actively controlled and tracked? How much falls under tail spend?

- Compliance rate: Are purchases made through approved suppliers, contracts, and processes?

- Supplier defect rate: How often are suppliers delivering incorrect, late, or low-quality goods or services?

- Supplier lead time: How long does it take for suppliers to deliver after you place an order?

- Purchase order cycle time: How long does it take from request to approved PO?

These are just some examples of KPIs—choose the ones directly tied to objectives you want to achieve. The process doesn’t stop once you finalize the strategy. Review it regularly to factor in other influences, such as market fluctuations, business growth, and technological development.

What a procurement strategy should include: A practical template

Document the strategy based on the steps outlined in the strategic procurement process. A detailed document can serve both as a reference point and a roadmap for the procurement team.

Here’s what to include:

- Strategy statement: A short summary of what the procurement strategy is designed to achieve and why it matters to the business. It should give a clear picture of the strategy’s purpose.

- Strategic objectives and benchmarks: The specific outcomes and targets that contribute to the broader business goals.

- Governance structure: Defines who’s responsible for what. This section should include approval levels and escalation paths.

- Spend and supplier analysis: A breakdown of current and projected spend by supplier, category, or department. Includes insights on supplier performance and risk.

- Risk management: Key risks you found during research and how you plan to prevent them.

- Category management approach: A strategy for how spend will be organized by category and who owns each one.

- Contract management: How your organization will manage supplier contracts, renewals, and potential conflicts.

- Capabilities and resources: An overview of your team’s current skills and tools. Include a plan for how you’ll fill the gaps with training, hiring, or new software.

- Sustainability and ESG considerations: Any environmental, social, or compliance standards your procurement strategy planning needs to support (local sourcing, emission tracking, etc).

- Implementation roadmap: A step-by-step plan outlining who will do what and in what order, with timelines.

- Key performance indicators (KPIs): Metrics you’ll use to monitor performance.

- Data and analysis methods: Spend analysis, SWOT analysis, Porter's Five Forces, etc.

- Tools and technology: The platforms you’ll use to support the strategy, such as ERP systems or modern procurement tools like Precoro.

- Review and update schedule: A set timeline for reviewing and updating the strategy, usually quarterly or annually.

Frequently asked questions about procurement strategy

There isn’t one. Each company's needs, objectives, and business goals are unique. Organizations can choose from several typical procurement strategies. However, any strategy can work if it’s customized to meet your company's requirements. Use tools like Porter's Five Forces to understand where your company stands in the market.

Strategic procurement management is the process of planning and managing purchases to support long-term business goals. It includes setting clear priorities, negotiating contracts, and tracking supplier performance.

Check performance against KPIs like cost savings, supplier lead times, compliance rates, and purchase order cycle time. If your strategy reduces risk, improves supplier performance, and helps hit financial targets, you’re on the right track.

Procurement and finance professionals usually lead the process, but input from stakeholders across the business is critical. That includes operations, legal, and department heads. External consultants who offer strategic procurement services can add value if your team lacks the resources or insight.

Strategic procurement is long-term and goal-driven. It focuses on sourcing, cost reduction, and supplier performance. Operational procurement manages day-to-day purchases through set policies and processes.

Why a procurement strategy is important

Procurement strategy defines how a company manages spending, supplier relationships, and operational risk. It gives teams a clear structure, a roadmap they can fall back on when making purchases. Additionally, a clear strategy gives the company the stability to experiment, test, and search for ways to innovate. Without one, even the best procurement tools or policies can fall short.

There’s no fixed format. Some companies need a cost-focused approach; others require a more complex procurement strategy planning to support compliance, ESG, or global sourcing. It might even depend on the industry you’re in, whether it's the construction business, the renewable energy sector, hospitality, healthcare, or other industries.

What’s important is that the strategy reflects the company’s goals, works within existing processes, and can be applied consistently across teams. Regular updates ensure it stays relevant as conditions change.