17 min read

Vendor Relations 101: From Transactions to Strategic Decisions

Discover how to build long-term vendor relations with practical frameworks and actionable advice.

Stable vendor relations make day-to-day operations easier for any business. They help you get what you need when you need it without worrying about running out of supplies or stalling the production pipeline.

In the current climate, with inflation on the rise and uncertainty in the global economy, these relationships carry even more weight. In fact, working with suppliers is one of the main focus areas for 2025. According to Deloitte’s 2025 Global Chief Procurement Officer (CPO) survey, 41% of CPOs are actively renegotiating with existing vendors to deal with volume volatility and price hikes.

Having a partner who can meet you halfway and genuinely cares about your company makes all the difference. But supporting these connections isn’t always easy and requires effort and input from both sides.

In this article, we’ll walk you through the key stages of these partnerships, pitfalls that weaken them, and vendor management best practices that help you sustain them.

Find out more about:

What is vendor relations?

What are the key stages of the vendor relationship management lifecycle?

Challenges that break down vendor relations

Best practices of vendor relationship management

Tools to manage vendor relationships

Frequently asked questions about vendor relations

What is vendor relations?

Vendor relations is the ongoing management of your company’s partnerships with suppliers who provide goods, materials, and services. It involves communicating with vendors, handling conflicts, and working together on a strategic level. Over time, a company may decide to deepen the relationship when it sees clear long-term benefits like lower costs, more consistent service, or better product quality.

Business relationships aren’t strictly “just business”—there’s more under the surface. Effective vendor collaboration isn’t built on iron-clad contract terms and purchase orders. Soft skills and human factors play a role here, with mutual respect and shared priorities often having a bigger sway than money.

Strategic vs. tactical vendor relations

Not all vendors play the same role. When all suppliers are treated with the same level of attention and time, you risk investing in low-critical suppliers and neglecting those with the biggest impact. Companies need to draw the line between tactical and strategic sourcing so as not to stretch themselves too thin.

- Tactical vendor relations are usually short-term, low-risk, and purely transactional. The majority of these purchases falls under tail spend. These vendors cover basic needs like office supplies or catering. Often, the company places an order, the supplier fulfills it, and that ends the interaction.

- Strategic vendor relations have a direct impact on business operations. Think of raw material suppliers, logistics providers, or outsourced IT firms. If they’re unresponsive, your company will feel it immediately. For example, if an outsourced IT team was responsible for your website and stopped responding when it crashed, you could lose out on sales. That’s why these relationships require collaboration and regular check-ins. Trusted vendors can even contribute to the final product or executive discussions. Here, it’s less about short-term savings and more about the total cost of ownership.

Most vendors, however, fall somewhere in the middle, between tactical and strategic partnerships. Those partnerships can grow more valuable over time and are worth exploring. Not sure how to manage vendor relationships or where your company stands with suppliers? The CIPS Relationship Spectrum outlines how your partnership moves from purely transactional to strategic.

Is vendor relations the same as vendor relationship management?

Vendor relationship management (VRM) consists of policies and procedures within the company that help a dedicated VRM team manage vendor relationships starting from the first RFP. On the other hand, vendor relations focus on the human aspect of the partnership, how you communicate, work together, and resolve conflicts.

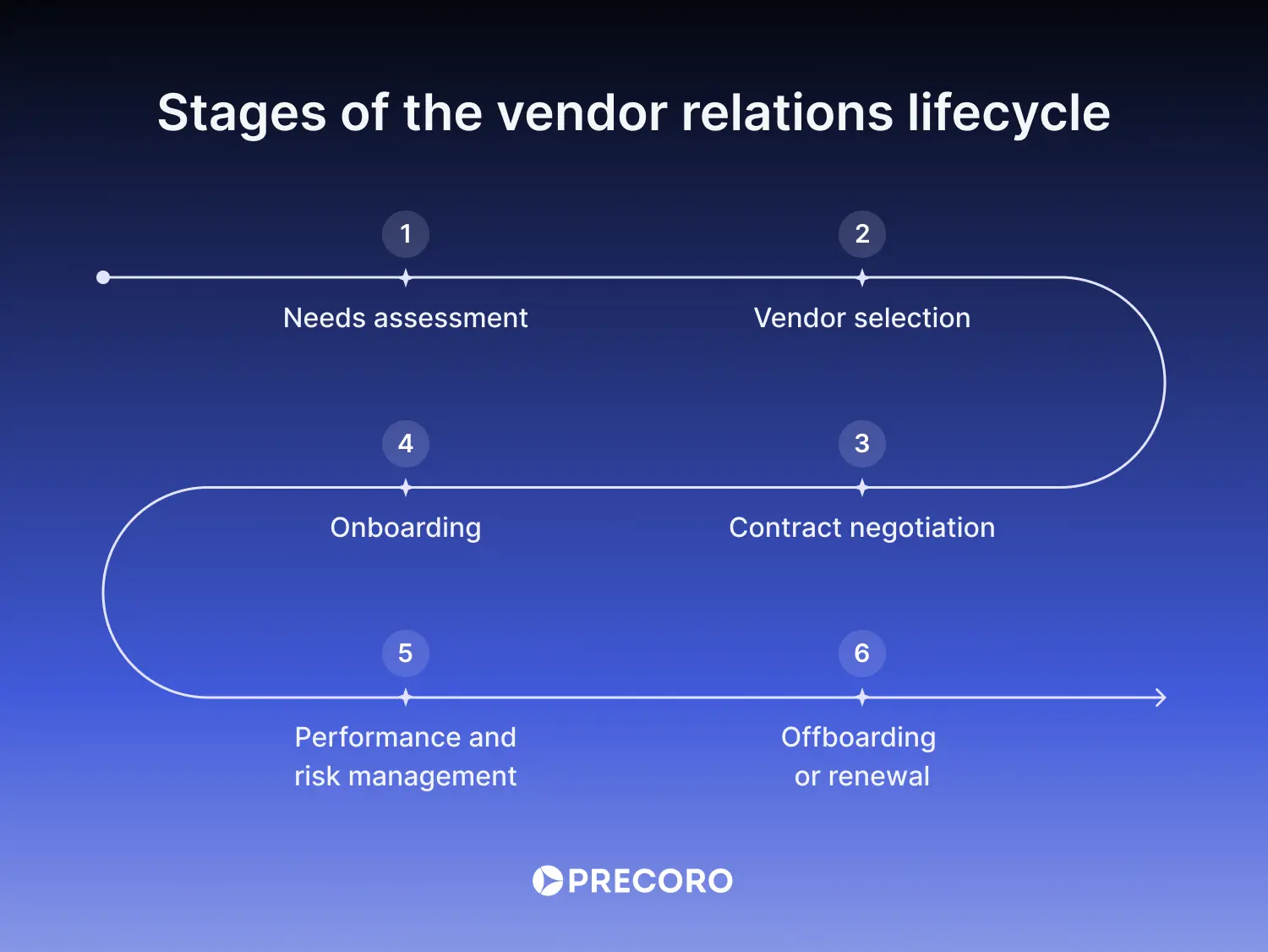

What are the key stages of the vendor relationship management lifecycle?

To understand what vendor relations is, let’s break down the entire process of how a relationship between a customer and a vendor forms, evolves, and ultimately ends. To build a strong VRM strategy, most companies typically follow a clear set of steps, also known as a vendor management lifecycle:

1. Needs assessment

Vendor relations begin long before the first vendor enters the picture. Before selecting suppliers, procurement collaborates with all relevant departments to define what exactly the business needs and why. Key questions during this stage include:

- What goods or services do we need and why?

- How much, how often, and by when?

- What is our budget?

- How do we measure whether the deal was successful?

- What compliance, legal, or technical standards must the vendor meet?

- How is the partnership going to develop if it’s successful?

Involve all relevant stakeholders in supply chain planning to avoid conflicts or hidden requirements down the road. Legal, operations, finance, accounts payable, and even end users can provide valuable input that changes the game.

2. Vendor selection

Once business needs are clear, procurement starts looking for potential vendors who could fulfill them. The team researches if the supplier has required certificates, seeks references and feedback from other customers, and schedules meetings with potential candidates.

In vendor management, best practices for this step dictate using the Request for Proposal (RFP), which outlines the project’s requirements and invites vendors to submit proposals. Procurement then compares these submissions and narrows them down to the most qualified vendors. The team negotiates the terms with them and finally asks for the best and final offers before making a decision.

3. Contract negotiation

Now’s the time to draw up a contract, which sets the tone for the entire customer-vendor relationship. The goal is to set clear expectations for both sides. The supplier wants to make sure the company will meet volume commitments, pay on time, and define clear terms. The customer wants confidence that the supplier delivers quality goods, performs consistently, and responds quickly to any concerns.

The legal team should always be involved when drafting any type of agreement. Don’t overlook these key elements:

- A pricing structure that scales as you grow.

- Service-level agreements (SLAs) with defined performance metrics and deliverables.

- Termination clauses and procedures for different scenarios (for cause, for bankruptcy, and for force majeure).

- Escalation clauses with triggers, responsible employees, and resolution steps.

4. Onboarding

Supplier onboarding is where the working vendor relationship truly begins. At this stage, a procurement team—or a vendor management team, if there is one—introduces the vendor to the company tools, communication channels, and main point of contact.

If your company uses vendor management software, make sure that all required data (such as payment and contract info) is entered there. The vendor should also have access to the system itself if it’s used to send invoices and receive POs. For example, Precoro has a dedicated Supplier Portal where suppliers can communicate with the team and review all relevant documentation.

5. Performance and risk management

All the planning finally transforms into execution. Now’s the time to monitor how the supplier performs and ask yourself: Are the goods delivered on time? Are costs staying within budget? Is the quality consistent across every order? Once the supplier proves they’re reliable, the focus shifts from the goods they deliver to how you can grow together.

Don’t just ask questions—back up answers with numbers. Compare vendor performance against these key KPIs to determine if the vendor relationship meets promises.

- Lead time: The number of days between placing an order and the final delivery.

- Defect rate: The percentage of products or services delivered with quality issues or errors.

- Compliance rate: How often the supplier meets contract and procurement compliance terms.

- Availability: The supplier’s ability to fulfill orders without stockouts or delays.

- Order accuracy: The number of orders delivered correctly.

6. Offboarding or renewal

Eventually, all vendor relations come to a crossroads with two arrows pointing in different directions: renewal or termination.

Termination can happen for many reasons: the vendor may choose to exit the partnership, procurement might be unhappy with performance, or the company simply doesn’t require these services anymore.

Before ending the relationship for good, both sides need to evaluate whether continuing makes sense. The company gathers feedback from stakeholders on future needs and vendor performance, while the vendor considers their own goals and capacity.

If termination is final, the offboarding process begins. Ending a vendor relationship on a good note is just as important as starting it right. First, review the contract terms and confirm that everything was delivered. If something doesn’t add up, reach out to the supplier and work on a solution. Make sure that all unpaid invoices are settled before the contract is officially terminated.

Next, revoke the vendor’s access to your company’s databases and systems. That’s just the beginning when it comes to managing security risks in vendor management. The best practice is to review all data and informational security policies and confirm that the former supplier can’t access sensitive procurement intelligence, whether it’s through API, shared credentials, or cloud procurement software. Finally, return or collect any borrowed or lent property and update your vendor management database.

If you’re renewing the contract, the process is more straightforward: check with vendors and internal stakeholders if they’d like any changes to the contract, negotiate new terms, sign, and you’re good to go.

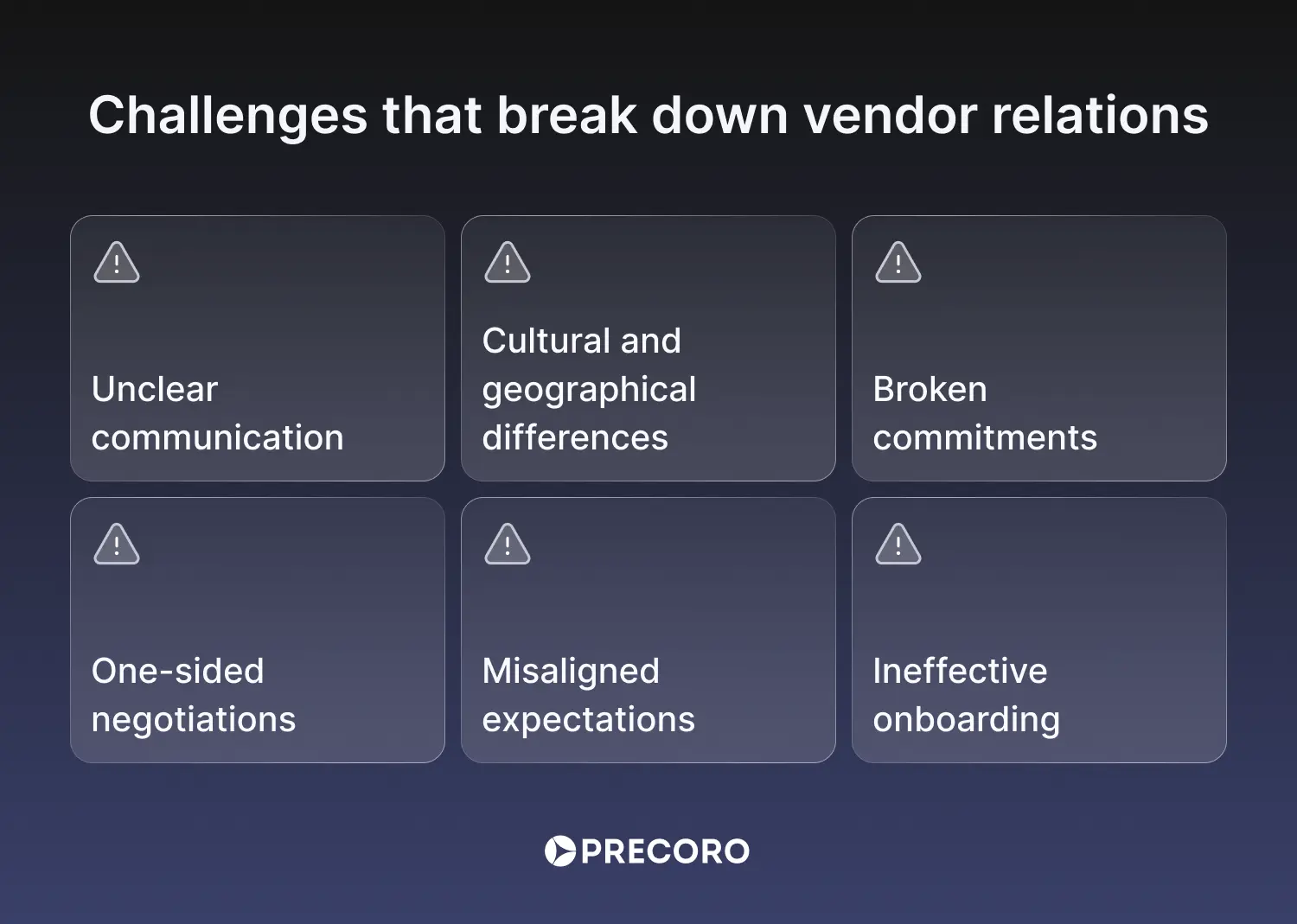

Challenges that break down vendor relations

Even the most stable partnerships can fall apart once the cracks start to show. More often than not, it has nothing to do with quality issues or bad intentions. The underlying causes usually lie deeper and slowly weaken the partnership over time.

Roughly 40% of customer-vendor relationships span over 3 years, and some don’t even have a formal contract. Longevity doesn’t always mean productivity, however. The same report from ADR International shows that vendor relationships that last more than 15 years either meet the bare minimum or underperform but are too expensive to replace.

To prevent reaching that point, recognize warning signs early. Here are the most common challenges you might encounter when managing vendor relationships.

• Unclear communication

If changes or feedback don’t reach the supplier in time, they can’t deliver what you need when you need it. It’s not uncommon for a vendor to ship the wrong product or deliver late simply because no one updated them or the message was lost in a long email thread.

Set up a clear communication channel that works for both sides, such as email, Zoom, or a vendor management system. Document each change as it might impact not only the relationship with the vendor but also the company’s budget and production.

• Cultural and geographical differences

If you opt to source from international suppliers, remember that each country has its own way of doing business. What seems like direct and clear feedback in one culture can sound harsh or unconstructive in another. In one country, employees work late nights to go the extra mile, while in others, you won’t be able to reach them after 5 pm.

Time zones can also be tricky, especially if your team expects instant responses. If you’re thinking of working with foreign suppliers, vendor relationship management best practice is to spend some time learning about the way they work and communicate.

• Broken commitments

One late payment might be an honest mistake, but two or three start to look like a pattern. It works both ways—when deliveries get delayed several times, you lose confidence in the supplier. Recurring broken promises cause the vendors to pull back and disengage from the process, which might hinder the quality of the supplies.

Always communicate with the suppliers when your company can’t follow through on something, and fix the issue as soon as possible. This should apply to them as well. Make it clear that you expect the same treatment in return.

• One-sided negotiations

Asking for steep discounts or quicker delivery without changing quantity or scope puts strain on the customer-vendor relationship. Yes, the supplier might agree under pressure, but they’ll compensate in other areas, whether it’s customer service or lower-quality products.

If you plan to work with the vendor long-term and aren’t looking for the cheapest, quickest solution to your needs, listen to them and try to meet in the middle.

• Misaligned expectations

When your team expects a vendor to act like a strategic partner, but the vendor sees the relationship as purely transactional, things quickly get messy. For instance, procurement might be looking for input on how to improve the product with the vendor’s materials, but the vendor thinks their job ends once the order ships. This disconnect means that you’re working for different goals.

If you’re looking for a supplier who can contribute to the product development or other areas beyond just delivery, say it upfront. Additionally, set up regular check-ins with vendors to keep everyone on the same page.

• Ineffective onboarding

Onboarding shapes the partnership. If the supplier doesn’t understand how your procurement team operates, it’s only a matter of time before they ship without a PO or proper approval. When you manage vendors, walk them through the company’s goals and its main systems. Explain who to contact, how decisions are made, and what KPIs they are expected to keep up with. Also, notify them about any changes to business policies and systems, like procurement transformation initiatives.

Vendor relationship management: Best practices

Vendor relationships require putting in effort where it matters most. While some partnerships may be easy to manage, most need the right approach to stay productive. Let’s look at the key ways you can support your existing connections:

- Assign a dedicated VRM team. Vendor obligations often fall on the shoulders of procurement, especially in smaller companies. Create a dedicated vendor relationship management team to act as the main point of contact for vendors. Not only will their concerns be resolved faster, but they will also feel more prioritized and valued.

- Segment vendors. Group vendors based on how critical they are, how much you spend with them, and the risk they carry. Does this supplier impact day-to-day operations? Would their unavailability cause disruptions? Does this partnership align with your business goals? From there, separate suppliers into categories and develop workflows for how to manage vendors based on the analysis.

- Avoid dependency on a single vendor. If you’re relying on a single supplier for critical materials, you’re putting all your business operations at risk. If that vendor experiences issues, you might have to scramble for a backup or delay your entire production. Always have an alternative contact for essential supplies or split orders across several vendors.

- Regularly monitor performance. Even if you don’t notice any issues on the surface, track vendor performance against defined KPIs every few months. Subtle changes in delivery time or a one-off substandard product might be early signs of bigger problems. And if the performance is consistent, say so. Positive feedback is just as important as constructive criticism and helps vendors understand that they’re doing everything right.

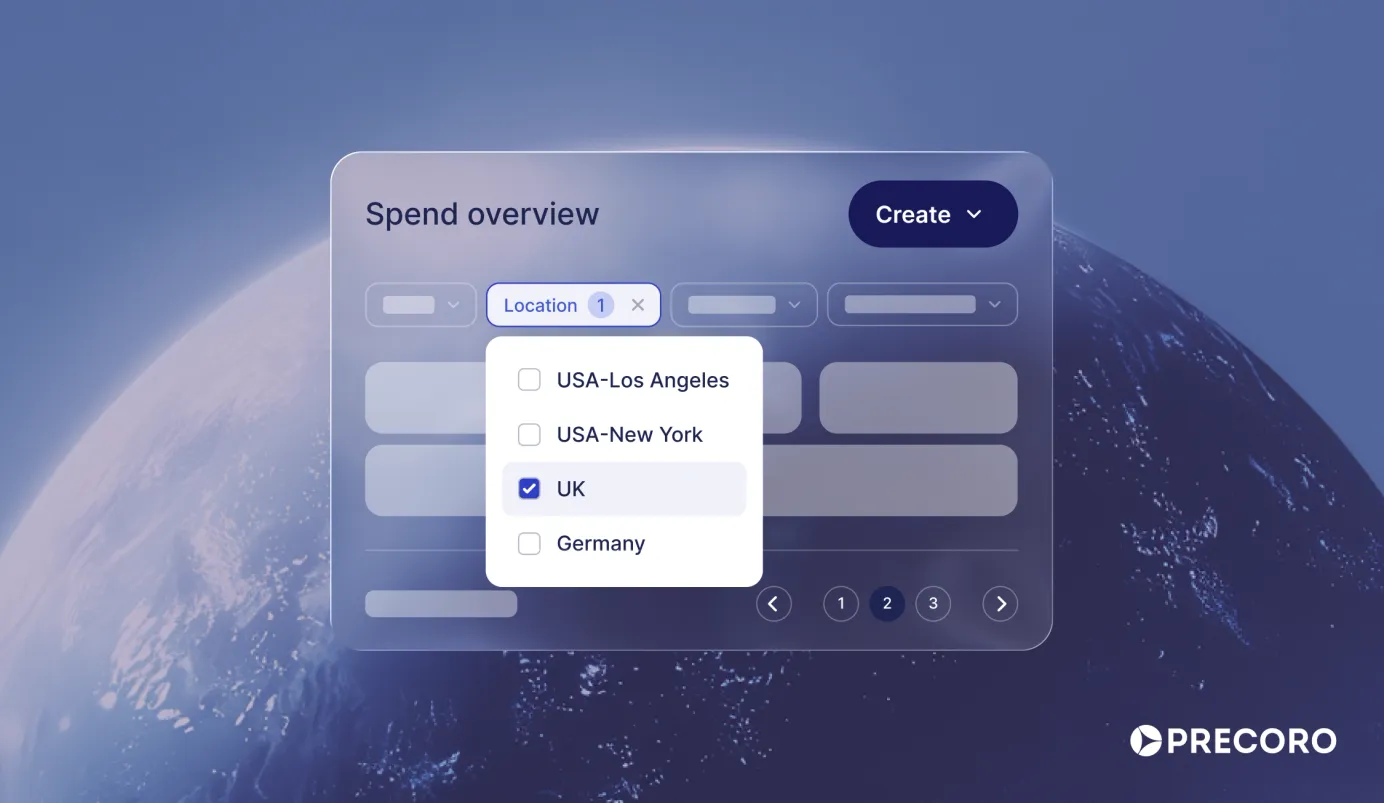

- Use an automated VRM platform. Trying to manage vendors in spreadsheets and email chains can only go so far. A dedicated VRM solution keeps all supplier documentation in one place and automates manual tasks like approvals or 3-way matching. Look for tools with self-service options for suppliers so they can upload documents, view status updates, and communicate directly with your team.

- Encourage two-way dialogue. Check-ins shouldn’t be just a formality. Use them to ask suppliers what’s working for them, what’s not, and what could be improved. For example, if they feel like they won’t be able to keep up with the demand, listen and work on solutions together. Open communication builds trust and makes vendors feel heard and appreciated, just as any customer would expect to be treated.

Tools to manage vendor relationships

Now’s the time to put theory into practice. Let’s take a look at some hands-on frameworks and tools companies use today to manage vendors effectively.

Vendor scorecard

A vendor scorecard is a structured method used to measure a supplier’s performance against KPIs like delivery, quality, cost efficiency, and responsiveness. It’s typically updated every three to six months and helps understand which areas the supplier excels in and which need improvement. Each scorecard criterion has a weighted score based on how important it is to the company’s goals.

Learn more about creating your first vendor scorecard and what it looks like in this article.

RACI chart

This framework clarifies who is Responsible, Accountable, Consulted, and Informed when managing vendor relationships.

- Responsible: Does the work

- Accountable: Owns the outcome and makes final decisions

- Consulted: Provides input

- Informed: Kept in the loop but not directly involved

Here’s a simple example of a RACI chart that demonstrates how involved teams are in the vendor management lifecycle.

As you can see, procurement takes on most of the vendor management tasks in this case. However, every company has a different workflow when it comes to vendor relations. Some have a dedicated vendor relationship management team, while others hand over all supplier-related activities to procurement. Adjust the RACI chart to your specific needs and team roles to clearly define who’s responsible.

If you’re looking for ready-made templates, these platforms are a good place to start:

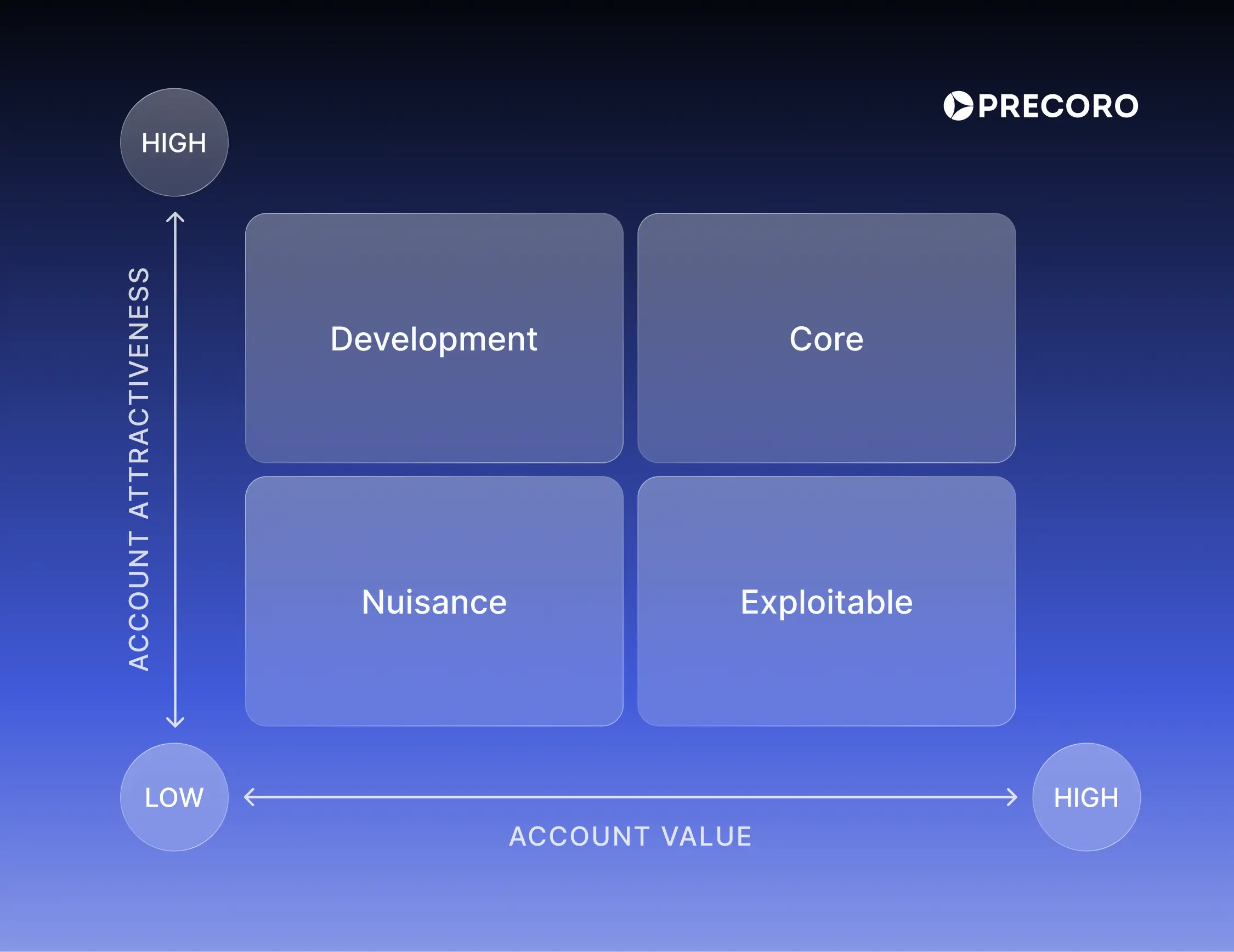

Supplier preferencing matrix

This tool helps you see how the supplier views your company as a customer and where you stand on the priority list. The supplier preferencing matrix places your company into one of four quadrants based on account attractiveness (strategic business value) and account value (financial contribution):

- Core: High value and high attractiveness. You’re a priority. The vendor is invested in the company's growth and will put in extra work.

- Development: Low value but high attractiveness. You’re growing in importance. The vendor sees the potential, and the relationship may grow beyond purely transactional.

- Exploitable: High value but low attractiveness. Your company is a great source of revenue for the vendor, but they don’t view it as a strategic asset. They aren’t likely to invest more of their resources than needed.

- Nuisance: Low value and low attractiveness. The vendor doesn’t see any financial or strategic benefits. The company is probably not purchasing enough to justify the effort. Suppliers are often disengaged from the process with these customers.

Kraljic matrix

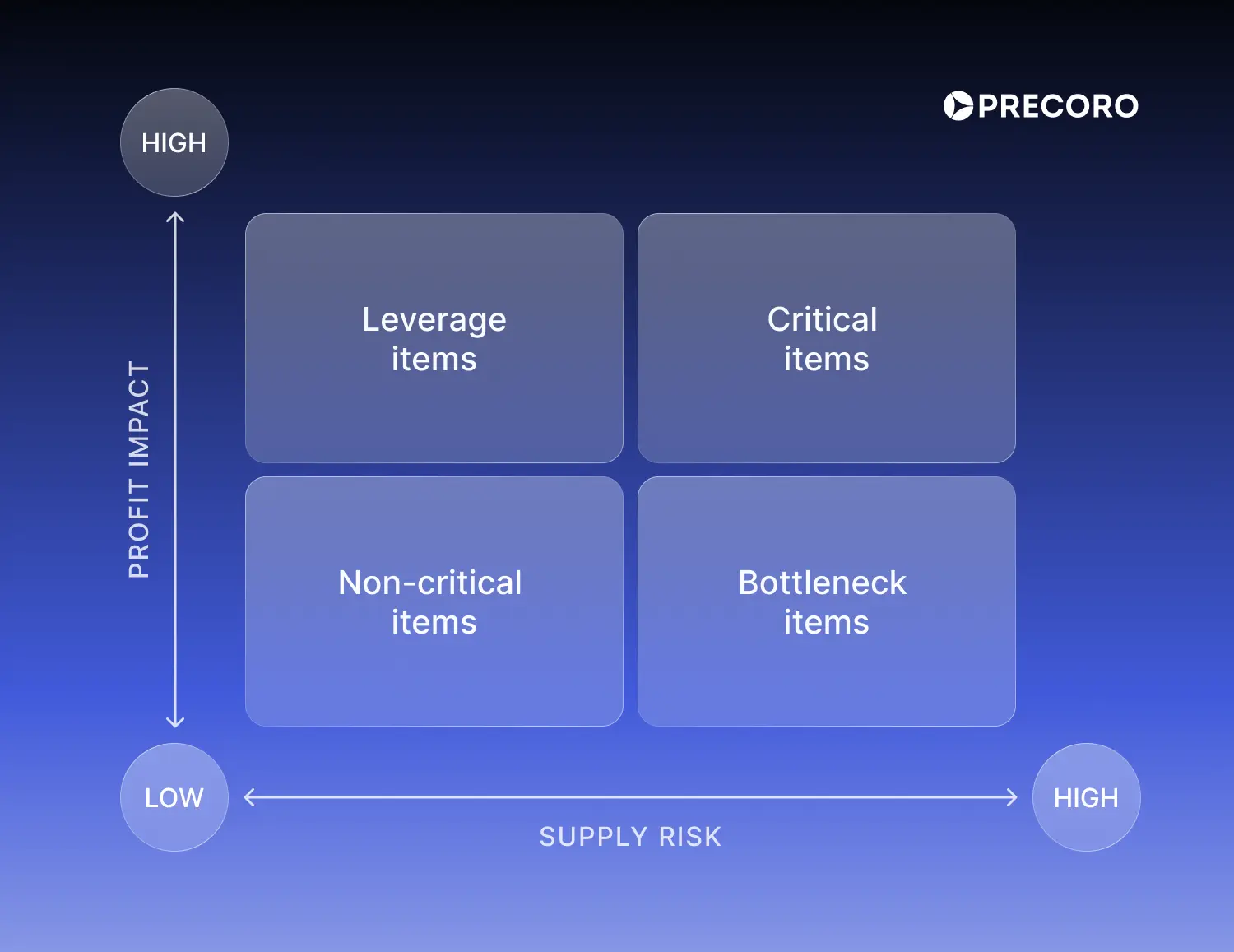

The Kraljic matrix categorizes suppliers based on the supply risk (sourcing complexity, geopolitical risks, and potential disruptions) and profit impact (cost savings and influence on customers and product quality).

The matrix divides purchases into four categories:

- Critical items: High risk, high impact. Those are strategic vendors with whom you need to collaborate closely, as their supplies have the most impact on your operations.

- Leverage items: Low risk, high impact. These supplies are sourced from a highly competitive market, which gives you leverage in negotiations. Discuss better pricing and contract terms with these vendors.

- Bottleneck items: High risk, low impact. Such items are difficult to source and prone to risks like price increases or supply chain disruptions. While they don’t directly impact profits, they can create a bottleneck in the company’s operations. Have a backup supplier for these purchases.

- Non-critical items: Low risk, low impact. Think office supplies and consumable goods. They’re easy to source, don’t affect profit, and are easily managed through bulk orders and e-procurement solutions.

Used together with the supplier preferencing framework, the Kraljic matrix can help you determine which suppliers are the most crucial to the company (strategic) and which don’t require deep investment and collaboration (tactical). Both tools also give you a chance to reevaluate which suppliers you want to work with moving forward based on their performance and level of commitment.

Voice of the Supplier (VoS) survey

The VoS questionnaire helps you understand vendor relations from the supplier’s perspective. It usually includes a set number of questions designed to explore what it’s like to work with your company. Responses can reveal communication gaps and increased pressure on the supplier.

Some questions to add to your VoS survey include:

- Does our company communicate expectations clearly?

- Are you satisfied with the payment process?

- Do you have a clear point of contact for communication?

- What is your general experience working with us?

Frequently asked questions about vendor relations

Vendor relations is the management of your company’s interactions with suppliers to turn them into lasting partnerships. It covers important steps in the VRM lifecycle, like onboarding, communication, contract management, performance monitoring, and contract renewal or termination.

Yes, vendor relations often require time, experience, and expertise to master. To manage vendors, companies often need to think strategically and assess risks while simultaneously building rapport with suppliers. Strong vendor relations skills help you identify growth opportunities in partnerships, resolve conflicts, and maintain positive relationships where they matter most.

Let’s say your company sources critical supplies from a certain vendor. Instead of just placing orders, the team involves them in product development conversations and demand forecasts and regularly checks in on any supply chain updates. Both sides communicate any issues openly—a sign of a healthy customer-vendor relationship.

Address them early. If there’s a delivery delay or price dispute, don’t let it get out of hand. Document the issue, loop in the right people, and talk to the vendor directly, preferably in a call or meeting, not just via email. Focus on solving the problem, review what went wrong, and put policies in place to prevent it from happening again.

Start by reviewing the contract terms, including any termination clauses and commitments. Communicate with the vendor and explain the decision. If any invoices are still left unpaid, settle them now. Next, revoke any access to company tools and systems and ask to return the property as well.

Key insights on managing vendor relationships

At the end of the day, vendor relations are about people, not just processes. Make no mistake—structure and strong policies matter. However, an open two-way dialogue is where you get the most value. Being transparent about challenges or the direction you want your partnership to take is often much more important than paying more.

Instead of focusing on cutting costs, think about where you can invest, especially in trust and effective vendor collaboration. The key is to treat your vendors like partners, not just transactions. Relationships built on communication often deliver more in the long run than short-term deals.