17 min read

Purchase Order Process—The Definitive Guide

A complete guide on purchase order process steps, the best optimization practices, and ways POs make a difference in your business operations and expenditures.

Managing purchase orders manually can be costly. According to APQC, processing a single PO manually can range from $50 to $150, with the median cost around $100. This adds up quickly, especially in larger organizations.

By automating the purchase order process, companies can significantly reduce these costs, sometimes down to just a few dollars per order. This means not only saving money but also freeing up valuable time and resources, allowing teams to focus on more strategic priorities.

Given the significant impact of an effective PO process, it’s crucial to understand the steps involved and how to optimize them. We’ve prepared a simple purchase order process flowchart to guide you through the key stages.

Scroll down to find out:

- What is a purchase order in procurement?

- Why is a purchase order important in the procurement process?

- How does the purchase order process work?

- Purchase order process flow

- Common challenges in a purchase order process

- Best ways to streamline the PO process

- Why automation is key

- Quick answers to related questions

What is a Purchase Order in Procurement?

Before we dive deeper into the purchase order process, let’s recall what a purchase order is. A purchase order (or a PO) is an official document sent by a buyer to a supplier that confirms the purchase and contains all the necessary information about it.

The purchase order process starts with identifying a need, then moves to creating and approving a purchase requisition. Next, a purchase order lists the items, quantities, prices, and delivery terms, and the system sends it to the vendor. Once accepted, the vendor delivers the goods or services.

The buyer receives and inspects the order for accuracy and quality, then performs a three-way match by comparing the PO, receiving report, and vendor invoice to authorize payment. Afterward, the PO is closed and all records are stored for future reference.

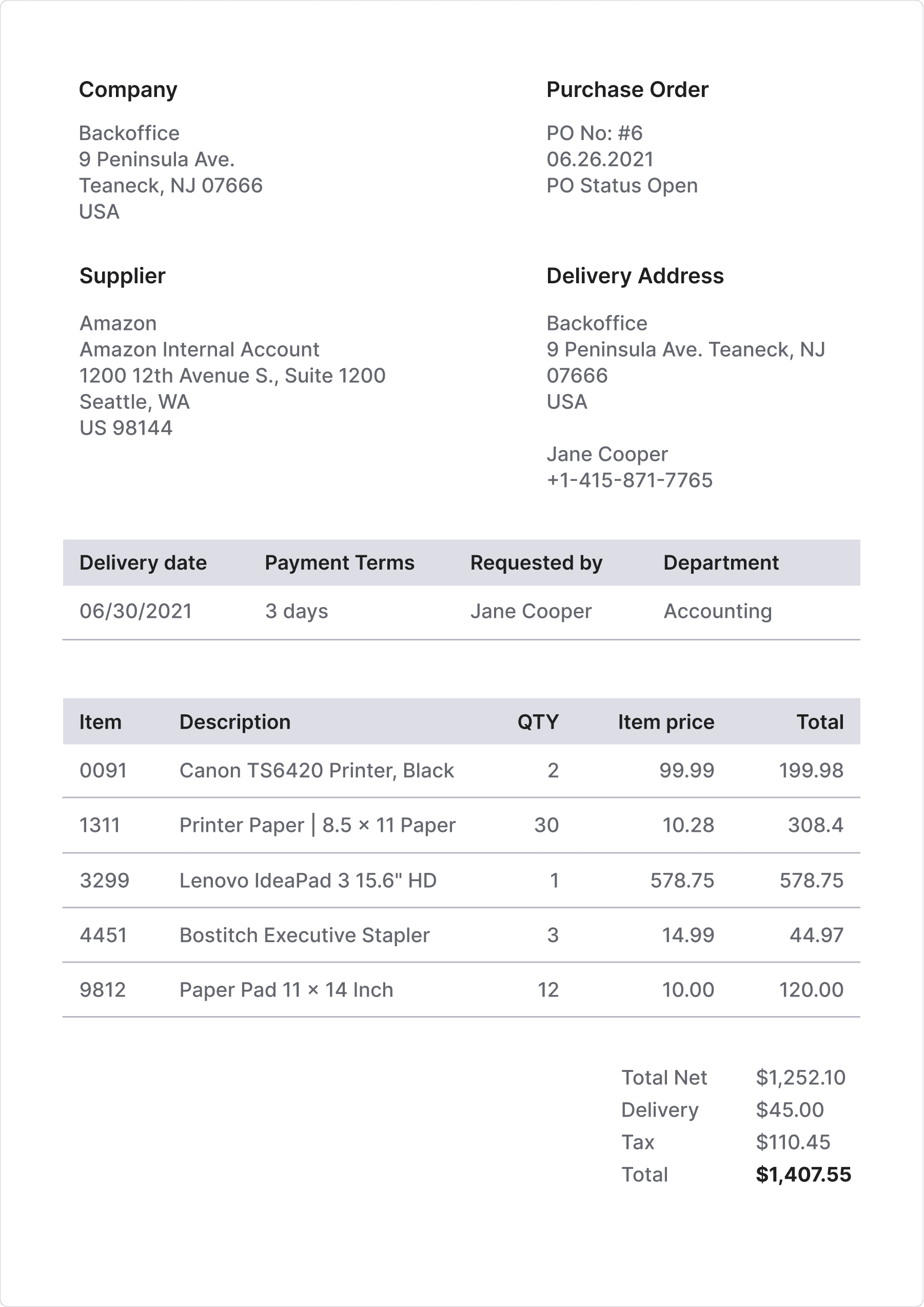

We’ll talk more about why companies use POs later in this article, but now let’s look at what precisely a purchase order should contain:

- Order date and a PO number

- Information about a buyer and a supplier (full contact details for both parties, including the primary contact person, email, address, and phone number)

- Order details (item descriptions, quantity, unit price, and total cost)

- Payment information and payment terms (due dates, discounts (if any), tax details, and agreed payment conditions)

- Shipping method (if applicable)

- Delivery date and address

- Invoice address

- Sign-offs from authorized personnel to ensure compliance and accountability (if required).

- Any additional contractual agreements, warranty policies, or return conditions specific to the order.

Here’s an example of a typical purchase order:

The purchase order process includes several compliance checks and approval steps to ensure POs are processed efficiently and on time. Here are the common steps involved:

- Create a purchase order

- Send out multiple requests for quotation (RFQs)

- Review quotes and select a vendor

- Negotiate the contract and issue the PO

- Receive goods or services

- Receive and verify the invoice (3-Way Matching)

- Approve the invoice and make payment

- Maintain records

- Close the purchase order

Why is a purchase order important in the procurement process?

Purchase orders are an essential part of an organization’s purchasing process flowchart and can help businesses improve budget control. Here are the advantages of using POs:

- They help set up clear expectations from suppliers, enhance communication with vendors, and ensure that a company gets what it needs.

- As legally binding documents, when approved by suppliers, POs can protect both parties from unsatisfactory outcomes.

- They allow tracking purchase history, avoid duplicate purchases or unexpected invoices, and prevent uncontrolled spending.

- POs increase financial control and provide evidence for auditing transactions.

What is the purchase order process?

The purchase order (PO) process is a structured method businesses use to buy goods and services from vendors. It includes submitting a purchase request, getting approvals, issuing a PO, sending it to the vendor, receiving and checking the goods or services, and completing the payment. This organized workflow helps ensure every purchase is properly authorized, documented, and tracked, reducing errors and the risk of fraud.

The PO workflow is a key piece of the bigger procurement process flow. Procurement covers the entire process of acquiring goods and services, from finding suppliers and negotiating deals to managing inventory. The PO process is the operational core, where purchases are requested, tracked, and managed to ensure everything stays organized and on budget.

The process is most effective when carried out through a clear, repeatable set of steps that guide procurement. A strong purchase order process guarantees that all involved parties have the resources and approvals needed to order the right products in compliance with company policies. It also establishes a structured workflow for purchase approvals and documentation, while maintaining comprehensive records of all transactions to support budgeting, spending oversight, and future analysis.

How does the purchase order process work?

The PO process can vary depending on a company’s size, structure, and spending needs. However, it typically includes these steps:

- PO creation

- PO approval

- Sending of PO to supplier

- Binding contract

- Receipt of goods or services

- Three-way matching

- Purchase order closure

The purchase order process includes several compliance checks and approval/input steps to ensure POs are processed efficiently and on time. Here are the common steps involved:

Step 1. PO creation

In most cases, the procurement process flow begins with an employee submitting a purchase requisition (a PR), which must then be approved by key stakeholders, such as department heads and the CFO.

After the PR is approved, the next step in the procurement process flowchart is selecting a supplier. In some cases, the PR may already specify a supplier if one has been pre-approved or is the preferred vendor for the item or service. However, in other situations, the company may need to choose a new supplier, for example, through the request-for-proposal process.

Once the supplier is chosen, the procurement team (in larger organizations) or a designated individual, such as a financial or operations manager (in smaller companies), creates a purchase order based on the approved requisition.

For recurring purchases, a PO can often be created directly without the purchase requisition. This simplifies the procurement process flow for routine orders while still ensuring proper documentation.

Step 2. PO approval

After the PO is created, it goes through an approval process involving the relevant authorities within the organization. Who exactly needs to approve the PO depends on the company’s approval workflow, which can vary based on factors like company size, hierarchy, spending thresholds, and the type of purchase.

For example:

- In a small business, the PO might only require approval from the operations or financial manager.

- In a large corporation, it might pass through several layers, such as the department head, procurement manager, and financial director, before final sign-off.

- For high-value purchases, additional approvals may be required, such as from the CFO or CEO, to ensure alignment with strategic priorities.

- For specific categories of spend, like IT or marketing, the PO might need approval from the relevant department head or a category-specific manager.

Step 3. Sending the PO to the supplier

Once the purchase order has been approved, the business is ready to send it to the supplier. In some cases, companies may use online procurement systems with supplier portals where they upload the PO directly, while in other cases, they might simply email the document.

Step 4. Binding contract

Regardless of the method, sending the PO marks the formal commitment to purchase the goods or services outlined in the order. The supplier then reviews the PO and either accepts it as is or may request adjustments. Once accepted, the PO becomes a binding contract, ensuring both parties are aligned on the terms.

Step 5. Receipt of goods or services

Once the delivered items have been inspected and meet the requirements, the next step in the purchasing flowchart is to formally acknowledge receipt by issuing a Goods Received Note (GRN) or a similar document. The receipt serves as official confirmation that the items were delivered as specified in the purchase order (PO).

Step 6. Three-way matching

After the goods or services are delivered and inspected, the next critical step in the purchase order process is to ensure that everything is in order before the payment is made. This is where three-way matching comes into play, a phrase in PO invoice processing that involves comparing the PO, the goods receipt, and the received invoice.

For example, if the supplier ships 90 units instead of the 100 ordered or if the price listed on the invoice is higher than agreed upon, the company can flag these issues and resolve them with the supplier before releasing payment.

Ultimately, the three-way match ensures that the company only pays for what was actually ordered, received, and invoiced in the correct quantity and price. It acts as a safeguard against errors, fraud, or miscommunication, providing a solid audit trail that helps protect the business financially.

Step 7. Purchase order closure & record-keeping

If the data on all documents matches, the confirmed invoice is forwarded to the finance department for payment. The payment completes the purchase order flowchart. The purchase order, along with the associated documents (invoice, GRN, and payment details), is then saved and archived for record-keeping purposes. This is essential for a few key reasons:

- The records serve as a trail of documentation for audits, helping the company prove that payments were made for legitimate, correctly priced, and correctly delivered goods or services.

- Proper documentation ensures compliance with internal policies, tax regulations, and legal requirements, making it easier to resolve any potential disputes or claims.

- These records may be useful for reference in future orders with the same supplier or for reviewing historical spending data when making budget decisions or negotiating with vendors.

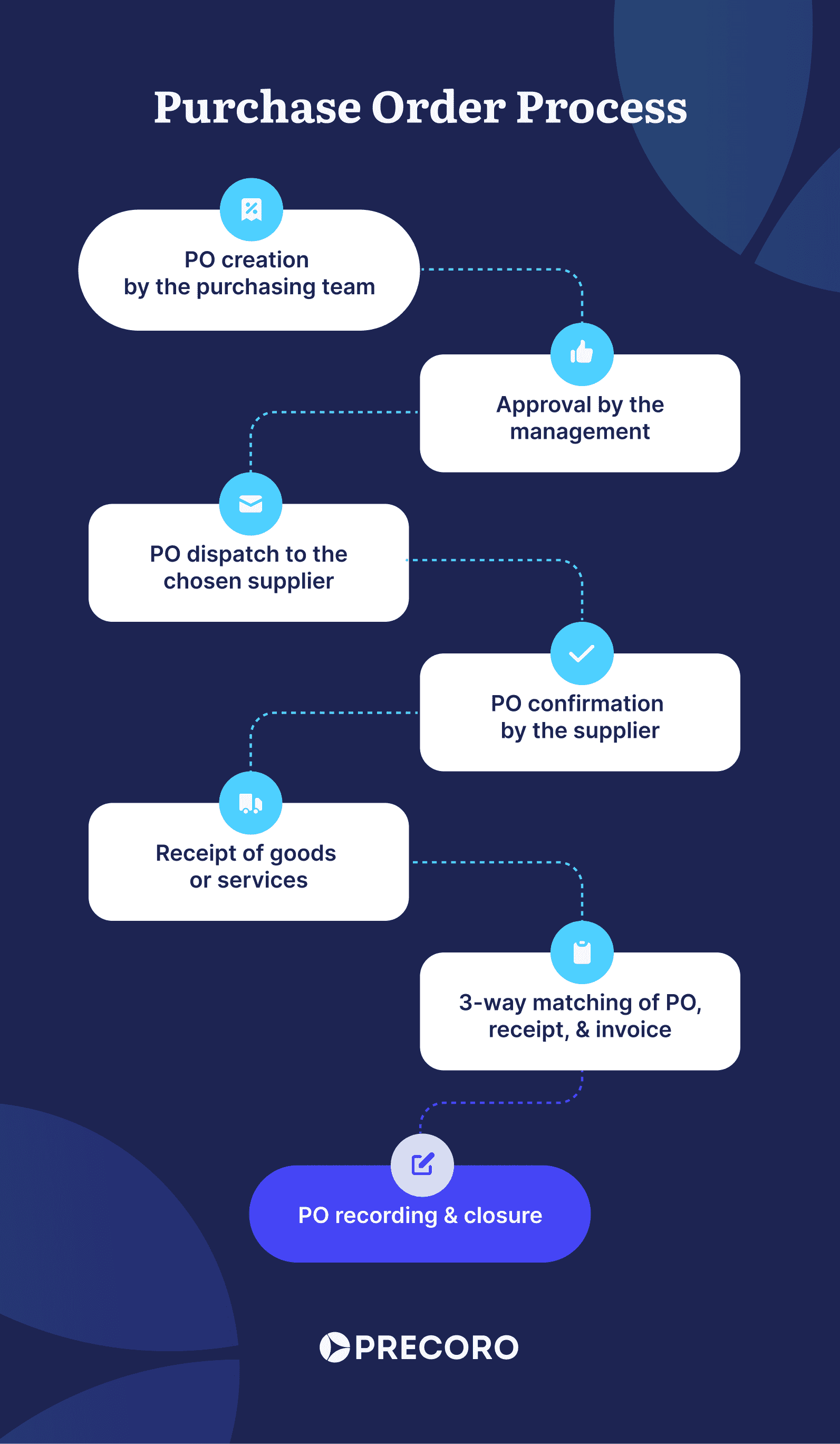

Here’s a purchase order flowchart to guide you through the process.

Once in a while, a company receives a customer order that’s too large to fulfill with available inventory. Replenishing inventory immediately would require a substantial cash injection, which isn’t always an option. That’s when business owners seek assistance with purchase order financing. Read more about PO financing in our article.

Purchase order process flow

Let’s look closely at the purchase order process flowchart and sum up the exact steps a company must take to process a PO and buy necessary products.

So, what are the required steps in the purchase order process?

- Create a purchase requisition;

- Create a purchase order;

- Issue a request for proposal (RFP);

- Evaluate supplier quotations and select a vendor;

- Negotiate contract terms with the chosen supplier;

- Send a PO to a supplier;

- Receive a confirmed PO;

- Receive the delivered order;

- Receive an invoice and perform three-way matching;

- Make a payment;

- Record a purchase order;

- Close a PO.

Common challenges in a purchase order process

The purchase order process can be a real pain if not established thoughtfully. There are a few common traps that businesses often fall into, causing delays, added costs, and headaches. Here are some of the most common challenges you’ll want to watch out for during the purchase order process steps:

Inconsistent processes

When different departments or teams establish their own approaches to the purchase order creation process, it can lead to confusion, delays, and errors. For example, imagine a scenario where one department approves orders based on a simple email confirmation while another requires detailed paperwork and multiple sign-offs. Or if some department approves a purchase without considering budget limits. This inconsistency makes it difficult to track orders, keeps everyone out of sync, and often results in issues like unapproved purchases or missed deadlines.

Lack of clear visibility

Without a centralized system for the procurement process flow, it’s hard to keep track of where each order stands in the process. This lack of visibility makes it difficult for teams to know what’s been ordered, what’s been approved, and whether the purchases are staying on budget. For example, if multiple departments are ordering the same product without knowing what others have already ordered, it can lead to overstocking and unnecessary expenses.

Approval delays

In larger organizations, the PO approval process can quickly turn into a bottleneck, causing frustrating delays. When multiple people need to sign off on an order, things can easily get stuck if an approver is unavailable or if the approval steps aren’t clear. A single missed or delayed approval can disrupt the entire purchase order processing timeline, leading to stockouts, production halts, or customer dissatisfaction, especially in fast-paced industries.

Supplier management headaches

Choosing and managing the right suppliers is a crucial part of the procurement process flowchart. But if your supplier records are out of date, that’s like shooting yourself in the foot. You might end up ordering from a supplier who no longer gives you the best price or, worse, from one who can’t deliver on time.

Imagine setting up a PO for a product you need fast, only to find out that your supplier has changed delivery times without anyone updating their information. Suddenly, you’re stuck waiting for goods that should have been here yesterday! Also, if your supplier details aren’t up to date, you might accidentally order the wrong product or the wrong quantity, leading to returns and extra costs.

Tech integration struggles

Switching from a manual approach to automated or e-procurement systems can be tricky, especially when it comes to integrating new technology with your existing tools to create a smooth procurement process flow. For example, if the new PO system doesn’t sync well with your accounting software, you may experience issues like duplicate orders, delays in processing, and mistakes in reporting. This can cause frustration and errors, but with careful planning, integration challenges can be overcome or avoided altogether.

Best ways to streamline the PO process

Ready to conquer those common PO process challenges? Here are the best practices that can help you.

Standardize your PO process

To keep the purchase order processing smooth, it’s crucial to standardize purchase orders across departments. One of the best ways to do this is by using unified templates that ensure every PO includes the essential information — like supplier details, quantities, payment terms, and delivery dates.

A consistent document format for the purchase order process makes it easy to spot missing information and helps with tracking across different teams. For example, you can use a template in the procurement software that lets users select the correct options from drop-down menus for key details like budget codes and addresses, minimizing the risk of errors.

Approval workflows also need to be standardized but can vary depending on the PO creator, department, or order size. A smaller order might only need approval from a team leader, while larger orders will require more levels of approval — like from a finance manager or senior executive. Automated PO management systems can help streamline this by routing the order to the right approvers based on preset rules. This ensures everyone knows who needs to approve what and when, keeping the process organized and efficient.

Ensure visibility

Visibility is a game-changer that streamlines the PO process. With procurement software, you can easily track POs in real time — from creation to approval to delivery. This means no more confusion or missed steps; everyone involved knows exactly where the order stands at any moment. For example, automated reminders keep approval workflows moving smoothly, preventing delays when an approver is unavailable.

Beyond tracking, visibility provides valuable insights. Procurement software allows companies to spot recurring issues, like slow approvals or late deliveries, so you can take action before they become bigger problems. With real-time data and reporting tools, you can proactively manage suppliers, adjust timelines, and negotiate better deals, making your entire procurement process more efficient and effective.

Improve the PO approval process

To speed up approvals and reduce delays in the purchase order flowchart, companies can automate approval workflows. By using an automated PO system, approval hierarchies are predefined, and the system automatically routes POs to the right people at each step.

For example, if a financial manager is unavailable, the system can automatically forward the PO to a backup approver, ensuring no delays in the purchase order process. With automated alerts and tracking, you can quickly see where a PO is in the approval process, helping to avoid bottlenecks and keep orders moving on time.

Automate the three-way matching process

For faster, more accurate invoice processing and order completion, automate the three-way matching between POs, invoices, and receipts. Many modern procurement systems offer this feature, which compares the details automatically and informs users about any spotted discrepancies.

For instance, if the quantity on an invoice doesn’t match what was ordered, the system flags it for review before payment is processed. Automating this step of the purchasing process flowchart reduces the need for manual checks, saving time and decreasing the chance of errors. It also ensures that you never overpay for a product or pay for something that was never delivered.

Manage inventory and supplier relationships proactively

To stay on top of inventory issues and supplier relationships, it’s important to proactively manage stock levels using tools that integrate seamlessly with your procurement system. A system like Precoro, with its inventory module, can track your stock levels in real time and automatically notify you when they’re getting low. This helps prevent any last-minute rush orders or stockouts. The platform can alert you well in advance, giving you enough time to adjust orders and maintain steady inventory levels without scrambling for supplies at the last minute.

Building strong relationships with suppliers is also key for a smooth procurement process flow. This means regularly communicating your needs, adjusting orders based on production schedules, and negotiating better terms as your supplier relationships grow. It’s easy to do when a procurement system lets users track supplier performance and analyze purchasing operations. For example, by tracking purchases per category, you can make bulk purchases from preferred suppliers. Plus, by reviewing spending per supplier, you can negotiate discounts with those suppliers you work with the most.

Choose a well-integrated solution

To unlock the full potential of the procurement process flowchart, integrate your selected procurement system with key tools like ERP systems, accounting software, and PunchOut catalogs. This creates a more connected and efficient workflow, removing the need for manual data entry and reducing the risk of errors across departments.

When your procurement system is linked to your ERP, it streamlines the flow of data, ensuring that purchase orders and financial details are instantly available to your team. This helps keep budgets accurate and allows for better decision-making. In addition, integrating with accounting software automates financial processes, ensuring smooth and accurate syncing of invoices and payments.

The integration between a procurement system and suppliers’ PunchOut catalogs further simplifies the buying and purchase order creation process by allowing employees to access the relevant list of items from pre-approved suppliers directly from within the procurement system. This ensures purchases remain compliant with company standards while also speeding up the ordering process and reducing friction between procurement and other teams.

Why automation is key

When it comes to our daily routine, we’re really unlikely to go with a skiffle board instead of a washing machine, aren’t we? But this change was gradual and just like that, many companies are slowly realizing that outdated methods, like spreadsheets and paper, no longer cut it when it comes to the purchase order process.

Sure, manual processing may seem like a tried-and-true method, but it has proven to be error-prone and time-consuming, not to mention the financial losses associated with old-fashioned workflows.

As your company grows and requires increasingly more goods or services, the number of purchase orders and invoices becomes too much for your finance team members at a certain point. This is where you should turn to e-procurement and automate your PO process in a centralized system.

Rebooting your internal processes may seem daunting at first, but if you switch to intuitive and straightforward purchase order software like Precoro, the full onboarding and implementation process won’t take more than a couple of weeks.

Here are some benefits you can reap at once by taking this step toward the procurement process automation:

- Get rid of stacks of paperwork or multiple spreadsheets and the inefficiency that comes with them.

- Creating purchase orders using customizable templates and converting them directly from the purchase requisitions with a click of a button.

- Minimize manual data entry with the ability to choose from drop-down menus and item and supplier catalogs.

- Set up a smooth approval process in the system, where POs are automatically routed to the right people.

- Visible available budget for requesters, buyers, and approvers.

- Manage your supplier base inventory, store contact information, and receive invoices in one place.

- Perform the 3-way match automatically and sync documents with your ERP or accounting system.

And much, much more.

Frequently Asked Questions

The main difference is that a PO is created by a buyer, while an invoice is issued by a supplier. A buyer issues a PO to a vendor at the beginning of the purchasing process to request goods or services. On the contrary, a seller sends an invoice to a buyer almost at the end of the purchasing cycle to ask the buyer to pay for the delivered goods.

A buyer is responsible for creating a purchase order. It can either be a procurement department, a financial manager, or an operations manager within an organization.

Approval workflows in the purchase order process can vary among organizations. Most companies (in particular, larger ones) have a PO approval workflow that defines which employees are responsible for approving a PO. Usually, the approval is needed from a head of the department that requires the goods to be purchased and a financial director. In addition to approval within the organization, a PO also has to be confirmed by a supplier.

A company needs a defined PO process to streamline its purchasing cycle. Purchase orders also specify supplier expectations, serve as legal documents, enhance budget control, and assist with financial auditing.

If a supplier has confirmed the PO, then yes, it becomes a legally binding contract.

The PO reconciliation process (also known as PO recon) involves reconciling POs with invoices and goods receipts as a part of the three-way matching.

Achieving efficiency in the PO process is easier than it seems

Purchase orders or POs are documents that a buyer sends to a supplier when requesting an order. Once confirmed by the vendor, they become legally binding contracts. The PO should include a description of requested goods or services, the quantity of items, and the agreed pricing and payment terms.

A purchase order process is a subset of the broader procurement process flow. It includes the following steps: PO creation with an assigned PO number, approval, dispatch to a supplier, receipt of delivery, 3-way match, payment, and PO closure. Depending on your company size, industry, and requirements, the PO process steps may vary.

Among the best practices for purchase order processing are establishing a company-wide purchase order process flow and automating it using procurement software. Automation not only ensures complete transparency and accurate approval routing but also gives you full control over inventory and budgets. Plus, it saves your employees valuable time, reduces paperwork, and virtually eliminates costly errors.