13 min read

Procurement Mistakes: How to Spot, Respond, and Prevent

Procurement mistakes are widespread but preventable. Identify common procurement errors, understand why they happen, and take action.

Even the most organized procurement structures aren’t immune to mistakes.

A single oversight or lapse of judgment can cost the company money, time,

and credibility. One typo turns a $500 order into a $5,000 expense. Miss one budget meeting, and you might accidentally order supplies someone already purchased.

Small procurement mistakes often point to issues bigger than one person’s mishap. Instead of dismissing them as one-offs, think of them as signs of a strained system that either hasn’t been working for years or is starting to break down. The key is to notice these warnings early and look beyond who’s to blame. As much as it’s an opportunity to fix what’s broken, it’s also a chance to build something better.

In this article, we’ll focus on the key challenges in the procurement process, why these mistakes happen, and the best course of action to take in each situation.

Keep reading to learn:

The root causes of procurement mistakes

Common procurement problems and solutions

Procurement mistake response checklist

Frequently asked questions about procurement mistakes

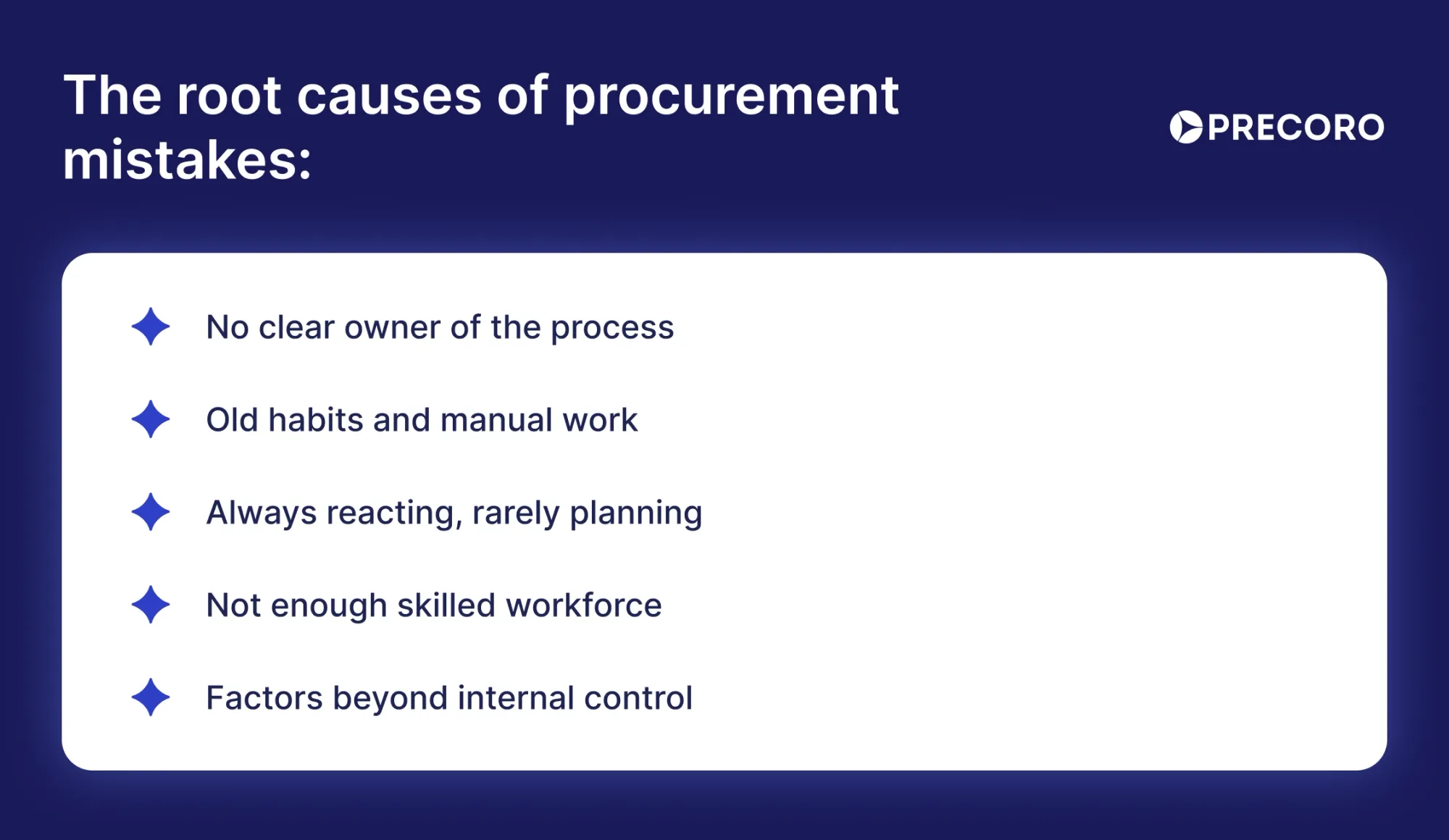

The root causes of procurement mistakes

Procurement mistakes don’t just appear out of nowhere. Most of them have a clear cause-and-effect link that points to bigger issues within the system. In fact, organizations lose around 5% of spend annually because of procurement errors and fraud. If the yearly spend is $10 million, then $500,000 is wasted on problems that could be prevented.

Most of the reasons for procurement mistakes can’t be spotted at first glance. Deep-rooted company culture and outdated compliance policies that appear harmless on the surface can do more damage than any lack of technology or oversight ever could.

Let’s take a closer look at the key reasons behind procurement challenges:

No clear owner of the process

The entire supply chain may fall apart when roles aren’t clearly defined. Different teams can follow their own policies, which might lead to a number of procurement issues, from mismatched invoices to confusion about who’s responsible for the task. The situation grows even worse when no one tracks transactions end-to-end or oversees the full procurement cycle.

Old habits and manual work

A major challenge in the procurement process is that 8 out of 10 Requests-for-Proposals (RFPs) are still created through email and spreadsheets. It’s a staggering number, especially if you consider the hours employees lose drafting documents and composing appropriate emails. Manual processes might be easy to learn and follow, but they can really hold the team back once volumes of purchases scale up.

They’re also hard to let go of—after all, if you have years' worth of records in Excel, you’ll be reluctant to switch to an unfamiliar system. With limited time and dozens of purchases on your hands, one small mistake can cost the company money, time, and, possibly, even customer loyalty.

Always reacting, rarely planning

Putting out fires after they start isn’t a sustainable approach to procurement if the end goal is control and consistency. Too often, teams step in only when something goes wrong. This reactive mindset keeps procurement stuck in crisis mode. Instead of identifying potential warning signs to prevent procurement mistakes, they end up fixing the problems after the damage is done.

Not enough skilled workforce

There’s a significant talent gap—nearly 34% of CPOs listed a lack of skilled employees as a key challenge in the procurement process. Without the right expertise, purchasing can become a constant cycle of paperwork, not a strategic function it’s meant to be. You spend more time on approval tracking and invoice management than on strategic vendor relationships and cost-saving initiatives. Although fine at first, this focus on routine tasks can hinder business growth, as all resources are spent on operational tasks.

Factors beyond internal control

Some challenges in the procurement process are just out of your hands and can’t be predicted or avoided. The last five years alone left 93% of businesses facing disruptions that they couldn’t predict. Raw material shortages, changing laws, or global events can all slow things down.

When a company’s process lacks flexibility, even minor disruptions cause setbacks. The more optimized your supply chain is, the easier it becomes to stay on track, no matter what global procurement mistake you’re facing.

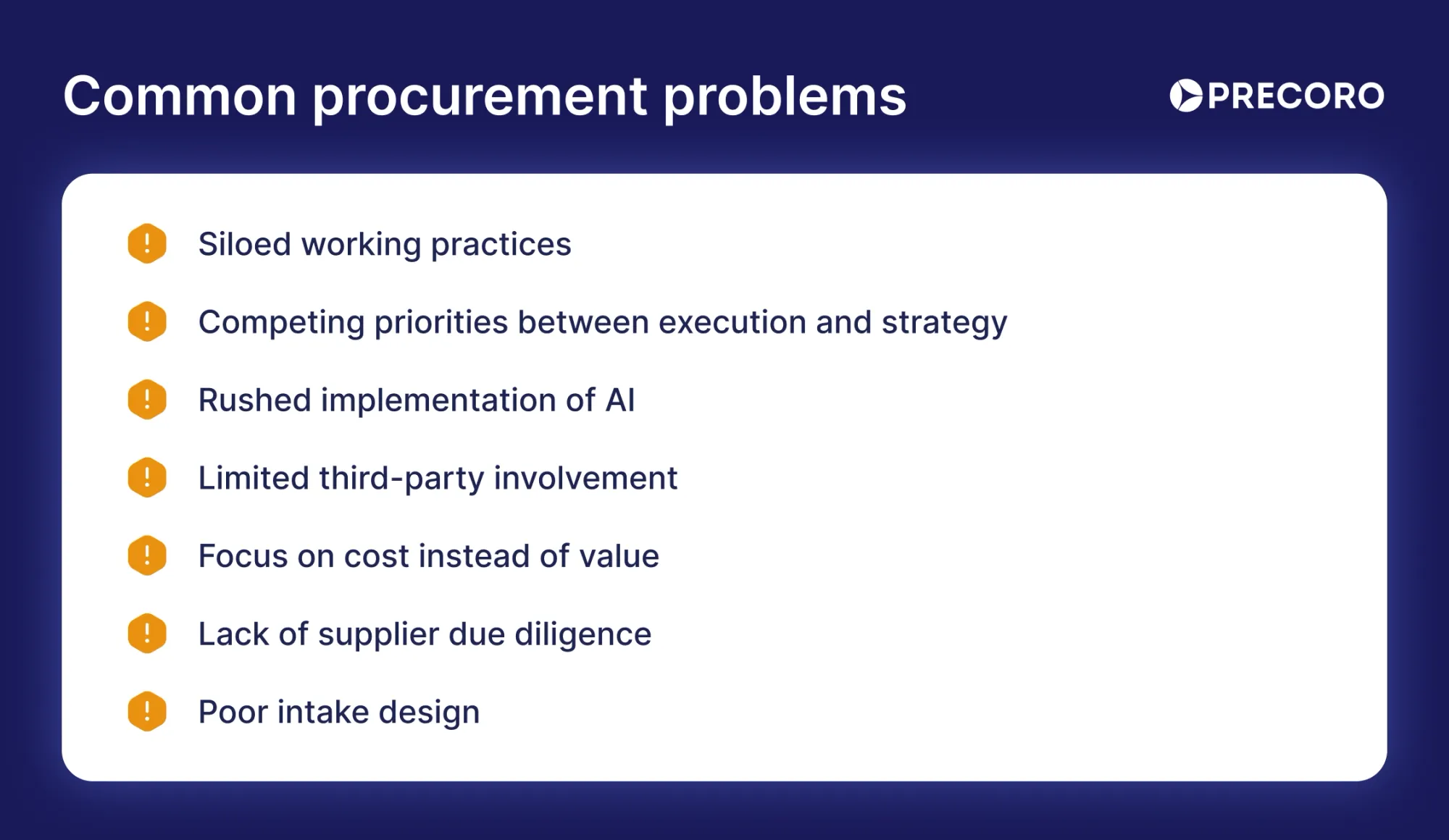

Common procurement problems and solutions

Knowing the root cause is a good start, but it’s only part of the solution. To actually protect your purchasing process, you need to understand what can go wrong if issues are left untreated and how to prevent them before they escalate. In this section, we’ll walk through common procurement mistakes and how to turn each into an opportunity for improvement.

Siloed working practices

Deloitte’s 2025 Global Chief Procurement Officer (CPO) Survey found that 57% of CPOs think disconnected team structures are the top barrier to successful purchasing. It’s a common procurement issue in many companies, as procurement, accounts payable, and operations often use different systems

and follow their own processes.

This approach leaves each team isolated and unaware of what other employees

are doing. For example, if the purchase requires sign-off from multiple departments, things can quickly get messy with additional follow-ups and different systems.

Recommended approach

If your company’s procurement is riddled with silos, it’s time to address procurement challenges and solutions together. The key is to align department heads and their teams on what exactly the company wants to achieve with its purchasing and how to structure it. Here’s a course of action you can take:

- Get leadership on board: discuss organizational goals and identify who will be held accountable.

- Establish policies that encourage collaboration, not decision-making by yourself.

- Create cross-functional teams, if possible, and define who is responsible for what across each project and each team.

- Introduce joint incentives and shared communication channels to keep everyone connected and in the know.

- Centralize procurement on a single platform so data and workflows are in one place.

- Use platforms that integrate with your other tools to sync data and track progress without switching tabs.

If you’re unsure where to start, look for a centralized procurement platform with real-time visibility no matter where you are. Precoro delivers exactly that.The system ranks among the best procurement solutions for companies worldwide, from Denmark to Thailand. Its advanced dashboards pull all spend, procurement, and AP data into one workspace, so you instantly see where costs go and can catch procurement issues early. Each role benefits: CFOs can track spend patterns, procurement can monitor POs and suppliers, while AP can see overdue invoices.

Competing priorities between execution and strategy

Procurement teams often have to juggle strategic initiatives with day-to-day operations, while still achieving quick wins that can show stakeholders measurable results. Balancing procurement challenges and solutions is tough, and the time that should go to supplier development, risk reduction, or cost efficiency is usually spent on long-winded approvals or sourcing last-minute purchases.

More often than not, teams don’t monitor how flexible or innovative their processes are, since these factors are difficult to track. Instead, they focus on cost and speed. This procurement strategy mistake then results in purely transactional vendor relations, without any knowledge of whether suppliers can improve products or adapt to change. As a result, procurement loses its influence in the organizational structure and is also seen as a purely transactional function rather than a strategic priority.

Recommended approach

Start by setting clear strategic priorities at the leadership level and make sure daily metrics support them. Don’t just track savings or cycle time: include other KPIs in your reports, like supplier defect rate, purchase order accuracy, contract compliance, or inventory aging. Use quarterly reviews to see whether day-to-day work is slowing down strategic progress: if yes, then it’s time to rethink your approach to both.

Rushed implementation of AI

Procurement AI has been on every company’s radar for the better part of the last decade. The technology is promising: what once took hours of manual work can now be automated in minutes, while vast amounts of data can be analyzed in seconds.

However, despite the benefits, rushed implementation can be a costly SaaS procurement mistake. 79% of companies expect to incur “AI debt”—time and money lost on fixing the fallout of badly implemented AI—because they’re integrating AI without the right infrastructure or planning. The truth is, AI isn’t

a quick fix. In many companies, digital burnout has risen to 88% and workload to 77%, even after new tools were introduced.

Recommended approach

Define what procurement problems and solutions you want AI to address. Start slow with time-consuming, low-value tasks like data entry or document matching. Record initial KPIs and compare them with AI performance results to see whether procurement automation actually makes a difference.

The more disorganized the data, the more likely AI is to break down. Before feeding the data into your preferred tool, check that it’s accurate, complete, and accessible to all involved parties. The process might be tedious, but if any information doesn’t match or turns out to be outdated, you might receive misleading or incorrect findings.

Limited third-party involvement

Keeping everything in-house means all purchasing information is contained strictly within the company. It’s beneficial for security reasons and gives you more control and visibility over how organizational budgets are spent.

However, an in-house approach means your team handles everything, from day-to-day routine to strategic tasks. Additionally, you’re missing out on specialized expertise that outsourced candidates can provide without the company paying the usual costs to maintain an in-house expert. With outsourcing, you get the best of both worlds: reduced expenses, new insights from external parties, and more time for your team to focus on more critical initiatives.

Recommended approach

Evaluate which parts of your procurement process could benefit from outside expertise without compromising control or data security. Outsource specific, time-consuming tasks such as data entry or spend analysis. Track the results to see how much time and costs you save, then gradually expand outsourcing to other areas that might also benefit from it. You’re not replacing your team—you’re freeing their schedule for work that directly benefits the procurement process.

Focus on cost instead of value

Sometimes, you might focus on tactical priorities instead of strategic ones. For 28% of supply chain leaders, cost reduction is one of the top priorities. Sometimes, a company may need to urgently order supplies to meet demand, and focusing on cost can prevent immediate losses. However, looking at purchasing purely from a cost standpoint means you’re missing how organizational spend aligns with broader strategic goals.

Recommended approach

Include Total Cost of Ownership (TCO) in every purchasing decision and take into account all costs involved in the purchase, such as maintenance, logistics, and potential risks. Review historical data and compare the TCO of low-priced versus high-quality (but more expensive) suppliers. That way, you’re not just focusing on discounts but on consistently reliable partnerships.

Lack of supplier due diligence

Ignoring supplier vetting is a common mistake in procurement risk assessment. Without risk mitigation, you’re exposing the entire supply chain to unnecessary disruptions. According to the Business Continuity Institute, 49.6% of companies have never reviewed their suppliers’ business continuity plans, even though this step is a critical part of due diligence that shows how a supplier will keep operating during unexpected events.

Besides continuity, it’s essential to review a supplier’s background, including their financial health, reputation in the market, and compliance with industry and legal standards. A supplier struggling with debt, negative press, or past regulatory issues can quickly become a liability.

Recommended approach

Request business continuity and risk management documentation during supplier onboarding. Ask for specifics: how quickly can they resume production, what backup systems they have, and who manages crisis response. Review and update this information regularly, especially for critical or single-source suppliers, to protect the entire supply chain. Conduct a thorough vendor diligence check-up: refer to the helpful checklist in our article about the vendor management lifecycle.

Poor intake design

The intake stage sets the tone for the entire procurement process, but it’s often overlooked. If your requests don’t follow a specific structure, you’re bound to end up with documents that are missing key details or require additional follow-up to decipher. The chance of mistakes and inaccuracies is higher.

Not only that: if the process is too complicated or slow, employees may be tempted to bypass it entirely and order something of their own accord. These one-off instances of maverick spend can quickly bloat your budget.

Recommended approach

Review how purchase requests flow into your system and identify where they stall or are returned for corrections. Automate routing so requests go straight to the correct approver without manual handoffs. To ease the entire process, use an intake-to-procure system like Precoro, where you can:

- Use easy-to-configure templates with custom fields and dynamic forms, so only relevant fields appear.

- Automate approval workflows and send requests to the right approvers depending on department, thresholds, or requester.

- See real-time status updates (pending, approved, completed) and know exactly where each request stands.

- Integrate the system with your ERP, accounting tools, or PunchOut catalogs, and use API connections to avoid duplicate data entry.

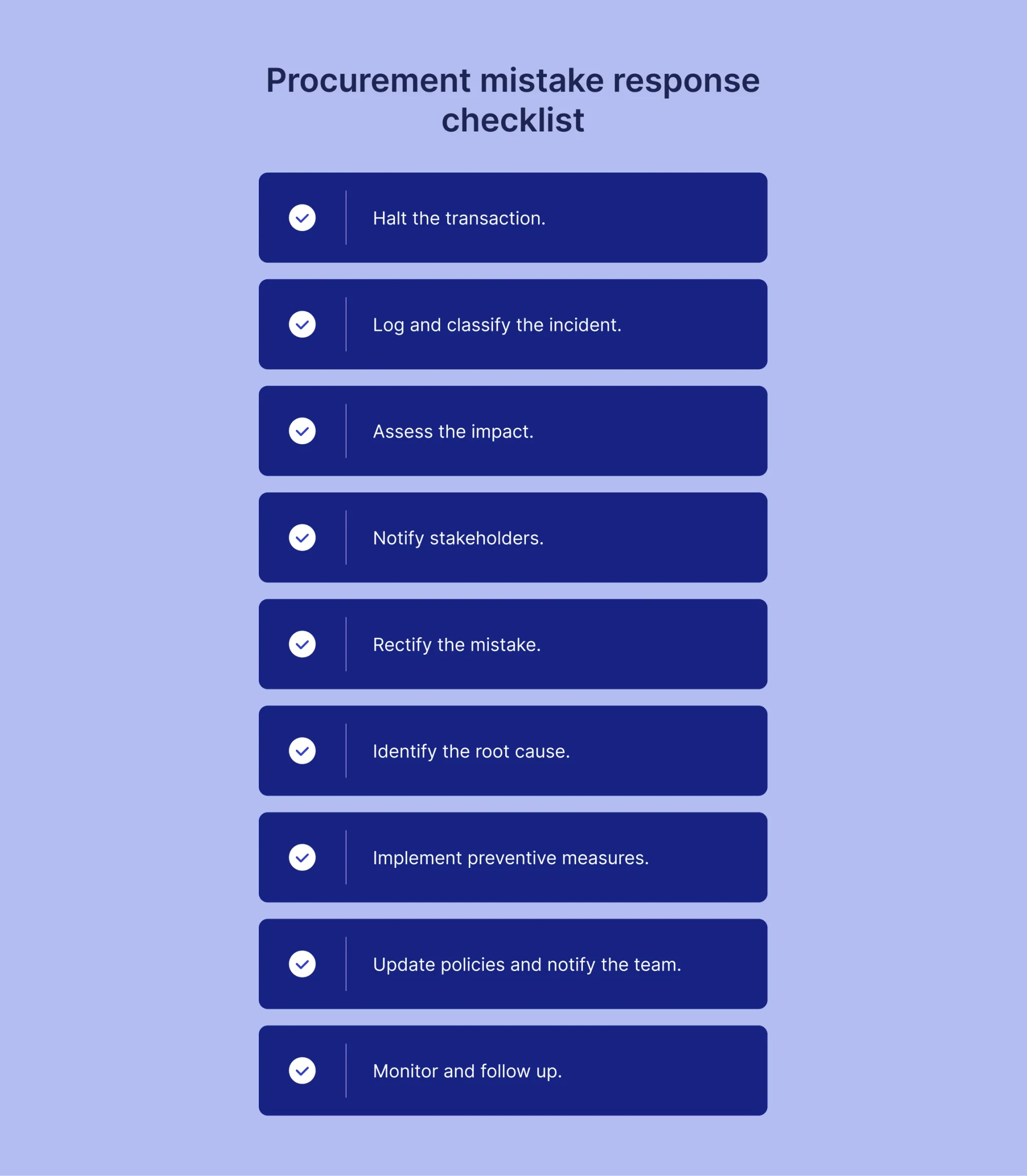

Procurement mistake response checklist

Mistakes are bound to occur, no matter how prepared you are. Even if you cover every possible scenario with thorough policies, a simple slip-up can happen—and that’s okay. What’s more important is how quickly and effectively you deal with these errors.

Instead of guessing what went wrong and looking for someone to blame, follow a clear set of steps to quickly identify the issue, address it, and prevent it from happening again.

- Halt the transaction. Pause the PO, invoice, or shipment to prevent further costs or delays. Hold payments if needed. Contact suppliers and any involved parties to explain the situation and next steps.

- Log and classify the incident. Record the date, type, impact, affected system, and supplier involved. If you already know why it happened, document that too.

- Assess the impact. Check how much money, time, or resources were affected. Note any supplier or compliance issues.

- Notify stakeholders. Inform involved teams and stakeholders of what happened, with clear, factual details. Include the scope and how you are planning to address the incident.

- Rectify the mistake. Fix as much as you can at that very moment. Update POs, contracts, or invoices and renegotiate with suppliers if necessary. Make sure budgets, records, and reports accurately reflect the correction.

- Identify the root cause. Look at the entire process to see where problems occur. Check the data and look for patterns among previous incidents, suppliers, or teams. Talk to the people directly involved.

- Implement preventive measures. Start with easy fixes that give the biggest impact, then tackle larger system or workflow improvements. Look into automation options.

- Update policies and notify the team. Create a clear plan of action for how to address the issue and share it with the employees. Turn the mistake into a training opportunity for the team. Highlight the root cause, fix, and prevention plan.

- Monitor and follow up. Review results regularly and adjust processes to ensure the mistake doesn’t happen again.

Frequently asked questions about procurement mistakes

The biggest challenge in the procurement process is dealing with disconnected teams and competing priorities. Departments often work in silos, use their own systems, and follow their own rules. No one has a full picture of what’s happening, which leads to delays, confusion, and duplicated work. On top of that, procurement teams are expected to run strategic projects, manage supplier relationships, and still handle daily approvals and last-minute orders. With priorities constantly clashing, it’s easy to lose focus on what really matters.

Maverick spend is usually a symptom of deeper issues in the process. Employees bypass procurement policies when the system is too slow, confusing, or doesn’t offer what they need. It doesn’t necessarily mean employees are “bad” or “undisciplined”. The process itself is difficult to follow. Make it simple and transparent, implement procurement software to automate tedious tasks, and maverick spend will naturally drop.

Automation helps by removing the weak spots that cause most procurement challenges. Manual work like copy-pasting data, matching invoices to POs, or tracking approvals in emails often leads to delays and inaccuracies. Digital tools step in to handle these tasks automatically. They flag price mismatches, block duplicate invoices, and route approvals to the right people, all in real time.

Procurement errors are signals, not setbacks

At the end of the day, procurement mistakes are inevitable, but their impact doesn’t have to be. Every error reveals which parts of your procurement process work and which don’t. Make peace with the fact that mistakes will occur. What matters most is how quickly your team can learn, adapt, and prevent issues from happening again.

When mistakes are addressed systematically, with clear ownership, connected data, and smart automation, they become signals for improvement. Take it step by step: simplify intake, centralize data, track the right KPIs, and don’t be afraid to bring in outside expertise when it makes sense.

Are you ready to minimize mistakes and automate procurement?