30 min read

Complete Guide to Procurement and Supply Chain Management Differences

Confused about procurement and supply chain management? Understand their key differences and how they work together to drive business success.

Would you assign the task of restocking your inventory or sourcing new materials to a supply chain manager or the procurement team? While many think these terms are interchangeable, procurement and supply chain management have interconnected yet different functions within a business.

Procurement plays a crucial role in supporting operations and providing the resources needed for daily activities. Supply chain management focuses on turning those resources into finished products and getting them to customers. Therefore, procurement is part of the broader supply chain function—at its core, it's all about securing the goods that eventually reach the end buyer.

This article will clarify and highlight the differences between SCM and procurement and their interconnectedness. Finally, armed with this guide, you will ultimately know what procurement is in the supply chain, how to benefit from each, and how to optimize cash flow for efficient supply management and overall business operations.

Scroll down to find out

What is Procurement?

Key Steps in Procurement

Role of Procurement in Organizations

What is Supply Chain Management?

Key Phases of Supply Chain Management

Role of Supply Chain Management in Organizations

The Difference of Procurement and Supply Chain Management

What is Procurement in the Supply Chain?

Interlink of Procurement and Supply Chain Management

Benefits of Aligning Procurement and SCM Strategies

Upcoming Trends of Procurement and Supply Chain Management

Procurement and Supply Chain Management Integration: Best Practices

Case Studies of Procurement and Supply Chain Management Integration

Frequently Asked Questions

What is Procurement?

Supply chain purchasing, or procurement, is the strategic process of acquiring the goods, services, and equipment a company needs for its operations and production. This process includes identifying needs, sourcing and negotiating with suppliers, placing orders, and ensuring that materials meet quality and compliance standards. The goal is to maintain an efficient and cost-effective flow of resources within the broader supply chain.

The process begins by identifying what the company needs, whether it’s materials for manufacturing or everyday office supplies to support routine activities.

Procurement is often viewed as a part of the broader supply chain, but it plays a strategic role in its own right. It involves:

- Pinpointing business needs

- Sourcing the right materials and services

- Negotiating pricing and contract terms

- Carrying out the actual purchases

- Ensuring the goods and services meet quality standards and compliance requirements

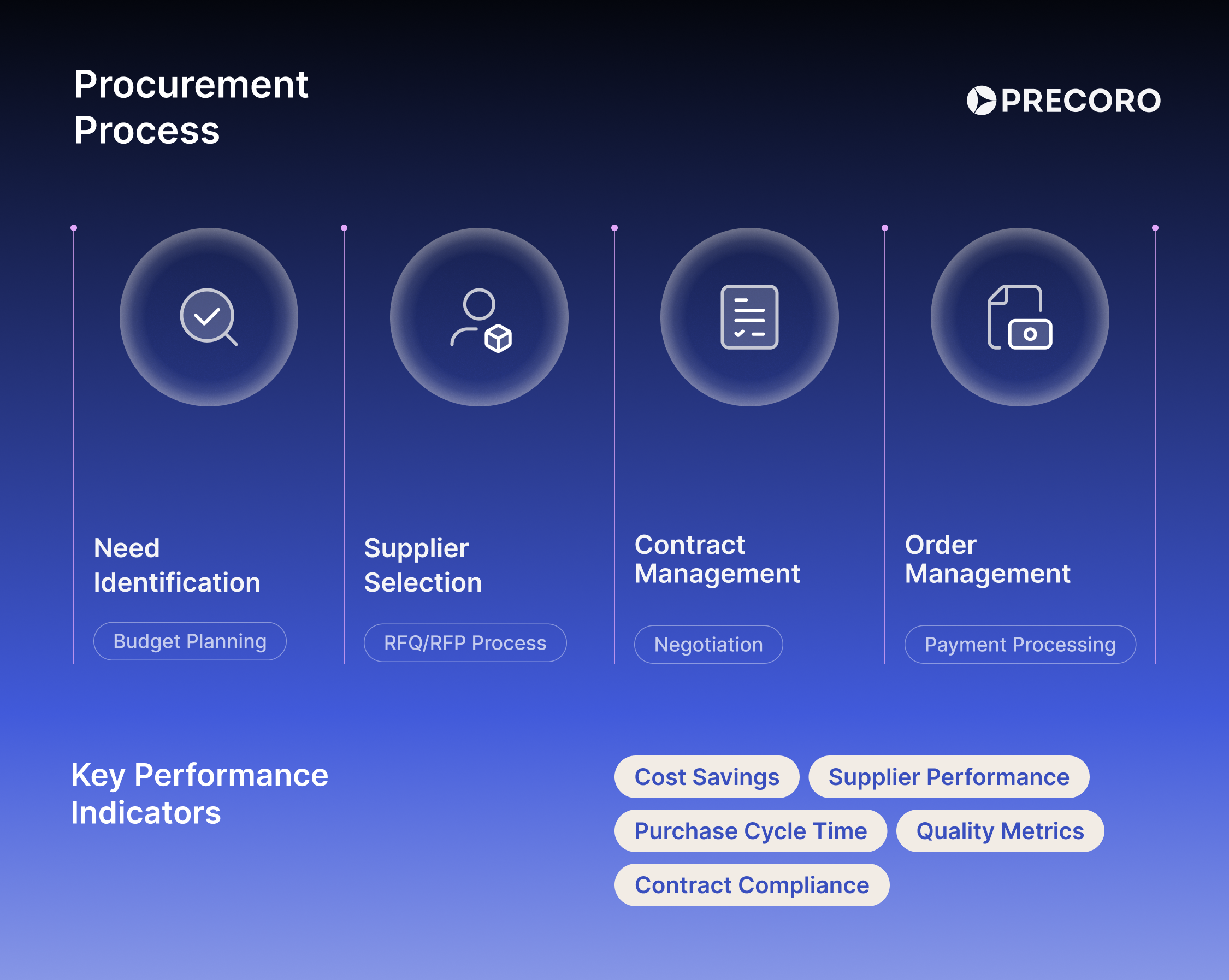

Key Steps in Procurement

The procurement lifecycle or buying cycle isn't a one-step action; it's a continuous process. Steps differ from organization to organization. Some of the most important, however, are:

Sourcing

- Identify Needs. Determine the goods or services required and outline their specifications.

- Find Suppliers. Use industry databases and networking to find reputable suppliers. They should have high capacity and a proven track record.

- Submit an RFI. Issue a request for information to explore supplier capabilities and offerings.

- Submit an RFP or RFQ. Prepare and issue a formal request for a proposal or quotation detailing the requirements for suppliers.

Purchasing

- Review and Choose Suppliers. Analyze suppliers' bids or proposals and select the best-suited based on cost, quality, and delivery time.

- Negotiate and Finalize Contracts. Discuss and agree on the terms with the selected suppliers, including pricing, payment options, and delivery schedules. Prepare and finalize contracts that clearly state these terms.

- Issue Purchase Orders. Prepare and send purchase orders (POs) to the chosen suppliers, specifying the transaction details, including quantity, price, and delivery requirements.

- Receive and Inspect Deliveries. Upon delivery, regularly review supplier performance, quality, and quantity of goods and services against order specifications.

Receiving

- Perform Three-Way Matching. Verify that the purchase order, receipt, and supplier's invoice match quantities, prices, and delivery details.

- Authorize Invoices and Process Payments. Review and approve invoices. Then, the accounts payable team will process payments according to the agreed-upon terms.

- Keep records. Maintain thorough and accurate records of the procurement process, including contracts, purchase orders, invoices, and all related communications.

Note! To build strong, lasting relationships with key suppliers, practice supplier relationship management (SRM). Overall, procurement and supply management go hand in hand with constant feedback, fixing issues, and finding ways to improve processes and cut costs.

Role of Procurement in Organizations

In fact, procurement zeroes on innovation, compliance, stakeholder satisfaction, sustainability, and talent development. Below, we present a detailed description of the objectives of procurement:

Strategic Sourcing. The strategic sourcing plans align with the organization's long-term goals. This approach helps companies quickly find low-cost, high-quality, and reliable suppliers.

Supplier Relationship Management. Effective procurement relies on stable relationships with suppliers, straightforward contract negotiation, and compliance with agreed-upon terms. The focus on this strategy can help organizations boost product quality, reliability, and innovation.

Cost Management. Procurement teams aim to cut costs while maximizing value. They negotiate favorable terms, leverage discounts, and streamline operations. Thus, organizations remain financially healthy.

Risk Mitigation. Procurement departments identify risks and develop ways to reduce them. This strategic act allows organizations to swiftly adapt to market shifts and geopolitical events in the face of supply chain and procurement disruptions.

Cross-Functional Collaboration. Procurement teams closely work with departments like finance, logistics, and marketing. Together, they ensure the organization gets the right resources to support the company's overall goals.

Contract and Compliance Oversight. Procurement specialists oversee initial requests for proposals to the final delivery of goods and services, including contract renewals. They ensure compliance with industry regulations and standards for both suppliers and the organization. As a result, companies with strong procurement achieve compliance rates of over 90% and generate cost savings.

Data and Analysis. Procurement analysis can uncover insights into spending, suppliers, and market trends. This can guide better decisions across the enterprise.

Sustainability and Ethical Practices. Modern procurement goes beyond price and quality. It now considers environmental impact, ethical sourcing, and social responsibility, which helps enterprises solidify their reputations while following regulations.

Innovation and Continuous Improvement. With market insights and supplier ties, procurement experts find and source cutting-edge products that provide a competitive edge.

Education and Training. Ongoing training is crucial, as it keeps procurement teams up-to-date on industry trends, tools, and best practices, all of which are vital for businesses in the long run.

Stakeholder Satisfaction. At its heart, procurement focuses on delivering value to stakeholders. Organizations must understand stakeholder needs and involve them in supply chain planning to achieve their goals. Integrating procurement activities with strategic objectives like cost reduction, innovation, and sustainability is essential. Technology and data analysis ensure a more efficient and resilient supply chain and procurement. This stakeholder-focused approach is crucial for boosting organizational effectiveness and helping it succeed in the long run.

Precoro best fits a seamless procurement process. It’s a fully customizable, mobile-friendly platform that equips requesters with real-time tracking tools. It empowers procurement teams to automate 80% of manual tasks. The platform speeds up approvals by 3.5x faster and cuts purchase cycles by 78%, which results in strategic growth.

With Precoro, you might save up to 5% of the budget and optimize the overall procurement and supply.

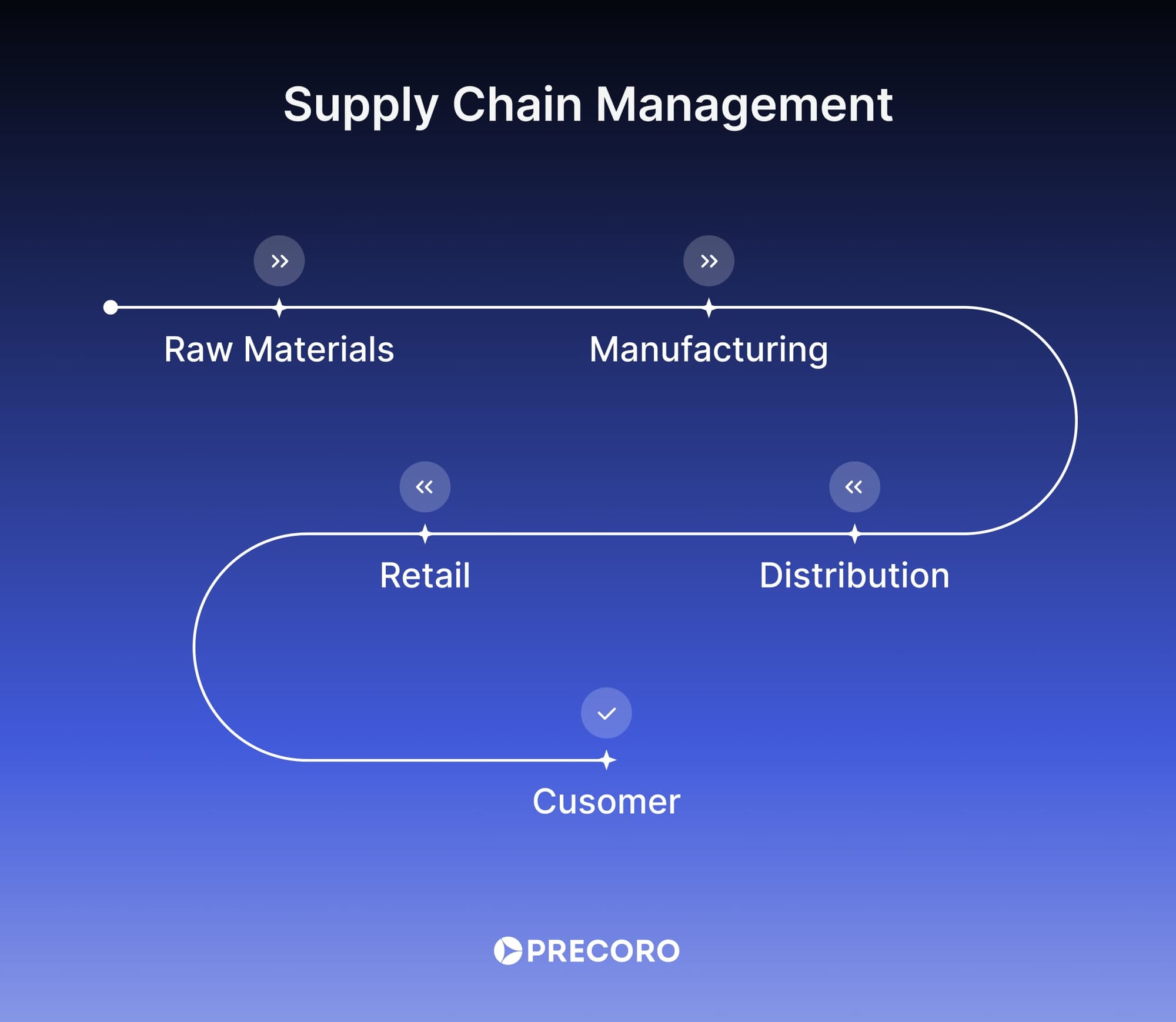

What is Supply Chain Management?

Supply Chain Management (SCM) coordinates the people, activities, information, and resources needed to move a product or service from supplier to customer. It covers the entire journey, from sourcing raw materials to delivering the finished product.

The supply chain process is a vital, ever-moving system that transforms raw materials into finished products ready for customers. It involves a web of connected activities that require thoughtful planning, coordination, and control.

It all starts with sourcing. Here, procurement managers work with suppliers to secure the right materials at the best possible terms, balancing quality, cost, and reliability.

Once sourced, materials enter the production phase, where they’re turned into finished goods. The way this stage is managed affects everything from product quality and cost to how quickly items can reach the market.

Thus, Supply Chain Management (SCM) coordinates and optimizes these processes. It aims to move products or services efficiently, improve production and distribution, eliminate waste, increase customer value, and gain a competitive edge.

Key Phases of Supply Chain Management

SCM goes far beyond traditional logistics and purchasing. Its main goal is to optimize the flow of goods, services, and information from origin to consumer. Key SCM activities improve efficiency, lower costs, and boost quality. They also raise customer satisfaction, meet market demands, and cut supply chain risks. SCM drives innovation, too.

SCM managers aim to find ways to increase efficiency and keep costs down while avoiding shortages and preparing for unexpected contingencies. The SCM process consists of these phases:

Planning

Initially, planning matches supply with customer and manufacturing demands for the best results. Companies must try to predict their future needs and act accordingly. This means considering the raw materials or components needed during each manufacturing stage, equipment capacity and limitations, and staffing needs. Large businesses often rely on ERP software to coordinate the process.

Sourcing

This procurement and supply management phase entails identifying, evaluating, and selecting suppliers for raw materials and services. Notably, this step hugely relies on vendor relations to get materials for production and a well-structured vendor management lifecycle to support partnership's growth. Effective sourcing involves several key considerations:

- Quality Compliance. Raw materials or components must meet specific manufacturing specifications, such as Good Manufacturing Practice (GMP), ISO 9001, and industry-specific regulations that govern the quality and sourcing of raw materials to ensure compliance, safety, and product integrity.

- Market-Competitive Pricing. Supplier prices should meet market expectations to stay cost-effective.

- Supplier Flexibility. Vendors must demonstrate they can handle unexpected situations and deliver materials on time.

- Reliability. Choose suppliers with a proven record of delivering quickly on time and maintaining quality, especially concerning perishables.

Also, companies must consider lead times. They should check if a supplier can meet their specific needs.

Purchasing

This stage involves contracts negotiation, purchase orders placement, and ongoing supplier relationships management. The purchasing phase serves as a solid foundation for a successful supply chain and ensures that materials are available when needed.

Manufacturing

Manufacturing is the heart of the SCM process, which transforms raw materials into finished products through carefully planned production and process management. This phase includes sub-tasks: assembly, testing, inspection, and packaging, all of which incorporate both machines and labor.

Effective manufacturing focuses on quality control, waste reduction, and improvement. It aims to boost productivity and maintain high quality, ensuring the final product meets expectations. This phase is one of the main differences between procurement and supply chain.

Note! All potential deviations (e.g., excess material from lack of training) must be considered. If necessary, corrective action must be taken. While the manufacturing process results in the final product, it is not the final stage of SCM.

Delivery and Logistics

Once manufactured, products proceed to the distribution phase. They are warehoused until needed. Efficient order fulfillment ensures accurate and prompt processing and shipment of customer orders. On the other hand, it's important to allocate inventory wisely across distribution centers to meet the needs of different regions.

Transportation

Efficient transportation is the backbone of SCM. Companies must select the best transportation methods (road, rail, air, etc.) since they help reduce delivery times and ensure products reach their destinations on time.

Returns Management

At this point, the company must ensure it can receive returned products and correctly issue refunds. Whether it's a large-scale recall or an individual customer complaint, the company must address the customer's concern. Failing to identify the underlying cause of a customer return might influence the whole SCM process, resulting in continuous returns.

Note! Don't be afraid of product returns. They can provide valuable feedback, highlighting defects and poor designs. This can significantly assist in modernization and innovation while fostering clients' trust.

Customer Service

Customer service is a cornerstone of SCM, impacting customer satisfaction and loyalty. Order tracking boosts transparency and builds trust. Meanwhile, efficient returns handling resolves issues quickly and collects feedback to enhance service quality.

Inventory Management

This phase focuses on maintaining optimal inventory levels and meeting customer demand without incurring excess costs. It is based on real-time monitoring of stock levels to prevent shortages or excess inventory. Techniques like JIT inventory align stock with actual demand. They reduce holding costs and improve cash flow.

Collaboration and Integration

Successful SCM requires collaboration among various stakeholders, including suppliers, manufacturers, distributors, and retailers. Integrating processes across these entities creates a cohesive procurement & supply chain that can respond quickly to changes in demand or supply.

Quality Control

This phase is essential for maintaining product integrity. Regular inspections at various points ensure compliance with industry standards and regulations. A focus on improvement sparks innovation and boosts quality over time.

As you can see, effective procurement and supply management demands a comprehensive strategy that integrates manufacturing, distribution, transportation, inventory management, customer service, and quality control. Optimizing each component might create a resilient supply chain that meets customer needs while driving operational efficiency and reducing costs.

Role of Supply Chain Management in Organizations

Within a company, SCM focuses on ensuring that all operations are aligned to deliver maximum value to the end customer while also serving the needs of the business. This broad aim is supported by ten core objectives, including:

Efficiency and Speed. To speed up the movement of goods and services in the supply chain and procurement while cutting waste and reducing time to market.

Cost Reduction. To streamline operations and reduce costs throughout the supply chain while still maintaining quality and customer satisfaction.

Quality Improvement. To ensure each part of the supply chain consistently delivers high-quality products to customers.

Flexibility and Adaptability. To build a supply chain that can quickly adjust to changes in market demand, supplier availability, or logistical issues.

Collaboration and Integration. To integrate processes and systems for seamless operations to foster cooperation among all supply chain stakeholders.

Risk Mitigation. To identify potential disruptions and implement strategies that minimize risk to ensure a reliable supply chain.

Sustainability. To build a supply chain that meets economic objectives and operates responsibly for social and environmental factors.

Customer Satisfaction. To align the supply chain's objectives with customer needs, ensuring timely delivery and high-quality service.

Innovation. To leverage new technologies, processes, and ideas to improve and potentially transform the supply chain.

Visibility and Control. To gain end-to-end visibility across the supply chain, enabling better control and decision-making.

How Procurement and Supply Chain Management Differ

Procurement and supply chain management (SCM) are commonly mistaken for the same. In fact, they are distinct business functions with different scopes, goals, and methods.

Procurement, often seen as the first step in the supply chain, plays a crucial role in an organization’s operations. It’s responsible for sourcing the goods and services, ranging from raw materials to essential supplies, that keep the business running.

On the other hand, SCM is a linear process by nature. It involves coordinating the people, processes, information, and resources needed to move a product or service from its origin to the end customer. SCM covers every stage of production, from sourcing raw materials to manufacturing, logistics, and final delivery.

Shortly speaking, supply chain management oversees the entire journey of a product, from raw materials to the end customer. Procurement is a specialized part of this process, focused on sourcing and acquiring the goods and services a company needs from suppliers. Procurement activities include identifying vendors, negotiating contracts, and managing supplier relationships to secure high-quality, cost-effective inputs. Once the necessary materials are procured, the supply chain manages production, storage, and delivery to the final consumer.

Let's examine all the differences in detail:

Scope and Focus

Procurement:

- Primarily concerned with the purchasing function.

- Focuses on supply chain purchasing processes and supplier relationships.

- Emphasizes cost savings and value for money.

- Deals with immediate organizational needs.

Supply Chain Management:

- It is responsible for the end-to-end procurement and flow of goods, from raw materials to the consumer's hands.

- Focuses on overall efficiency and value creation.

- Takes a long-term, strategic view of resource movement.

Organizational Position

Procurement:

- Usually, it operates as a departmental function.

- Reports to finance or operations.

- Interfaces primarily with suppliers and internal stakeholders.

- Focused on specific transactions and contracts.

Supply Chain Management:

- Functions at a strategic level.

- Often reports directly to top management.

- Interfaces with multiple departments and external partners.

- Oversees the entire value chain.

Key Activities

Procurement:

- Needs identification.

- Supplier selection and evaluation.

- Contract negotiation.

- Purchase order processing.

- Vendor relationship management.

- Quality control of purchased items.

Supply Chain Management:

- Demand planning and forecasting.

- Production planning and scheduling.

- Inventory procurement and supply management.

- Warehouse operations.

- Transportation and logistics.

- Supply chain optimization.

- Risk management across the network.

Performance Metrics

Procurement:

- Cost savings.

- Purchase order cycle time.

- Supplier performance ratings.

- Contract Compliance.

- Payment terms optimization.

- Quality of received goods/services.

Supply Chain Management:

- Order fulfillment rate.

- Inventory turnover.

- Supply chain cycle time.

- Perfect order percentage.

- Total supply chain costs.

- Customer satisfaction levels.

- Cash-to-cash cycle time.

Note! Organizations that recognize key differences in supply chain vs. procurement can harness the power of both methods. They could create a more fluid supply network by weaving together daily procurement actions and wide-reaching supply chain strategies. This dynamic fusion not only sharpens operational efficiency but also catapults them to leadership positions in their industry.

What is Procurement in the Supply Chain?

Procurement has evolved; now, it is a cornerstone of supply chains, not just a cost center. As the gateway to an organization's supply chain, procurement managers build complex supplier relationships while acquiring materials and services.

Procurement teams create value by picking the right suppliers based on quality, reliability, and total costs. Collaboration usually results in new ideas and better products. Overall, both sides benefit from sharing knowledge and developing solutions together.

The procurement team works closely with other departments, such as logistics, and warehouse teams. This integration aligns sourcing strategies with business goals while keeping operations agile. In addition, procurement teams optimize costs while managing risks. It is especially relevant when markets change quickly, and supply continuity is necessary for a competitive edge.

In short terms, to answer the question of "What is procurement in the supply chain?," it is important to highlight that effective procurement helps companies swiftly adapt to market fluctuations while maintaining high quality. When companies get the right materials at reasonable prices, they can outperform their competitors and run more efficiently.

How Procurement Decisions Influence the Supply Chain and Vice Versa

The procurement and supply chain relationship is a classic cause-and-effect cycle, shaping everything from production timelines to delivery efficiency.

Impact of Procurement Decisions on the Supply Chain

- Quality Matters. Picking the right suppliers directly affects the quality of a business's products. Better materials mean better products, fewer problems, and a more substantial reputation.

- Cost Counts. The price a business pays for materials impacts the overall costs. Savvy negotiations can lead to lower supplier prices and higher profits for companies.

- Timing is Everything. Strategies like just-in-time buying can save money but require reliable suppliers and good timing.

- Stay Protected. Spreading out the supplier base helps protect businesses from surprises like natural disasters, political issues, or supplier failures.

Influence of the Supply Chain on Procurement Decisions

- Plan Ahead. Sales forecasts and inventory data help procurement teams decide when and how much to buy, allowing them to match demand without overspending.

- Know Your Partners. Feedback from the supply chain team shows which suppliers are doing a great job and which ones might need a second look.

- Adapt to Change. New technologies in the supply chain procurement might require finding different suppliers or renegotiating contracts to keep up with innovations.

Procurement can't operate in a vacuum — it must work with the supply chain. When they're in sync, organizations can avoid problems, manage costs better, and run smoother. If procurement managers ignore the supply chain, and vice versa, businesses risk delays, extra fees, and lost opportunities.

The Interlink of Procurement and Supply Chain Management Explained

Procurement and supply chain management are deeply intertwined, and their relationship goes far beyond a simple business necessity. They are two sides of the same coin, each playing a critical role in an organization's overall success.

In this section, we'll explore what procurement is in supply chain management through real-world case studies. These examples will illustrate how the alignment (or misalignment) of SCM and procurement can either lead to remarkable success or serve as valuable lessons for future improvement.

Case Studies Illustrating the Symbiotic Partnership

The relationship between procurement and supply chain management (SCM) truly comes to life in real-world situations where their interconnectedness is crucial. Below are cases that show the procurement vs. supply chain dynamics in action across different industries:

Case Study 1: Biotech

A biotech firm faced challenges identifying who was buying what and for which project. There was no central repository of all the information involved in supply chain purchasing. To address these challenges, the firm implemented a strategic sourcing approach. This strategy focused on establishing long-term supplier relationships, facilitating better price and terms negotiation.

This case study shows that the firm addressed several challenges through procurement and supply chain management. They resolved issues with exporting over 500 purchase orders from their old system. Instead of developing a complex ERP system, they appointed an office manager to efficiently handle supplier product catalogs. Additionally, they improved internal communication, eliminating initial slowdowns in the approval process.

Case Study 2: Manufacturing

Within the manufacturing sector, supply chain management and procurement thrive the most. E-bike company Serial 1, which built an efficient procurement ecosystem, is one of the notable manufacturing case studies. They adopted a centralized procurement strategy, resulting in easy supplier onboarding and management, manual and paper-based work elimination, transparent purchase order status tracking, and a customized approval workflow. This minimized stockouts and excess inventory, leading to smoother operations and higher profits.

Case Study 4: Logistics

A logistics-focused case study demonstrates how multinational transportation giant Bolloré has eliminated manual work in purchasing operations. By optimizing routing and consolidating shipments, the company has significantly reduced transportation costs. The procurement team played a crucial role by negotiating contracts with carriers that offered flexibility and cost savings, which improved overall service levels and customer satisfaction.

Implementing an automated procurement and supply chain management system brought multiple benefits. It enabled better utilization of existing data for improved analysis and decision-making. Moreover, centralized data storage and sharing replaced fragmented systems. Manual and paper-based work was eliminated, reducing operational costs. Additionally, the system facilitated automatic 3-way matching of invoices.

Case Study 5: Technology

A technology firm faced challenges in managing its complex supply chain procurement due to rapid changes in market demand. To address this, a French electric vehicle charging startup built a successful procurement process using purchasing software.

The firm focused on strategic procurement practices by developing strong relationships with key suppliers. It implemented a procurement system that enabled swift purchase order creation with drop-down menus and catalogs. The system also streamlined approvals, simplified order tracking, and ensured structured and secured procurement documents. Additionally, the software provided insightful reporting and easily retrievable financial data for investors.

Case Study 6: Farming

Supply chain management procurement in agriculture is strategically linked to sourcing seeds and fertilizers. A case study shows how Cropnuts, an analytical laboratory from Kenya, optimized its procurement process and significantly decreased lab downtime by switching to e-procurement. This strategic approach led to significant cost savings for member farms while ensuring they had access to the best resources available. Ultimately, the cooperative significantly enhanced productivity.

Case Study 7: Hospitality

The hospitality industry relies heavily on procurement to manage food, beverages, and linen supplies. With efficient procurement and SCM, the Southern Californian cosmopolitan oasis, The Greater Palm Springs Convention & Visitors Bureau (CVB), gained accuracy and time-effectiveness in purchasing operations by switching to e-procurement.

By centralizing procurement and fostering strong supplier partnerships, they significantly cut costs. This approach has improved operations and service quality, and enhanced overall guest satisfaction.

Case Study 8: Education

Effective procurement strategies are essential for managing educational institutions' resources, like textbooks and technology supplies. The public charter school case study illustrates how an automated procurement tool has sped up Capital City's purchasing process and enabled remote buying post-COVID. Now, employees can access documents and track purchases anytime. In addition, purchase requests are simplified with drop-down fields and supplier catalogs. The approval process is also streamlined with a custom workflow.

Case Study 9: Finance

In finance, supply chain management procurement is critical for acquiring technology solutions that support operations. A VC studio implemented procurement software to manage purchases for 10 portfolio companies in addition to its own. Redbud Brands went from not knowing if a purchase order was approved to making every payment on time. This approach not only optimized costs but also ensured compliance with regulatory requirements.

These case studies show how procurement and supply chain management work together across different industries, highlighting how innovative procurement strategies can boost efficiency, cut costs, and improve overall results.

Unlocking Business Excellence: The Benefits of Aligning Procurement and SCM Strategies

In today's dynamic business landscape, the alignment of procurement and supply chain management strategies has evolved from a nice-to-have to a critical business imperative. Organizations that successfully integrate these two functions are witnessing transformative results. Let's examine how strategic procurement within the supply chain can generate significant business value and create a competitive edge.

Driving Operational Excellence through Enhanced Efficiency

When procurement and SCM strategies work harmoniously, the impact on operational efficiency is immediate and substantial. Organizations are seeing up to 20% reductions in operational costs through streamlined processes that eliminate redundancies and optimize workflows. By consolidating purchase volumes across divisions, companies can leverage their buying power more effectively, securing better terms and pricing from suppliers.

Consider how Toyota revolutionized its operations by integrating procurement with its just-in-time manufacturing system. Through this strategic alignment, the company achieved lower inventory costs without compromising production efficiency.

Building Stronger Supplier Relationships

The days of adversarial buyer-supplier relationships are over. Modern business success relies heavily on collaborative partnerships built on trust and mutual benefit. When procurement and supply chain management strategies align, organizations can develop more profound, strategic relationships with key suppliers.

These enhanced partnerships often lead to the following:

- Early supplier involvement in product development.

- Joint innovation initiatives.

- Shared risk and reward programs.

- More reliable procurement & supply chains.

- Better quality outcomes.

Mastering Risk Management

Risk management has never been more crucial in an era of global uncertainty. Aligned procurement and SCM strategies provide greater visibility across the entire supply chain, enabling organizations to identify and mitigate risks proactively. This increased transparency helps companies spot potential disruptions before they impact operations.

Innovative organizations are implementing diverse supplier networks while maintaining strong relationships with key partners. A balanced approach ensures business continuity while optimizing costs and maintaining quality standards.

Elevating Quality Standards

Quality isn't just about the final product but consistency throughout the supply chain. Organizations can implement standardized quality processes across their supplier network when procurement and SCM strategies align. This alignment ensures:

- Consistent quality standards across all suppliers.

- Better compliance with regulatory requirements.

- Reduced defect rates.

- Lower quality-related costs.

- Enhanced brand reputation.

Fostering Innovation and Growth

The innovation potential may be the most exciting benefit of aligned procurement and SCM strategies. When these functions work together, organizations can better adapt to market changes and capitalize on new opportunities. Suppliers become partners in innovation, contributing their expertise to product development and process improvement.

Tesla's approach to battery procurement and supply chain management perfectly illustrates this. By closely aligning these functions, they've secured critical materials and driven innovations in battery technology through collaborative supplier relationships.

Enhancing Customer Satisfaction

Boosting customer satisfaction is the primary goal of all business initiatives. Armed with effective procurement and supply chain strategies, organizations can:

- Ensure more reliable product availability.

- Maintain consistent quality.

- Reduce lead times.

- Offer competitive pricing.

- Provide better overall value to customers.

Embracing Sustainability

Sustainability isn't optional in today's environmentally conscious market – it's essential. Aligned procurement and SCM strategies enable organizations to:

- Implement ethical sourcing practices.

- Reduce environmental impact.

- Support local communities.

- Meet regulatory requirements.

- Build brand value through sustainability initiatives.

For example, Patagonia's aligned approach to procurement and supply chain management has made it a leader in sustainable business practices, proving that environmental responsibility and business success can go hand in hand.

As we move forward, the organizations that thrive will recognize and act on the strategic importance of alignment between procurement and SCM. The question isn't whether to align these functions but how quickly and effectively you can make it happen.

The Future of Procurement and Supply Chain Management: A Digital Transformation Journey

The future of procurement and supply chain management lies at the intersection of technological innovation, strategic thinking, and sustainable practices. Organizations that embrace this transformation while addressing emerging challenges will be better positioned to create resilient, efficient, and value-driven supply chains and procurement processes.

Success in this new era requires a balanced approach that combines technology adoption with human expertise, sustainable practices with business efficiency, and global reach with local responsiveness. By understanding and adapting to these evolving dynamics, organizations can build procurement and SCM operations that meet current needs and are prepared for future challenges and opportunities.

Let's explore the key drivers shaping the future of these critical business functions and how organizations can position themselves for success.

Technological Advancements and Their Impact on Procurement and SCM

Integrating cutting-edge technologies has become the cornerstone of modern procurement and SCM strategies. These technological advancements are not merely enhancing existing processes but fundamentally reimagining how organizations manage their supply chain procurement operations.

Artificial Intelligence and Automation

Artificial Intelligence (AI) and Robotic Process Automation (RPA) are revolutionizing procurement processes in several ways:

- Predictive analytics algorithms now accurately forecast demand patterns, enabling proactive supply chain purchasing decisions.

- Automated purchase order processing reduces manual errors and accelerates procurement cycles.

- AI-powered supplier evaluation systems provide real-time insights into vendor performance.

- Smart inventory management systems optimize stock levels and reduce carrying costs.

Blockchain Technology: Ensuring Transparency and Security

Blockchain technology has emerged as a game-changer in supply chain transparency. The implementation offers several key benefits:

- Creation of immutable, transparent records of all supply chain transactions.

- Enhanced traceability of products from raw materials to end consumers.

- Reduced risk of counterfeit products entering the supply chain.

- Improved supplier accountability and compliance monitoring

Internet of Things (IoT) Integration

The proliferation of IoT devices has transformed supply chain visibility and control:

- Real-time tracking of shipments and inventory movements.

- Environmental monitoring for sensitive goods during transit.

- Automated inventory replenishment systems.

- Predictive maintenance for supply chain equipment.

Evolving Roles in Procurement and SCM

Today's procurement professionals are seeing a significant shift in their roles and skills. A modern procurement expert wears many hats and has diverse responsibilities.

Procurement: From Tactical to Strategic

The role of procurement has evolved from a purely operational function to a strategic business partner:

- Development of long-term sourcing strategies aligned with organizational goals.

- Identification of innovation opportunities through supplier collaboration.

- Implementation of risk procurement and supply chain management frameworks.

- Creation of value beyond cost savings.

Data-driven decision-making in Procurement

Modern supply chain and procurement professionals must be adept at leveraging data analytics:

- Analysis of spending patterns and supplier performance metrics.

- Utilization of predictive analytics for market trend forecasting.

- Implementation of data-driven supplier selection processes.

- Development of performance measurement frameworks.

Emerging Challenges and Solutions in Procurement and SCM

As the procurement and SCM landscape evolves, organizations face several critical challenges that require innovative solutions.

Cybersecurity in Digital Procurement

The digitalization of procurement processes introduces new security considerations:

- Implementation of robust data protection measures.

- Regular security audits of digital procurement systems.

- Secure supplier portal for procurement and supply chain management.

- Employee training on cybersecurity best practices.

Sustainability and Ethical Sourcing

Environmental and social responsibility has become a core component of procurement strategy:

- Development of sustainable sourcing policies.

- Implementation of supplier sustainability assessment programs.

- Creation of circular economy initiatives.

- Monitoring and reporting of environmental impact metrics.

Global Supply Chain Complexity

Managing international supply chains requires sophisticated approaches:

- Navigation of diverse regulatory environments.

- Cultural sensitivity in supplier relationships.

- Currency risk mitigation in procurement and supply chain management.

- Geopolitical risk assessment and mitigation.

Future-Proofing Your Procurement and SCM Operations

To remain competitive in this evolving landscape, organizations must take proactive steps to enhance their procurement vs. supply chain capabilities:

Investment in Technology

- Evaluate and implement relevant digital solutions.

- Develop integration strategies for new technologies.

- Create technology adoption roadmaps.

- Measure and optimize technology ROI.

Talent Development

- Implement continuous learning programs.

- Develop digital literacy training initiatives.

- Create career development pathways.

- Foster innovation and analytical thinking.

Risk Management

- Develop comprehensive risk assessment frameworks.

- Create supplier diversification strategies.

- Implement early warning systems.

- Establish business continuity plans.

Transforming Supply Chains: The Rise of Sustainable Procurement

Sustainable procurement is no longer a mere trend. It's not just about getting the best price — it's about ensuring that every dollar spent contributes to a healthier planet, fairer workplaces, and more resilient businesses. With rising environmental and social concerns, ethical procurement and sustainable supply chain management are no longer optional but crucial to modern business operations.

Thus, by integrating ESG principles into procurement strategies, businesses contribute positively to societal and environmental goals and enhance operational efficiency and profitability. As consumers become more discerning about corporate responsibility, companies prioritizing sustainable practices will likely find themselves better positioned for long-term success.

For further insights into implementing sustainable procurement strategies, read on:

Key Practices in Sustainable Procurement

- Green Sourcing

Choose products and services with minimal environmental impact. Look for suppliers that use renewable energy, cut waste, or innovate sustainable processes.

- Life Cycle Assessments (LCA)

Assess a product's full environmental impact — from raw materials to disposal — to identify options with smaller ecological footprints.

- Circular Supply Chains

Source materials that can be reused, repaired, or recycled to build a circular economy, reduce waste, and conserve resources.

Key Ethical Procurement Practices

- Labor Standards

Work only with suppliers who ensure safe working conditions, fair wages, and the absence of forced labor or human trafficking.

- Anti-Corruption Measures

Ensure transparency in procurement and supply chain management by preventing corruption and maintaining integrity in all transactions.

- Supplier Diversity

Support minority-owned, women-owned, and small businesses to foster inclusivity and drive economic equity.

Benefits of Sustainable Procurement

- Cost Savings

Better resource procurement and supply chain management and reduced waste lead to lower expenses. For example, local sourcing cuts transportation costs.

- Stronger Brand Reputation

Sustainability commitments boost customer loyalty and improve public perception, often increasing sales.

- Risk Mitigation

Avoid supply chain disruptions and regulatory penalties by complying with environmental standards and adopting sustainable practices.

- Innovation Opportunities

Partnering with sustainable suppliers can create new, eco-friendly products and services.

Sustainable procurement is more than a trend — it's a strategic necessity for businesses aiming to thrive in today's eco-conscious world. By adopting these practices, companies can protect the planet, strengthen communities, and drive long-term growth.

Best Practices for Procurement and Supply Chain Management Integration

Integrating procurement with supply chain management drives operational excellence and market agility. Success requires three key elements:

- Digital procurement transformation through integrated systems that connect purchasing data with supply chain operations.

- Cross-functional teams that combine procurement expertise with supply chain knowledge.

- Continuous skill development to keep pace with evolving technologies and market demands.

This integration helps companies respond swiftly to market shifts while maintaining cost control and supply chain efficiency. At a deeper level, procurement and supply chain management are aligned around key goals such as operational excellence, a strong collaboration framework, risk management, and continuous improvement.

Strategic Alignment

Aligning procurement with a company's strategic objectives is both crucial and complex. It requires a blend of planning, effective communication, collaborative efforts, and continuous monitoring. We’ve listed below some of the best strategies for such alignment.

Unified Strategy Development

The combination of procurement and supply chain management strategies with corporate objectives can help companies with resource allocation, reduce inefficiencies, and create a more agile, responsive supply chain that drives competitive advantage. Main steps of such unified strategies include:

- Joint planning sessions between procurement and SCM leadership.

- Shared KPIs and performance metrics.

- Integrated risk management approaches.

- Ongoing sustainability and ethical sourcing goals.

Technology Integration

Technology integration enhances data access, communication, and productivity. It connects different technologies, cutting manual data entry and errors. Here are ideas on what to implement in integrated systems and platforms to enable seamless information flow:

- Enterprise Resource Planning (ERP) systems that connect procurement and SCM functions.

- Supplier relationship management platforms.

- Real-time inventory management systems.

- Integrated analytics and reporting tools.

- Platform for procurement centralization & automation.

Operational Excellence

Organizations that focus on operational excellence can anticipate risks. They can also improve customer experiences by ensuring timely deliveries and high-quality products. This fosters brand loyalty and a competitive edge.

Process Optimization

By implementing uniform procedures, organizations can minimize errors, reduce processing time, and create predictable workflows. This approach enables more strategic resource allocation and helps control operational costs. Streamline processes with these steps:

- Standardized procedures for procurement and supply chain management.

- Automated purchase order-to-payment cycles.

- Integrated quality control processes.

- Joint supplier performance monitoring.

Data Management

A unified data approach connects procurement and supply chain teams, breaking down information silos. Centralizing critical data sources improves decisions, transparency, and forecasts. Real-time data integration empowers leaders to make informed, strategic choices quickly and confidently. Establish a unified approach to data for both procurement and supply chain management:

- Single source of truth for supplier information.

- Shared demand forecasting data.

- Integrated inventory management metrics.

- Common reporting frameworks.

Collaboration Framework

Cross-functional teams and rotational programs help break traditional departmental barriers, promoting a holistic understanding of organizational challenges. These collaborative approaches encourage innovation and develop more versatile, adaptable professionals. Create organizational structures that promote integration, implementing these steps:

- Joint procurement and SCM teams for major projects.

- Regular cross-functional meetings.

- Shared training programs.

- Rotational programs between departments.

Supplier Relationship Management

Strategic supplier management transforms vendors from transactional partners to collaborative allies. Organizations can build stronger, mutually beneficial relationships by creating shared metrics and evaluation frameworks. Plus, proactive risk assessment and joint development programs help avoid supply chain issues. Here is what to pay attention to in comprehensive SRM development:

- Joint supplier evaluation criteria.

- Collaborative supplier development programs.

- Integrated supplier performance metrics.

- Shared supplier risk assessments.

Implementation Guidelines

Procurement and supply chain management need a strategic, systematic approach. It should transform capabilities, drive excellence, and create a competitive edge. This requires a blend of technology and a human focus.

Change Management

Use change management to align strategies, adopt tech, and adapt culture. Systemic changes will transform procurement and supply chain management and minimize disruption while maximizing efficiency.

- Clear communication of integration benefits.

- Comprehensive training programs.

- Phased implementation approach.

- Regular progress monitoring.

Performance Measurement

Develop comprehensive procurement and supply chain performance metrics that capture end-to-end value creation:

- Total cost of ownership.

- Order fulfillment cycle time.

- Supplier reliability index.

- End-to-end supply chain visibility.

Tools and software solutions

Select integrated procurement and supply chain technology platforms that enable real-time visibility, predictive analytics, collaborative capabilities, and seamless ecosystem connectivity across purchasing, logistics, and strategic sourcing. These solutions streamline processes, reduce errors, and provide actionable data for better decision-making:

- E-Procurement systems.

- Supply chain management software.

- Advanced analytics and AI.

- Cloud-based collaboration platforms.

Training and professional development

Create a strategic learning ecosystem that develops procurement and supply chain professionals' technical capabilities, strategic thinking, technological adaptability, and cross-functional collaboration skills:

- Continuous learning culture.

- Specialized training programs.

- Cross-functional knowledge sharing.

- Certifications and qualifications.

- Leadership development.

- E-learning platforms.

- Mentorship and coaching.

- Assessments and feedback.

Risk Management

Risk management in procurement and supply chain transforms uncertainty into strategic advantage through proactive, intelligent risk mitigation and organizational resilience.

Integrated Risk Assessment

By aligning advanced risk strategies, businesses can convert uncertainty into competitive intelligence. To develop comprehensive risk procurement and supply chain management strategies, follow these ideas:

- Joint risk identification processes.

- Shared contingency planning.

- Collaborative risk mitigation strategies.

- Regular risk review sessions.

Compliance and Governance

Establish unified compliance frameworks for procurement and supply chain management that ensure ethical sourcing, regulatory adherence, sustainability standards, and strategic alignment across procurement and supply chain operations.

- Common supplier compliance standards.

- Integrated audit processes.

- Shared ethical sourcing guidelines.

- Joint sustainability initiatives.

Continuous Improvement

Continuous improvement is a dynamic, strategic process. It transforms procurement and supply chain operations through innovation, collaboration, and adaptive learning. Organizations need to build flexible systems. These systems should allow quick tech integration, share knowledge across teams, and work with suppliers to create mutual value.

Innovation Management

By fostering collaborative innovation ecosystems, organizations can build adaptive skills. These skills can transcend traditional boundaries, enabling breakthroughs in technology and operations. Foster continuous improvement:

- Joint innovation initiatives with suppliers.

- Regular process review sessions.

- Collaborative technology adoption.

- Shared best practice documentation.

Knowledge Management

Develop a dynamic knowledge infrastructure that captures, synthesizes, and distributes procurement and supply chain intelligence, enabling organizational learning and strategic knowledge sharing:

- Common knowledge repository.

- Shared lessons learned database.

- Cross-functional training materials.

- Best practice documentation.

Successful integration of procurement and SCM requires a comprehensive approach that addresses strategy, operations, technology, and people. Organizations must commit to long-term transformation while focusing on short-term operational excellence.

Frequently Asked Questions About the Difference of Supply Chain vs. Procurement

Yes, procurement is a key part of the supply chain. It involves sourcing and buying goods and services for production and operations.

Neither is "better" — they serve different but complementary purposes. Procurement is about making smart purchasing decisions. Supply chain management oversees the flow from raw materials to final delivery. It's like asking if your heart or circulatory system is more important. They're both part of the same team.

The cost strategies are quite different. Procurement zeroes in on getting the best deals, negotiating prices, and managing supplier relationships. Think of it as smart shopping at a corporate level. In the context of procurement vs. supply chain, the supply chain team looks at the bigger picture: optimizing inventory, transportation, warehousing, and production costs across the entire network. They're trying to make the whole system more cost-efficient and smoother.

Procurement managers measure success by five key KPIs: cost savings vs. market prices, supplier scores, order accuracy, contract compliance, and purchase processing time. These metrics reveal operational efficiency and vendor relationship quality. Supply chain performance hinges on inventory turnover, order fulfillment speed, transportation costs per unit, perfect order rate, and cash-to-cash cycle time. These measurements provide insights into operational responsiveness, logistical expenses, and financial effectiveness.

Technically, yes, procurement can exist alone, but it's like having a purchasing department without worrying about how goods move through your company. It's possible but inefficient. Modern businesses need both procurement and supply chain management to work together for maximum effectiveness.

Conclusion

Procurement and supply chain management often go hand in hand, but they serve distinct roles within a business. Procurement focuses on strategically sourcing goods and services and handling tasks like supplier selection, contract negotiations, and supply chain purchasing.

On the other hand, SCM oversees the entire journey of goods, services, and information — from raw materials to the final product reaching customers. Procurement is just one piece of the bigger SCM puzzle, which also includes manufacturing, logistics, and distribution.

While their roles differ, procurement and SCM must work together to ensure success. Their collaboration helps businesses reduce costs, improve efficiency, and create operations that can withstand market changes. Organizations can stay competitive in today's challenging business environment by understanding the unique functions of procurement and supply chain management and encouraging teamwork.