19 min read

Procurement Organization Structure and Design: How to Build a Fail-Proof System

Learn how centralized, center-led, and decentralized procurement organization structures impact your team and how to optimize your setup.

Have you ever wondered just how many levers and tiny gears you have to pull and turn for a single corporate purchase to happen? The answer is a lot, and all of them are well-hidden. Procurement is often measured in transactions: how many purchases were processed, how much was saved on negotiated contracts, and how many invoices were paid off.

The outcomes are always the first priority, but before you see any, you need to understand the engine behind them—a well-designed procurement organization structure. Beneath the surface, its hidden connections keep the entire purchasing machine moving.

Learn what a procurement organization structure really is, why companies can’t function without one, and how its design shapes every purchase decision that follows.

What is a procurement organization structure?

What is procurement organization design?

Procurement hierarchy dilemma: Authority vs. information

Key roles in the procurement team structure and their responsibilities

Types of procurement organization structure

How and why organizations shift from decentralized to center-led procurement

How to design the procurement structure that lasts

Common mistakes in procurement organization design

How Precoro works for each role in the procurement organization structure

Frequently asked questions about procurement organization structure

Structure defines how procurement works

What is a procurement organization structure?

Procurement organization structure is an established system that defines employees' roles and the processes they carry out to complete purchasing activities. It’s essentially a skeleton behind the entire procurement function and explains why and how purchases are made within the company. To be effective, the procurement organization structure has to cover:

- Roles each of the personnel plays during various stages of the procurement process (sourcing, supplier management, accounts payable).

- Ownership and accountability: who’s responsible for completing the task and who should be held accountable.

- Approval and reporting levels: who has to sign off on requests and purchase orders, and to whom they report.

- The communication and collaboration framework between procurement and other departments: communication channels, access level, and stakeholder involvement.

Procurement is like a beehive: each employee has a role to play and a certain level of responsibility to uphold. The structure, of course, varies by company. Startups often adopt a relaxed, horizontal approach to procurement organization, where one person may handle everything from purchase orders to accounts payable.

Larger companies or those in highly regulated industries tend to implement a strict framework from the very beginning, with clear reporting lines and defined responsibilities. Find the structure that works for you, but be aware of the complexities that each type brings.

What is procurement organization design?

Procurement organization design is the process through which the company builds and sets the policies and roles in the procurement function. Simply put, the structure is the outcome of the design, which shapes how it operates in practice.

The company outlines the day-to-day aspects, like processes and roles, as well as more strategic elements, including policies, strategies, and procurement’s long-term impact on the company. The entire procurement team structure has to align with the bigger organizational goals and the desired market position.

Procurement hierarchy dilemma: Authority vs. information

Procurement has its own little ecosystem inside the company. It has layers that dictate how decisions are made and by whom. These layers can be linear and horizontal (flat organizational structure), where everyone has the same level of authority with fewer middlemen between the leadership and front-line employees, or hierarchical, where the upper management has the final say.

The flat structure sounds ideal for smaller companies: fewer hoops to jump through, everyone feels heard, and each employee gets more ownership. In fact, a study published by Oxford University Press found that consumers are more likely to purchase from a flatter organization, rather than a hierarchical one. It seems like a no-brainer—the company gets both satisfied employees and positive customer perception.

However, the more you scale and hire employees, the harder it becomes to keep the structure flat. In the two decades between 1986 and 2008, the number of employees reporting directly to the CEO doubled. Roles grow more ambiguous, and reporting lines blur, leaving employees confused. That’s the moment layers are added.

Hierarchy isn’t all bad. Yes, more layers often mean the entire process is much slower and less efficient. However, for exhausted managers who are spread too thin between reports, hierarchies can actually be a good thing.

Such procurement organizational designs help allocate decision rights equally and reduce the workload of a single senior member. Everyone knows who makes decisions and who reports to whom. Employees clearly see where they can move up, and the decisions themselves go through several checks before they’re put into action.

However, the hierarchy has an apparent trade-off between authority and information when building a procurement team. 75% of companies report that their procurement function only partially aligns with their overall strategic objectives. People on the ground, at lower levels, know more about their work but have less power to make actual decisions. Higher-ups, or upper levels, have that power but not all the information. It creates a noticeable gap in the procurement organization that can lead to misguided decisions if left untreated.

For example, a procurement specialist working with raw materials might know that a particular type of steel performs better under certain conditions. They have detailed, hands-on knowledge but can’t authorize bulk purchases. Meanwhile, senior management can approve large orders but doesn’t fully understand the nuances, which could lead to buying a material that doesn’t perform as needed.

A good hierarchy delegates decision-making power to employees with the most information, as long as leadership doesn’t lose control of the process.

In that case, the procurement specialist could be given the authority to recommend or even approve certain material purchases within predefined limits, while senior management handles larger or higher-risk decisions.

You can also shrink the gap between information and authority with modern procurement software that gives access to real-time data. Requesters and managers can see orders, supplier catalogs, and budgets in one place. Employees on the ground have easy access to the information they need to make decisions, and managers stay informed without being snowed under with data.

Take Precoro, for example. With advanced interactive dashboards, you see an overview of spending, purchasing, and accounts payable. Filter by supplier, department, or timeframe, and you get even more specific data to match your role.

What is a procurement team?

A procurement team is the group that handles a company’s purchasing needs and monitors its expenses. The general goal of the team is to make sure the company’s spend is cost-efficient and controlled. Still, the large number of responsibilities means the team often either has to be split into subteams or simultaneously juggle several obligations. The procurement team typically has to:

- Identify business needs across departments.

- Source, select, and evaluate suppliers.

- Negotiate contracts to secure favorable terms and manage risk.

- Review and approve purchase requisitions.

- Issue and track purchase orders.

- Manage supplier relationships.

- Ensure compliance with budgets, policies, and regulations.

- Analyze spend data to uncover savings and improvement opportunities.

Smaller companies sometimes don’t have a dedicated accounts payable team or outsource the function. In these cases, the procurement team handles additional tasks: they process and pay invoices, match them with purchase orders, approve payments, and maintain supplier records.

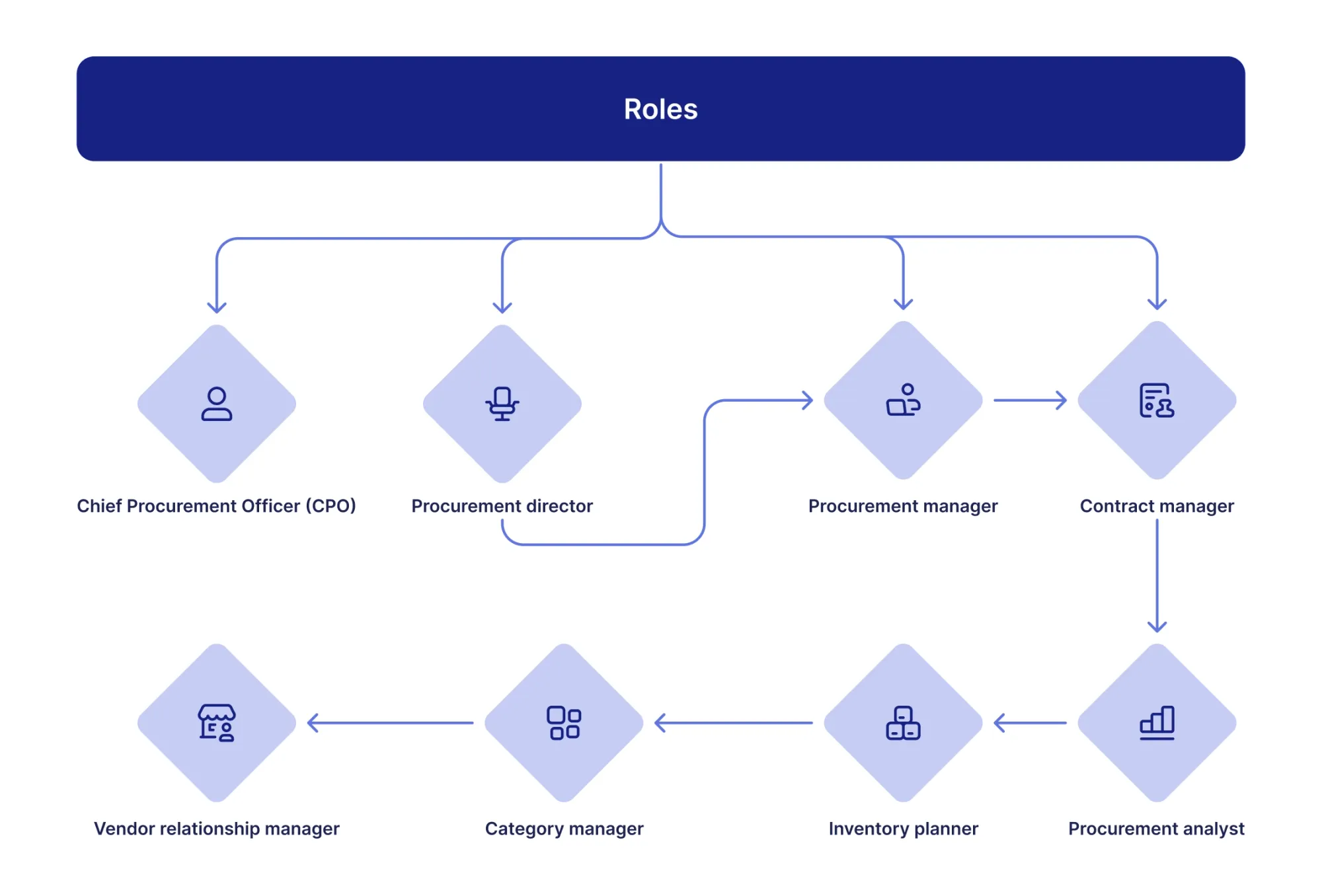

Key roles in the procurement team structure and their responsibilities

A single employee can’t take on every procurement responsibility alone. The workload is divided among team members, each with a defined role and level of authority. The list of roles is non-exhaustive: companies often tailor it to their needs when building a procurement team. For example, a manufacturing company might hire a category manager focused solely on raw materials.

We’ll examine the main roles in typical procurement team structures, their responsibilities, and the essential skills required for each position.

Chief Procurement Officer (CPO)

A Chief Procurement Officer (CPO) is a senior executive who leads an organization’s sourcing, procurement, and supply chain operations and sits at the top of the procurement organization chart. They develop and execute procurement strategies, build strong supplier relationships, and spearhead digital transformation in the company. Their job is to make sure purchasing aligns with the company’s long-term business goals.

A CPO needs strong leadership to guide teams and achieve results, strategic thinking to challenge existing processes, persuasive communication and negotiation skills, and experience with procurement management systems.

Procurement director

A director of procurement is a level below the CPO in the procurement team structure and turns the procurement strategy they developed into an actionable plan. The director handles day-to-day execution: they approve major purchases and contracts, oversee the vendor management lifecycle, identify cost reduction opportunities, and support the team in routine operations.

Key skills for the position include in-depth knowledge of procurement and vendor management, as well as experience with industry-standard ERP and procurement systems.

Procurement or purchasing manager

A procurement manager oversees the acquisition of goods and services for an organization. They select and negotiate with suppliers, monitor contract performance, and ensure policy compliance. They also coordinate with operational teams on demand planning and maintain accurate spend data. Key skills for a procurement manager include strong analytical ability, negotiation skills, attention to detail, and expertise in cost management.

Contract manager

A contract manager handles the full lifecycle of contracts to ensure agreements meet business goals and legal standards. They draft and review terms, negotiate with suppliers or clients, track performance, and resolve issues that arise during contract execution. The role requires strong attention to detail, negotiation skills, legal knowledge, and clear communication with all parties involved.

Procurement analyst

A procurement analyst is a specialist who examines purchasing data to help the company make smarter buying decisions. The role focuses on tracking spend, analyzing supplier performance, identifying cost-saving opportunities, and supporting procurement teams with accurate reports and insights. Strong analytical and Excel skills, attention to detail, and clear communication are essential here.

Inventory planner

An inventory planner makes sure products and materials are available when needed. They balance demand and supply so customers get what they need without the company overstocking. The planner forecasts demand, checks stock levels, and adjusts orders to keep service targets and costs in line.

They work closely with procurement and logistics to manage lead times and prevent shortages. Strong data skills, attention to detail, and solid teamwork with sales and operations are crucial for success in this role.

Category manager

A category manager oversees a specific group of products or services, such as IT, logistics, or marketing. Their job is to maximize value and performance from a particular category of purchases. They develop and execute strategies for their category, analyze spend and the market, and select and manage suppliers.

Category managers collaborate with other departments so that the category strategy aligns with organizational goals. A category manager needs strong interpersonal and negotiation skills, market awareness, and in-depth product development knowledge to succeed.

Operations manager

An operations manager coordinates people, processes, and resources to ensure that products or services reach customers on time and of the right quality. They oversee daily workflows, set performance targets, review output and efficiency, and support teams so work moves without friction.

They also manage budgets, track costs, and ensure compliance with workspace health, safety, and compliance standards. The required skills include strong coordination, fast decision-making, process discipline, and the ability to guide teams and fix real-time issues.

Vendor relationship manager

The vendor relationship manager maintains strong partnerships with key vendors. Some companies have a dedicated VRM team, while others delegate this work to procurement staff. Their job is to ensure that suppliers meet performance goals and resolve any disputes that arise during the purchasing process.

They select and onboard vendors, monitor service levels, communicate with suppliers, and align them with the company's business needs. The role requires sharp relationship and communication skills, the ability to negotiate efficiently, and a data-driven approach to performance and risk monitoring.

Types of procurement organization structure

Most companies build their procurement around one of the three most common organizational structures (also known as operating models):

- A decentralized structure places responsibility for purchasing on each department or location. Each team knows what it needs and can spend its resources as it sees fit. This setup gives the decision-making power and more flexibility to employees who are actually doing the work. However, if every department buys separately with no centralized plan, teams might overspend, purchase the same supplies twice, and even miss out on volume discounts they could have shared with other departments.

- A centralized procurement organization structure consolidates all corporate purchasing decisions in a single team or department. This approach is ideal when you want to standardize purchasing company-wide and have complete visibility over organizational spending. The main drawback is the lack of flexibility: some might feel that such a structure constrains day-to-day operations and doesn’t account for ad hoc purchases.

- A hybrid (center-led) structure means a core procurement team sets the company strategy and handles supplier negotiations, while local teams run day-to-day purchasing and make decisions on the ground. It’s a mix of both approaches that heavily relies on delegation. A central procurement team handles the heavy-duty, high-value work but passes the torch to employees closer to operations regarding the day-to-day upkeep. Often, these employees know more about what’s happening on an operational level than the leadership.

How and why organizations shift from decentralized to center-led procurement

As a company grows, its procurement organization structure naturally evolves and becomes more complex. Most companies start with decentralized procurement and, through a path of trial and error, slowly progress towards centralized procurement.

If centralization proves too constricting or more flexibility is needed, the company might switch to center-led procurement, where the procurement team handles the most strategic work, and everyday business-specific purchases are delegated to the local team or even outsourced.

Here’s how the company evolves from a decentralized framework to a hybrid, center-led approach.

How to design the procurement structure that lasts

Constant procurement transformation keeps companies on their toes and pushes them to improve processes. Digitalization has been one of the top three priorities for the past five years, with businesses setting an ambitious goal of a 70% digitalization rate by 2027. The gap between ambition and reality is still big: the actual digitalization rate hovers around 33-41%. Essentially, the procurement organizational design must work for people at every level, stay effective in daily operations and strategic planning, and stand the test of time.

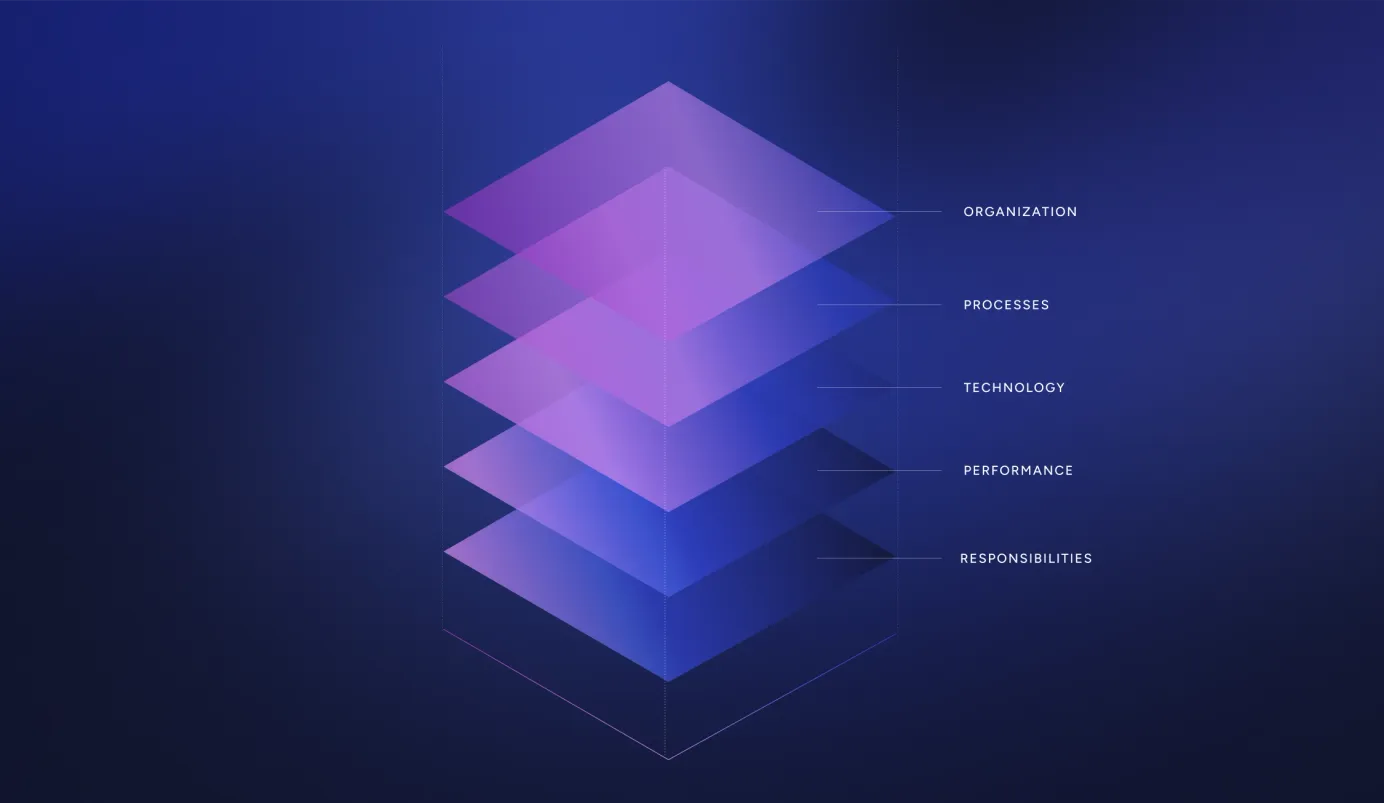

Both McKinsey and PricewaterhouseCoopers (PwC) point to four foundational elements that define whether a procurement structure can scale and last: organization, processes, technology, and performance.

Organization

Start with clear ownership. Whether you should centralize or decentralize procurement depends entirely on what you purchase and who handles it. Segment transactions based on the level of criticality and user knowledge. For instance:

- Specialized equipment or production supplies specific to your organization are best purchased and managed by the team with the most knowledge (e.g., closest to production). Procurement can play a supporting role and help with research or transaction management.

- Less critical supplies and equipment can be managed by the procurement team, which facilitates the process and sets guidelines, while operations or other departments provide input on specifications.

- General office supplies or standardized items can be managed entirely by the central office without input from other teams, since such purchases don’t require specialized knowledge.

Category management is your friend in procurement organization design. Some categories are best managed by end-to-end procurement, while others only require support on a transactional level. There’s no one-size-fits-all: analyze your spend, choose what’s critical and what can be managed by procurement only, and go from there.

Processes

Effective procurement organization design standardizes processes across the company, but keeps them flexible enough for different risk and spend levels. It’s important to map out every step, so everyone knows who’s responsible for what. Clear rules help end users avoid confusion when they encounter exceptions.

A good sourcing strategy sets the tone. It should be relatively simple and based on real data and market insight. Day-to-day work runs best on simple systems that make each step easy to follow and track.

Treat suppliers as partners, not just sellers. Meet regularly, share performance data, and look for ways to improve together. The same holds true internally: open communication within the procurement department structure helps prevent silos and miscommunication early.

Technology

Technology must support your structure. Pick a tool based on your organization's needs, not just what the latest tech magazine says you need. The procurement software market has grown fast for a reason—90% of companies already use a P2P solution.

The ideal tool can support your procurement organizational structure with:

- Centralized spend data for full visibility and control

- Automated approval flows that match your structure and policies

- Contract and supplier tracking in one place

- Real-time reporting to spot trends and risks early

- Integration with other systems to sync data between departments and entities

And to do that, you don’t even need a complete replacement of your trusted ERP. A cloud-based procurement centralization solution like Precoro can work hand in hand with your legacy tools. Such simple features can make a real difference in terms of visibility and control.

Performance

Measuring performance and what you’ve achieved so far is often the primary motivation for the procurement teams. Focus on a specific set of metrics. There’s no need to disperse your attention on metrics that have no effect on the final process.

Intuitive dashboards are incredibly useful here. Track company-wide spend, zoom in on category performance, and spot patterns that could be warning signs of potential issues. After you have all the data you need, compare it to your KPIs. Here are some focused and actionable metrics to monitor, depending on your goal:

- Spend under management: How much spend is actively managed.

- Policy compliance rate: How well teams follow the agreed-upon buying process.

- Maverick spend share: The percentage of purchases made outside approved processes.

- PO cycle time: Time between request creation and PO submission.

- On-time approvals: How often managers approve requests within the expected timeframe.

- System adoption rate across teams: The number of users, locations, or entities using the procurement platform.

Common mistakes in procurement organization design

Sometimes, even the golden rules fall through, and the reason for failure might be completely preventable. The most common mistakes you might’ve experienced during procurement organizational design include:

- Too many layers. Adding extra management levels may seem like a way to strengthen control, but it often does the opposite. Each new layer between the CFO and a line employee weakens the leadership’s grasp of reality at the operational level.

- Delegating without controls. Empowering teams with decision-making power is motivating and should be done, but delegation without clear limits or oversight quickly leads to inconsistency. Without defined approval thresholds or reporting rules, employees may make purchases that conflict with company policy or be confused about who should be held accountable.

- Failing to adapt over time. A structure that worked five years ago won’t fit today’s business. Growth, mergers, or digital tools can change how procurement should function.

- Centralizing everything. Full centralization improves cost control and gives you complete visibility over spend. However, when one team handles all purchasing decisions, it might not understand the specific needs of different departments or have product-specific knowledge.

- Overlapping responsibilities. When multiple teams share ownership of the same categories or approval steps, it’s unclear who’s responsible for what. Employees do the same work twice, suppliers receive mixed messages, and no one feels fully responsible for the outcome.

How Precoro works for each role in the procurement organization structure

Whether your team is small or growing fast, Precoro adapts to each level of responsibility. Here’s how it supports key roles in the procurement organization structure:

- CPOs and procurement directors receive a unified view of all procurement activity across departments, projects, and entities. Dashboards highlight budget adherence, spend patterns, and unusual spend. Because Precoro supports multiple entities, currencies, and locations, leadership can scale procurement as the business grows.

- Procurement managers see all purchase orders, suppliers, and budgets in one place. They can configure approval workflows with thresholds and roles that match the organization’s hierarchy and easily approve documents on the go in Precoro’s mobile app. On an operational level, with AI-powered OCR and automated 3-way matching, invoice processing becomes both hands- and error-free.

- Contract managers benefit from automatic notifications that alert users before contract expiration. All contracts are kept in a single system and can be linked to suppliers and procurement documents.

- Category managers see category-level insights directly in the system, thanks to Precoro’s custom reports with more than 150+ data points. They can configure automatic budget controls that block any POs exceeding set limits.

- Procurement analysts get structured data in one place, clear audit trails, and specific filters that reveal spend patterns with a single click. Advanced, intuitive dashboards let employees monitor risks and spend by category, supplier, or location. There’s also an AI Assistant that gives quick, informative answers to your questions, so you can focus on insights instead of digging through data.

- Requesters use an easy, guided interface to submit purchase requests. The forms can adapt to your company’s needs (departments, locations, custom fields). You can see real-time status updates (what’s approved, in review, or ordered). Moreover, thanks to the Approval SLA, each request has a clear timeframe, so employees always know when it will be reviewed and don’t have to guess what’s causing delays.

Frequently asked questions about procurement organization structure

Structuring a procurement department means defining clear roles, responsibilities, and processes so purchasing runs efficiently and aligns with company goals. Employees should know what they are responsible for and who they report to. It’s also important to set approval levels and communication channels with other departments to prevent silos. To support all of this, modern procurement software provides real-time visibility into budgets, requests, and supplier data, which helps employees make informed decisions and control spending.

Procurement organization structure is the system that defines how purchasing activities are carried out and who is responsible for them. It sets the framework for roles, ownership, approval processes, and communication with other departments. Essentially, it explains why and how supplies are purchased and ensures that each procurement decision supports the company’s overall strategy.

Procurement hierarchy refers to the levels of authority and decision-making within the department. In a flat structure, employees have more ownership and fewer layers between them and leadership, which is ideal for smaller teams. In a hierarchical structure, decisions pass through more layers, providing clarity, defined accountability, and structured approval processes, which are important for larger companies. A good hierarchy balances authority and information by delegating decision-making to employees with the most relevant knowledge.

In a decentralized structure, each business unit or department runs its own purchasing. It gives autonomy but often causes spend fragmentation and compliance gaps. A centralized structure consolidates all purchasing decisions under one team, which improves cost control, sets standard processes, and provides full visibility over spending. However, it can reduce flexibility for local teams. A hybrid, or center-led, structure combines both approaches: a central team defines strategy and tools, while local teams handle execution within set rules.

Base it on process complexity, spend volume, and digital maturity. If you use automation to handle intake, approvals, and reporting, keep layers minimal, with three key levels: leadership, category managers, and operational buyers. Add another only when the organization scales or manages diverse regions. Every level should add measurable value to cost, control, or supplier performance.

Structure defines how procurement works

Procurement organization structure is more than a chart of roles and titles. It defines how decisions are made and how regular expenses can actually make a difference. A strong structure sets ownership for every step of the process, connects data and approvals, and keeps responsibility clear from request to payment.

Don’t set your structure in stone, however. Business models change, teams expand, and technology transforms how work gets done. A rigid design that worked a decade ago won’t be effective now. The best procurement organization structures are easy to adapt and ready to evolve with new risks and digital tools that the changing market conditions throw at them.

A practical framework helps keep that balance:

- Organization: Define clear ownership, roles, and authority.

- Processes: Standardize the steps, but allow flexibility for local needs and spend levels.

- Technology: Support the structure with systems that connect data and provide real-time insights.

- Performance: Measure results and adjust before blind spots turn into actual problems.

Companies that treat procurement organization structure as a living system that adapts to business change instead of resisting it have a clear advantage over their competitors. In the end, people drive procurement forward, but structure holds it together.

Ready to build a procurement organization that scales without chaos? Get your personalized demo now.