24 min read

Direct vs. Indirect Procurement: Key Differences, Challenges, and Tips

Learn the differences between direct vs. indirect procurement as we explore the unique challenges and best practices for each.

Can a construction company complete a project without raw materials like steel, concrete, or lumber? Of course not! These are essential items directly involved in the building process. But what about the safety equipment, office supplies, or cleaning services? While important, they don’t directly contribute to building construction. These examples illustrate the key difference between direct vs. indirect procurement.

Direct procurement refers to purchasing items that go directly into a company’s final product or service, such as raw materials or components. Indirect procurement, on the other hand, covers goods and services that support daily operations but are not part of the finished product, like office supplies, software, or cleaning services. The main distinction is that direct procurement supplies inputs for production, while indirect procurement supports the business’s operations.

Keep reading to find out:

- What is Direct Procurement?

- What is Indirect Procurement?

- Key Differences Between Direct Procurement vs. Indirect Procurement

- Challenges in Direct vs. Indirect Procurement

- Tips for Gaining Better Control Over Direct vs. Indirect Procurement

- Frequently Asked Questions About Direct vs. Indirect Procurement

What is Direct Procurement?

Direct procurement refers to acquiring goods and services directly involved in producing a company’s final product or service (hence the name). These purchases are the core supplies that keep production running on schedule.

For instance, furniture manufacturers need direct purchases like wood and fabric as raw materials, screws and hinges as components, and cutting machines as equipment. Similarly, direct procurement in the food and beverage industry focuses on ingredients, packaging materials, and production machinery.

Key Characteristics of Direct Procurement

Without a smooth direct procurement process, operations stall, costs rise, and revenue takes a hit. Here’s what sets it apart:

Direct Impact on Revenue

Direct procurement has a great impact on a company’s revenue as it ensures a steady supply of materials and resources for production. Late delivery of these critical items results in production delays and lost sales opportunities.

In addition, effective direct procurement helps maintain consistent product quality. Variations in the quality of sourced materials can lead to defects in the final product. Poor quality may result in reputational damage, costly product recalls or returns, and ultimately, a decline in revenue.

Supplier Relationships are Strategic

Since production depends on a steady supply of high-quality direct materials, long-term strategic supplier relationships are key to direct procurement. These partnerships are based on trust and collaboration and help both a company and a supplier achieve mutual goals like joint innovation and sustainability. For example, an automotive company might partner with a tire supplier to co-develop a product designed specifically for their new vehicle model.

Demand Forecasting is Key

Advanced analytics help companies strike the perfect balance between overstocking and production shortages. On the one hand, ordering too much raw material can lead to excess inventory costs, while on the other, ordering too little could result in production delays. Thus, procurement teams use historical data to optimize supply chain inventory while cutting costs.

High Sensitivity to Market Conditions

Direct procurement is highly sensitive to external market factors such as price fluctuations, geopolitical issues, and supply chain disruptions. Procurement managers need to stay ahead of these risks and come up with strategies to reduce their impact. That could mean diversifying suppliers, locking in long-term contracts, or finding ways to protect against price swings.

What is Indirect Procurement?

Indirect procurement refers to the process of acquiring goods and services that support internal operations rather than product development. In short, indirect procurement covers essentials for daily business functions.

For example, indirect procurement managers buy office supplies and IT equipment for furniture manufacturers. Or they purchase uniforms, furniture, and transportation services for food and beverage companies. Additionally, indirect procurement covers electricity, water, advertising, janitorial services, travel expenses, and much more.

Key Characteristics of Indirect Procurement

Indirect procurement handles a wide range of essential purchases that keep the company running efficiently. Here’s all you need to know about it.

Often Viewed as Non-Core but Still Important

Indirect procurement is often seen as less important. It neither earns revenue nor shapes the final product directly. Yet, it contributes to smooth internal operations:

- Employee satisfaction and productivity depend on the right tools, technology, and facilities.

- Effective marketing services drive brand awareness, which influences sales performance.

- Reliable IT services prevent downtime that could disrupt internal operations and records.

Thus, when companies neglect or mishandle indirect procurement, they set themselves up for major inefficiencies in performance and block their own growth.

Decentralized and Fragmented Operations

Indirect procurement often spans various departments, each with its own budget and suppliers. For example, the marketing department may collaborate with advertising agencies while HR deals with training vendors. This decentralized approach allows each team to meet its specific needs, yet it can also create challenges, like a lack of process visibility and potential maverick spending.

Higher Transaction Frequency, Lower Spend per Transaction

Indirect procurement often involves more frequent, smaller-scale purchases compared to direct procurement. For example, office supplies might be ordered weekly. But larger, less frequent purchases, like production machinery, are made only once a year. Even though each indirect procurement purchase costs less, the total adds up and ends up in tail spend. So, efficiency and cost management are ongoing tasks.

Direct Procurement vs. Indirect Procurement

Direct procurement refers to buying essential raw materials such as steel for construction, fabric for textile manufacturing, or chemicals for pharmaceutical production. Indirect procurement covers support goods and services like office equipment, cloud software subscriptions, marketing agencies, facility maintenance, and employee development courses.

Let’s examine the distinctions between direct vs. indirect purchasing and how they both drive value in different business areas.

1. Organizational Setup

The number one difference is the organizational setup for direct vs. indirect procurement. Typically, organizations have one team that manages direct procurement and works closely with production and R&D. This team operates under clearly defined budgets and ensures that what they do is in tune with production schedules and cost-efficiency targets. Their efforts are highly coordinated, with clear protocols for supplier selection, contract negotiation, and inventory management.

On the other hand, indirect procurement is often decentralized. Various departments make requests and, in some companies, can even place orders without a central team keeping everything in check. Budgets are more flexible, giving departments more freedom to meet their specific needs. However, this decentralized approach can hinder effective expense tracking and supplier management.

2. Spending patterns

Another key distinction between direct and indirect procurement lies in purchasing trends. On the one hand, direct procurement usually involves big budgets for bulk or high-value production items. These expenditures are typically predictable and closely tied to production schedules.

On the other hand, indirect procurement is characterized by smaller, more frequent purchases across multiple categories. Although individual transactions are less significant, the cumulative spending on indirect procurement can become quite substantial over time.

3. Supplier Relationships

Here are some key differences between direct sourcing vs. indirect sourcing. When it comes to direct sourcing, businesses usually put a lot of effort into building strong, long-term partnerships with suppliers. This ensures smooth production and reliable product quality. You’ll often see joint development projects, multi-year contracts, and a focus on collaboration and innovation.

With indirect sourcing, the approach to supplier relationships is more transactional. The relationships tend to be shorter-term, and there’s less of that deep, strategic engagement. Companies might switch suppliers more often to grab better deals or customer support.

4. Risk Management

There are various risks involved in direct vs. indirect procurement. Risks in direct procurement tend to carry higher stakes because they directly impact the company’s ability to deliver products or services. If raw materials or key components are delayed, production stops, deadlines are pushed back, and customers are dissatisfied.

That’s why teams that handle direct procurement focus on risk management strategies like diversifying suppliers, locking in long-term contracts for price and supply stability, and keeping a safety stock just in case something unexpected happens.

Indirect procurement comes with its own set of risks, though they’re more about inefficiencies than full-blown disasters. Over time, issues like overspending, disregarding company policies, and service delays — such as IT support or facility maintenance — can quietly drain budgets. These factors won’t stop operations, but they can chip away at profitability and disrupt workflows if not kept in check.

5. Procurement Processes

Indirect vs. direct procurement can differ in their processes. Direct procurement is usually highly structured and matches the company’s production schedule. It starts with demand planning to make sure that the necessary materials and parts arrive on time in order to meet the production needs.

Structured demand planning enables effective supplier negotiations, helping companies secure long-term supply contracts, bulk pricing, and reliable quality and delivery. Companies often adopt ERP systems to boost efficiency and link procurement to production.

In contrast, indirect procurement processes involve a broader range of stakeholders across multiple departments, such as HR, IT, marketing, and facilities management. Each department may handle indirect purchases differently, whether through formal purchase requisitions or more informal processes, with contracts in place or without them.

To tackle the challenges of decentralization, companies often lean on procurement tools to bring order to the chaos and enforce policies around indirect spending. Think a procurement centralization platform, expense management systems, or spend analysis software — all designed to make purchasing a little easier and keep expenses on track (but some are more helpful than the others).

6. Performance Metrics and KPIs

Since the procurement activities for direct vs. indirect procurement differ, the metrics used to measure their success are also not the same. In direct procurement, performance is often measured using Key Performance Indicators (KPIs) tied to production and cost efficiency, such as:

- On-time delivery rate (measuring the percentage of deliveries made on schedule)

- Defect rate (percentage of products or materials that do not meet quality standards)

- Cost savings (measuring the amount saved through negotiations or bulk purchasing)

- Inventory turnover ratio (measuring how often inventory is sold and replaced over a period)

In indirect procurement, metrics are more focused on operational efficiency and cost control, such as:

- Spend under management (percentage of total spend actively managed by the procurement team)

- Supplier consolidation ratio (indicating the reduction in the number of suppliers through vendor optimization)

- Cost avoidance (calculating the amount of potential costs prevented through strategic purchasing)

- Procurement cycle time (measuring the average time taken to complete an indirect procurement transaction, from requisition to delivery)

7. The Required Levels of Product Customization

Requirements for items in direct vs. indirect procurement also vary. Direct procurement often involves more customization since the materials or components are crucial to the final product and must meet certain specifications. For example, manufacturing and construction organizations may need specialized metals or custom parts that align with strict standards for quality, size, and function. In these cases, the procurement team works closely with suppliers to ensure the items meet detailed specs, sometimes customizing them for a project.

Indirect procurement, in contrast, deals with more standardized products or services. They are used across various departments in a company. For example, the quality of office chairs or printers is easier to compare across multiple suppliers. Similarly, temporary staffing services for administrative roles can be sourced from different vendors with similar offerings. As a result, indirect procurement focuses more on cost, availability, and the level of customer service and less on product customization.

8. Compliance and Sustainability

In direct vs. indirect procurement, compliance plays a crucial yet distinct role. In direct procurement, it’s essential to stick to industry regulations and sustainability goals since this choice can impact the company’s reputation and legal position.

Sourcing ethically produced direct materials (like sustainably harvested timber for construction projects) boosts a company’s brand with eco-conscious consumers. In highly regulated industries like healthcare, procurement compliance is vital. In fact, it extends beyond good practice; it is covered by law.

On the other hand, compliance in indirect procurement focuses more on internal objectives. It’s about staying within budget and supporting corporate social responsibility (CSR) goals. For example, using eco-friendly office supplies, like recycled paper, helps meet sustainability targets. However, it doesn't affect market position or legal requirements as much as direct procurement does.

9. Inventory Management

Another area of differentiation for direct vs. indirect procurement is the approach to inventory management. Companies must accurately estimate material demand in direct procurement to avoid production interruptions. JIT inventory management is one of the popular strategies, especially in industries such as manufacturing and construction. It involves working closely with suppliers to receive materials just in time for production rather than stockpiling them.

In contrast, indirect procurement typically involves products and services that are purchased on an as-needed basis without strict forecasting. While it’s important to maintain enough office supplies, there’s less urgency compared to managing raw materials for construction. That’s why inventory management in direct procurement is more flexible and less structured.

10. Impact on Industries

The impact of both direct and indirect procurement are crucial to overall business success, but the allocation between them depends on the industry. One of the key advantages of direct procurement is that in most businesses even stakeholders outside the purchasing process recognize its importance. All because of its immense impact on production and the significant cost-saving opportunities it offers.

In industries like manufacturing, construction, and retail, direct spend typically makes up the bulk of expenditures. However, in industries like IT services, recruitment, or consulting, much of the spending is directed toward services, tools, and software that support business operations (many of which are considered indirect spend).

Note!

Definitions of direct vs. indirect procurement can vary by function or industry. For instance, a manufacturer would classify ERP or CAD software as indirect spending. But, an IT company would consider it direct spending if it's vital to their product or service.

Challenges in Direct vs. Indirect Procurement

Direct vs. indirect procurement each comes with its own set of challenges, from managing supplier relationships to controlling costs and maintaining efficient processes. Addressing these issues is essential for keeping operations smooth and budgets on track.

Challenges Unique to Direct Procurement

Below are some of the most pressing challenges that professionals managing direct procurement must address to ensure a steady supply of essential products.

Supply Chain Complexity

Managing a supply chain for direct procurement often involves coordinating with multiple suppliers, often spread across various countries or regions. For example, a manufacturer sourcing electronics components may work with suppliers in Asia for semiconductors, Europe for specialized parts, and local vendors for packaging materials.

With each supplier, it’s important to consider several key factors, including:

- Cost structure

- Lead times

- Logistics requirements

- Reliability levels

- Compliance with industry regulations

Delays from a single supplier can cascade, upending production schedules. This is exactly why the professionals involved in direct procurement services must master contingency plans to mitigate risks effectively.

Quality Inconsistencies

Consistent quality is key in direct procurement. The materials or components impact the final product directly. For example, a single faulty part can cause recalls or delays in the auto industry.

Thus, procurement teams managing direct spend often work with quality assurance. They implement strict supplier evaluations, conduct audits, and check incoming shipments. In healthcare, following strict safety and quality standards is essential for patient safety. This makes it even harder to maintain quality assurance.

Cost Pressures and Tough Negotiations

Raw material prices are often volatile. They depend on supply shortages, geopolitical events, and changing exchange rates. For instance, steel prices can rise sharply due to tariffs or increased demand, putting pressure on manufacturers.

To stay ahead, procurement teams manage these risks with strategies like long-term contracts, currency hedging, and negotiating bulk discounts with direct vs. indirect suppliers. Sourcing from different regions can also help businesses take advantage of better pricing.

Regulatory Compliance Demands

Certain industries, such as pharmaceuticals, aerospace, or food production, have stringent regulatory requirements for direct procurement. For example, aerospace manufacturers must source materials certified to meet safety and performance standards like AS9100.

Key elements of compliance in direct procurement include:

- Extensive documentation (ensuring all required paperwork is in place for traceability and audits)

- Supplier certifications (validating that suppliers meet industry-specific standards)

- Traceability requirements (tracking the origin and movement of materials)

- Quality control measures (ensuring products meet safety and performance benchmarks)

Failure to comply can lead to hefty fines, production shutdowns, or reputational damage. That’s why procurement teams need robust systems to track supplier compliance and ensure all materials meet regulatory standards before use.

Challenges Unique to Indirect Procurement

Challenges of indirect procurement stem from its decentralized and less structured nature. Below are some of the most significant obstacles procurement professionals face in managing indirect procurement effectively.

Wide Range of Categories

Indirect procurement covers a wide range of categories, from office supplies and marketing services to IT tools and facilities management. This variety presents its own challenges when it comes to managing procurement efficiently. For categories like marketing or consulting, there’s often a lack of standardized criteria, which makes vendor evaluation a bit tricky. For instance, choosing an advertising agency could come down to creativity, which isn’t as straightforward to measure as cost or delivery schedules.

Then, there are areas like IT procurement, which require specialized knowledge. Take cybersecurity software: procurement teams need to understand compliance standards and technical compatibility, which might not always be in their wheelhouse. Without the right expertise, these gaps can slow things down and introduce inefficiencies into the process.

Complex Stakeholder Involvement

Cross-department collaboration is key when it comes to indirect procurement services, especially since it’s decentralized and covers such a broad range of categories. Procurement teams have to work closely with different departments to really nail down what’s needed.

Take marketing, for example. If they need new software or tools, the procurement team has to sync up with them to understand the following:

- Exactly what features they’re after

- How user-friendly the software needs to be

- Whether it should integrate with the systems already in place

The same goes for HR when they’re looking for wellness services. Procurement needs to know the scope of what’s required and the quality standards. These conversations are super important for ensuring the procurement decisions actually meet each department’s specific needs.

Spend Leakage and Compliance Issues

Indirect procurement involves making many small, recurring purchases. Although they may seem minor alone, they still can pose significant administrative challenges over time. For example, a $10 office supply order could cost $50 in admin time if processed manually. These repetitive tasks can bog down procurement teams and affect their overall efficiency.

On top of that, indirect procurement hides some costs that often fly under the radar. As procurement teams handle all these small transactions, things like spend leakage and compliance issues can start to pop up. Employees might skip the approved suppliers or go over budget because it’s easier, which leads to maverick spending.

For instance, a department might order branded merchandise directly from a new supplier instead of an approved vendor. It would drive up costs and cut into purchasing power. That’s why cost optimization is one of the top priorities for procurement managers who handle indirect spend.

Limited Supplier Relationships

Indirect procurement often involves more transactional, short-term relationships with suppliers, which can result in missed opportunities for long-term cost savings and collaboration. For instance, a vendor might offer discounted IT support packages to clients they’ve worked with for years, but those deals aren’t usually available for one-off engagements.

Other challenges in indirect sourcing include:

- Inconsistent service levels (especially with new, untested suppliers)

- Fragmentation of suppliers (a large number of vendors, which increases the risk of miscommunication and duplicate efforts)

- Missed bulk discounts (due to lack of supplier consolidation)

- Increased logistics costs (because of fragmented supplier base and inefficient transportation management)

Lack of Focus and Visibility

Indirect procurement often gets overlooked compared to direct procurement, which means it tends to receive less attention and fewer resources. This can lead to delays in decision-making, and the procurement team might have a harder time enforcing the right processes to stick to policies. As a result, companies can miss out on the full potential of what effective indirect procurement can offer.

Here are some of the reasons why the importance of indirect procurement is often underestimated:

- Savings are less visible

Smaller, ongoing savings from indirect procurement are often overshadowed by the larger, more obvious savings from direct purchases. - Challenges in quantifying benefits

The positive impact of indirect procurement on employee productivity, morale, and retention can be hard to capture and demonstrate. - Lack of clear ROI

While direct procurement usually shows a direct return on investment through cost reduction, indirect procurement’s ROI is often seen in longer-term operational gains that are harder to track. - Fragmented data

Indirect procurement activities often span multiple departments and categories, making it more difficult to consolidate data and track overall performance across the organization.

Tips for Gaining Better Control Over Direct vs. Indirect Procurement

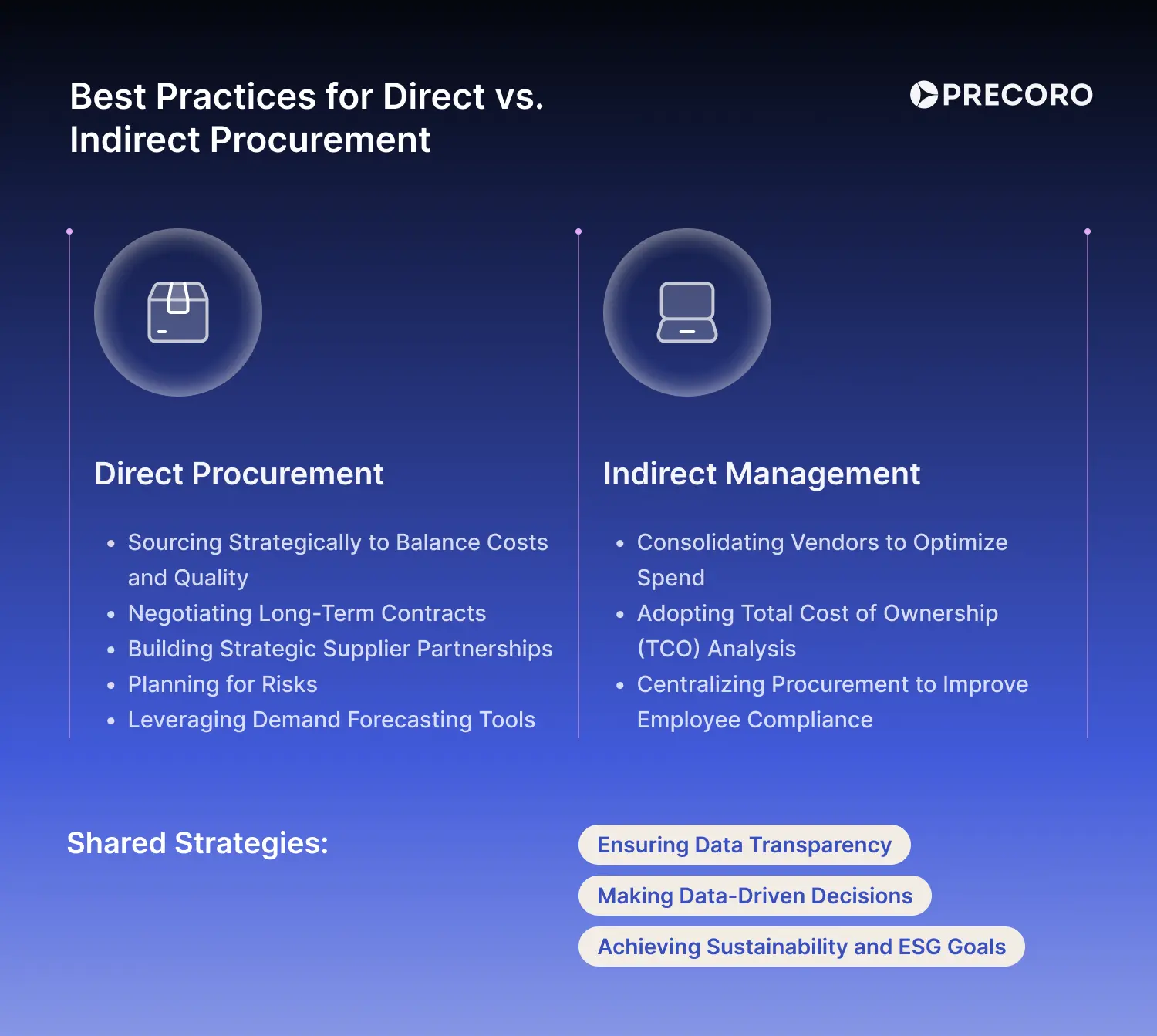

Effective procurement strategies vary between direct vs. indirect procurement due to their distinct purposes and impacts. While both require careful planning, the approaches can have different focuses.

Best Practices in Direct Procurement

To achieve greater efficiency and performance, businesses can benefit from embracing these best practices in direct procurement.

Sourcing Strategically to Balance Costs and Quality

Strategic sourcing goes beyond just finding the lowest price. It’s a proactive approach to identifying new suppliers that focuses on value throughout the entire procurement process. For professionals who excel at building close partnerships, emphasis on supplier relationships is a major advantage of direct procurement.

First, organizations perform comprehensive spend analyses to pinpoint key spending categories and suppliers. This insight prompts them to research the market for potential alternative suppliers, perhaps those located in different regions or offering innovative sourcing solutions.

The selection process shifts from a purely price-driven approach as procurement managers develop evaluation frameworks that consider quality certifications, delivery reliability, environmental sustainability, and financial stability. This might involve issuing a request for proposal (RFP) to gather offers from multiple qualified suppliers and then meticulously evaluating them based on these broader criteria.

Additionally, procurement managers involved in strategic sourcing consider the overall cost of ownership. This includes factors like transportation, inventory holding costs, quality issues, and potential warranty claims. By viewing the entire cost picture, companies can identify and select suppliers that offer the most value over the long term.

Negotiating Long-Term Contracts

Locking in long-term contracts with key suppliers can help organizations minimize risks like price changes and supply disruptions. When it comes to services, it’s a good idea to negotiate shorter contracts (usually under three years) and include termination clauses (30-60 days), so you stay flexible and don’t get stuck with possibly lousy service. This also helps keep pricing stable during the contract.

For products, negotiating based on quantity is smart, and setting up open purchase orders with regular reorders can help manage inventory and costs. You can also save money by looking for discounts on bulk purchases, especially from suppliers who offer multiple products. Regular tracking of spending allows for the opportunity to negotiate better discounts over time. Alternatively, switching to new suppliers can save costs quickly. But be careful. Check product quality, reliability, and customer service before rushing into cheaper agreements.

Building Strategic Supplier Partnerships

Direct procurement thrives on cultivating long-term, collaborative relationships with suppliers. Treating vendors as mere line items on a balance sheet is a significant misstep. Instead, companies gain a substantial advantage by actively enhancing their supplier relationship management (SRM) — a proactive approach to nurturing supplier relationships throughout the entire procurement and vendor management lifecycle.

Imagine a scenario where a manufacturer of high-end bicycles sources lightweight, high-performance carbon fiber frames. Rather than simply making purchases, a strategic approach would involve:

- Identifying key suppliers: Researching and selecting suppliers with a proven track record of quality, innovation, and sustainability.

- Building trust and transparency: Fostering open communication channels, sharing critical information, and demonstrating mutual respect.

- Jointly defining success metrics: Collaboratively establishing KPIs such as on-time delivery rates, defect rates, and customer satisfaction. This could involve implementing a supplier scorecard system to track and evaluate performance, identifying areas for improvement, and rewarding top performers.

- Continuous improvement: Regularly reviewing performance data, conducting joint problem-solving sessions, and implementing corrective actions proactively.

Planning for Risks

In today’s volatile global market, direct procurement teams must be vigilant in managing potential disruptions. Risks can originate from various sources:

- Supply chain disruptions (such as natural disasters or transportation bottlenecks).

- Raw material shortages (due to unforeseen events like pandemics or geopolitical conflicts).

- Sudden shifts in market demand

To mitigate these risks, proactive risk management strategies for direct procurement are crucial.

Diversifying the Supplier Base

Relying solely on a single direct vs. indirect supplier can create a huge point of failure. McKinsey highlights that nowadays, procurement teams not only ensure supply security but also diversify the supplier portfolio to minimize the risks and impacts of disruptions.

Procurement managers can better protect themselves by building relationships with qualified suppliers in various regions. For example, an automotive company might source key components like engines, transmissions, and electronics from suppliers in Asia, Europe, and the U.S. Hence, it isn't overly dependent on any single location.

Maintaining Buffer Stock

A strategic reserve of critical materials can act as a buffer business against unexpected supply chain disruptions. This safety stock keeps production going if a supplier delays or fails due to unforeseen challenges. For instance, a pharmaceutical company might maintain a buffer stock of essential raw materials to ensure uninterrupted production of life-saving medications.

Developing Contingency Plans

Creating well-thought-out contingency plans for disruptions are the smart way to manage risks. These plans should include backup suppliers, alternative production strategies, and clear communication protocols. For example, a food processing company might prepare for drought by lining up backup suppliers for key crops and finding backup production methods.

Leveraging Demand Forecasting Tools

Accurate demand forecasting plays a huge role in direct procurement. It helps prevent costly overstocking and frustrating stockouts. Modern forecasting tools go beyond just looking at past data — they use predictive analytics to analyze sales trends, market data, and even social media to predict future demand. This helps businesses adjust inventory levels, like a retailer getting ready for the holiday rush.

AI-powered tools take this even further by analyzing large amounts of data and spotting patterns that might not be obvious. For example, a consumer electronics company might use AI to predict how new product launches or economic recessions will affect demand. And when these forecasting tools are connected to other systems, like CRM or ERP, they provide a more complete picture of demand signals. This allows for real-time data analysis and better procurement decisions, like adjusting stock levels based on customer purchase history.

By using these advanced tools, businesses can achieve great advantages of direct procurement: easily optimizable inventory levels, improved production planning, and, ultimately, a competitive advantage in the market.

Best Practices in Indirect Procurement

These strategies help businesses manage their non-core purchases more effectively and ensure smoother processes across departments.

Consolidating Vendors to Optimize Spend

Indirect procurement involves dealing with a multitude of vendors, which can make it difficult to negotiate favorable terms and have full visibility into overall spending. While indirect procurement covers various categories, a strategic approach to consolidating spending within similar product or service groups can deliver real value.

For example, the UK’s National Audit Office reported that a more centralized approach could save at least £500 million over five years. These savings could be a result from cutting duplication and taking advantage of bulk buying — concepts that also apply to the private sector.

Thus, vendor consolidation helps simplify the sourcing process by focusing on a smaller group of trusted suppliers. When companies concentrate their spending with particular suppliers, they can often achieve better deals like lower prices, volume discounts, and improved contract terms. For instance, a company might consolidate its office supplies purchases with a single national supplier, using their total spend to negotiate better rates and additional benefits.

Adopting Total Cost of Ownership Analysis

Evaluating the Total Cost of Ownership (TCO) goes beyond simply comparing upfront prices of indirect purchases. TCO analysis considers the entire lifecycle of a product or service, including all associated costs from acquisition to disposal. This comprehensive approach helps prioritize long-term value over immediate savings in procurement decisions.

Here’s a breakdown of key TCO considerations:

Acquisition Costs

- Initial purchase price

- Taxes and duties

- Shipping and handling costs

- Installation and implementation costs

- Training and onboarding costs

Operating Costs

- Energy consumption (e.g., electricity for equipment)

- Maintenance and repair costs

- Consumables (e.g., ink cartridges, printer paper)

- Software licenses and upgrades

- Employee time spent on operation and maintenance

Disposal fees

- Recycling costs

- Data migration and decommissioning costs

- Potential environmental liabilities

Centralizing Procurement to Drive Employee Compliance

When purchasing decisions are made by individual departments or employees without much control from one centralized team, it can lead to maverick spending. This refers to unauthorized purchases that fall outside company guidelines and result in overspending.

Organizations shift towards a more centralized procurement approach to address the risks associated with decentralized indirect procurement. Procurement centralization requires establishing a clear and end-to-end procurement policy that serves as a roadmap for all purchasing activities. The document can outline acceptable spending limits, preferred suppliers, and the necessary approval processes.

Shared Strategies Across Indirect vs. Direct Procurement

Even though there are significant differences between direct vs. indirect procurement, some approaches are perfectly applicable to both.

Ensuring Data Transparency

Procurement managers often struggle to gain a unified view of indirect vs direct procurement. Fragmented systems, disparate data sources, and a lack of integration across departments can obscure the overall spending picture.

However, by improving data transparency across both direct and indirect procurement categories, organizations have significant benefits. For example, they can have a better chance of capitalizing on cost-saving opportunities and identifying hidden inefficiencies in procurement processes.

The best way to achieve this for direct vs. indirect procurement is to implement a procurement centralization platform. It would be a win-win strategy for all! Employees across the company could create purchase requisitions. Stakeholders could then review and approve them. Buyers would generate and track purchase orders. Finally, the accounts payable team would verify invoices.

All purchases and expense reimbursements can be documented in one system, simplifying audits and procurement analysis. Additionally, with centralized procurement, it’s easier to do the following:

- Identify duplicate spend, where the same goods or services are purchased from multiple suppliers at varying prices.

- Find opportunities to consolidate spend with fewer, higher-performing suppliers, thereby increasing leverage and negotiating more favorable terms.

- Determine areas of excessive spending across departments or categories and investigate potential cost-saving measures.

- Compare spending data with industry benchmarks to identify areas for improvement and identify best practices.

Furthermore, data transparency in direct vs. indirect procurement fosters better collaboration. It provides requesters and buyers with real-time order status updates and enables approvers to easily verify budget availability.

Making Data-Driven Decisions

By leveraging data analytics, procurement teams can move beyond reacting to issues. Instead, they can conduct procurement analysis to proactively identify ways to improve and optimize their indirect vs. direct procurement strategies.

For instance, spend analysis reveals spending patterns, highlighting areas of high expenditure and potential for consolidation across departments. Another example is predictive analytics, which helps forecast demand for direct vs. indirect procurement and anticipate potential supply chain disruptions.

Here, the procurement centralization platform also comes in handy, as many solutions offer reporting capabilities. Some, such as Precoro, integrate with Power BI so that teams can easily pull the relevant data from the system and visualize it clearly and concisely.

Achieving Sustainability and ESG Goals

Integrating sustainability into direct and indirect procurement strategies benefits both the environment and the bottom line. Procurement managers who handle direct purchase orders can prioritize suppliers that utilize recycled materials, renewable energy sources, and sustainable farming practices. For example, a manufacturing company might source sustainable wood for furniture production, minimizing deforestation and supporting responsible forestry practices.

For indirect categories, companies could select green-certified service providers that demonstrate strong environmental and social responsibility. For example, organizations can prioritize energy suppliers that use renewables. They can choose office suppliers with recycled or eco-friendly products, or partner with logistics providers with a low carbon footprint.

Frequently Asked Questions About Direct vs. Indirect Procurement

Direct procurement involves sourcing goods and services that are directly used in the production process, such as raw materials and components.

Indirect procurement focuses on acquiring goods and services that support business operations but aren’t directly involved in producing the final product. Examples of indirect spend include travel costs, utilities, and marketing.

Direct procurement involves sourcing critical raw materials and components for production. It requires long-term supplier relationships and large budgets due to its impact on the end product. Indirect procurement, in contrast, focuses on goods and services that support business functions, including office supplies and IT services. It has shorter-term, transactional supplier relationships and smaller budgets.

Yes, because indirect procurement supports business operations by ensuring employees have the necessary tools and resources to perform effectively, which leads to improved satisfaction and productivity. For example, sourcing comfortable office furniture, reliable IT services, or high-quality wellness programs helps create a functional and positive work environment.

Regardless of your industry, all organizations face common challenges in indirect procurement. These include maverick spending, a wide range of categories and suppliers, and limited visibility into overall spending.

Final Thoughts About Direct vs. Indirect Procurement

Direct procurement is the process of buying the materials and services that go straight into making a company’s final product or service. Indirect procurement covers the goods and services needed to keep the business running smoothly but aren’t part of the finished product. Simply put, direct procurement is about what you sell, while indirect procurement is about how you run your business.

The main difference between direct vs. indirect procurement lies in the functions they perform and the goals they try to achieve. Direct spend is more end-customer-oriented, while indirect procurement is business-oriented. For both, evaluating and optimizing procurement processes can result in better spending and an improved bottom line.

Implementing a centralized procurement system offers tangible benefits for both direct and indirect procurement. For direct procurement, it ensures that raw materials and production components are ordered in bulk, reducing unit costs through economies of scale. In indirect procurement, centralization allows a company to better manage recurring purchases like office supplies, IT services, and facility maintenance.

Thus, procurement digitalization not only leads to cost savings by leveraging negotiated contracts but also improves efficiency by reducing duplicate purchases and minimizing administrative overhead. Plus, a centralized system gives companies real-time visibility into direct vs. indirect procurement and overall expenses. This helps them track budgets, optimize cash flow, and ensure compliance with procurement policies.