11 min read

Top 5 KPIs for Purchasing Managers

Purchasing manager job responsibilities can vary greatly depending on the company. With some simple metrics, you can assess how well they are managing purchasing processes.

The purchasing department plays a critical role in the success of an organization. Thought-out practices and well-managed workflows within the purchasing department are crucial for making sure that the company has the necessary resources available at the right time and at a reasonable cost.

At the heart of the whole process is the purchasing manager – a supply chain and logistics professional who works to secure the required materials, goods, and services necessary for running the business. This individual also ensures that established purchasing practices align with the general company financial strategy and business objectives.

In other words, the purchasing manager is responsible for securing inventory requirements within the company’s budget and overall efficiency of the company’s purchases.

The American Purchasing Society, an association of buyers and purchasing managers, has established its own code of ethics and requirements for purchasing professionals to follow if they want to get certified.

Its main recommendations include buying without personal prejudice from suppliers who offer the optimum value, avoiding conflicts with suppliers, and working in good faith. The framework provided by the American Purchasing Society can help purchasing managers conduct retrospective analysis and set up professional goals.

Whether or not the purchasing manager decides to incorporate outside guidelines, like those from the APS, they should work together with upper management to define these goals. These goals can be expressed as key performance indicators (KPIs) – relevant functional metrics that can be tracked regularly to make sure that the business makes purchases in an efficient way.

Keep reading to find out more:

- The responsibilities of purchasing manager

- Skills required to be a good purchasing manager

- Top 5 key performance indicators for a purchasing manager to track

- Tips to achieve good KPI metrics

Purchasing Manager Job Description and Workload

A purchasing manager is responsible for planning and strategizing company purchases so that they are as cost effective as possible while fulfilling company needs. Everyday purchasing manager duties include:

- Closely collaborating with the stakeholders and teams across the company to determine their needs and expectations

- Introducing and implementing the company’s purchasing regulations

- Developing purchasing strategies and leading their execution

- Assessing possible risks and preparing risk mitigation strategies

- Overseeing and approving purchases

- Developing inventory control systems and tracking the demand for inventory replenishment

- Determining optimal delivery times and quantities

- Optimizing purchasing costs by identifying best possible deal terms and streamlining internal workflows

- Supervising the process of sourcing (researching, choosing, and negotiating with the suppliers for raw materials or vendors for goods and services)

- Managing suppliers and vendors, maintaining their database

- Tracking KPIs and metrics and comparing them against business objectives

- Analyzing the markets to forecast trends

- Managing purchasing team (including buyers, purchasing agents, etc.)

- Overseeing the processes of hiring and training new purchasing team members

- Providing reports for upper management

What It Takes to Become a Good Purchasing Manager

Purchasing management might not be for everyone, especially in times of digitalization, when requirements and tools change rapidly following market trends. A good purchasing manager should possess the following qualities:

- Deep understanding of the procurement principles and business sense

- Strong leadership and decision-making capabilities

- Effective communication skills and good interpersonal competence

- Negotiation skills

- Ability to manage time well and stay organized

- Proficiency in gathering and processing data, as well as research and analytical skills

- Analytical mindset

- Knowledge of procurement tools

Five KPIs Every Purchasing Manager Should Consider

Purchasing professionals track various metrics in order to evaluate the efficiency of their current procurement strategy. We have selected 5 fundamental KPIs that purchasing managers should consider.

Cost Savings

One of the most important KPIs, cost savings measures the difference between the anticipated costs and the actual costs of purchased goods and services.

The expected costs are initially determined based on three components:

- the budget limits

- the market price of the selected goods and services

- the logistics cost per unit (including delivery, storage, labor costs, etc.)

By tracking the cost savings, the purchasing manager can determine how effectively they are negotiating with suppliers and planning the logistics.

Performance and Reliability of Contracted Suppliers

This KPI is a reflection of how efficiently the company cooperates with the contracted suppliers. Suppliers that meet expected quality standards help the company increase its operational efficiency and ensure reliability for the final customers – the purchasing company’s clients. Delays in supply deliveries, on the other hand, can lead to downtime at the manufacturing step and cause setbacks in meeting final customer expectations.

To evaluate supplier performance, purchasing managers should consider the following metrics:

- full deliveries (%)

- on-time deliveries (%)

- damaged goods delivered and inadequate services provided vs. goods and services delivered and provided as expected (%)

- rejections and returns due to low-quality levels (%)

By tracking these numbers, the purchasing manager can identify suppliers who don’t meet the anticipated quality standards and then take corrective action.

Inventory Management Efficiency

This is an evaluation of how efficiently the purchasing team maintains the right level of inventory. There are three key metrics to track to understand inventory efficiency:

- inventory turnover

- inventory-to-sales

- inventory accuracy

You can read about these metrics in more detail in this dedicated article about supply chain metrics.

By keeping track of these metrics, the purchasing manager can identify inefficiencies in inventory planning and discrepancies in tracking inventory. If there are any shortages or excesses discovered, especially if occurring repeatedly, that might be a signal for the purchasing manager to review the inventory practices.

Value vs. Quality of Purchases

Another important factor is how the company maximizes the goods’ value. The ultimate goal of a purchasing manager is to find the best option for a needed material, product, or service – and for the lowest price. Minimizing expenses while maintaining the quality is important for the purchasing manager.

The purchasing manager should evaluate if the goods meet the company's quality requirements while, at the same time, keeping track of pricing options. It’s not unusual that the cheapest options might be of insufficient quality and require costly repairs or adjustments, making them not as cost efficient as they seem. On the other hand, selecting the most expensive item doesn’t guarantee the highest quality.

Purchasing managers should balance the value vs. the quality of purchases to ensure that purchased items fit within budget limitations and corporate quality standards.

Emergency Purchase Rate

This KPI helps purchasing managers measure how successful they are at handling unforeseen procurement needs.

Emergency purchases are made to procure materials in situations when initial procurement strategy was inadequate, or when an unexpected event occurred.

It’s important to realize that emergency purchases are bound to happen at some point. However, purchasing managers strive to minimize them for routine business processes by keeping track of emergency purchase rate and taking action if it's high.

How to Improve KPI Outcomes

Let’s see what a purchasing manager can do to achieve the best values for the abovementioned KPIs.

Find Cost-Saving Opportunities

The purchase manager tracks cost savings by:

- calculating the expected cost of goods and services based on the company’s needs and budget

- comparing the actual cost to the expected cost

To achieve cost savings, purchasing managers focus on maximizing efficiency at every step of the purchasing cycle.

One of the ways to achieve cost savings is to build strong relationships with vendors. This way, the purchasing manager can negotiate better prices, delivery fees, and other agreement terms. Additionally, by developing trustworthy communication channels suppliers, the purchasing manager can expect to be among the first ones notified about special deals and discount offers.

The next factor in achieving cost savings is staying alert to new prospective suppliers and products on the market, as new entries can offer better value. To help them do this, the purchase manager can design and implement a supplier evaluation process for their company, which will help them continuously weigh options to find the best one.

Purchasing managers should also take a similar approach towards the delivery partners and monitor new offers and fees across the markets, as well as build good relationships with the existing delivery partners. By finding the cheapest (but reliable) delivery method and negotiating special pricing, the purchasing manager can cut significant costs.

Ensure the Performance and Reliability of Contracted Suppliers

Purchasing manager should start by setting a target for supplier performance. This target should include the following metrics: full deliveries, on-time deliveries, defective goods or services, and rejections and returns.

Once the target is set, the purchasing manager should track these percentages for each individual supplier, evaluate them against the target, and identify any issues.

To achieve the desired level of performance, the purchasing manager takes charge of communicating their company’s requirements and expectations to the suppliers. When it comes to quality standards, everyone should be on the same page. Both sides should establish performance metrics and agree on them, preferably in writing.

Finally, the purchasing manager should regularly review supplier performance and provide the supplier with feedback based on the established criteria. This should be done via communication channels that are comfortable for both parties to use. They might choose to do this via reports sent by emails or available within the procurement system, or via conference call sessions.

Another aspect of such feedback sessions is that they should ideally be planned ahead of time. If both the purchase manager and supplier representative have the time for evaluation carved out in their calendars, they are more likely to actually progress in giving, receiving, and processing the feedback regularly.

Honest assessment from the purchasing companies can help suppliers recognize their drawbacks and improve performance if possible.

Improve Inventory Management Efficiency

To track the inventory management efficiency KPI, a purchasing manager should start by researching the market for the inventory metrics averages. These include turnover rate (typically per year), inventory-to-sales ratio, and records accuracy. Managers should also retrieve the company’s historical data to compare the current inventory numbers against the previous ones.

After completing this research, purchasing managers should have a good understanding of desired inventory metric ratios.

By comparing current inventory ratios to the industry standard, purchasing managers can also determine if the competition has found a way to streamline their inventory management, and, if yes, analyze how.

Sometimes, purchasing is limited by the external factors out of a company’s control. For instance, stock fluctuations due to seasonal demand or delivery constraints due to local regulations can keep the buying company from achieving the industry averages.

In this case, it’s important for a purchasing manager to consider their company’s historical data to determine if there’s a positive inventory management tendency and whether it's becoming more efficient, meaning higher turnover, more balanced inventory-to-sales ratio, and better record accuracy.

On the other hand, if inventory management metrics are not high enough, that might mean there is consistent overstock or that the inventory isn’t moving quickly enough. Production, marketing, and sales teams can help to discover bottlenecks in current processes, but the purchasing manager should always be monitoring and adjusting inventory levels.

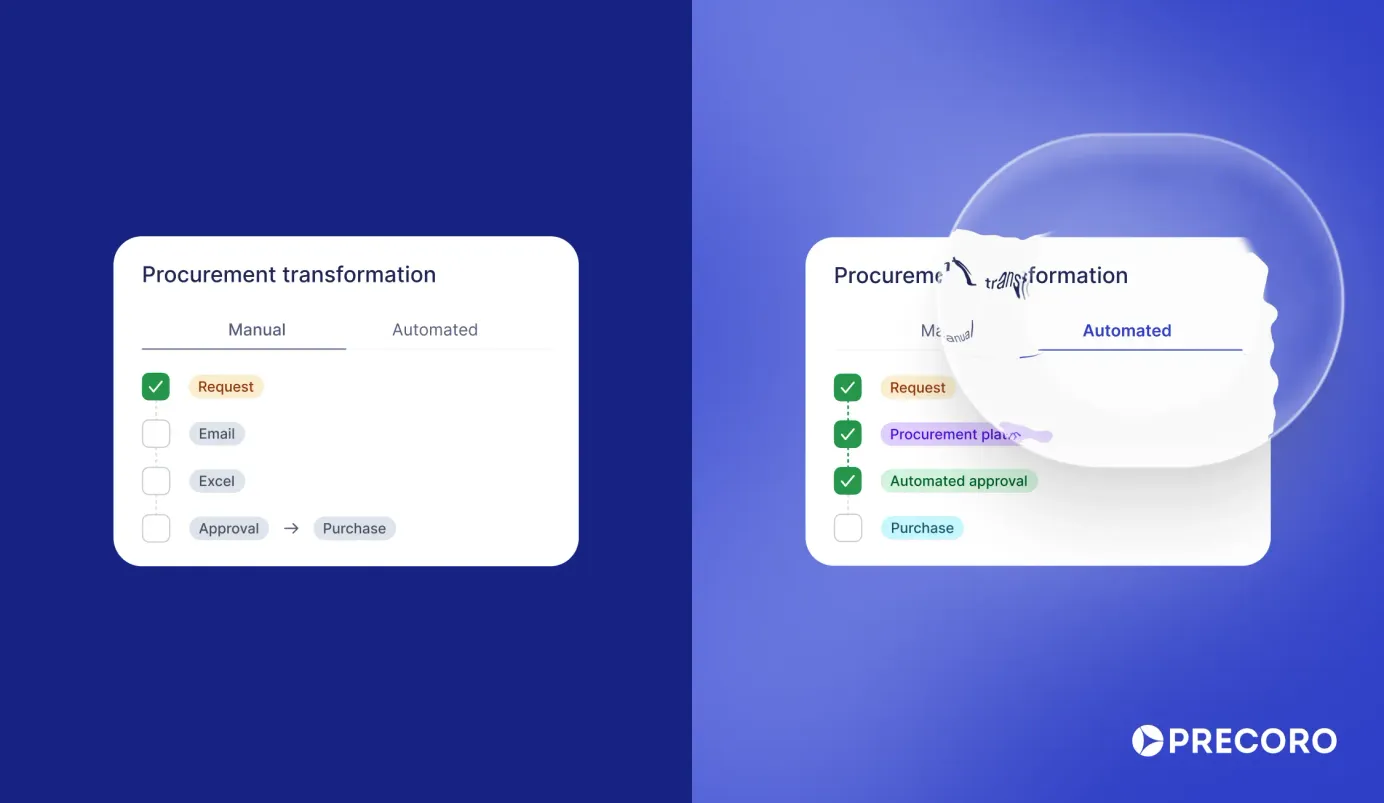

To streamline inventory management, purchasing specialists can implement automated solutions. Dedicated software minimizes human errors caused by manual interventions and therefore increases inventory accuracy. The software also provides managers with comprehensive reports and analytics. With accurate numbers at hand, purchasing managers can focus more efficiently on supply chain management and make informed purchasing decisions.

Find the Perfect Balance Between Quality and Value

To ensure quality and price needs are met and balanced, purchasing managers should first understand and compile the needs of the company when it comes to items and their value.

A great step towards this is to make a list of required parameters that includes the quality markers of various materials, products, or services. Such a list will, of course, vary greatly across different industries and from company to company. But the key point here is to clearly establish and describe these criteria.

When the quality side of company needs are clear, it’s time to consider budget limitations. Purchasing managers should pose these questions:

- Is the budget set in stone for each type of goods and services? Or can the purchasing manager adjust spending priorities?

- Is the budget negotiable? If an item doesn't fall within budget, can the purchasing manager negotiate a budget shift between departments in order to purchase it?

To improve this KPI, the purchasing manager should develop good relationships with contracted suppliers, establish how often the company gets price quotes for items, and negotiate favorable contracts. For instance, there is a higher chance that a supplier will offer a better price for a long term deal compared to a short term one. Large purchase volumes can also be an incentive for vendors to sell at wholesale prices. They might also offer better prices to businesses with aligned values — for instance, those that prioritize manufacturing sustainability.

Other than negotiating good contracts with selected partners, a purchasing manager should always be on the lookout for alternative suppliers. In a modern globalized economy complete with rapid technological development, markets are constantly evolving. Therefore, purchasing managers should have a good understanding of market trends and recognize suppliers that already offer or are about to offer new solutions.

So, in order to maintain a good balance of quality vs. value KPI, a purchasing manager should:

- be clear about quality requirements and their flexibility

- know the budget limits

- constantly scan the market for suitable opportunities

Decrease Emergency Purchase Rate

To minimize emergency purchases, managers should focus on clear communication with procurement colleagues and heads of departments.

Purchasing managers should regularly cross-reference the initial procurement plan with feedback from department heads, who can offer insights into the current reality. If things are not going according to plan it means there is something wrong with processes or the plan itself that the purchasing manager must work to fix. This will help employees avoid panic-buying at the last moment.

Another important step towards ensuring a low emergency purchase rate is implementing an efficient purchasing process. It should include clear guidelines and procedures for purchasing, including review and approval. Everyone involved must be aware of their role, responsibilities, and accountability. When the purchasing process consists of routine steps, well-communicated across the company, it’s easier to handle and prevent unexpected situations.

Efficient inventory management can also help organizations lower their emergency purchase rate. Having the right amount of inventory on hand helps organizations avoid last-minute purchases. To improve inventory management efficiency, organizations can consider using inventory management software. Tech-savvy managers can select good procurement software for tracking inventory levels, setting reorder limits, and monitoring inventory turnover. By having a better understanding of their inventory levels, organizations can avoid stock-outs and, therefore, reduce emergency purchase rate.

Finally, emergency purchase rates can be minimized by introducing risk assessment and management practices. It’s important to recognize possible external and internal threats to the company’s supply chain and production. Keeping the possible threats in mind, a purchasing manager can design several possible workflows to tackle eventual problems. Action plans and backup options help cut down on last-minute purchases, leaving only for the absolutely necessary emergencies.

To Sum Up

The purchasing manager is a member of the procurement team who plays a crucial role in establishing and executing the company’s purchasing workflows. This individual gathers purchasing requirements from various company departments and stakeholders, analyzes them, and communicates with his team.

As a part of their workload, purchasing managers also carry out analytical work. They select purchasing KPIs and track them regularly to ensure that the company has the necessary resources of the required quality, at an affordable cost, and at the right time. If the selected metrics do not meet established standards, the purchasing manager takes corrective actions. That’s why continuous KPI tracking is important.

There are five KPIs — cost saving, performance and reliability of contracted suppliers, inventory management efficiency, value vs. quality of purchases, and emergency purchase rate — that can be considered the most important KPIs for a purchasing manager to track.

If they can achieve good numbers for these metrics, purchasing managers can add significant value to their organizations. This can be done by leveraging the right data, optimizing the supply chain, introducing clear purchasing workflows, building good relationships with suppliers, and implementing procurement automation solution.