17 min read

Vendor Management Lifecycle: How to Choose, Manage, and Offboard Vendors

Bring structure to your partnerships with the vendor management lifecycle. Discover the steps, pain points, and best practices to address them.

Every business depends on vendors, whether it’s for goods, services, or software. The right vendor keeps the day-to-day business moving, while the wrong one leads to unforeseen delays and risks. The vendor management lifecycle gives you control over those relationships. It lays out a clear process: choose a vendor, assess their work, then decide to renew or end the contract.

In this guide, we’ll break down the structure of the vendor lifecycle, common pain points you’ll run into, and ways to deal with them.

Read on to find out:

What is the vendor management lifecycle?

The stages of the supplier management lifecycle

Common vendor management lifecycle pain points: Tips to deal with them

Best practices for vendor lifecycle management

Frequently asked questions about supplier lifecycle management

How Precoro can bring visibility to the supplier lifecycle

What is the vendor management lifecycle?

The vendor management lifecycle is a structured approach a company follows to manage suppliers. It begins with research and selection, proceeds through onboarding, contract management, performance and risk review, and ends with renewal or offboarding.

Each stage of the vendor lifecycle has its own role to play. Needs assessment and vendor selection help you discover the right fit based on price, quality, and company requirements. Due diligence stops risky suppliers before they enter your supply chain. Contract management is where the vendor and the company reach the best possible terms for both sides—their new framework for collaboration.

Supplier onboarding sets expectations and puts controls in place from day one. Performance and risk management keep the partnership on track and highlight issues before they spiral. Finally, renewal or offboarding wraps up the partnership, either with a stronger agreement or a clean exit.

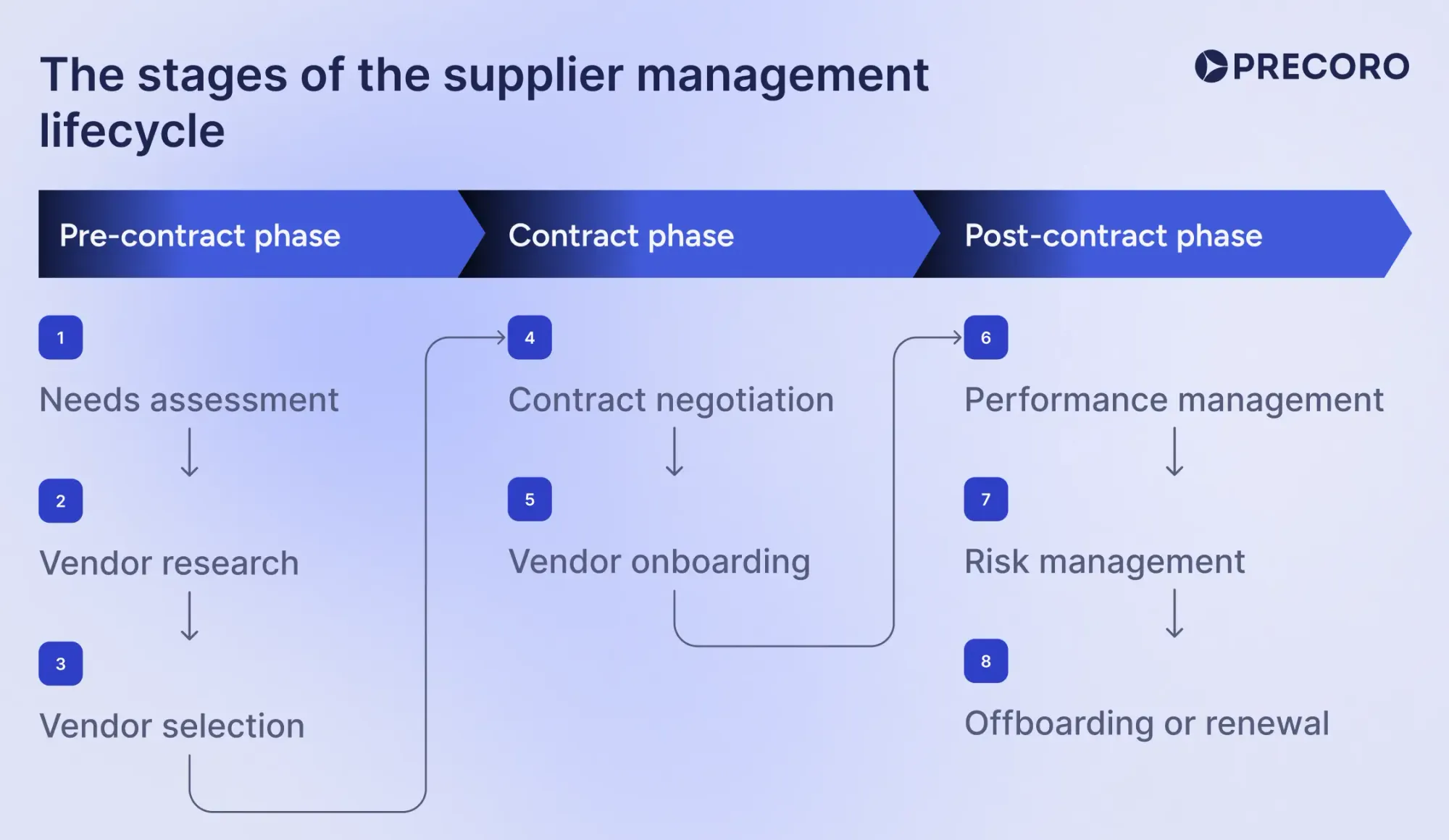

The stages of the supplier management lifecycle

Each supplier relationship goes through three phases: pre-contract, contract, and post-contract. Companies might handle the steps differently, but the overall structure stays the same. What really matters is that decisions made early on have a big impact on what happens down the road. Here are the three main stages of the supplier lifecycle management.

Pre-contract phase

During the pre-contract stage of vendor lifecycle management, your team defines what the business actually needs, scans the market for possible vendors, and requests proposals or quotes to find the best fit. A lot of research goes into this phase: companies check financial health, compliance, quality standards, sanctions, and media coverage of each vendor. The prep work done here sets the foundation for your entire partnership with the vendor, so it shouldn’t be taken lightly.

-

Needs assessment

Your partnership begins the moment your team realizes there’s a gap to fill. A thorough needs analysis forms the bones of your future contract and supplier lifecycle. Stakeholders, typically led by procurement, outline exactly what the company requires, the timeline, frequency, and budget. If you’re struggling to define the current needs of the company, think about:

- What are the current processes missing?

- If you have a specific product or service in mind, what specs or features would fill those gaps?

- What compliance, technical, or legal standards need to be met?

- How much, how often, and how quickly do you require delivery?

- What’s the budget? What’s the total cost of ownership you’re expecting?

- If demand grows, how should the supplier scale with your company?

For clearer supplier lifecycle management, separate all requirements into “must-haves” and “nice-to-haves”. For example, if you want to store all your data in one place, then a procurement centralization solution is a must—it’s likely the main reason you’re looking for a new tool.

On the other hand, extra features like custom reports might be nice to have if you don’t plan to run reports regularly. They’re useful, but you can do without them. This simple rule helps you prioritize what you actually need and avoid overpaying for features that no one’s going to use.

-

Vendor research

Once you’ve laid out the groundwork for your research, evaluate potential candidates. Don’t focus only on the most popular options: scan the market for suppliers who can actually meet your needs. Ask industry peers and consultants for advice and recommendations, communicate with stakeholders on their preferences, and check reviews to understand each vendor’s customer experience.

When reaching out to the supplier, send out Request for Information (RFI) forms. They’re used to understand the vendor’s capabilities and get a clear overview of what they provide. RFI gives enough surface-level information to decide if the vendor can meet your requirements.

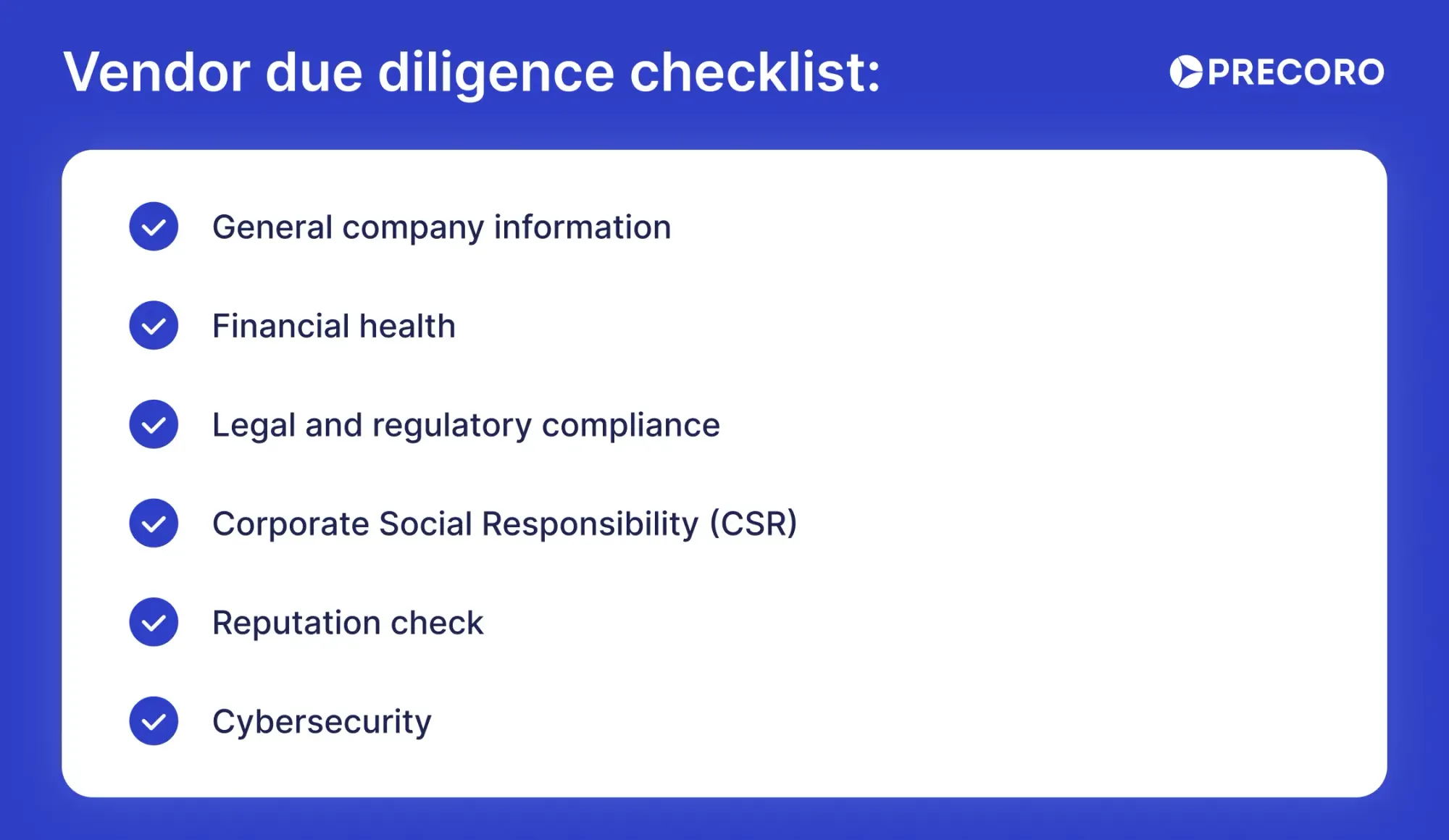

Carry out a due diligence check as part of a broader vendor management process and flow. Vendor due diligence is the process of assessing the supplier risk before a company signs a contract or renews an existing one. Start early, then check regularly, since it’s important to keep the partnership clear and compliant over time.

Use this checklist to make sure you cover all the key factors during vendor due diligence:

- General company information: Verify the vendor’s background, size, years in business, client base, and reputation. Request their registration, business license, company structure, and a list of executives. Also, consider the supplier’s location if they operate in a high-risk country.

- Financial health: Before partnering, confirm the vendor’s financial health. Request tax records to ensure compliance with local regulations. Review sales, assets, and debts to determine if the vendor can meet the volume and performance standards in your supplier lifecycle management. Also, pay attention to whether the vendor invests in research and development (R&D); this is a clear green flag that signals a focus on growth and innovation.

- Legal and regulatory compliance: Check for any industry-specific certifications and standards related to the product or service they’re supplying. For instance, vendors handling sensitive information must comply with HIPAA, ISO, or similar standards. Also, screen for sanctions or politically exposed persons (PEP) to avoid potential political or legal risks.

- Corporate Social Responsibility (CSR): Although ESG is no longer a top priority in 2025, more and more emphasis is placed on how businesses treat their employees, the community they serve, and the environment they operate in. Check for fair labor practices, diversity and inclusion policies, community engagement initiatives, sustainability programs, and transparent CSRD reporting.

- Reputation check: Research the supplier online and look through any publications about them. Sites like Capterra or G2 provide helpful customer feedback for software vendors. Additionally, look into any awards or achievements they’ve received from reputable industry organizations.

- Cybersecurity: If a vendor handles sensitive data, regular security checks should be part of vendor lifecycle management. Look for ISO 27001, SOC 2, or similar certifications. For cloud or SaaS providers, verify encryption, access controls, and incident response plans. For logistics, manufacturing, or operational vendors, check how they secure connected devices and manage third-party system access.

-

Vendor selection

During this stage, your team meets with potential vendors and discusses what both sides want to achieve from the partnership. Here, you align your expectations with what the vendor can offer. Intro calls and product demos are key: they show how the vendor presents themselves, how their solution works in practice, and whether it fits your day-to-day operations. Ask them:

- How does your solution handle this specific business need?

- What does ongoing support look like?

- Can you share examples of similar clients?

- Are there any limitations we should be aware of?

- What are the plans for risks and disruptions?

You can also request reference calls with current clients to see what an actual experience looks like, not just a flashy presentation. Once you’ve narrowed down the pool of candidates, it's time to get specific about time and cost: what exactly can the vendors offer, for how much, and for what period of time? That’s where RFPs and RFQs come in:

- A Request for Proposal (RFP) is a detailed document that asks vendors to explain how they would solve a specific business need. It should include a specific approach, pricing, timelines, and service levels. Use an RFP when your requirements are complex, for example, software or hardware solutions.

- A Request for Quote (RFQ) is a simpler option focused specifically on price and terms for clearly defined products or services. Use an RFQ when requirements are straightforward, and you only need to compare prices between vendors.

You can send both documents earlier in the supplier lifecycle management process, especially if the requirements are clearly defined. Procurement reviews all the responses, shortlists the vendors that best meet the requirements, and negotiates terms with them. Afterward, the team requests “the best and final” offers to finalize their choice.

Contract phase

In the contract stage, you negotiate the contract terms, finalize them, and onboard the vendor on the company processes. Both sides align on pricing, service levels, KPIs, and exit terms before signing the contract. Vendor lifecycle management team then takes over and begins the onboarding process.

-

Contract negotiation

A contract sets the tone for the entire vendor management process and flow, so it’s important to include clauses and safeguards that keep both parties accountable and in control. The more detailed the contract, the fewer issues you’ll run into later. During the negotiation stage of vendor lifecycle management, make sure to cover all the bases, including:

- Clear KPIs: Metrics to measure the performance and success of the partnership.

- Deliverables: The specific goods, services, and results the vendor must provide.

- Timelines: A clear timeframe for the supplier management lifecycle.

- Penalties: Consequences for missed deadlines, poor performance, or non-compliance.

- SLAs: Service level agreements that outline response times, uptime, and quality standards.

- Escalation clauses: A straightforward process for resolving issues with responsible parties and next steps.

- Exit and termination clauses: Terms explaining how either side can end the agreement without disputes.

- Points of contact: Named people on both sides to keep communication clear and consistent throughout the supplier management lifecycle.

-

Vendor onboarding

Onboarding is the step in the vendor management lifecycle where you set up clear communication channels, integrate the vendor into your company’s systems, and make sure both sides are ready to work together. Typically, the supplier management team leads this process.

To finalize the contract, the vendor submits tax forms, banking details, and compliance certificates. The company prepares infrastructure, completes risk checks, and registers the supplier in their ERP or vendor system. At this point, assign a clear contact person for any vendor’s questions, updates, and concerns.

Handling all this manually could take hours or days. Switching to automated solutions like Precoro’s Supplier Portal makes supplier lifecycle management clear from the start. Vendors review all relevant documents and communicate directly with your team, while all information stays in one place and is easy to track.

Post-contract phase

The last phase of the vendor lifecycle focuses on handling supply chain risks, tracking performance, and deciding whether to renew the contract or move on.

-

Performance management

Once a vendor is onboarded, shift your focus to whether they actually deliver. No matter how many promises were made during the vendor lifecycle management process, monitor and track everything against clear KPIs. Set up check-in calls and clear communication channels to identify any issues early on. Communicate to the vendor the way you’d like to be updated on the progress, deliveries, and any other news.

We’ve compiled a list of tools that can make performance management more structured and effective:

- Vendor scorecards help track KPIs and compare vendors.

- The supplier preferencing matrix shows how important your company is to the vendor and where you stand on the priority list.

- The Kraljic matrix categorizes suppliers by risk and profit value, which helps guide strategies for different vendors.

- Voice of the supplier (VoS) surveys help gather vendor feedback on how easy it is to work with your company and where collaboration can improve in supplier lifecycle management.

- Internal surveys collect input from your own teams about vendor performance in daily operations.

- Vendor management systems help centralize contracts, performance data, and communication in one platform.

Measure clear KPIs to keep vendor relationships on track. For example, if the vendor supplies critical, time-sensitive goods, the delivery rate matters most. Here are some KPIs you can use during the vendor management lifecycle:

- On-time delivery rate: How often the vendor delivers on schedule.

- Defect or return rate: Tracks the percentage of goods returned or found defective.

- Contract compliance: Checks adherence to agreed terms and policies.

- Cost savings or avoidance: Reductions in spend.

- Responsiveness: Average time the vendor takes to resolve issues.

Monitoring these metrics isn’t about micromanaging. It helps you spot problems early, reward top performers, and make informed decisions when it’s time to renew contracts. Don’t just focus on the negatives—communicate any wins and successes you and the vendor were able to achieve together during the supplier lifecycle management process.

-

Risk management

Risk management isn’t a one-off fix. It should be woven into every stage of the vendor management lifecycle. The purpose is to identify supply chain disruptions and threats as early as possible, prevent them, and minimize operational and reputational damages. Despite how much these risks impact the overall supply chain planning, only 16% of organizations actively manage them.

Use the tools from earlier in the supplier management lifecycle, like the Kraljic matrix, to separate vendors by risk and profit value. Focus on the critical or high-risk ones: they have the biggest impact and need more frequent checks. It might be tempting to treat all vendors as critical, but over-classifying can do more harm than good. After all, over-classified critical suppliers can increase oversight costs up to 35%.

As part of the vendor risk management lifecycle, this stage is also where you can make the most of the escalation paths written into the contract. If the issue comes up more than once, flag it to the vendor and set a clear response plan.

-

Offboarding or renewal

The last step of the supplier lifecycle management is where you either make the decision to continue working with the vendor or end the partnership for good. The reasons for both cases vary. To make matters clearer, focus on all the information from the previous stages:

- Performance: Did the vendor deliver as promised? Were the metrics stable during the entire vendor lifecycle management process?

- Business alignment: Have your needs and priorities changed? Are your expectations different from before?

- Risk exposure: Are there new or ongoing risks? Have you encountered any issues with this vendor in the past? If so, how did they affect your company, and how were they resolved?

Answer these questions and decide the next step. If you choose to end the partnership, offboarding is the logical next stage. A pre-defined exit plan, ideally created during the onboarding phase of the vendor management lifecycle, should cover:

- Return and destruction of sensitive data.

- Removal of access to company systems and devices.

- Return of any company or vendor property.

- Data transfer (for software).

- Closure of all contract obligations.

- Final administrative tasks (paying outstanding invoices and updating ERP or vendor systems).

Handle these steps carefully and include the company’s legal and IT teams so nothing gets missed. One mistake could lead to IP theft or sensitive data leaks.

If you’d like to continue supplier lifecycle management with this vendor, review the current contract terms and the vendor’s role in your supply chain. Do they provide critical goods or services? Renegotiate if necessary and suggest a deeper strategic involvement. If the terms work for both, extend the contract and proceed as usual.

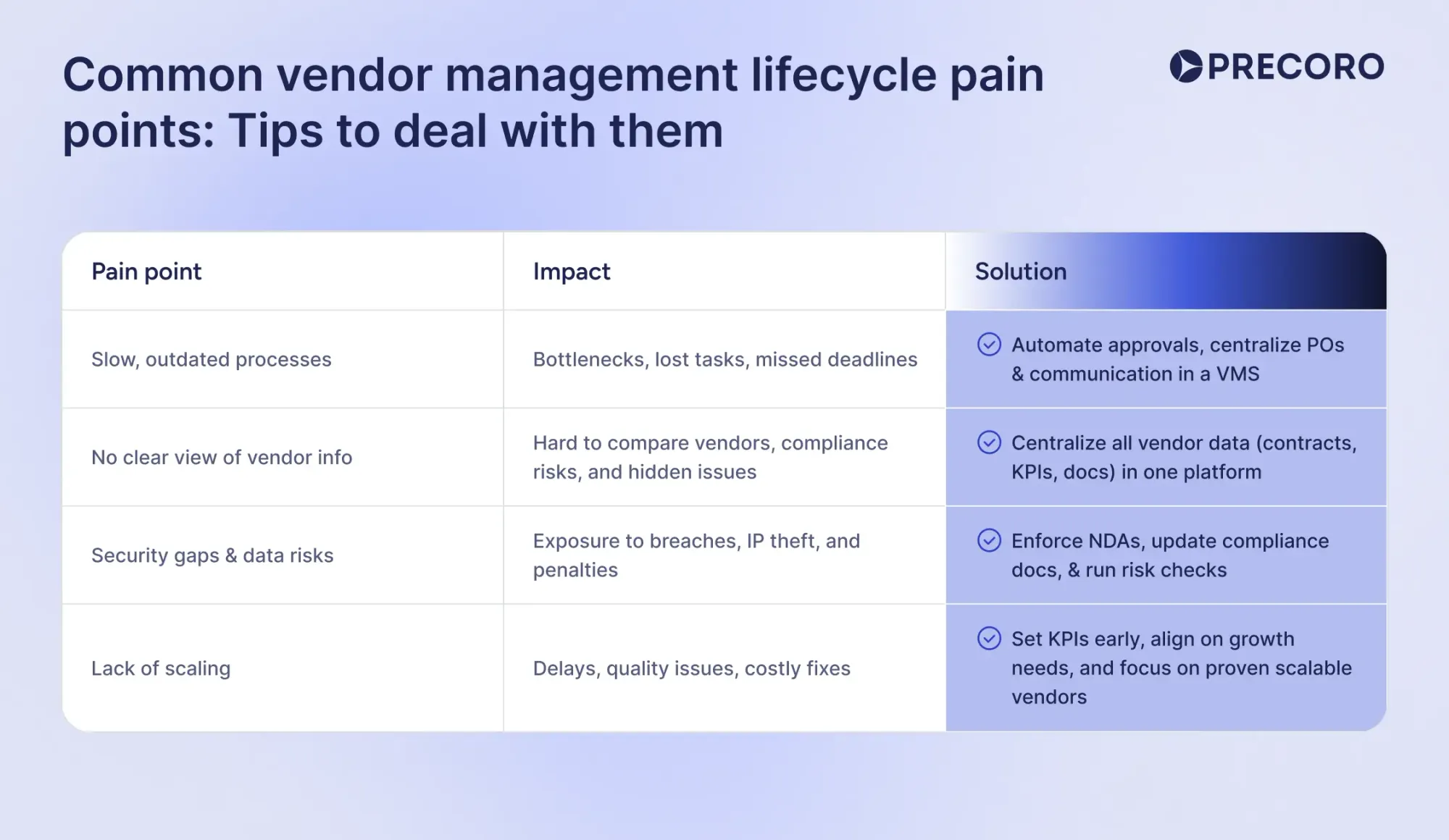

Common vendor management lifecycle pain points: Tips to deal with them

Managing vendor relationships isn’t always smooth sailing. During each contract vendor lifecycle, you’ll likely run into numerous challenges. Here are the most common issues and how to tackle them:

1. Slow, outdated processes

Manual approvals, long email chains, and scattered spreadsheets create bottlenecks in the vendor lifecycle management process. Tasks get lost, deadlines slip, and teams spend more time tracking progress and looking for paperwork than actually getting work done.

Solution: Use a vendor management system (VMS) to automate approval workflows, track purchase orders, and centralize communications. Both your team and the supplier can see order status, pending invoices, and upcoming deadlines in one place.

2. No clear view of vendor info

When contracts, certifications, and performance data are scattered across multiple systems or spreadsheets, it’s hard to get a full picture of any supplier. Teams waste time hunting for documents and struggle to compare vendors or make informed decisions during supplier lifecycle management. Lack of visibility can also hide performance issues until they get out of control.

Solution: Centralize all vendor information in a single platform. Store contracts, contacts, compliance documents, and communication logs in one place. With everything accessible in real time, teams can quickly identify top-performing vendors, flag potential risks, and have more leverage during contract negotiations.

3. Security gaps and sensitive data risks

Vendors frequently access critical systems, proprietary data, or customer information. Any weak link—missing NDAs, incomplete documentation, or poor security practices—can put your company at risk of data breaches, intellectual property theft, or regulatory penalties. These risks are not hypothetical; even a single oversight can disrupt operations or damage your reputation.

Solution: Treat vendor access like part of your own security. Require NDAs, keep compliance documents up to date, and monitor vendor systems for vulnerabilities or changes. Regular reviews ensure they stick to security standards and let you address gaps quickly. Put security at the center of the vendor lifecycle management process to cut risk and protect sensitive data.

4. Lack of scaling

Not all vendors can handle growth or sudden demand spikes. Don’t simply assume, “They can handle it.” Better discuss it first to avoid delays or drops in quality. When expectations aren’t clear, scaling problems are often found too late and lead to bottlenecks and costly last-minute fixes.

Solution: Set clear KPIs for performance, capacity, and delivery from the start. Share your expected growth and future needs so vendors know what’s required. Focus on suppliers that have shown they can scale, and regularly review performance to adjust your vendor portfolio as needed.

Best practices for vendor lifecycle management

Know exactly what goods or services you require, set realistic budgets, and involve all relevant stakeholders, from procurement and finance to operations and end users. State your needs clearly at the start of supplier lifecycle management to prevent misunderstandings and avoid future issues

Centralize and automate as much of the process as possible. Keep contracts, compliance documents, and communications in one system, so your team can access the information they need the second they need it.

Vendor lifecycle management tools also make it easy to keep communication open with your vendors at every stage. Set clear expectations from the start, provide regular updates, and address issues promptly. Intro calls, demos, and regular check-ins help ensure both sides are aligned and working toward the same goals. Open dialogue also builds trust and allows you to spot potential issues before they escalate.

Finally, embed risk protocols into every step of the supplier lifecycle management process. Assess risks during onboarding, monitor performance and compliance continuously, and maintain contingency plans for critical vendors. Treat security, compliance, and operational risk as an ongoing responsibility rather than a one-off task.

Frequently asked questions about supplier lifecycle management

There’s no real difference. “Vendor” and “supplier” are often used interchangeably. Some companies use “supplier” for physical goods and “vendor” for services or software, but both terms refer to the same process: managing third-party relationships from start to finish.

First, review financial stability, compliance with regulations, and security policies. Then check performance factors like pricing, quality, delivery times, and customer support they offer during the vendor lifecycle management process. Don’t forget references and reviews: they often reveal how easy the vendor is to work with in practice.

Third-party risk management (TPRM) is used to identify, assess, and control risks brought on by external vendors, suppliers, or service providers. It follows a dedicated vendor risk management lifecycle to prevent issues like operational failures, data breaches, compliance violations, financial instability, or reputational damage. Vendor lifecycle management (VLM) fits directly into TPRM because it provides the structure for handling every stage of a vendor relationship—from selection to offboarding—while keeping risk in check.

Address it in the early phases of the vendor lifecycle management process. Use the KPIs in your contract to show evidence, set a timeline for improvement, and escalate if needed. If performance doesn’t improve, your vendor management lifecycle should already have an exit strategy.

The number depends on your company, but focus on a handful of high-impact vendors. Trying to monitor hundreds of low-impact suppliers wastes time and resources. KPMG recommends no more than 100 critical vendors to keep oversight manageable.

How Precoro can bring visibility to the supplier lifecycle

59% of companies say their tools don’t give them the visibility they need to keep third-party risks in check across the supply chain. That’s why choosing a solution that can give you complete control over your data is key. Precoro covers both procurement centralization and automation with these smart features:

- Centralized supplier database: Access all supplier info, contracts, and orders needed in the vendor management lifecycle in one place. No more scattered emails or missing records.

- Supplier Portal: Vendors upload documents, update catalogs, receive POs, and submit invoices directly, which gives you accurate and up-to-date data without manual oversight.

- Integrated analytics & reports: Review spending and track supplier performance with customizable reports to support data-driven decisions.

- Automated procure-to-pay process: Convert requests into POs, match invoices automatically, and maintain audit-ready records for every transaction.

- Audit trails: Get full visibility into every purchase order, change, and approval for procurement compliance and accountability.

Our procurement software is one of the best solutions available for Canada, Japan, and South Korea. Precoro unifies the entire supplier management lifecycle under one roof. From onboarding to renewals, the platform keeps your team aligned, spots risks before they grow, ensures compliance, and saves time on supplier management.