9 min read

The Importance of Visibility In the Supply Chain

Over the last few years, companies from all industries have seen true turbulence. With unexpected disruptions caused by increasingly frequent natural disasters, the COVID-19 pandemic, and the Russian war against Ukraine, supply chain visibility has become a new "must-have" for businesses.

In today’s globalized economy, extraordinary events on one continent can be felt worldwide, as companies tend to have complex supply chains involving suppliers from multiple countries. While this complexity allows for cost-efficient production and a wider selection of goods, it also poses significant challenges to supply chain stability.

An undisturbed supply chain is vital for continuous production and, as a result, for customer satisfaction. Thus, businesses are always looking for ways to prevent disturbances and mitigate risks. This can be achieved by improving supply chain visibility.

In this blog post, we'll answer the following questions:

- What is supply chain visibility?

- What do high-visibility supply chains look like?

- How can supply chain visibility be achieved?

- What are the main challenges for supply chain visibility?

- Why is supply chain visibility important?

What Is Supply Chain Visibility?

Supply chain visibility is a company's ability to keep track of raw materials, components, and final products – in batches or individually – as they move through the entire supply chain from suppliers through production or assembly to retailers and end customers.

To streamline the supply chain performance and monitor stability, companies must track the movement of products and services into, within, and out of their premises.

Depending on the product, the scope of the supply chain may vary. For example, a company that produces furniture has to order raw materials and trace the manufactured items sent to the customers (forward tracing) and occasionally the items that are returned (backward tracing). On the other hand, a software development company wouldn’t need to purchase raw materials but rather goods – such as hardware – and services, like software subscriptions.

With globalization, companies worldwide have outsourced their supply chain components, making greater business transparency through supply chain visibility especially important.

By keeping track of all supply chain components, responsible officers can access comprehensive information on any order from the supplier and any shipment to the customer. In practice, supply chain visibility means instant, unrestricted access the following information:

- A purchase order with specified items and purchasing terms

- Supplier contact information

- Delivery information: date, address, and mode of transport

- Regulatory information

- End customer's order details

- Current status of the product according to the relevant supply chain stages, such ase raw materials delivery, manufacturing or development, or shipment to customer

Sometimes it's also necessary to look into the tier 2 and tier 3 suppliers in order to recognize the possible disruptions that may affect your suppliers’ supply chains.

What Do High-Visibility Supply Chains Look Like?

A key characteristic of a high-visibility supply chain is the ability to determine the current status of any element of the supply chain at any given moment and investigate it for more details.

In a high-visibility supply chain, it should be possible to quickly determine whether all the required items – meaning anything from raw materials to subscription renewal – are available.

Another predominant characteristic of the highly visible supply chain is a certain level of synchronicity with the suppliers’ and logistic operators’ systems for verifying the current status of incoming or outgoing orders. When these systems are well integrated, it results in better transparency and ensures the purchasing company is notified of any red flags on the supplier’s side immediately, and has enough time to address them.

Cargo Status

Current information about the location and status of cargo is the first pillar of supply chain visibility. In order to plan inventory and estimate cash flow, companies should know when to expect shipments to arrive, when to pre-order the next one, and how to budget the payments.

Shipping Rates

Delivery cost makes up a significant part of a company’s procurement expenses, so visibility is essential for taming the spending. Delivery can be a pretty straightforward process for some companies, but when a business grows and expands globally, it can become more complex.

In highly visible supply chains, responsible officers can confirm the inbound and outbound shipping rates, compare them to the quality-level and speed, and select the best delivery option available.

Documents

With every step, transactions should be documented; this means creating a purchase order, a bill of lading, a receipt, a customer's order, and others.

Ideally, supporting documents can be easily retrieved at any moment to resolve potential disputes between any of the counterparts, such as the shipper, the carrier, the consignee, the manufacturer, the retailer, and the customer.

How Can Supply Chain Visibility be Achieved?

Even with a well-managed supply chain, there’s a high probability that at some point something will go wrong. Too many factors play a part in making transactions happen, so anything can disrupt them: from internal issues of the involved parties to natural disasters and geopolitical events.

While businesses cannot predict everything, they can certainly improve supply chain visibility so that they have the insight to respond to whatever disruption comes their way. Let’s go over the key steps for doing so.

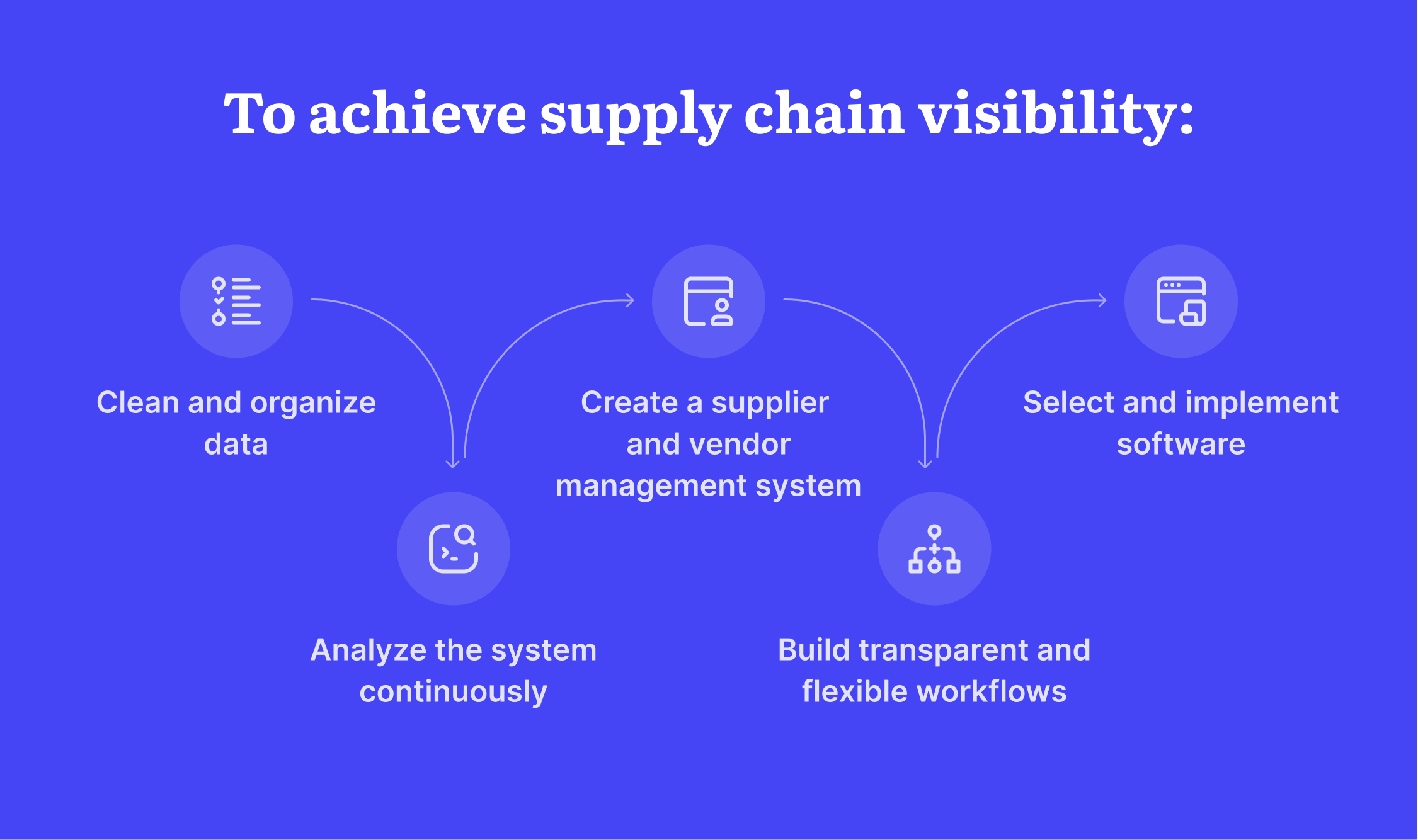

Clean and Organize Data

Data is necessary for understanding the current transaction status and projecting the future ones. Supply chain managers need reliable information both to prepare P&L strategies and to make sound decisions on the fly.

The first step towards supply chain visibility is to identify all available data sources within the network and import the data from wherever is most relevant: for instance, automatically via API or from manual, shared spreadsheets.

The next steps include cleaning this data to correct possible errors and making the measurement units uniform to make the data more legible. After that, it can be sorted into different categories. Companies will decide these categories depending upon their unique needs and supply chain structure.

To name just a few, some categories are inventory levels for particular items, anticipated production schedules for the regional branches, consumer demand as per country, and many more.

Analyze the System Continuously

To ensure supply chain visibility, managers should process the aforementioned data on a regular basis to ensure that required goods are in the right places, services are arranged, and everything is budgeted for and expected on time.

Only with the real-time picture of every stage of the supply chain can managers recognize the weak spots, as well as opportunities for improvement. Things to check continuously include safety certifications, compliance with legal requirements, order and supplier information, and current location. This way, any issue can be recognized and rectified on time.

Clean data allows companies to move beyond descriptive analytics to those that are more action-oriented:

- predictive analytics to answer the question “What will happen?” and

- prescriptive analytics to define “What should we do?”

Create a Supplier and Vendor Management System

To ensure supply chain visibility, a business must build good relationships with vendors and suppliers and create an efficient supplier management system. Such a system paves the way for clear communication and helps to avoid order mix-ups or delivery delays, thus saving time and money for both parties.

For example, a supplier management system includes setting supplier due diligence procedures before entering a contract with them. Due diligence is conducted to make sure that the supplier can meet the purchasing company's needs and requirements. Companies also ought to hold regular meetings with their suppliers to get updates on performance and expectations.

To bring contracted terms to life, managers should establish reliable communication channels with suppliers for placing orders, exchanging documents, and inquiring about shipment status. Examples of such channels might include traditional emails, shared spreadsheets, or marketplace accounts. Technologically advanced companies also implement dedicated software with supplier management functionality.

Build Transparent and Flexible Workflows

Supply chain visibility is only possible when everyone involved is aware of their roles and responsibilities and follows established guidelines.

Numerous workflows can coexist within one company’s supply chain and vary by document type, company department or branch, item type, price threshold, and even specific supplier. No matter how many workflows a company implements within the supply chain, they should all be transparent and unambiguous for any supplier representative, employee, or customer.

It might be a good idea to document these workflows to prevent possible confusion. However, it’s also important to remember that nothing’s set in stone and even well-established practices should adjust to the changing world. Supply chain workflows also should be flexible enough to meet the company's ever-changing needs. That could mean, for example, adjusting the sequence of approval steps or reassigning employee duties.

Select and Implement Software

All of the things mentioned above are much easier if done using a dedicated software. This might be a tool developed specifically for supply chain management, or it might be procurement software or an ERP system.

Software solutions can automate a range of supply chain processes and facilitate ordering, approval, and payment workflows. They also make tracking transactions in real time much easier by offering instant status updates. In addition to this, collecting and organizing data becomes easier and error-proof, and analytics reports or dashboards make it easy to see and understand data at a glance.

Sophisticated supply chain management technology also supports various integrations with for example, accounting software, ERPs, and marketplaces. Some even offer an embedded supplier portal for easier direct communications.

What Are the Main Challenges for Supply Chain Visibility?

As we’ve mentioned before, many factors can affect the supply chain — some are in the hands of the supplier or the buying business, and others are out of human control. When a wrench is thrown into the works, companies may be caught off-guard and realize that their supply chain visibility is insufficient even if they’ve followed all of the above steps.

In order to be prepared and mitigate all possible risks, supply chain managers need to stay aware of these potential challenges to supply chain visibility:

- Adjusting to unexpected changes can be challenging, especially for companies that operate on the international market and have to adapt differently for different locations

- Long-term forecasting is problematic in the face of constantly changing geopolitics and possible climate catastrophes that might severely disrupt supply chains

- Taking fast corrective actions requires prior preparation and elaborate risk management strategies, which are often put aside as a non-priority agenda

- Ensuring that suppliers deliver goods and services of the required quality for adequate price requires proper due diligence and regular status updates, which are often overlooked

- Risky codependencies in the supply chain might not be obvious at first sight and require deeper exploration of the suppliers and their sub-suppliers

- Delivery time is a delicate issue, as it can be influenced both by the supplier’s internal inefficiencies and by external geopolitical factors

- Data exchange can be compromised by the siloed systems implemented by every partaker of the supply chain

- Customer expectations are rising for product quality and sustainability, as well as for logistics transparency, speed, and cost-efficiency

Of course, other challenges might crop up, but staying on top of these will mitigate major risks such as missing products or order delays that would ultimately affect the end product and customer satisfaction.

Why is Supply Chain Visibility Important?

As we’ve mentioned before, supply chain transparency gives organizations the benefit of control over current transactions and the freedom of planning for future ones. Every supply chain is a complex process involving several parties, and businesses can benefit from providing their partners access to the supply chain data.

For example, businesses can cooperate with their suppliers to create cost-reduction opportunities, manage inventory more efficiently, and enhance customer experience.

Now let’s dive a bit deeper and discuss how some advantages of supply chain visibility manifest in everyday company life.

- Visibility into the supply chain helps mitigate the disruptions, as responsible officers and managers can register discrepancies in time

- Managers can get a better understanding of supply and demand by following the orders and movement of goods and services, as well as inventory levels

- Supply chain visibility also allows for greater inventory control, as inventory managers know exactly when to expect the next shipment and when to schedule the re-order

- Supply chain visibility allows managers to introduce more sustainable procurement and trade practices by identifying areas where waste disposal, energy use, and other environmental impacts can be reduced

- Naturally, visibility also improves supply chain efficiency and reduces processing costs, as everyone involved can get insights into the transaction lifecycle and detect opportunities for improvement

- Supply chain visibility also allows for better flexibility to adapt the course of action when it comes to tackling an unforeseeable issue or dealing with misconduct

- In high-visibility supply chain, inquiry response time can be shortened on all levels, as each participating party can benefit from available data to form a specific question and find the requested information promptly

- Building trust with suppliers and customers is easier when comprehensive information about transactions is honestly disclosed and available on the table at any moment

- Customer experience is significantly better when order status is updated immediately and shipments can be tracked along the way

Conclusion

Overall, supply chain visibility is crucial for modern businesses, especially the ones that expand internationally and have to build complex global supply chains. High-visibility supply chains allow every involved party to have immediate access to the transaction status and adjust the flows of incoming and outgoing goods and services.

By having real-time data and insights into the supply chain, businesses can improve collaboration and communication with suppliers and purchasers, enhance end customer experience, comply with local and international regulations, manage inventory better, and reduce costs.

As technology continues to advance, it is becoming easier for businesses of all sizes to achieve supply chain visibility. Software like Precoro enables companies to design custom workflows and bring them to life in the most efficient way.