13 min read

What Is Procurement? A Comprehensive Overview of Key Processes

Procurement plays a key role in business operations, from the simplest to the most complicated ones. Companies of all sizes and in all industries have to purchase things in order to function. Read how procurement ensures it’s done efficiently and why approaching it strategically is so important.

The work that goes behind purchasing for a company is often taken for granted. Materials and things seem to appear on the warehouse shelves in several clicks, and services are just provided upon a brief request. Yet, in reality, it’s all part of the comprehensive process of procurement that includes a number of steps before and after the purchase.

Understanding the significance of procurement can be a game-changer for any enterprise. Let's look closer at the procurement function, explore its purpose and value, and discuss the impact that a well-organized procurement process can have on businesses of all sizes.

Keep reading about:

- Procurement meaning

- Types of procurement

- The procurement process

- The importance of procurement in practice

- Procurement technology and innovation

- FAQs

Procurement Meaning

Procurement refers to the comprehensive process encompassing sourcing, acquiring, and inspecting goods or services that a business needs to operate effectively. Items purchased under the procurement process include anything the company needs to run the business, from tangible things like raw materials or office supplies to consulting services or IT licenses.

Procurement involves not only purchasing but also activities before purchasing, as well as after. For instance, sourcing for suitable suppliers is an integral part of the procurement process that happens before the actual purchasing. As part of the procurement process, purchasing activity and other operations in the process are analyzed regularly to ensure everything is as efficient as possible.

In short, procurement’s meaning in business isn't limited to simple purchasing. It includes strategic supply chain management and maximizing the value of every single deal.

Types of Procurement

Procurement is a complex process, so even though it has some standard steps applicable to all circumstances, it is also a highly customizable procedure that can vary significantly depending on the nature of the goods or services needed by the business. Naturally, the procurement process varies across companies, depending on their size, structure, industry, or other unique factors. Once companies establish a standard process for employees to use, procurement managers can also create different workflows depending on purchase urgency, product type, or supplier.

One of the first distinctions companies typically make between their purchases are whether they fall under direct or indirect procurement. Direct procurement includes the goods and services that are directly used to produce the company’s final product and generate revenue. For instance, raw materials used for manufacturing the end product would be obtained under direct procurement.

Indirect procurement, however, considers purchasing goods and services that support the company daily but do not directly contribute to the revenue. Office software subscription would be an example of a service purchased under indirect procurement.

Depending on the procurement type, specific steps of the process can vary. For example, goods related to direct procurement typically have to be examined more closely, so the direct procurement process may have more steps, while indirect procurement can follow simplified procedures.

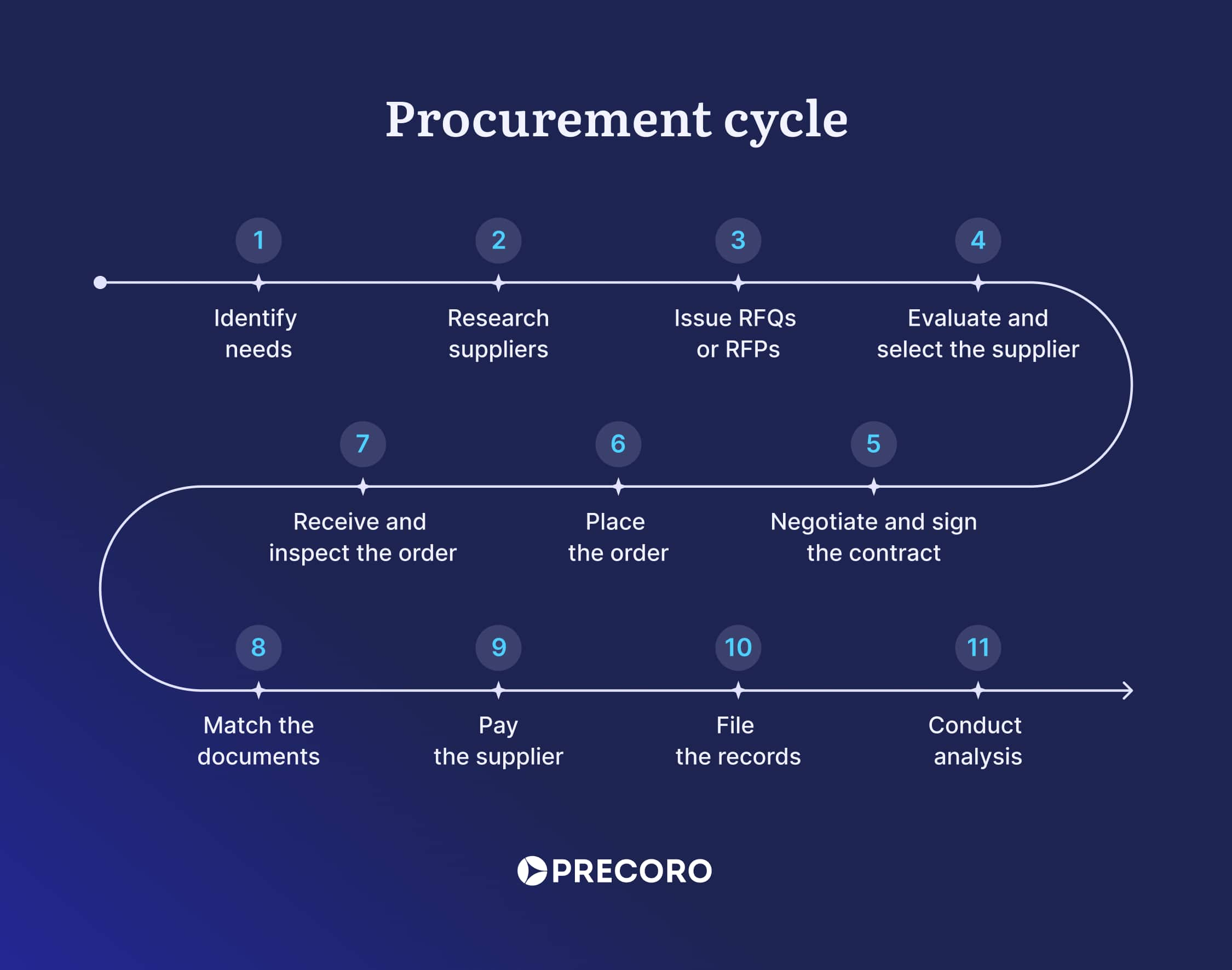

What are the procurement steps? Let's look at an example of the standard procurement cycle.

The Procurement Process

There are several stages of a typical procurement process. Each of these stages can be further broken down into smaller stages, for the sake of efficiency and to make procurement management simpler.

For instance, the sourcing stage includes identifying suppliers, negotiating deals, and managing contracts. Acquiring means purchasing the goods and services, confirming the documents, and paying for the purchase. At the stage of inspecting, relevant employees check the actual items in the order, and then confirm documents.

Procurement process can be different across different companies, whether it's a construction business, renewable energy sector, hospitality, healthcare or other industries. But some of the key steps are the same. Let's look at a typical procurement process and the main steps to help paint a better picture.

Identifying Needs

The first step of the overall procurement process is to identify a need for purchase. This often starts with an employee notifying their manager that they require something to perform their job. The employee then issues a purchase requisition with a detailed description of their needs and assigns a matching requisition number. Typically, the manager must approve the purchase request, therefore acknowledging the need. The initial submission and approval of requests is typically referred to as intake management.

Researching Suppliers

When it's clear that something needs to be purchased, the procurement team researches the market and identifies potential vendors or suppliers to buy from. The procurement team evaluates the potential suppliers based on their reputation, capabilities, and pricing.

If the employee who initially made the request has a specific vendor in mind, they can mention this option to the procurement specialist. Insights from the employees who work directly with the required goods and have tested different suppliers can prove invaluable while researching for the potential selling partner.

Issuing RFQs or RFPs

The procurement team selects several supplier candidates who meet the company's criteria and contacts them regarding the intended purchase. In this step, the buying company requests specific offers from the potential suppliers to select the best one. Depending on the nature of the purchasing need, the buying company can make two types of inquiries.

The first type is a request for quotation, which is used if the procurement team knows precisely what they need and just wants to ask for the price. If the procurement team isn’t sure what exactly they need, they can instead issue a request for proposal, in which they describe their need and ask the supplier to come up with a proposal to solve the issue.

Evaluating the Suppliers and Selecting One

Once the procurement team receives responses from potential suppliers, it's time to choose whom they would buy from. The purchasing professionals compare the offers, typically considering several factors at once: price, quality, delivery terms, reputation, and possible risks. Based on the evaluation result, the most suitable supplier is selected. Typically, the procurement team chooses the supplier with the best price-quality balance and acceptable delivery terms.

Negotiating and Contracting the Supplier

When the supplier is selected, it’s time to formalize the agreements in a contract. Procurement contracts are typically generated by the buyer’s procurement and legal teams. However, in many cases, contracts require negotiations before confirming and signing the final version. Representatives of the buying and selling companies — typically procurement or legal professionals — discuss the contract terms and adjust them until the conditions are satisfactory for both parties.

Parties have to reach an agreement about the conditions of cooperation. The key areas to negotiate typically include price and quantity of goods or services, delivery schedule and payment details, return policies, and contract validity period. Once the contract terms are decided, it’s time to put them on paper and formalize them with a signature.

Ordering

Once both sides have signed the contract, it's time to move on from the stage of sourcing to the actual purchasing. The procurement team issues a purchase order (a PO)— a document that contains the purchase date and essential information about the buyer, the seller, and the purchased goods or services, including the price and delivery details. Companies often use purchase order software to create, approve, and track POs.

The purchase order goes through the buying company’s custom approval process, during which relevant managers either approve the purchase, reject the order, or return it with comments for revision. Approval workflows typically depend on the nature of required goods or services and the total amount due. Businesses often choose to set up several levels of approval based on the purchase cost.

When the purchase order is approved, it is sent to the selected supplier. Once the supplier confirms, the purchase order becomes a legally binding agreement between the ordering and the selling parties.

Receiving and Inspecting the Goods and Services

When the ordered goods are delivered, the receiving employees inspect their quantity and quality. If a service was purchased, the receiving company examines whether the service was provided on time and in full.

If the delivery doesn't meet the contracted terms, the procurement team notifies the supplier, and both parties must agree on what to do next. There are several ways to remedy the situation. Suppliers can agree to correct the mistake and provide the goods or services as agreed. Also, the buyer can accept a partial delivery at a discount and amend the initial purchase order. For instance, the price can be reduced if not enough items were received or if they were not of the right quality.

When all the issues are solved, and the goods inspection is finished, the buying company issues the delivery receipt. However, if it's a recurring purchase, some companies might choose not to conduct the delivery inspection and skip this step.

Matching Documents

After the delivery, the accounts payable department matches the invoice and receipt to the purchase order to check for discrepancies. This process is also known as three-way matching.

As mentioned in the previous step, some companies also find it sufficient to leave out the receipt and conduct two-way matching instead, simply checking whether the invoice and purchase order match. This is often the case for software subscriptions, for example.

Paying

At this point, the accounts payable department gets the green light to pay the supplier. They follow the payment terms outlined in the documentation — typically in the contract, if applicable to all purchases from the supplier, or specified in the invoice.

Payment is often perceived as the final point of the whole process, but it is not so. Paying is the last step in the purchasing cycle. This is where it becomes obvious that the procurement process isn’t just about purchasing; it goes beyond and involves looking back at each completed transaction and evaluating it.

Filing the records

After the transaction is completed, procurement and accounts payable managers file the related documents for safekeeping. Depending on company policy and/or government regulations, companies tend to keep original documents like purchase requisitions, receipts, invoices, and contracts on file or make copies. Keeping records is essential for information retrieval during tax season, audits, or settling possible disputes.

Analyzing

The final step of the procurement cycle is analysis. In this step, procurement managers reflect on the completed transaction and compare it against internal KPIs. Each company sets up custom standards against which the procurement manager evaluates each transaction. These standards depend on the industry and business goals and can be measured for each particular transaction — for instance, purchase order cycle time — or observed in multiple transactions over time — for instance, supplier compliance rate.

Analyzing procurement KPIs is essential for understanding whether internal processes and contracted suppliers are efficient. Doing this can help the buyer scout for better sellers, reveal and remove operational inefficiencies, and discover the potential for improving the cost-efficiency of the procurement function as a whole. At the same time, if some contracted partners show especially good results, KPIs can be used to identify them and score more deals from them.

The Importance of Procurement in Practice

Procurement is not merely a transactional function. A well-prepared procurement strategy can have a significant impact on the long-term success of the business. In some cases, procurement is the factor that actually drives long-term success, especially in material-dependant companies like manufacturers. Let's see how companies can boost their performance by implementing an efficient procurement process.

Ensure Cost-Efficiency

When designed and executed well, the procurement process can make an immense difference in the company's operations. To start with, strategic sourcing and skillful negotiations with the vendors and suppliers can lead to favorable pricing terms. In addition to this, transparent purchasing workflows and employee accountability help minimize financial losses due to operational inefficiency or negligence.

Another integral part of strategic procurement that is otherwise overlooked is the analysis of sourcing and purchasing efficiency. When businesses establish KPIs and regularly compare their expectations to actual business results, there's a high chance that any irregularity will be identified and dealt with in time.

Improve Product Quality

By approaching procurement strategically, a business can maximize production potential and improve the quality of their end product. This is relevant for both tangible items and services. The procurement department sets the quality standards every potential supplier or vendor should meet. Upon contracting a supplier, responsible procurement specialists overview the purchases and track supplier compliance.

In this way, procurement plays a vital role in ensuring that the company receives goods and services of the expected quality. High-quality end product, in turn, leads to customer satisfaction and loyalty and, as a result, to a steady growth of the company base.

Enhance Process Efficiency

Establishing and implementing a clear procurement process across the organization can improve operational efficiency and minimize delays. Nowadays, most progressive companies also choose to implement e-procurement software to streamline every step of the procurement cycle.

By automating the procurement process and ensuring that everyone within the organization is in line with the steps, the business can enable faster decision-making and execution and significantly reduce the time and resources required to procure goods and services.

Mitigate Risks

An efficient procurement process helps businesses identify and mitigate risks associated with supply chain disruptions or inventory shortages. An experienced procurement team plays a crucial role in ensuring supplier reliability and regulatory compliance. In addition to this, proactive procurement managers can adjust to the supply chain developments and make the most out of the current market circumstances.

One of the ways procurement managers can minimize potential risks is by diversifying their supplier base. This way, the company can make sure that alternative goods or services are available for purchase if one of the key suppliers faces their own disruption and can’t meet the expected conditions. The procurement team meanwhile conducts regular supplier audits so that they can recognize unfavorable trends with a supplier – if such conditions occur – before a disruption.

On the operational level, a well-designed procurement process is essential for minimizing human errors, miscalculations, or document processing delays that may cost the business money in penalties or interest payments. Also, when the procurement cycle is transparent and predictable, it's easier to plan for the future, estimate the impacts of possible market shifts, and prepare several reaction scenarios.

Drive Innovation

Another way in which procurement contributes to business success is by driving innovation. Innovation is crucial for gaining and maintaining a competitive advantage in the market. Especially in today’s fast-paced world, businesses should be able to react to the newest technologies and software to seize momentum. Mostly, it's the task of R&D and procurement to discover and obtain the materials, goods, or services as soon as possible and under the best conditions.

Procurement necessitates close collaboration with suppliers, which is a good foundation for building trustful relationships with them and being the first to try out the latest developments in materials, goods, and services offered by the suppliers. Access to innovative technology allows the buying company to gain a competitive advantage and win customers. With the latest technology and materials from the best suppliers, the business can experiment with its final product and come up with new ways to satisfy the customers' demands.

Meanwhile, open communication channels allow buyers and suppliers to exchange honest feedback, ideas, and insights, therefore speeding up the development of products or materials a supplier has to offer. When there’s trust and a shared commitment to the best result, both buying and selling companies cooperate to optimize the costs while meeting the market demands. And that is an ultimate win-win.

Support Sustainability

Lastly, procurement plays a crucial role in promoting sustainability, which has become an integral part of the corporate responsibility strategy and a must-have for the image of a modern company. Strategic procurement can promote sustainability initiatives by prioritizing socially and environmentally responsible suppliers and striving to reduce waste.

Sustainable sourcing often means higher costs, so if a company decides to prioritize sustainability, it also should prioritize the strategic procurement process. By approaching procurement strategically, businesses can ensure the lowest possible price for the highest quality and maximize the value of purchased goods.

Procurement Technology and Innovation

In today's digital age, technology plays a crucial role in revolutionizing procurement processes. Procurement software empowers businesses to gain full control over their sourcing, purchasing, and reporting, therefore making company spending much more efficient. Software like Precoro lets companies spend smarter by helping to establish a transparent and efficient procurement cycle. It's a top procurement solution available in multiple regions, including the USA, the UK, Australia, and South Africa.

Procurement software enables businesses to automate processes of requesting, approving, and ordering goods or services, which is a sure way to streamline the whole procurement process and minimize human errors, especially with the help of AI technology. In addition to this, software solutions help improve the visibility of each step and the accountability of employees. Finally, good procurement software is a one-stop shop where companies can safely store, quickly process, and regularly analyze their procurement data. Immediate access to such data allows stakeholders to make informed decisions.

Check out Precoro to see how software can enhance your procurement:

Good Procurement Drives Competitive Advantage

To sum up, let's point out that procurement is a strategic function within the company that drives value, innovation, and competitive advantage for businesses. By understanding the procurement process and embracing its best practices, businesses can unlock new opportunities for growth, cost-efficiency, and sustainability.

From the initial request for purchase, through the sourcing and purchasing procedures, and all the way to analyzing the KPIs, procurement professionals are at the heart of ensuring that the company has all it needs to achieve its business goals. To thrive in today’s dynamic markets, organizations can leverage technologies and find a procurement solution to optimize every step of the procurement process.

FAQs

Simply put, procurement is a process that ensures that the company has everything it needs to function correctly. The standard procurement process includes finding, purchasing, receiving, and inspecting the required items to sustain business operations.

The terms procurement and purchasing are often used interchangeably but they are not the same. Purchasing is the activity of obtaining goods and services; it focuses on the short-term goal of securing a successful transaction. Procurement, however, is a broader concept that includes activities before and after the actual act of buying. Purchasing is a part of the overall procurement process.

The procurement process as a whole encompasses several operational activities. These include sourcing goods and services, negotiating prices and conditions, purchasing the items, receiving them, and inspecting them. It is vital to analyze each of these processes on their own as well as how they operate as part of the whole procurement process.