16 min read

Supply Chain Optimization: Signs You Need It and How to Take Action

Learn why supply chain optimization is now a must-have: key pressures, benefits, best practices, and case studies from Precoro customers.

Supply chains used to focus on one thing: cost. The cheaper the company could get supplies, the better. With the Global Supply Chain Pressure Index far from the stability of the pre-pandemic days, that approach doesn’t work anymore.

Simple cost reduction won’t protect you from a raw material shortage driven by new sanctions or a non-compliant supplier. Companies are thinking bigger. They’re now trying to find a balance between making operations efficient, resilient to external and internal shocks, and sustainable.

The pressure comes from all sides. Disruptions in the Red Sea increased transit times to the US by 47%. Companies say they care about resilience, but don’t review supply chain risks regularly and leave them exposed. At the same time, stricter compliance regulations like the EU Deforestation Regulation (EUDR) and the Corporate Sustainable Due Diligence Directive (CSDDD) demand detailed tracking of supply chains, with which manual processes just can’t keep up.

The stakes are high: even a small production delay can cost millions. To be useful long-term, supply chain planning and optimization must be constantly updated and adapted, not treated as one-time initiatives.

In this article, we’ll explore what supply chain optimization really means, the pressures behind it, the key benefits, and practical steps companies can take to improve every part of their supply chain.

Read on to discover:

What is supply chain optimization?

Stages of supply chain optimization

The tradeoff between cost, resilience, and sustainability in supply chains

Signs your supply chain needs optimization

How to put supply chain optimization into action

Case studies: Optimizing supply chain procurement with Precoro

Frequently asked questions about supply chain optimization

What is supply chain optimization?

Supply chain optimization is the process of aligning how you design, plan, and run your supply chain so it delivers the right products at the lowest total cost, with fewer risks, and as efficiently as possible. Optimization doesn’t just mean, “Let’s make this faster and cheaper.” The process itself is driven by data and careful analysis of potential blind spots in the supply chain. The end goal is to deliver high-quality goods to customers at a favorable price and at the right time.

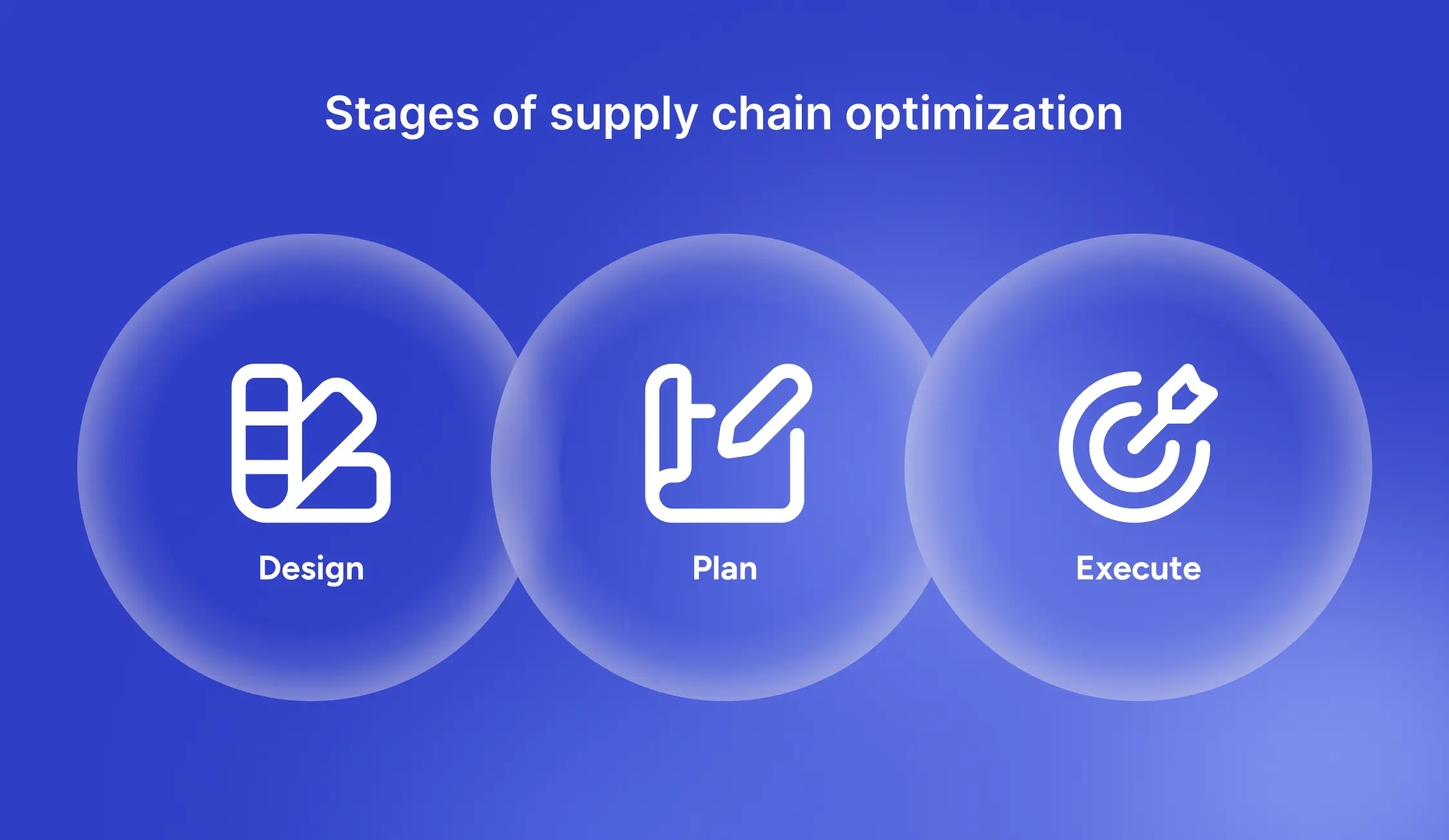

Stages of supply chain optimization

Optimization in supply chain management doesn’t happen all at once. It has three key stages: design, planning, and execution. In the design stage, you set up the backbone of your supply chain: pick the suppliers, map logistics routes, and decide on warehouses.

During planning, you align demand, inventory, and budgets, use data to forecast needs, and coordinate with partners to avoid surprises. Finally, execution puts the plan into action—your job is to make sure everything runs smoothly, add tweaks if needed, and monitor performance.

Let’s take an in-depth look at each stage:

1. Design

This stage forms the foundation for everything that follows and what supply chain optimization is. The purpose is to create a supply chain structure that aligns with the company’s strategic goals. The team has to select suppliers, choose locations for warehouses and plants, and outline shipping routes.

Design also considers risk and sustainability: Which suppliers meet compliance standards? Which routes use less fuel and produce fewer emissions? Decisions here have long-term consequences and shouldn’t be taken lightly. Factor in backup plans, like secondary suppliers or alternative transport routes, so one disruption doesn’t put a stop to the entire supply chain.

Tech infrastructure matters just as much as suppliers and routes. The right systems, whether ERP platforms or cloud-based tools, help track orders, monitor inventory, and spot issues before they snowball.

2. Plan

At the supply chain planning stage, the ideas proposed in the design phase become tangible. It starts with demand forecasting, which predicts what customers will order, when, and in what quantity. With data about sales, market trends, and seasonality, companies can avoid producing too much of what won’t sell or too little of what will.

Next comes supply planning. Here, you match the forecast with what you can actually deliver. The team checks their current inventory, how much they can produce with the available resources, and whether the suppliers are available. In supply chain planning and optimization, every effort is made to ensure the products are delivered on time.

Afterward, it’s time to plan and manage the inventory. The trick is to keep enough stock to meet demand, but not so much that it ties up capital or goes to waste. Finally, production planning schedules manufacturing to align with demand and available resources.

3. Execute

All the planning and design get put to work in the execution stage. Here, you can actually see the results of your labor. During this step, the team manages the daily operations of all supply chain-related processes, including procurement, logistics, and accounts payable.

Success at this stage depends on visibility: you need to ensure everything runs as intended and be able to quickly adjust if something goes wrong. Real-time automation tools help track orders, flag issues, and allow quick course corrections when supply chain disruptions appear. Strong ties with suppliers and logistics partners ensure goods move as promised and arrive in good condition.

The final test is the customer: orders must arrive on time, in full, and without issues. If execution was handled well, they get exactly what they expected and the company earns trust.

The tradeoff between cost, resilience, and sustainability in supply chains

You lose some, you win some—that’s the harsh reality many supply chains face today. Choose a cheaper supplier to save money, and you might expose yourself to risky regions or poor sustainability standards. Double down on resilience, and you’re paying more than you can handle. Focus only on sustainability, and you risk slower lead times or higher prices.

One objective isn’t enough. Modern supply chain strategies have to consider cost, resilience, and sustainability at the same time.

78% of companies are back to focusing on spend management in their supply chains. Cost will always matter, but not at any price. For example, a manufacturer that relies on a single supplier may save a few cents per unit. Yet if that supplier shuts down, production can grind to a halt and cost the company years of savings.

Cost control has its benefits: you save money for potential growth opportunities and have a financial cushion to fall back on in case of issues. But the mindset has shifted to the “cost of resilience.” This approach means spending more upfront, for example, by adding a secondary vendor for critical supplies, to protect your supply chains from bigger risks. The stakes are real: disruptions cost companies an average of $182 million in losses a year.

Supply chain planning and optimization are the key to success here. You can make your supply chain more resilient by multi-sourcing suppliers, such as working with two or three vendors for critical components. Holding strategic safety stock also helps when demand spikes or a delay happens.

Both customers and regulators expect companies to focus on the final optimization objective—sustainability. Governments all over the globe now require businesses to track emissions, verify that suppliers follow social and environmental standards, and make conscious choices across the supply chain.

And sustainability isn’t just a checkbox; it has actual benefits. Companies with more ethical practices are less vulnerable to reputational damage and have a safer working environment. The downside is that responsible sourcing and ethical supply chain management optimization cost more upfront. However, the fact that you can avoid fines, reputational damage, and disruptions far outweighs the investment.

Finding the middle ground between cost, resilience, and sustainability looks different for every company. Your priorities are the starting point: identify what matters most for the company’s goals and determine where improving one area might impact another.

Signs your supply chain needs optimization

If issues go unnoticed, even the best supply chains can come to a halt. It’s important to spot the warning signs early before unexpected costs or delays start impacting your company. Here’s what to look for:

- Orders take too long to process

If purchase orders, approvals, and invoices crawl through your system, it’s a clear sign of an inefficient supply chain with room for improvement. When your team spends hours on spreadsheets, emails, and follow-ups instead of analysis and strategy, you waste precious time and resources. Automation and software solutions can help: while they handle repetitive tasks, you can focus on actually improving processes or managing suppliers.

- Costs are rising

Unexpected fees, duplicate invoices, excess inventory, or late shipping charges can slowly but surely add up and cost you thousands. Without full visibility, it’s hard to pinpoint where money is going.

- Frequent stockouts or overstocks

Running out of essential supplies means you’re losing sales and potentially frustrating customers. Unsold stock is just money that could be used elsewhere. If any of these situations happen frequently, it’s time to rethink your approach to how you predict demand or calculate safety stock.

- Supplier relationships feel transactional

If supplier interactions mostly involve confirming deliveries or correcting errors, you’re missing opportunities for strategic collaboration. Of course, not every vendor partnership has to be strategic. But when it comes to critical supplies, it’s worth considering a long-term approach that serves both the company’s needs and the supplier’s interests. With the right partner, you can work together to reduce costs or negotiate a more favorable deal for both parties.

- You struggle to respond to disruptions

Sudden demand spikes, market shocks, or regulatory changes cause more damage if your supply chain isn’t prepared for them. If every disruption sets you back and causes days (or weeks) of downtime, your system focuses too much on cost and not enough on resilience.

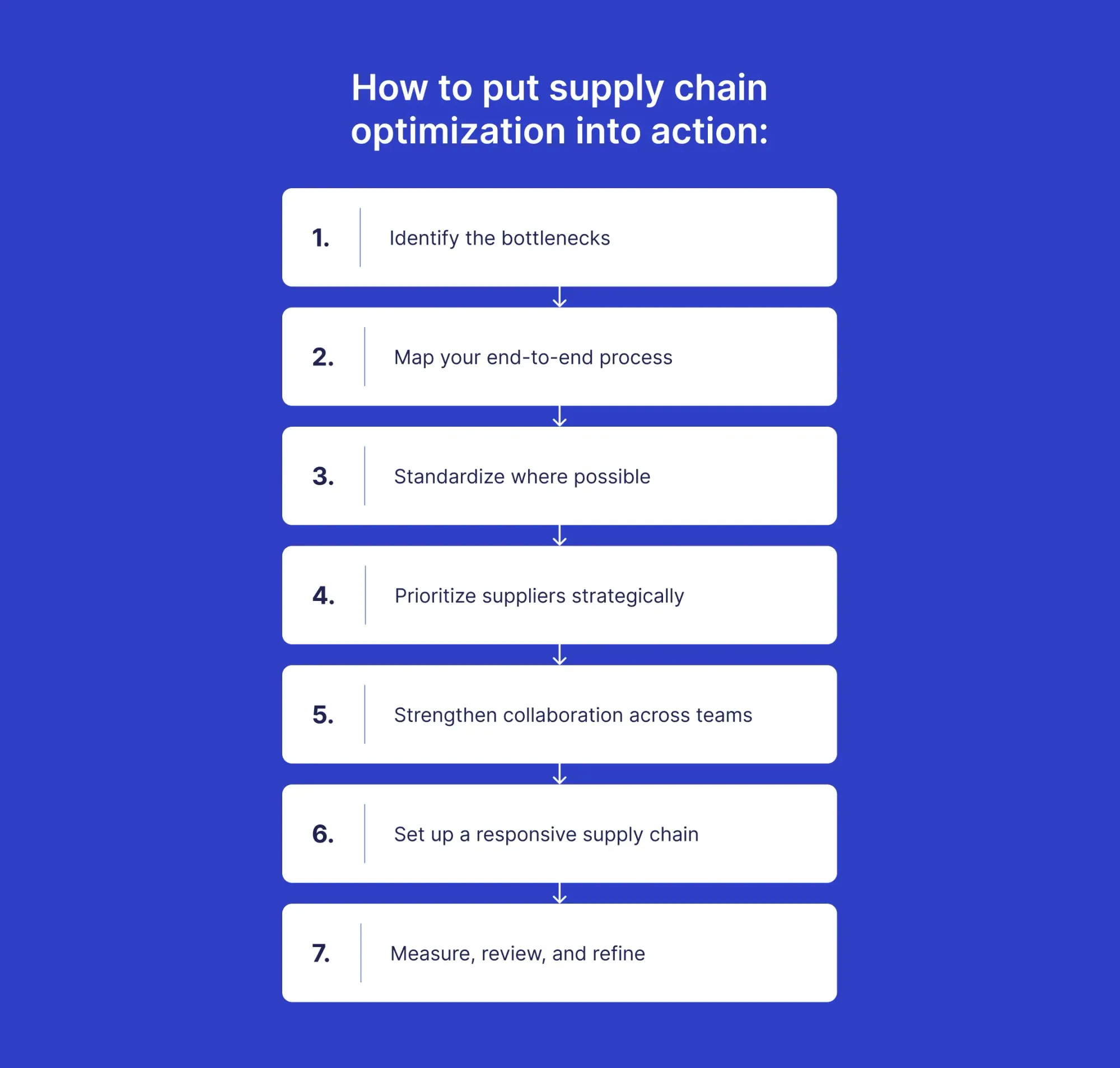

How to put supply chain optimization into action

You know the challenges. You’re aware of the risks. It’s time to decide how to put that information to the test. Supply chain management optimization doesn’t have to happen overnight. Take it one step at a time and implement small changes that add up in the long run. Here's how to get started:

1. Identify the bottlenecks

Look for the areas that slow you down or cost you the most. Are shipments delayed? Are approvals taking too long? Are suppliers inconsistent? Knowing exactly where your supply chain needs to improve allows you to focus your efforts where they’ll matter most.

For example, if your team spends hours manually processing invoices, automating that step can save time and reduce errors. Having all data in one place certainly helps too. With tools like Precoro, you can clearly see which orders are pending, approved, and paid, all in real time.

2. Map your end-to-end process

Visualize all the steps in the supply chain from order request to delivery to payment, including procurement, supplier management, and production. If you have a clear idea of the supply chain structure and what’s happening there, you can easily spot gaps and steps you missed. It also makes unsustainable practices easier to pinpoint.

Consider where inventory, assets, or technology can be optimized in your region to reduce costs and emissions. That way, you’re making small changes that affect the entire supply chain.

3. Standardize where possible

Consistency is the backbone of a smooth supply chain. Use standard templates, forms, and approval processes so every team follows the same steps. Standardized workflows make it easier to track performance, compare data across teams, and identify areas that need improvement.

However, leave room for flexibility: not every order or situation can be handled in the same way, so allow exceptions when needed without breaking the system. For example, urgent orders from pre-approved suppliers might benefit from a faster approval process.

4. Prioritize suppliers strategically

Identify your critical suppliers (those with the biggest impact on the company) versus low-risk or occasional vendors with tools like a supplier preferencing or Kraljic matrix. These key suppliers deserve extra attention: they can help improve product quality, suggest ways to cut costs, or are more inclined to negotiate.

Encourage open communication and use supplier relationship management software to centralize conversations, simplify onboarding, and keep everyone aligned.

5. Strengthen collaboration across teams

Supply chain issues often happen when departments simply fail to connect. Procurement, finance, logistics, and operations all have their own goals, but without alignment, it’s easy for information to slip someone’s attention. Involve them early on in the supply chain planning and optimization process to keep everyone on track.

The easiest way to improve communication and data sharing is to use a centralized platform that would store all purchase- and supplier-related information. Give access to the system to those teams that need it. For example, if finance can instantly see upcoming purchase orders, they can plan budgets better. Similarly, procurement teams can share demand forecasts with suppliers, which would give them time to prepare.

6. Set up a responsive supply chain

Your supply chain should be prepared for any risks or unexpected disruptions that happen in the market and globally. Collect data from market reports, social media, or industry publications to anticipate changes in demand or trends. This information can then be used to control inventory and predict demand and potential price increases.

Be prepared for surprises. Find multiple suppliers for critical goods, including local and regional options, and create mitigation plans for different scenarios like delivery delays, production halts, or sudden demand spikes. Assign backup suppliers for each key item and define the steps your team will take if a primary supplier fails.

7. Measure, review, and refine

Supply chain optimization is a continuous effort. Track KPIs like on-time deliveries, cost per order, or invoice accuracy. Schedule regular reviews to detect new bottlenecks or improvement opportunities. Small, continuous tweaks often have a bigger impact than overhauls of the entire system. Keep clear records of recurring processes and standard responses so your team knows exactly what to do.

Case studies: Optimizing supply chain procurement with Precoro

The easiest way to understand the impact of supply chain optimization is to see it in action. Procurement is a vital part of the supply chain, and when companies get it right, the results are hard to ignore. Let’s look at a few cases where companies improved their purchasing with Precoro:

Industry example: Venture capital and private equity principals

A venture capital firm managing procurement for more than 10 portfolio companies struggled with scattered processes. Purchase orders were kept in spreadsheets and sent via email to suppliers. Staff couldn’t clearly track whether the PO was received, viewed, or approved. The team didn’t know when the invoices would arrive and when they should be paid, which led to late payments. The company clearly lacked a centralized document flow.

Precoro helped:

- Unify the process for all companies with standardized purchase order templates.

- Make the PO’s status—created, approved, sent—visible in real time.

- Prevent late payments.

- Send POs to suppliers directly from Precoro, rather than by email.

Industry example: Biotechnology

A growing biotech startup had no procurement system in place. Employees went directly to the CEO for purchase approval, and invoices were manually tracked in Excel. Supplier onboarding took a lot of time and was prone to mistakes. As the company grew, purchases started to pile up, and the lack of process quickly became an issue.

Now, the company processes hundreds of invoices and POs each month, all fully aligned with budgets. Maverick spending is gone, supplier onboarding is faster, and management has instant access to budget analytics.

Precoro allowed them to build a complete procure-to-pay (P2P) process, step by step:

- Clear requisition and approval workflows for every purchase.

- Enforced budgets that made issuing a PO impossible if it was out of budget.

- Custom user roles so each user had the right level of access.

- Integration with their ERP for automated invoice processing.

- Supplier Portal that lets vendors upload invoices directly.

Industry example: Logistics and transportation

A logistics company operating across 12 branches relied on paper-based purchasing. Each purchase required handwritten signatures. Tracking who approved which request was virtually impossible since no monitoring system was set in place.

For a business where timing is everything, this manual approach directly hit the supply chain. Employees had to spend hours looking for lost and missing information. Orders were delayed, and unapproved purchases went through unnoticed.

With 80+ users now using centralized procurement software, approvals happen in hours instead of days. Managers approve on the go and have a complete picture of what’s spent on which supplies. Operational costs also went down thanks to the removal of manual work.

Precoro centralized everything:

- Automated approval routing tailored to departments, locations, and expense categories.

- Automated three-way matching of receipts, invoices, and POs.

- Centralized supplier database and catalogs to speed up PO creation.

- Customizable reports with commitments and available budgets at a glance.

Frequently asked questions about supply chain optimization

Supply chain optimization is the process of improving how a supply chain operates so that goods and services are delivered faster, at lower cost, and with higher quality. It involves evaluating and refining key stages such as planning, procurement, manufacturing, storage, distribution, and reverse logistics.

Warning signs that a company needs supply chain planning & optimization include frequent stockouts or overstocks, rising logistics costs, long lead times, inconsistent supplier performance, duplicate or off-contract purchases, and limited visibility into spend or inventory. If you often deal with last-minute budget overruns or struggle with delays, it’s a clear sign that optimizing the supply chain could make a big difference.

Any business that relies heavily on procurement and logistics can benefit from supply chain optimization, but it’s especially valuable in industries with thin margins or strict compliance requirements. In healthcare, it helps reduce unnecessary expenses in medical supplies. In construction, it helps make sure materials that take a long time to arrive are available when needed. With optimized supply chains, logistics can keep track of their deliveries in real time.

The first step of supply chain optimization is identifying bottlenecks. Before you can make things faster, cheaper, or more reliable, you need to see where the chain slows down or breaks. That could be a supplier that often delivers late, a warehouse that runs out of space, or a manual approval process that holds up orders. Once you know the weak spots, you can target improvements that make the biggest difference for your business.

Supply chain management optimization can be difficult because supply chains are complex and often spread across multiple systems, regions, and suppliers. Common issues include poor data quality, resistance to process changes, high costs of legacy tools like ERP modules, and the challenge of balancing cost savings with resilience or sustainability. Some companies also struggle to scale new processes across multiple sites or acquisitions.

Planning decides what needs to happen, like how much to order, when to produce, and where to ship. Optimization focuses on how to make it happen more efficiently, at lower cost, and with less risk. Both supply chain planning and optimization work hand in hand. Planning is the blueprint for the supply chain, while optimization is the fine-tuning that makes those plans work better in practice.

Final thoughts on supply chain optimization

Supply chains are no longer judged only by how cheaply they can deliver goods. Today, leaders face a constant balancing act between cost control, resilience, and sustainability. Freight disruptions, compliance rules like the CSRD, and persistent cost pressures have made it clear that manual processes and fragmented systems won’t cut it anymore.

Supply chain planning and optimization change the game. Companies that take a structured approach and design, plan, and execute their supply chain with data, technology, and collaboration gain real advantages. The most common examples include faster deliveries, lower costs, fewer disruptions, and more reliable service.

Practical steps make a big difference. Identify bottlenecks, map the end-to-end procurement process, standardize workflows, prioritize critical suppliers, build in flexibility for disruptions, and continuously measure and refine performance. Even small changes like automating approvals or centralizing data can affect the entire supply chain and prove valuable, as the case studies from Precoro customers show.

Ultimately, supply chain optimization should be a continuous process that evolves together with your company. Don’t let it stagnate: review processes regularly, track key metrics, and adjust to changes.