14 min read

Vendor Procurement: How to Bring Order to Your Supplier Landscape

Strengthen vendor procurement with practical steps: standardize selection, consolidate your supplier base, and give teams tools to buy the right way.

How many vendors does your company really buy from, and how many of them are unnecessary duplicates? Many SMBs have nine times more suppliers than staff, yet only rely on roughly 25% of them. Although seemingly insignificant, vendor sprawl leads to higher prices, inconsistent quotes, and a long list of low-value suppliers that slowly chip away at the budget.

That’s exactly why companies invest in vendor procurement. Its goal is simple: to keep the business running smoothly without wasting money or taking on avoidable risk.

With prices rising, margins shrinking, and operations spread across different teams and locations, getting control of your supplier list stops being “nice if we have time.” It becomes one of the quickest, most realistic ways to save money, tighten compliance, and bring order to how the company buys. Let’s break down what vendor procurement is and how it helps make that shift.

Scroll down to find out:

What is vendor procurement?

Key components of an effective vendor procurement framework

Don’t fall for these purchasing and vendor management misconceptions

Practical applications & real-life scenarios

Technology, automation, and visibility: The enablers of modern vendor procurement

Frequently asked questions about vendor procurement

Final thoughts on vendor procurement

Centralize your vendor procurement for better control

What is vendor procurement?

Many people use terms like vendor procurement, supplier management, or supplier lifecycle management interchangeably, but there’s an important difference. Vendor procurement is the structured process by which a company identifies, selects, contracts, and manages suppliers for efficient operations and control costs. Simply put, it helps to choose the best vendor fit.

Think of it this way: a company might have dozens of suppliers for office supplies, IT services, or logistics. Some are essential, some are rarely used, and some overlap. Vendor procurement helps businesses review these suppliers, pick key partners, and set formal agreements.

Therefore, it’s not just “buying from vendors.” It covers:

- How you find vendors (sourcing, RFPs, market scans)

- How you approve them (due diligence, KYC, risk checks)

- How you contract with them (terms, SLAs, pricing)

- How you order and pay (POs, approvals, invoices)

- How you evaluate and improve (performance, risk, ESG, cost)

- How you consolidate or replace them over time

In modern organizations, vendor procurement is often part of a procure-to-pay (P2P) or source-to-pay (S2P) framework. Instead of scattered spreadsheets, emails, and ERP add-ons, companies increasingly use centralized platforms that give visibility into all suppliers, contracts, and spending.

What is vendor management in procurement?

Vendor management in procurement focuses on the relationship with suppliers after they join your ecosystem. It ensures strong performance, reduces risks, strengthens collaboration, and enforces compliance over time.

Think of procurement as the “entry and setup” process, while vendor management is the “relationship and performance” phase. Both work hand-in-hand but cover different parts of the supplier lifecycle.

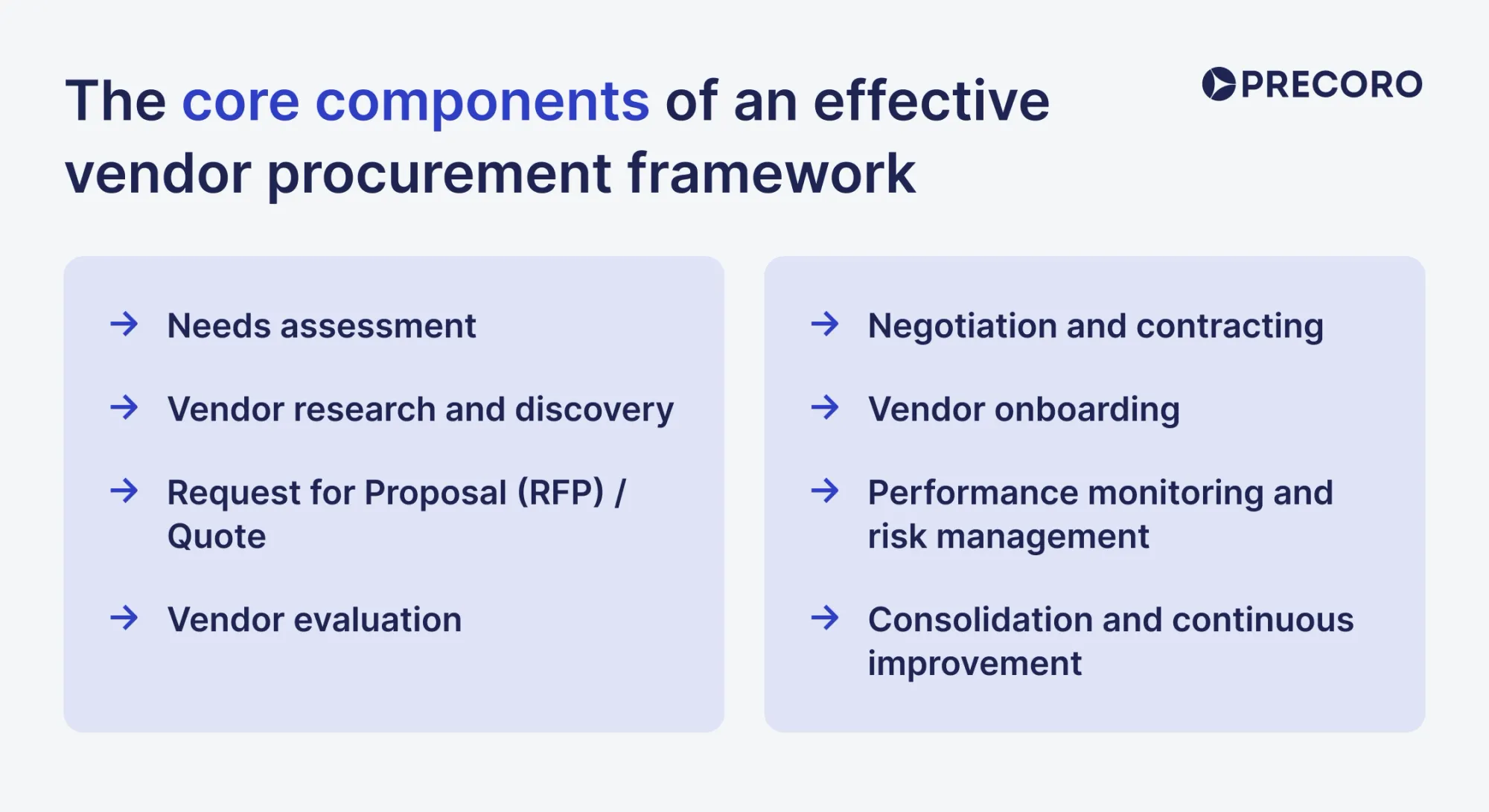

Key components of an effective vendor procurement framework

Effective vendor procurement doesn’t just happen by accident; it requires a clear plan. Here are the key steps in a modern vendor procurement process:

1. Needs assessment

Before engaging suppliers in purchasing and vendor management, define exactly what your team requires. List the goods or services, set quality standards, establish a budget, and agree on timelines. Engage end-users to ensure requirements reflect actual needs, not assumptions.

A clear needs assessment prevents over-ordering, off-contract purchases, and managing unnecessary suppliers. As a bonus, you get clear communication with vendors, trust, and zero confusion later in the process.

Tip: Store requirements in a shared file so all stay aligned and procurement has a clear reference.

2. Vendor research and discovery

Once your requirements are clear, look for vendors who can reliably meet them. Explore industry directories, professional networks, referrals, or online platforms. Evaluate each supplier based on experience, certifications, capabilities, and alignment with your company’s standards and values.

Thorough research helps you avoid surprises later in procurement and vendor management. When you clearly see each vendor’s strengths, weaknesses, and capabilities upfront, you can reduce the risk of delays, quality issues, or compliance problems.

Tip: Keep a shortlist with notes on each vendor to compare options more easily when it’s time to move forward.

3. Request for Proposal (RFP) / Quote

Once you have a shortlist of suppliers, send them detailed RFPs or RFQs. Include the exact requirements, deadlines, evaluation criteria, and key terms. The goal is to establish a transparent, fair, and competitive vendor selection process in procurement so suppliers know what you expect and can provide comparable proposals.

A clear RFP prevents confusion, reduces back-and-forth, and makes it easier to evaluate offers objectively. Suppliers are more likely to meet your requirements if they understand them upfront.

Tip: Standardize your RFP template to cover all critical points, including scope, timelines, quality standards, pricing expectations, and compliance requirements. This approach ensures every supplier responds in a comparable format.

4. Vendor evaluation

After receiving proposals, evaluate them against a set of objective criteria, such as price, quality, delivery timelines, and flexibility. Include additional checks like financial stability, certifications, regulatory compliance, and ESG performance if relevant. Also, consider site visits or virtual tours to verify capabilities and reliability.

Objective evaluation prevents bias, highlights the best-fit suppliers, and reduces the risk of selecting a vendor that might cause delays, quality issues, or compliance problems.

Tip: Use a scoring matrix to rate each proposal on the same criteria. It makes comparisons transparent and helps justify purchasing and vendor management decisions to stakeholders.

5. Negotiation and contracting

Once you’ve identified the preferred supplier, negotiate pricing, payment terms, service levels, and delivery commitments. Draft a contract that clearly states deliverables, timelines, responsibilities, and penalties for non-performance.

Well-defined contracts make obligations clear and offer a clear point of reference if issues arise. It’s important to cover potential risks and “what-if” scenarios early to prevent disputes later in the vendor procurement process.

Tip: Keep the contract simple but comprehensive. Include key clauses for performance metrics, reporting, compliance, and escalation procedures.

6. Vendor onboarding

Once you select a supplier, provide clear guidance on workflows, approval procedures, invoicing, and communication channels. Make sure suppliers know who to contact for questions and how your internal procurement and vendor management processes work.

Proper onboarding helps you avoid confusion, reduce errors, and ensure suppliers can deliver as expected from day one. Leave no room for misunderstandings in the future.

Tip: Create a standardized onboarding checklist to make sure every supplier completes the same steps and provides all necessary documentation upfront.

7. Performance monitoring and risk management

Track supplier performance using KPIs such as quality, delivery timeliness, compliance with contracts, and cost efficiency. Schedule regular reviews to identify and resolve issues promptly. Keep detailed records to support reporting and audits. When evaluating performance, also consider risks such as financial stability, regulatory changes, and ESG compliance to ensure a well-rounded assessment.

Monitoring performance prevents small problems from becoming big issues in purchasing and vendor management. It ensures suppliers meet your standards consistently and reduces risk to your operations.

Tip: Use a scorecard or dashboard to visualize supplier performance over time. This approach makes it easier to spot trends and take corrective action.

8. Consolidation and continuous improvement

Regularly review your vendor list to identify duplicates, low-value suppliers, or those who underperform. Consolidate spend with preferred vendors to negotiate better pricing, reduce administrative overhead, and simplify procurement management.

A well-established supplier base saves money and makes procurement and vendor management more strategic. It also strengthens relationships with key suppliers, which can improve service quality and innovation.

Tip: Schedule regular reviews of your supplier base (either quarterly or biannually). Tie consolidation decisions to clear business goals like cost savings or better service.

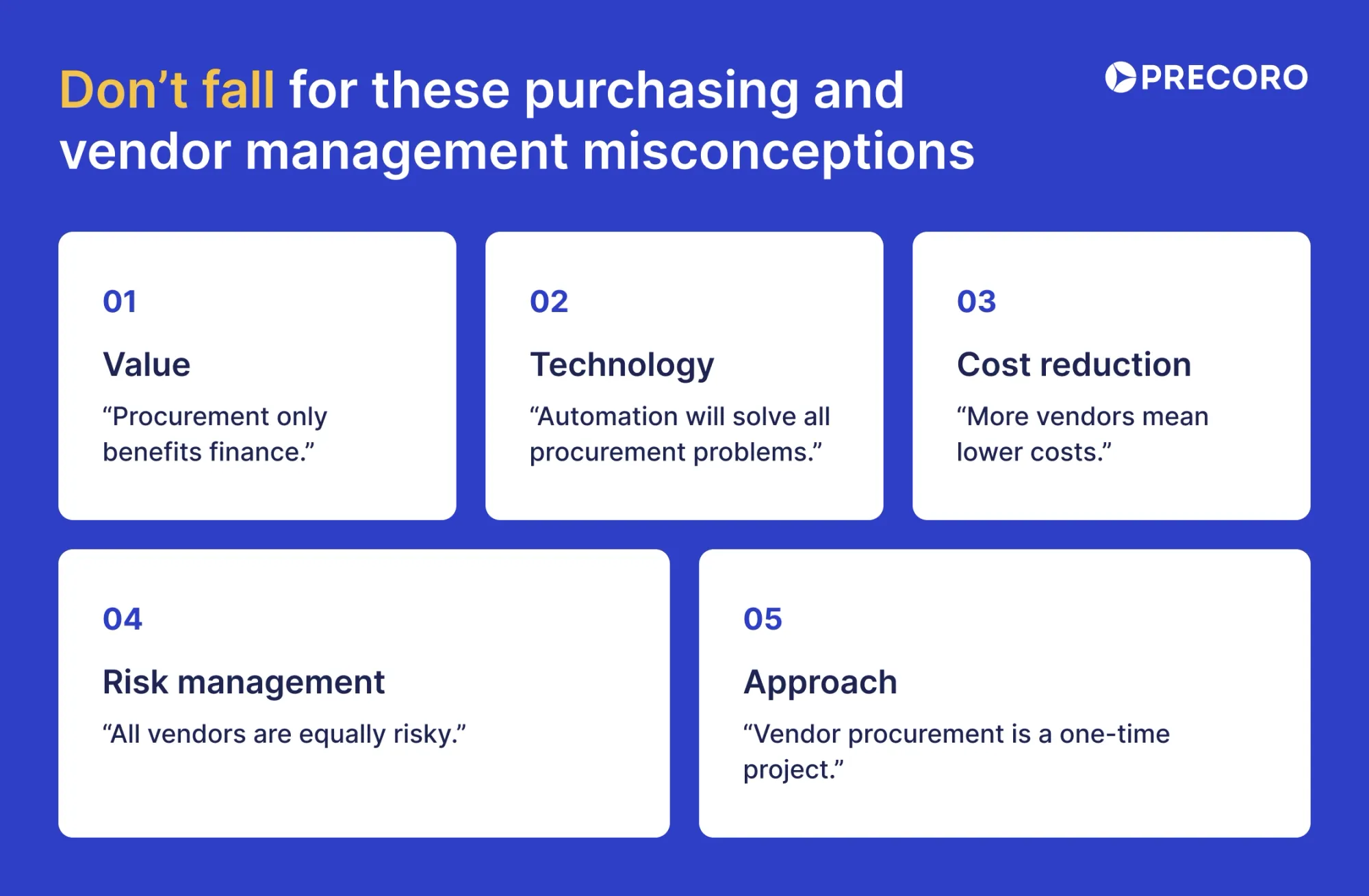

Don’t fall for these purchasing and vendor management misconceptions

Vendor procurement and management come with plenty of assumptions that don’t always hold true. Falling for these myths can slow down your processes and cost your company money. Let’s debunk the most common ones.

“Procurement only benefits finance.”

Many people assume procurement exists solely to save money for the finance team. While cost control is important, that’s just one piece of the puzzle. Vendor procurement affects the whole business: it ensures operations run smoothly, projects stay on schedule, and employees get the tools and services they need to do their jobs effectively.

If procurement focuses only on price, teams may struggle with unreliable suppliers, delayed deliveries, or subpar service. This approach can frustrate employees, slow down projects, and even block innovation initiatives.

Instead, think of procurement as a bridge between finance, operations, and other teams. It’s important to engage stakeholders in the vendor selection process in procurement, set clear expectations, and track performance not just by cost, but by reliability, quality, and service.

“Automation will solve all procurement problems.”

It’s tempting to think that once you have an automated system, your vendor procurement is “fixed.” But automation can speed up processes without improving decisions if you rely on incomplete or inconsistent information. According to McKinsey, data issues are still a major barrier for CPOs who try to realize the full potential of procurement automation.

The real power of automation comes when it’s paired with clean vendor data, clear rules, and strong spending visibility. With dashboards and reporting tools, your teams can spot duplicates, off-contract spending, or high-risk suppliers early on, and gain insights for smarter and faster decisions later on.

“More vendors mean lower costs.”

Some companies believe that adding more suppliers will increase competition and drive prices down. In practice, too many vendors in the same category dilute your buying power, create more paperwork, and make negotiations harder. Teams end up spending more time managing invoices and communications instead of securing better deals.

Instead, focus on a smaller group of preferred vendors. Spend consolidation allows you to negotiate volume discounts and build stronger relationships. Suppliers who see you as a strategic partner are more likely to deliver better service, faster problem resolution, and even innovative ideas.

“All vendors are equally risky.”

It’s easy to assume that every supplier carries the same risk, but in reality, each vendor comes with its own profile of potential challenges. A small local office-supply vendor is very different from a global logistics partner or a critical IT service provider. In fact, risks vary widely, from financial instability, regulatory or compliance issues, and operational disruptions to ESG concerns or reputational exposure.

If you don’t assess risk individually, a single underperforming or non-compliant supplier could cause delays, incur penalties, or damage your company’s reputation. At the same time, over-monitoring low-impact vendors wastes time and resources.

Develop a risk matrix that rates suppliers on financial stability, compliance, operational importance, and ESG factors. Then, focus audits on high-risk vendors and monitor low-risk ones less intensively. Let your team spend time where it matters most.

“Vendor procurement is a one-time project.”

Vendor procurement indeed might seem like a checklist: set up suppliers, sign contracts, and move on. Yet it’s much more than that. Markets change, supplier performance varies, and business needs evolve. If you never revisit your vendor list, you risk outdated contracts, duplicate suppliers, and missed opportunities for savings.

Regularly review your suppliers and contracts, at least quarterly or twice a year. Check performance, adjust your vendor base, and ensure that the vendor selection process in procurement aligns with your current business needs. Keep procurement strategic rather than reactive.

Practical applications & real-life scenarios

Vendor procurement shapes how work actually gets done. Let’s examine how you can use it to save time, reduce costs, and make operations more predictable.

Clean a chaotic vendor master

Companies often realize they maintain far too many active vendors for the same categories (office supplies, maintenance, logistics, and so on), and many are duplicates or rarely used. The first step is to analyze spending by vendor, category, and location to see where money actually goes.

From there, identify suppliers that add little value or overlap with others, and consolidate your spend with a smaller, more strategic group. This approach makes negotiations easier, reduces the number of invoices, and simplifies compliance.

Standardize vendor procurement across locations

In companies with multiple locations, each site often works with its own set of suppliers and informal agreements. This fragmented purchasing and vendor management can lead to big differences in pricing and leave central finance in the dark.

Creating a central catalog of approved vendors and items, along with consistent approval processes and budgets, brings order without tying teams’ hands. Local teams can still get what they need, but prices stay predictable, centralized control improves, and everyone spends less time navigating confusion.

Embed vendor procurement into procure-to-pay (P2P)

Finance teams often get bogged down by invoice mistakes, disputes, and manual reconciliations. Connecting your procurement and finance systems makes it easy to stay on top of every transaction.

Only approve invoices from suppliers linked to purchase orders, and keep vendor information synced between your procurement tool and ERP or accounting system. This way, your teams can spot off-contract spending quickly, minimize errors, and keep your budget under control.

Technology, automation, and visibility: The enablers of modern vendor procurement

Vendor procurement goes beyond choosing the right suppliers. You also need the systems and visibility to manage them consistently across the whole business. Technology is what turns good procurement intentions into repeatable, scalable processes. Here’s how:

Central vendor management systems vs. spreadsheet-based setups

Many companies still manage vendors in spreadsheets. This approach creates several problems:

- Data gets outdated.

- Duplicates appear

- Nobody’s sure which vendor is actually approved

- Every department tracks things differently

A dedicated system for vendor management in procurement gives you one clean, unified source of truth. You can control who gets added, enforce documentation requirements, and keep all vendor information in sync with your purchasing and AP workflows.

How Precoro helps:

Precoro keeps one unified vendor database across procurement, finance, and AP. Vendor profiles, documents, terms, and categories stay consistent across the entire P2P flow, so you don’t have to deal with conflicting spreadsheets or shadow vendor lists.

Automated workflows for onboarding, approvals, and renewals

Manual onboarding slows everything down. Someone emails a vendor form, then someone else double-checks compliance, but nothing is standardized, and that’s where errors creep in.

Automation creates structure:

- Vendors submit required details and documents once.

- Compliance or risk checks happen before the vendor is activated.

- Vendor and purchase approvals follow a predefined workflow.

- Contract or vendor reviews trigger automatically before expiration.

That’s how procurement and vendor management tools can remove bottlenecks and ensure vendors meet your standards before they show up in your system.

How Precoro helps:

Precoro integrates vendor onboarding into the procurement flow. Approval workflows, document requirements, and vendor status checks are built in, so you don’t end up with unvetted vendors entering the P2P cycle.

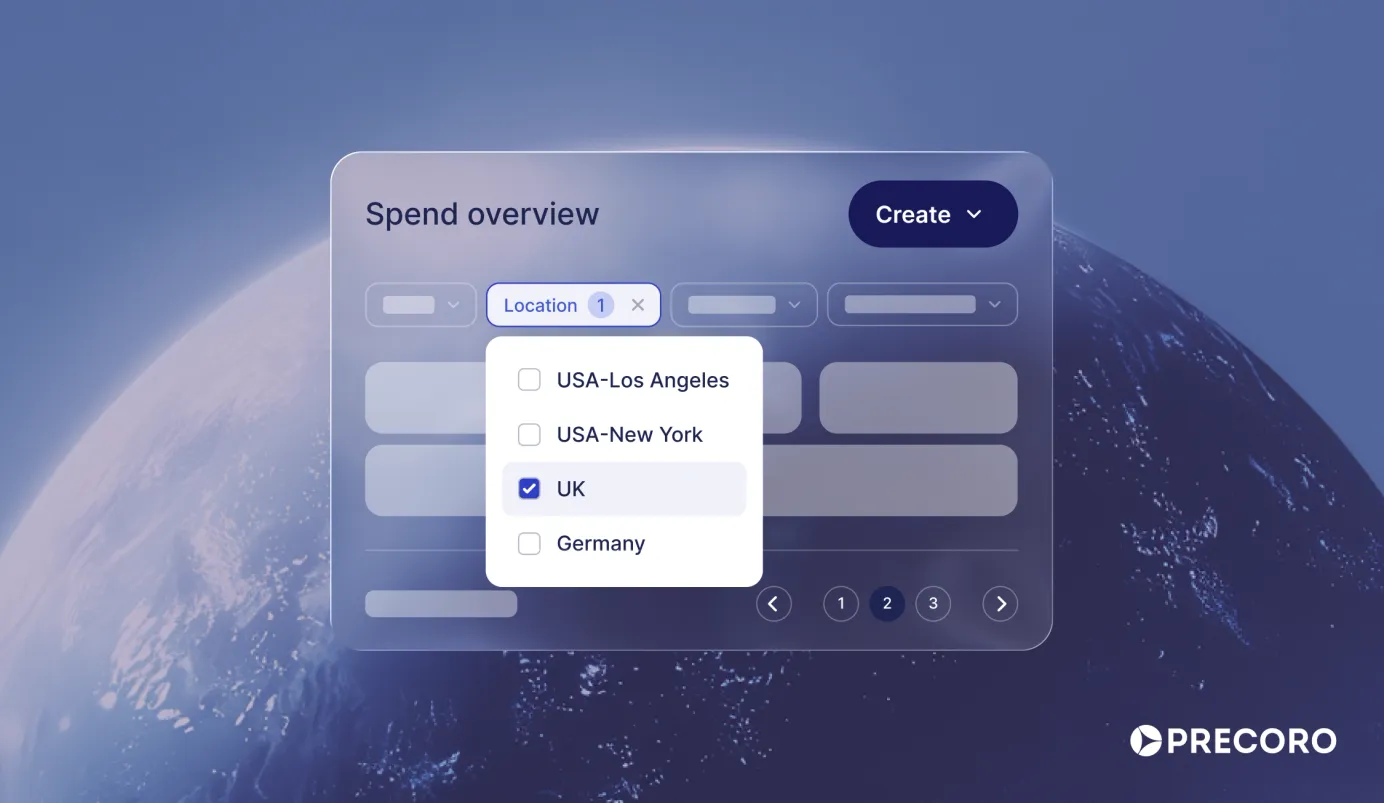

Spend analytics: seeing who buys what, from whom, and at what price

If you can’t see the full picture of your spending, you can’t control it. Analytics turn scattered purchases into actionable insight, such as:

- Vendors that receive the most of your spend

- Categories with too many suppliers

- Price variations across locations

- Off-contract or out-of-policy purchases

- Opportunities to consolidate and negotiate

This spend visibility shifts vendor procurement from reactive to strategic.

How Precoro helps:

Precoro’s dashboards and filtering let teams instantly see spend by vendor, category, location, project, requester, or time period. It’s easy to compare suppliers, spot anomalies, and identify consolidation opportunities.

Frequently asked questions about vendor procurement

Vendor procurement focuses on the buying side: identifying vendors, evaluating options, negotiating terms, creating contracts, and approving suppliers. Vendor management, on the other hand, covers everything after onboarding—monitoring performance, managing risks, reviewing contracts, ensuring compliance, and maintaining the relationship over time. The two processes aren’t separate but form two halves of the same vendor lifecycle.

There isn’t a universal number, because it depends on industry, scale, and complexity. But there are clear signs that your vendor list has grown out of control:

- You have multiple vendors supplying the same items or services.

- You see large price variance for identical SKUs across locations or departments.

- Your accounts payable team is overwhelmed with too many invoices from too many small vendors.

- No one can clearly explain why certain vendors are still active or how they were approved.

Yes, especially once the company grows beyond a single office or location. When spending is spread across teams, projects, or branches, informal purchasing quickly leads to different locations using different vendors for the same needs. As a result, you have to deal with missed volume discounts and off-contract buying. A simple, structured vendor procurement process prevents these issues without adding unnecessary bureaucracy.

Yes, but only when done poorly. If every request turns into a bottleneck, employees will find workarounds. The key is to combine control with usability. Use guided intake forms that are simple and user-friendly, so requests always include the necessary data. Set up budgets, approval workflows, and product catalogs, so the system enforces policy without slowing people down. With pre-approved vendors and PunchOut catalogs, making the “right choice” becomes the fastest and easiest option for your teams.

Final thoughts on vendor procurement

Organized vendor procurement creates clarity and control, not extra red tape. Most companies don’t struggle because they lack suppliers, but because they have too many vendors, spread across too many teams, with too little visibility. When you consolidate where it makes sense and establish a simple yet consistent process, you unlock the kind of savings, stability, and predictability that make day-to-day operations run more smoothly.

A strong vendor procurement framework gives you leverage: better pricing, cleaner data, fewer mistakes, and a clearer picture of how your organization actually buys. Additionally, it gives your teams confidence, as they know which vendors to use, how to make requests, and what to expect.

In the end, effective procurement and vendor management come from a set of simple, practical moves: set clear criteria for selecting suppliers, define who approves what, use technology that keeps your data accurate, and review your vendor base on a regular schedule. When these pieces fall into place, supplier management stops being a constant headache and becomes a real advantage for the entire company.

Centralize your vendor procurement for better control

Automation helps, but the real impact comes from centralizing the process. Precoro organizes vendor information, contracts, budgets, requests, purchase orders, and invoices in one place, so teams follow the same rules and finance always has full visibility.