18 min read

Global Sourcing 101: Meaning, Benefits, Challenges, and Trends

Learn how global sourcing works, explore its advantages, and understand how to manage suppliers effectively across borders.

After years of pandemic disruptions, shipping bottlenecks, and geopolitical tension, many expected companies to pull back and localize their supply chains. Yet the opposite is happening. A 2025 QIMA survey of more than 650 firms found that nearly two-thirds still plan to maintain or expand business with Chinese suppliers for global sourcing and procurement, despite tariff pressures and trade friction.

The reason is simple: global networks still deliver scale, cost efficiency, and speed — advantages too valuable to abandon. But the rules of the game have changed. Supply chains built for low-cost efficiency now face the test of resilience, compliance, and sustainability. What once worked seamlessly across borders must now adapt to new realities shaped by shifting U.S. trade policies, evolving EU regulations, and China’s drive for localization.

In this environment, global strategic sourcing can no longer rely on cost alone. It must meet new regulatory expectations, and pivot quickly toward opportunity — whether in India, Southeast Asia, or the Middle East.

Read on, as we reveal what global sourcing is, its benefits, challenges, trends, and the best countries for international sourcing.

What is global sourcing?

5 types of global sourcing

Benefits of global sourcing

Challenges in global sourcing

What are the best countries for global sourcing in 2025?

How to find the right global suppliers

Global vs. local sourcing: Which is right for your procurement strategy?

How to build a successful global sourcing strategy

Key global sourcing trends to watch

How Precoro helps with global sourcing

How Precoro works in practice, when it comes to global sourcing

Frequently asked questions about global sourcing

What is global sourcing?

Global sourcing is a procurement strategy where a company looks beyond its home country to find the best suppliers for goods, materials, or services. For instance, an electronics company might find it cheaper to source circuit boards in South Korea due to advanced manufacturing capabilities and lower costs. It could still keep assembly at home to stay close to customers and maintain quality control.

However, global sourcing goes beyond simply looking for products worldwide. It also aims to improve key aspects of the supply chain, including:

- Supplier selection and performance

- Speed to market

- Product cost estimation

- Trade compliance

- Auditing

For example, Apple sources rare-earth minerals used in its devices from countries such as China and Australia. The main benefits of global sourcing are reduced costs and improved quality. It unlocks many possibilities, from buying top-grade Indian cotton for textiles to sourcing premium steel from Germany.

Global sourcing examples

Global sourcing needs vary by industry. Manufacturers manage complex supply chains, sourcing raw materials, components, and equipment that meet strict quality and regulatory standards. Wholesalers and retailers focus on finished products, while service companies rely on software and external partners.

Restructuring efforts also differ by region and business priorities. Below are a few global sourcing examples:

Walmart, operator of one of the world’s largest international supply chains, is transforming its global sourcing through advanced automation and agentic AI — systems capable of taking autonomous actions rather than just generating recommendations.

Key capabilities:

- Predictive intelligence: AI models forecast demand and automatically reroute inventory across markets in Costa Rica, Mexico, and Canada.

- Operational efficiency: Automation reduces waste and simplifies routine tasks.

- Generative AI for innovation: Artificial intelligence identifies emerging consumer trends and turns ideas into products on shelves in as little as six weeks.

- Smart monitoring: Cameras and real-time performance tracking detect stockouts early, allowing agentic AI to redirect products before shortages occur.

Impact:

Walmart’s use of agentic and generative AI marks a major step toward a self-optimizing, responsive supply chain, where intelligent systems continuously learn, decide, and act to improve performance and reduce inefficiencies.

Lego, the Danish toy company selling in over 130 countries, is expanding its global manufacturing and distribution network to strengthen resilience and speed to market. The company’s procurement sourcing strategy emphasizes locating production closer to key consumer regions to minimize shipping times and reduce exposure to global trade risks.

Key capabilities:

- New regional hubs: Opened a second Asian factory and distribution center in Vietnam (2025), complementing existing operations in China.

- Announced a North American production and logistics center in the United States (opening in 2027), in addition to current facilities in Mexico.

- Global balance: Maintains manufacturing sites in Europe to ensure diversified regional coverage.

- Tariff awareness: Expansion into Vietnam aligns with industry trends driven by high U.S. tariffs on Chinese imports, enabling cost and trade flexibility.

Impact:

Lego’s geographic diversification supports a regionalized production model that enhances supply chain resilience, reduces delivery times, and mitigates tariff exposure. It illustrates a proactive shift toward localized manufacturing ecosystems across global markets.

5 types of global sourcing

Global sourcing develops through five key stages, starting with local purchasing and advancing toward a fully connected global sourcing system. The five levels are:

-

Domestic purchasing is the most basic procurement sourcing strategy, in which a business purchases from suppliers within its own country. Typically, companies use it to cut shipping expenses and support local industries.

-

At the second level — international sourcing — businesses find suppliers outside their own country, which opens new opportunities for cost savings and access to a fast-growing international market.

-

International procurement is the stage where businesses formalize how they buy goods and services from international suppliers. It requires strategic planning and attention to detail. Companies at this level establish specific standards to evaluate and select suppliers, negotiate detailed contracts, and implement systems to monitor quality. They also seek global efficiency, aiming to lower costs, shorten delivery times, and reduce cross-border risks. This structured approach helps companies build strong, long-term partnerships with trusted suppliers worldwide.

-

Centralized procurement across global locations consolidates purchasing activities from different business units into a single, coordinated system. It relies on strong communication, shared rules, and tools like source-to-pay platforms to make global purchasing more efficient and cost-effective across the organization.

-

An integrated global sourcing strategy is the highest level of sourcing, where procurement activities are fully coordinated and aligned across all global operations. At this stage, businesses strategically manage sourcing and trading with a broad network of international suppliers to maximize efficiency, quality, and competitiveness.

Benefits of global sourcing

Beyond cost-cutting, global sourcing helps companies achieve many other goals, such as:

1. Scalability

Global sourcing allows companies to grow without hitting capacity limits. By working with multiple suppliers in different regions, businesses can scale production up or down quickly without relying on a single source.

2. Supply chain resilience and risk reduction

Diversifying suppliers across multiple countries reduces exposure to regional risks such as tariffs, political instability, or natural disasters. It makes the supply chain more stable and adaptable.

3. Access to innovation, technology, and expertise

Sourcing globally connects companies with new technologies, advanced manufacturing capabilities, and specialized talent. Some regions lead in specific R&D areas, giving businesses early access to innovations not yet available locally.

4. Market expansion opportunities

Working with suppliers in a particular region can help businesses understand local practices, regulations, and customer behavior — opening the door to entering that market as a seller and building long-term global purchasing relationships.

5. Strengthened competitive advantage

By lowering production costs while maintaining or improving quality, companies can reinvest in growth, improve product offerings, and stay ahead of competitors in global markets.

Ultimately, the key advantage of global strategic sourcing is flexibility — it lets companies respond to changing conditions and secure the best value.

Challenges in global sourcing

Challenges in global strategic sourcing are multifaceted, spanning logistics, cultural, political, and regulatory domains. Key challenges include:

- Logistics and transportation costs: Companies can face high logistics expenses, complex customs, long transit times, and risks of supply chain delays due to crossing international borders.

- Cultural and language differences: Communication barriers and misunderstandings arising from diverse languages and cultural norms can disrupt collaboration and lead to production or quality issues.

- Political and economic instability: Changes in government policies, geopolitical tensions, trade restrictions, sanctions, and financial volatility in sourcing countries can threaten supply continuity and increase business risks.

- Quality control: Ensuring consistent product quality across countries with varying production standards, regulatory requirements, and quality of global purchasing practices requires rigorous monitoring and inspections.

- Ethical and social responsibility: Addressing ethical concerns related to labor standards, environmental sustainability, and social responsibility is critical to avoid reputational damage and legal issues.

- Regulatory compliance: Navigating complex, divergent international laws, trade regulations, customs requirements, and industry standards adds complexity and cost.

- Supply chain complexity and risk: Geographical dispersion of suppliers increases vulnerability to transportation delays, customs issues, and disruptions from geopolitical or environmental events.

- Currency fluctuations: Exchange rate volatility complicates cost forecasting and budgeting.

- Technological disruption and talent shortage: Implementing advanced global sourcing and procurement technologies demands skilled professionals, and talent shortages pose challenges.

- Data security and cybersecurity threats: Rising reliance on digital procurement systems increases exposure to cyber risks.

What are the best countries for global sourcing in 2025?

The ideal country for global sourcing depends on your industry, goals, and risk appetite — but certain nations consistently stand out due to their low costs, skilled labor force, and strong market access.

- China is still the go-to for electronics, apparel, and large-scale production. Its well-developed infrastructure and massive supply networks make it hard to beat in terms of efficiency. That said, rising costs and ongoing geopolitical tensions have prompted many companies to look elsewhere as part of their risk management strategy.

- India stands out for IT services, pharmaceuticals, textiles, and home goods. It offers a strong mix of low-cost, skilled labor and high English fluency. Plus, its digital procurement and industrial infrastructure is improving quickly, which adds even more appeal for global strategic sourcing and services.

- Vietnam has gained serious traction recently. Thanks to trade deals like the CPTPP and EVFTA, tariffs are low, which is a big plus. It's become a favorite global sourcing destination for footwear, apparel, and furniture. Many companies rely on sourcing software for Vietnam to manage suppliers and control cross-border purchases.Costs are competitive, and the political environment is relatively stable, making it a smart choice for companies diversifying out of China.

- Mexico is rising fast — especially for U.S. companies interested in nearshoring. Its closeness to the U.S., lower freight costs, and membership in the USMCA make it a strong global sourcing hub for auto parts, consumer goods, and packaging. The time zone alignment and fast delivery cycles are also big advantages.

- Eastern Europe, particularly Poland and Romania, is catching attention in sectors that require skilled labor and strong quality standards — think automotive, machinery, and IT. Its location near Western Europe, cultural fit, and growing infrastructure make it a solid option within the broader global sourcing landscape.

Note!

Don’t vote for the cheapest option when choosing where to source from. Consider also the country's financial and political stability, the reliability of its currency, whether it meets your quality standards, and how it handles unexpected supply chain issues.

Answer a few quick questions to see which sourcing country best fits your current business priorities.

How to find the right global suppliers

You can’t spot reliable global sourcing partners in a single click; success comes through research and disciplined outreach.

Online sourcing platforms help connect buyers with qualified international suppliers. They let you compare quotes, check ratings, and contact vendors directly. Filters by region, product type, or specialization make supplier selection faster and more precise.

Trade shows and local agents also play a vital role in global sourcing. Trade fairs let you inspect products firsthand, ask questions, and build trust. Local agents or sourcing consultants understand business culture and help prevent costly miscommunication.

Request for Quotation (RFQ) best practices are key. A clear, detailed RFQ with product specs, quality standards, timelines, and payment terms helps suppliers respond accurately. It also signals professionalism and sets the stage for lasting partnerships.

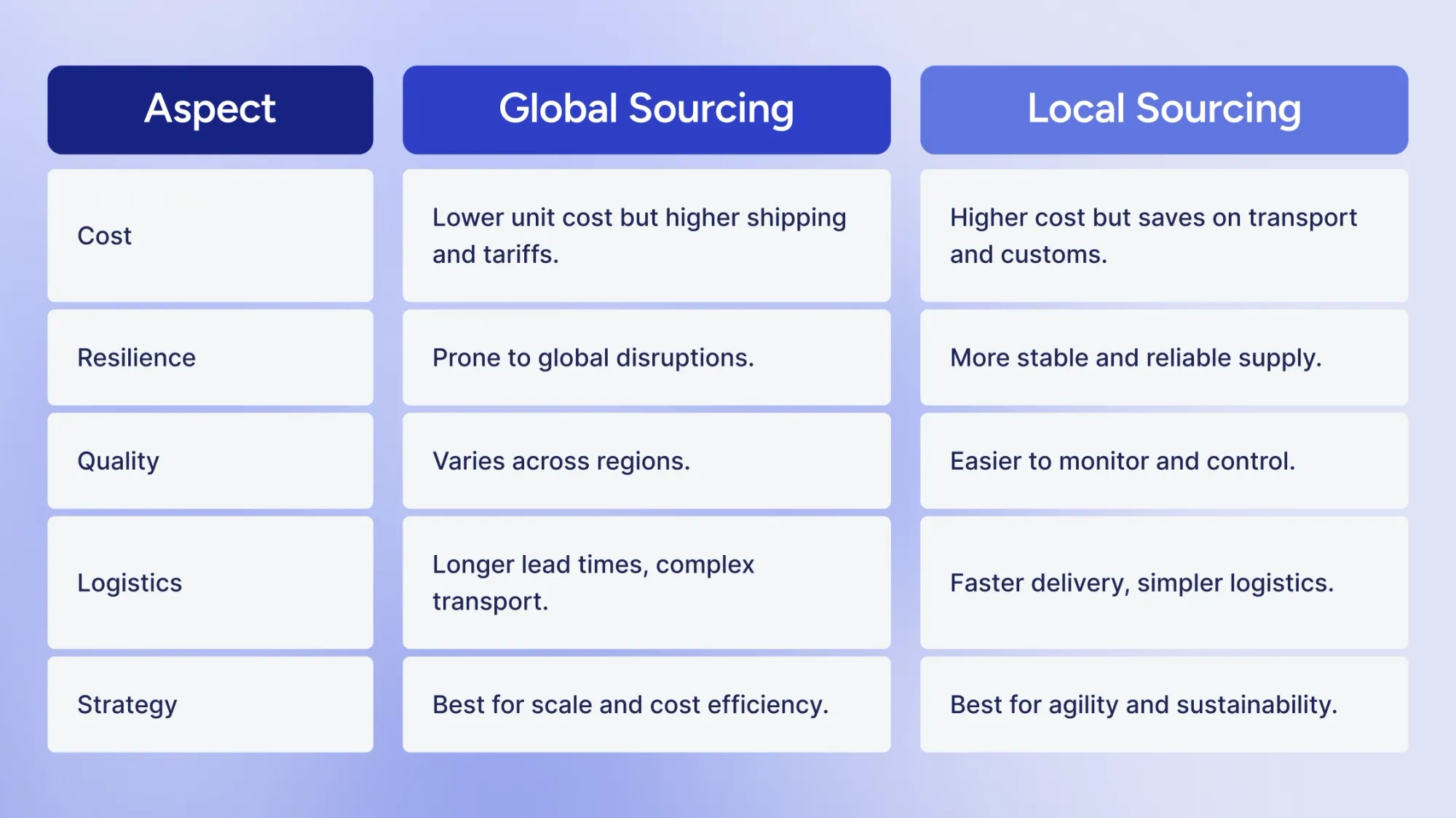

Global vs. local sourcing: Which is right for your procurement strategy?

Global sourcing vs. local sourcing: two procurement models with different strengths, risks, and strategic implications. Understanding how each affects your supply chain and operations is essential for making informed sourcing decisions. Here's what differentiates them.

- Cost of fulfilment: Global sourcing may reduce unit costs due to lower labor or production costs abroad, but consider additional logistics and tariffs. Local sourcing tends to have higher unit costs but saves on shipping and customs.

- Supply chain resilience: Local sourcing can mitigate risks from international disruptions, such as political instability or pandemics, ensuring a more consistent supply.

- Quality and reliability: Local suppliers may offer better control and faster communication; global suppliers may vary widely.

- Logistics: Shorter distances in local sourcing reduce lead times and transportation issues.

- Strategic goals: Global sourcing suits larger, globally diversified companies aiming for cost leadership and product range expansion. Local sourcing works best for companies that prioritize agility, sustainability, and support for local markets.

Note!

In sum, to decide which sourcing strategy fits your procurement, evaluate your cost priorities, risk tolerance, supply chain complexity, product requirements, and strategic objectives. After all, the global sourcing meaning today lies in finding the right balance — a hybrid approach that blends cost efficiency with supply chain stability and market agility.

How to build a successful global sourcing strategy

An effective global procurement sourcing strategy starts with thorough due diligence. Companies need to look closely at each supplier’s capabilities, financial stability, quality standards, regulatory compliance, and reputation. This process often includes supplier audits and on-site visits to confirm reliability and operational soundness — you can’t just blindly trust what’s written on paper. Doing this groundwork helps ensure that a company chooses dependable partners who are aligned with its long-term goals.

Next comes clear objectives and supplier identification. A procurement sourcing strategy only works when it’s built around well-defined objectives. Businesses should define and prioritize goals that directly align with what they want to achieve — whether it’s reducing costs, improving quality, or entering new markets. Once these objectives are clear, thorough market research becomes the next step to identify suppliers and sourcing regions that can meet those specific needs. This clarity keeps the sourcing process focused and efficient.

You can't have an effective global sourcing strategy without strong supplier relationships and communication. Building collaborative, transparent relationships with suppliers involves open communication, goal alignment, and mutual respect. With the help of e-procurement systems and digital tools, teams stay connected across time zones, exchange updates instantly, and resolve issues quickly. A supplier who feels like a partner rather than an average vendor is far more likely to deliver consistent quality and support long-term success.

No procurement sourcing strategy is complete without preparing for uncertainty. Companies should develop risk management and contingency planning that include supplier diversification, backup options, and ongoing quality control. Being proactive about geopolitical shifts, regulatory updates, or market changes helps reduce vulnerability to disruptions. The goal is to build flexibility into the supply chain so it can adapt when the unexpected happens.

The next step is to consider strategic sourcing and evaluation. Choosing the right supplier is as much about structure as it is about intuition. A well-organized evaluation process — considering pricing, production capacity, compliance, technology, and financial health — helps companies make informed choices. Careful bidding, negotiation, and contract management ensure transparency and fairness throughout the selection process.

Finally, all strategies need continuous monitoring and optimization. Global sourcing isn’t a one-time project — it’s an ongoing process. Regularly reviewing supplier performance, studying market trends, and monitoring costs help companies refine their global sourcing strategies and stay competitive. As business needs and external conditions evolve, sourcing plans should evolve too.

Key global sourcing trends to watch

Technology, climate concerns, and political shifts are changing how global sourcing works. These are some of the top trends:

Digital transformation and automation

With the help of AI-driven global sourcing and procurement tools, predictive analytics, and robotics, companies can more effectively evaluate suppliers, automate logistics, and anticipate supply chain disruptions in real time. Smart sourcing leverages AI, machine learning, and big data analytics to optimize supplier selection and risk management.

Sustainability and ESG integration

Environmental, social, and governance (ESG) criteria have become central to sourcing decisions. Companies prioritize suppliers with eco-friendly operations, fair labor standards, and ethical governance, building trust and long-term value.

Regional diversification and friendshoring

Due to geopolitical risks and rising labor costs, there is a shift from over-reliance on China toward friendshoring — partnering with politically allied countries such as India, Vietnam, Mexico, Taiwan, and Eastern Europe. Nearshoring, or sourcing closer to home markets, also gains traction to reduce lead times and supply chain disruption risks.

Transparency and traceability via blockchain

Blockchain technology is increasingly deployed to offer tamper-proof records, which ensure transparency from raw materials to finished goods, enhance compliance, reduce fraud, and increase consumer confidence.

Strategic supplier partnerships

Global sourcing and procurement is evolving from a transactional to a collaborative model. Companies build deeper partnerships focused on joint innovation, shared goals, and co-creation, resulting in more responsive, agile, and resilient supply chains.

Geopolitical and regulatory shifts

Heightened tariffs, export controls, and trade regulations, especially in high-tech sectors, require companies to rethink sourcing strategies, favoring reshoring or diversifying production hubs to maintain supply chain resilience.

Supply chain resilience

Companies stay agile and manage risks with technology that keeps track of market trends, tariffs, and supplier performance. They also prioritize sourcing locations that provide both cost savings and geopolitical stability.

How Precoro helps with global sourcing

Centralized global procurement management

Precoro consolidates all procurement activities — from purchase requests to approvals and payments — into one centralized system. It replaces scattered spreadsheets and siloed communication channels, giving global teams real-time visibility into every transaction, supplier, and budget. By providing a single source of truth, Precoro reduces miscommunication and ensures accountability across international operations.

Automated supplier and compliance management

With Precoro, global sourcing teams can easily onboard, track, and manage international suppliers. The platform simplifies supplier data collection, document storage, and compliance checks, helping companies adhere to country-specific tax and import/export regulations. Automated alerts ensure that supplier certifications and contracts are always up to date, minimizing the risk of delays or regulatory fines.

Speeded-up purchase-to-pay workflows

Global procurement often involves complex workflows with multiple currencies, approval hierarchies, and cost centers. Precoro automates these processes with customizable approval chains, automated purchase order (PO) creation, and real-time budget tracking. As a result, teams around the world can operate efficiently, while management retains full control and oversight of expenditures.

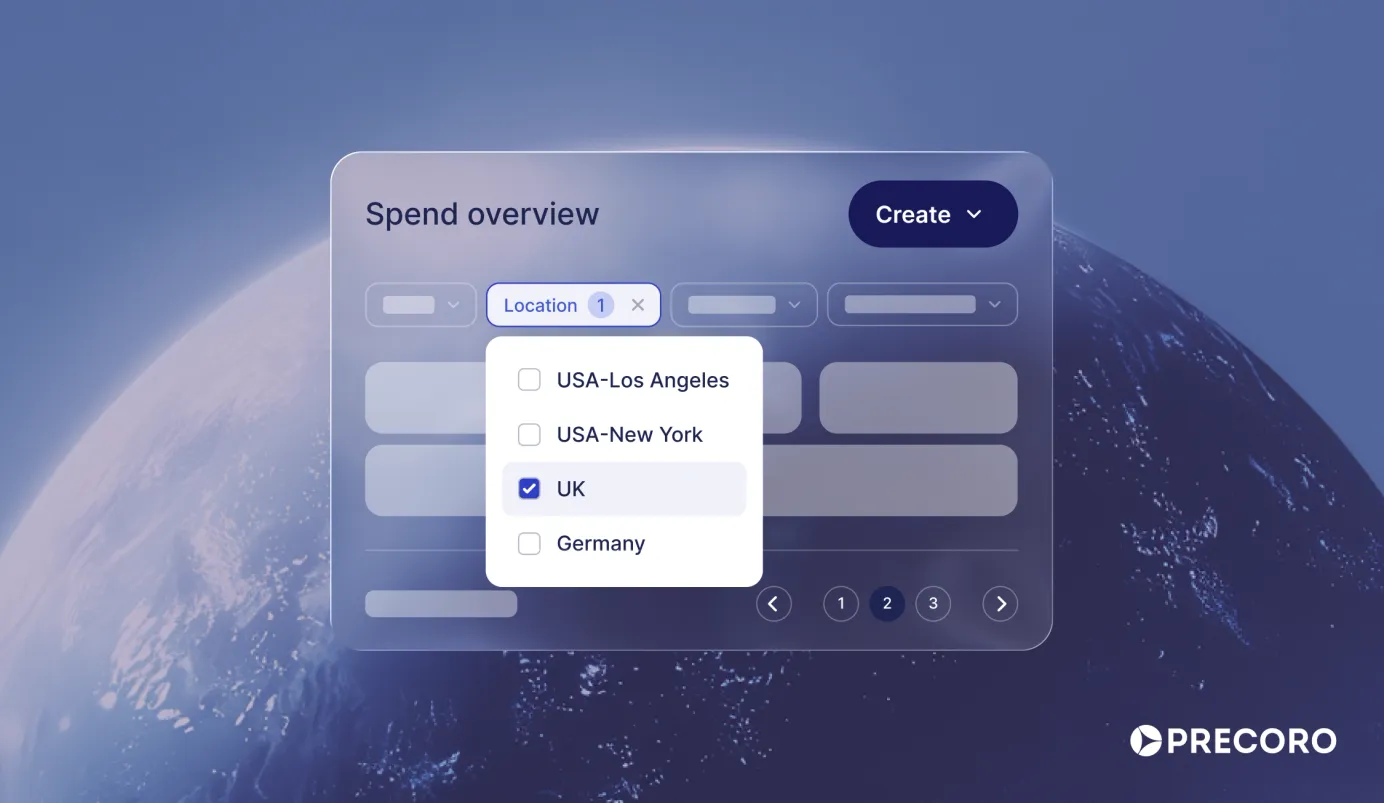

Real-time spend visibility across borders

Precoro’s analytics dashboards give procurement and finance teams a holistic view of global spending. Users can filter and analyze purchases by region, supplier, or category, allowing for better forecasting, spend optimization, and supplier negotiation. This data-driven visibility helps organizations identify cost-saving opportunities and maintain budget discipline across global operations.

Integrations for global finance efficiency

Precoro integrates seamlessly with popular ERP and accounting systems, syncing data across platforms to prevent duplicate entries and manual work. That’s how companies ensure accurate financial reporting and easy reconciliation for international transactions. Combined with automated approval and invoice matching, these features help global teams accelerate procurement cycles while maintaining accuracy and compliance.

How Precoro works in practice, when it comes to global sourcing

Let’s look at how Precoro fits into a real global sourcing scenario — say, a company buying components from Asia, Europe, and Latin America:

- The sourcing team uses Precoro to onboard new suppliers in each region. The forms capture all the important details: local compliance requirements, certifications, banking information, and even language and currency preferences.

- Buyers in Asia (and other areas) submit purchase requests through Precoro, and the approvals follow built-in workflows that differ by region. For example, requests from Asia go to the regional manager there. The system automatically tracks budgets and currency conversions, keeping everything aligned.

- Once the requests are approved, Precoro automatically converts them into purchase orders in the supplier’s local currency. When each invoice comes in — even if it’s in a different language or format — OCR and AI tools read it, match it to the PO and receipt, and highlight any mismatches.

- At headquarters, the finance team sees a live dashboard showing spend by region, supplier, currency, and category. They notice that Latin America’s cost per unit is higher than Europe’s and decide to consolidate by moving to a Europe-based supplier to cut costs — a smart global sourcing decision.

- Meanwhile, the contracts team uses Precoro to keep track of supplier agreements across Asia, Europe, and Latin America, getting automatic reminders before renewals are due.

- Finally, the procurement director uses spend analytics to negotiate better global pricing: “We spent $42 million across three regions with this supplier last year — let’s use that volume to get a discount.”

- Because all global sourcing activities are managed in one place, audits and compliance become much easier: budgets are controlled, approvals are visible, supplier data is clean, and duplicate or unauthorized vendors are quickly flagged.

Frequently asked questions about global sourcing

Global sourcing lowers costs and provides access to better-quality goods, services, or materials from international suppliers. It helps companies reduce production expenses, tap into expertise not available domestically, and protect themselves from supply issues through global diversification.

Not quite. While global sourcing is the ongoing process of identifying, selecting, evaluating, and managing international suppliers, global procurement focuses on global purchasing of goods or services from them. In short, sourcing = strategy (who and where to buy from), purchasing = execution (how to buy efficiently and compliantly across markets).

Key risks include legal and cultural differences, sudden regulatory changes, supply issues, and overreliance on low-cost markets.

Not exactly. Importing means bringing goods from another country into your own. Global sourcing is bigger — it’s about finding and working with suppliers around the world to get the best mix of cost, quality, and reliability.

No. Global sourcing means buying from foreign suppliers — for example, coffee beans from Brazil. Outsourcing means hiring another company to perform specific tasks — for example, contracting an accounting firm in India to handle your payroll.

Absolutely! Small businesses have just as much to gain from global sourcing as big companies do. With online tools and trade agents, it’s easier than ever to find reliable suppliers worldwide, reduce costs, improve product quality, and access unique materials unavailable locally. With research and smart planning, small enterprises can expand globally and thrive in competitive sectors such as apparel, electronics, and specialty goods.

Want to see how a modern procurement system can simplify global sourcing? Request your demo today.