29 min read

Procurement vs. Purchasing: Similar but Different

Detailed side-by-side comparison of procurement vs. purchasing. Learn why they aren’t the same and how the difference impacts your business.

What do you call it when you order, say, stationery for your office? Is it procurement or purchasing? Many use these terms interchangeably, but procurement and purchasing are distinct yet closely linked functions.

Procurement and purchasing often go hand in hand, but they aren’t the same thing. Procurement is the strategic, end-to-end process of acquiring goods and services. It includes sourcing, negotiation, and managing supplier relationships. Purchasing is the tactical, transactional component of that process, focused on placing orders, receiving goods, and processing payments. In short, purchasing is a subset of procurement.

In this article, we’ll break down all the differences between purchasing versus procurement and explore how they both contribute to the success of your business. With this in mind, you can fine-tune each process to deliver specific benefits for your company.

Keep reading to learn:

Procurement vs. purchasing at a glance

What is procurement?

What is purchasing?

Procurement vs. purchasing: Key differences explained

Procurement vs. purchasing vs. sourcing: What’s the difference?

Roles & responsibilities: Who does what?

Why the distinction between purchasing vs. procurement is important

Common challenges in procurement and purchasing

How to improve your procurement and purchasing processes

Frequently asked questions about procurement vs. purchasing

Procurement vs. purchasing: Key insights

Procurement vs. purchasing at a glance

Procurement is a complex, strategic process that involves sourcing, buying, supplier management, contract negotiation, and long-term planning. As a proactive function, procurement helps companies meet their internal needs and gain a competitive advantage.

In contrast, purchasing is a more straightforward and reactive process. It involves placing orders, managing deliveries, and processing payments. Purchasing has fewer steps and is more transactional, focusing on price rather than the overall value of the item.

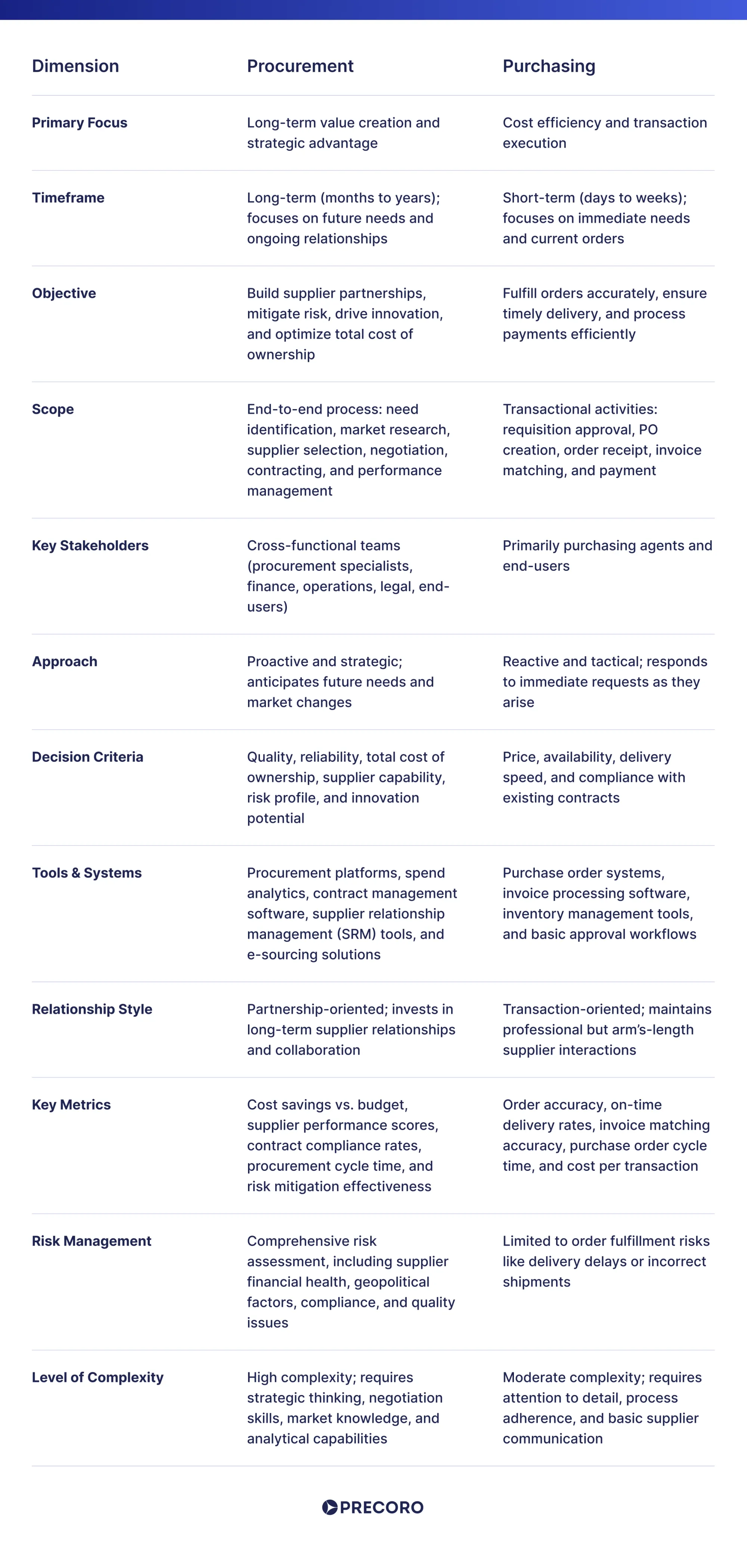

Here’s the table of key distinctions between procurement vs. purchasing.

Procurement is the strategic process of finding and acquiring goods and services with a focus on long-term value and relationships. Purchasing is the more straightforward part of this process and involves the actual buying of those goods and services.

Before we explore the in-depth differences between procurement vs. purchasing, let’s first examine what each process involves.

What is procurement?

Procurement focuses on sourcing and obtaining goods and services to satisfy both immediate demands and long-term business goals. Its main objectives include optimizing the supplier network, controlling costs throughout the product lifecycle, and nurturing strong relationships with key suppliers.

The most effective procurement processes and tools automate order management and supplier selection, while integrating data to enhance transparency and compliance, all in support of wider business objectives.

The procurement steps (also known as the procure-to-pay cycle) can vary depending on the business’s size and industry, but typically include:

- Identifying internal needs

The first step in procurement is determining what goods and services the organization needs. It involves assessing current operations and analyzing historical data. This step also requires cross-department collaboration to find gaps and accurately forecast needs for upcoming projects.

The most straightforward way to capture these needs is to set up a process for employees to create purchase requisitions (PRs) whenever they require products or services. After specifying the items and quantities needed, employees submit the PRs for approval from relevant authorities, such as department managers, finance teams, procurement managers, or senior executives.

- Researching the market and shortlisting suppliers

Once the organization’s needs are clear, procurement specialists can either select from existing suppliers or search for new vendors. The goal is to find those better suited to the company’s evolving demands.

To find a new supplier, the procurement team explores a wide range of options through industry databases, online marketplaces, professional events like trade shows, and recommendations from industry peers. After identifying relevant suppliers, procurement specialists narrow the list to those that best align with the organization’s requirements, preparing for a more detailed evaluation process.

- Issuing an RFQ or RFP and selecting the supplier

To assess potential suppliers, the procurement team typically issues a Request for Quote (RFQ) or a Request for Proposal (RFP). An RFQ is used when the buyer has a clear idea of the product or service needed and mainly compares prices. On the other hand, an RFP is used to also evaluate additional factors such as quality, delivery schedules, innovative solutions, and service terms, especially for large projects.

After receiving quotations or proposals from vendors, procurement specialists compare them to select the best one. Ideally, the chosen supplier should provide a balance of cost, quality, and dependability to support the business effectively.

- Negotiating terms and signing the contract

Negotiating terms is a key step in which the procurement team works with suppliers to agree on important details like pricing, delivery schedules, payment terms, and warranties. This process can take anywhere from a few days to several weeks, depending on the complexity of the agreement and the number of parties involved.

Negotiations often start with the procurement team sending the supplier a clear outline of their requirements, including expectations for pricing, delivery, and other key terms. From there, the supplier responds with their offer, and both sides engage in discussions to refine and adjust the details. Procurement teams may use leverage such as order volume, long-term business potential, or competitor offers to negotiate better terms.

A key to smooth negotiations is preparation — knowing exactly what the company needs, understanding the supplier’s position, and being open to compromise where necessary. Once both sides agree on the terms, the final step is to sign the procurement contract.

- Creating and approving a purchase order

A purchase order (PO) is a legal document that outlines the details of a purchase, including quantity, price, payment terms, and delivery schedules. If the company has a purchase requisition process, the approved PR is converted into a PO after the contract is signed.

If there’s no PR process, the procurement manager creates the PO from scratch, outlining the necessary details. The PO may also require approval before being sent to the supplier to ensure it aligns with company policies on spending and procurement.

The supplier reviews the purchase order, confirms they can fulfill it, and sends confirmation back. Once confirmed, the PO becomes legally binding, and the supplier proceeds to fulfill the order as agreed.

- Receiving and inspecting delivered items

When the order arrives, the receiving team verifies that the correct quantity and type of items have been delivered, checking for any visible damage or defects. If there are any discrepancies, like missing or damaged items, the procurement team steps in to work with the supplier to resolve the issue.

Once the products pass the quality check, the receiving team, often the warehouse team, generates the goods receipt, which is logged into the system. This officially records the items as received.

- Processing an invoice and making a payment

The accounts payable team reviews the invoice sent by the supplier, ensuring it reflects the correct price, quantity, and other terms, such as taxes or shipping costs. They check that the invoice matches the approved goods receipt and purchase order to confirm the details in the process called three-way matching.

Once the invoice is validated, the accounts payable team issues a payment to the supplier. This typically follows the agreed-upon payment terms outlined in the contract (typically net 30 days or net 60 days).

- Record-keeping

Record-keeping is about staying organized and making sure everything related to purchases is documented properly. This includes keeping track of purchase orders, invoices, contracts, and receipts. Having everything in order helps prevent overspending, ensures you’re following company rules, and makes audits easier.

Proper record-keeping also comes in handy if there are any issues with suppliers, as you can quickly refer back to the original documents. Plus, by keeping a history of your purchases, you can evaluate suppliers and make better decisions for future purchases.

- Evaluating the supplier and building strong supplier relationships

Supplier evaluation typically involves reviewing key performance indicators (KPIs) such as delivery times, product quality, and pricing accuracy. The procurement manager also looks at factors like profit margins and contract compliance to determine whether the supplier met expectations.

This assessment helps in understanding if the supplier is reliable and provides value to the business. If the supplier has performed well, the procurement manager may decide to continue the relationship and possibly negotiate for better terms in future transactions. On the other hand, if performance was lacking — whether in product quality, delivery consistency, or customer service — the manager may explore other suppliers for future needs.

Building a strong supplier relationship means creating mutual benefits over time by fostering positive, long-term partnerships with suppliers who reliably meet the company’s needs. This process involves open and transparent communication, collaborating on forecasts, joint problem-solving, and timely payments.

What is purchasing?

Purchasing involves the specific tasks of acquiring the goods and services an organization needs. It’s a smaller part of the broader procurement process and includes activities such as ordering, expediting, receiving, and processing payments. Top-performing purchasing teams also actively monitor suppliers to ensure they secure the best prices and delivery options.

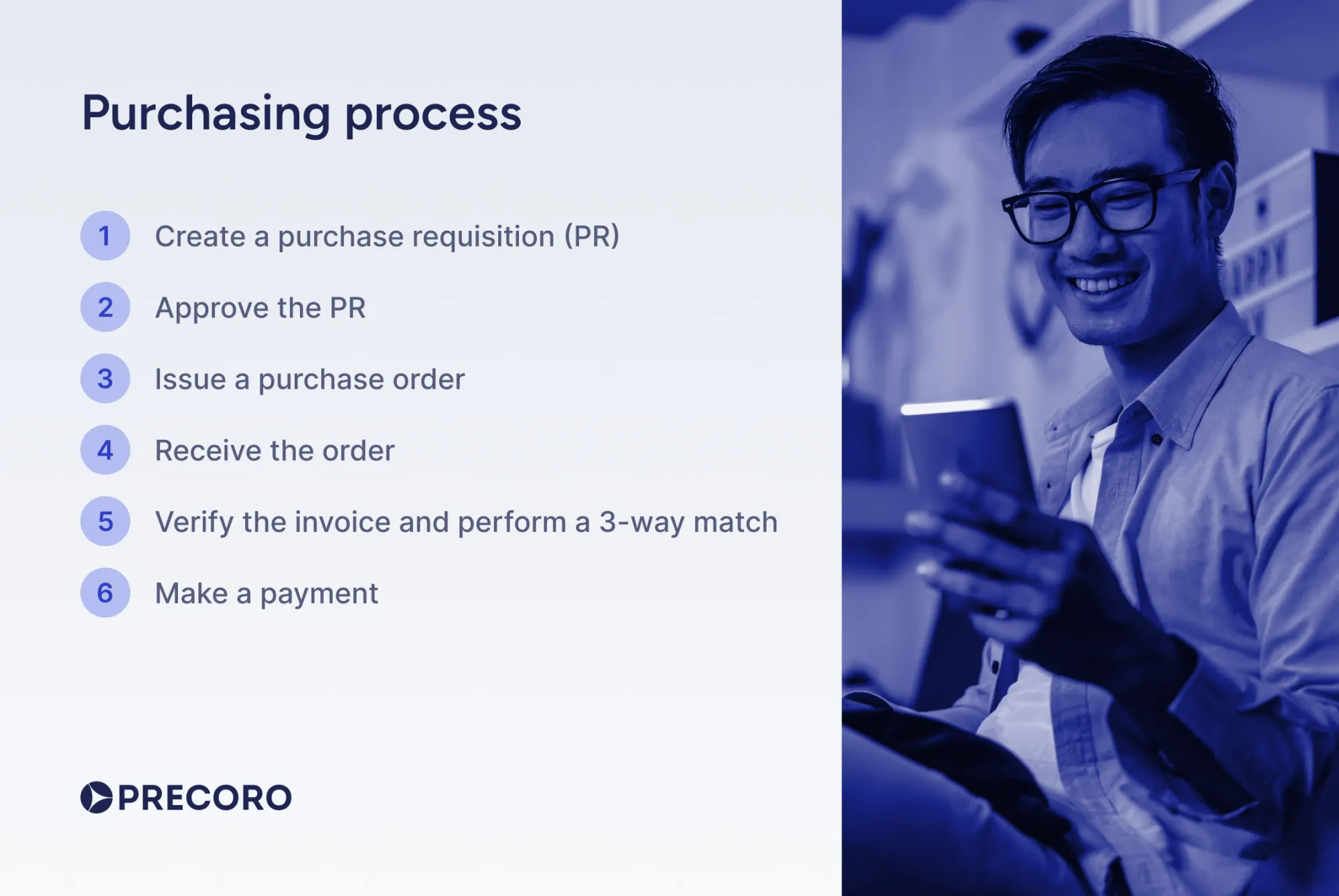

The purchasing process usually includes:

- Creating a purchase requisition (PR)

The purchasing process begins when a department or an individual submits a purchase requisition with details of the needed item, quantity, and desired delivery date. This document provides the initial information needed to begin the purchasing process and helps to prevent errors or misunderstandings regarding the employee request.

- Approving the PR

The approval process ensures that the expense is justified, within the organization’s budget, and complies with company policies, such as procurement guidelines or spending limits. That’s why an employee may need approval from relevant authorities, such as department heads, the finance manager, the procurement manager, or C-level executives.

- Issuing a purchase order

Once the purchase requisition is approved, the purchasing team generates and sends a purchase order (PO) outlining items, quantities, agreed prices, and delivery terms. In some companies, however, the purchasing process may begin directly with the purchase order, skipping the requisition step.

- Receiving the order

When the ordered items are delivered, the receiving team checks the order against the purchase order. This step includes verifying that the right quantities have been delivered, inspecting the items for any defects or damage, and ensuring they meet the agreed-upon specifications and quality standards.

- Verifying the invoice and performing a 3-way match

After the goods or services are received and verified, the supplier sends an invoice. The accounts payable team performs a three-way match, comparing the invoice with the purchase order and the receiving documentation. This ensures that the quantities, prices, and any agreed-upon terms, such as discounts or additional charges, are consistent across all documents. If everything matches, the invoice is approved for payment.

If any discrepancies arise, such as incorrect pricing or missing items, the invoice may be sent back for clarification or adjustment. In some cases, to ensure proper validation and authorization of payment, invoices may require additional approvals from department heads or finance managers. This step helps prevent errors and ensures financial accuracy.

- Making a payment

The accounts payable team checks that the payment terms, such as discounts or penalties, are met. Then, the appropriate payment method (for example, wire transfer, credit card, or check) is used to pay the supplier. After payment, the transaction is recorded in the company’s financial system, and the supplier is notified.

When you look at the actual steps in the procurement vs. purchasing processes, it’s clear that the latter is part of the former.

Procurement vs. purchasing: Key differences explained

As you can see, both purchasing and procurement processes are related to acquiring the goods and services a business needs. However, they play different roles in how companies manage spending.

Before we dive into the specifics, here’s a complete comparison that captures the core differences. This matrix shows how procurement and purchasing differ across the dimensions that impact your business operations. Keep it handy as we explore each distinction in more detail below.

As you can see from the table, procurement and purchasing serve fundamentally different purposes.

Procurement focuses on finding and acquiring the goods and services a business needs, both now and in the future. It involves choosing the right suppliers, controlling costs over time, and building strong relationships with providers. The best procurement teams rely on smart tools that automate ordering and make the process more efficient, transparent, and easier to manage.

Purchasing handles the more hands-on tasks: placing orders, ensuring deliveries arrive, and processing payments. Good purchasing teams also monitor suppliers to secure the best deals and guarantee timely fulfillment.

Let’s break down the key differences between procurement vs. purchasing:

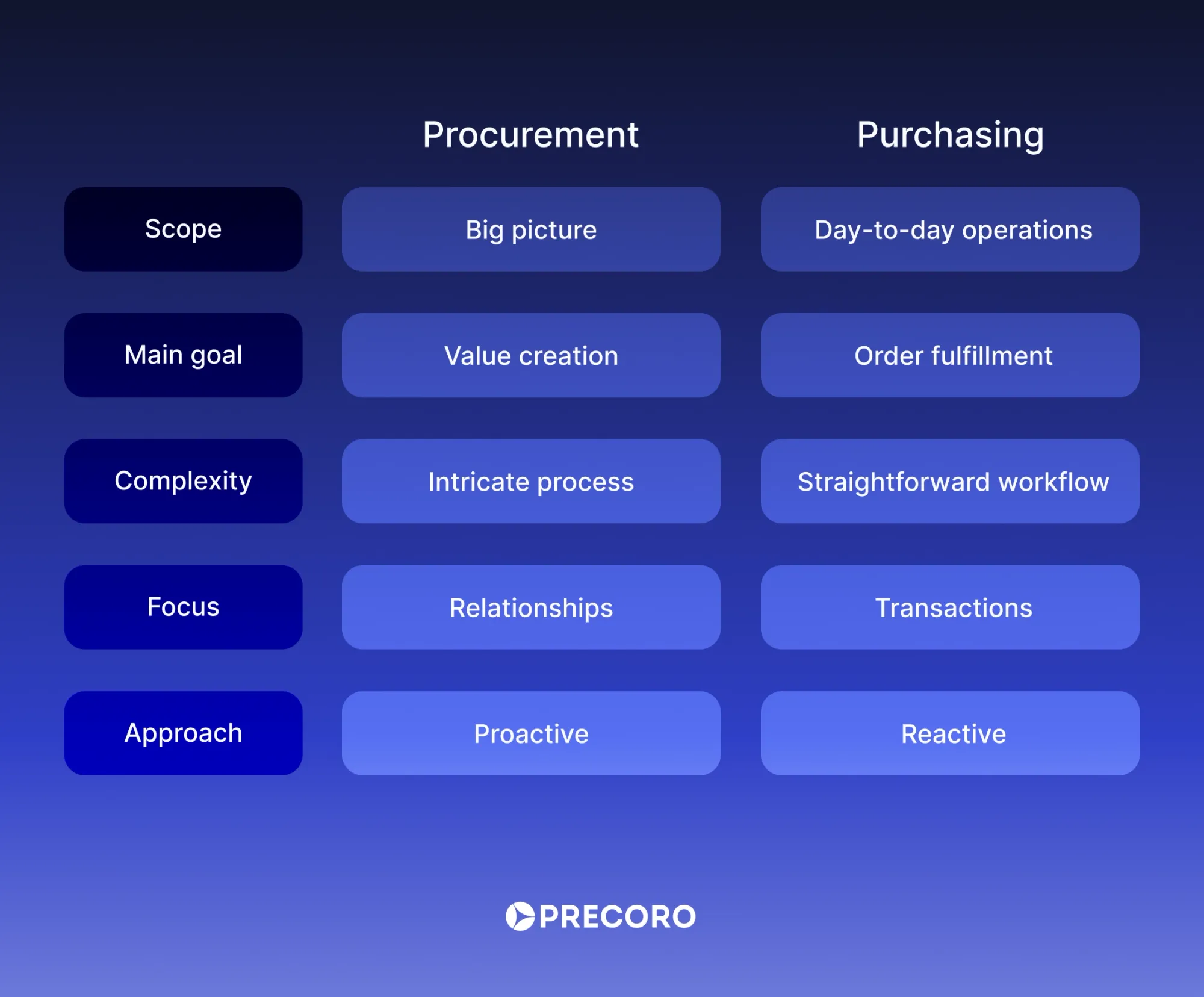

Scope: Big picture vs. day-to-day operations

Procurement and purchasing reveal clear differences in scope and complexity. Procurement is the big picture — it’s a strategic process that involves planning, sourcing, negotiating, purchasing, and managing supplier relationships and contracts. It’s all about making smart, long-term decisions to support the company’s goals.

Purchasing, on the other hand, focuses on day-to-day transactions, taking a more tactical approach than strategic. It involves executing orders, processing payments, and ensuring goods or services are delivered as expected. As a result, purchasing managers focus more on the cost of items.

Main goal: Value creation vs. order fulfillment

When exploring procurement vs. purchasing, it’s clear that both processes have different objectives. The goal of procurement is to create long-term value. This includes reducing costs, building strong supplier partnerships, managing risks, and finding innovative solutions to meet the company’s needs.

In fact, now is the moment for procurement leaders to embrace a new era of value creation. According to McKinsey, the role of Chief Procurement Officers (CPOs) has evolved beyond merely safeguarding a portion of enterprise costs. Today, more than ever, they can become strategic partners to CEOs, CFOs, and COOs, driving value and influencing key business decisions.

Purchasing, however, is all about buying goods and services efficiently. Its primary goal is to ensure the right items are ordered, delivered on time, and paid for without errors. Therefore, purchasing operates within the parameters set by procurement.

Complexity: Intricate process vs. straightforward workflow

The difference between procurement vs. purchasing becomes evident when comparing their complexity. Procurement is a multi-step process that requires strategic thinking, thorough planning, and collaboration across departments. That’s why it’s a more complex process, which involves more people and requires additional resources.

Purchasing, on the other hand, is only a part of a broader procurement process, which is focused on placing orders. As a result, the purchasing process engages fewer people, making it less bureaucratic and time-consuming.

Focus: Relationships vs. transactions

The focus of procurement vs. purchasing reveals another important differentiator. Procurement emphasizes building and maintaining strong relationships with suppliers. It’s about working together to achieve mutual benefits, like better pricing, quality improvements, or sustainable practices.

Purchasing is more transactional and less relationship-driven. It’s about completing specific orders with the existing supplier base under agreed-upon terms.

Approach: Proactive vs. reactive

Another key area where procurement and purchasing differ is their approach. Procurement is proactive and forward-thinking. The procurement team anticipates the organization’s needs, strategically plans for sourcing the necessary goods or services, and negotiates long-term contracts. Thus, procurement isn’t just about addressing immediate requirements but also about mitigating risks, optimizing costs, and aligning with business objectives in the long run.

Purchasing, on the other hand, operates reactively. It steps in once a specific need has already been identified, focusing on executing orders to fulfill it. Purchasing agents act quickly and efficiently to address immediate demands, often based on terms and suppliers already established by procurement.

Procurement process vs. purchasing process: Step-by-step comparison

Earlier, we mentioned that purchasing is actually part of procurement, not a separate function. But what does that really mean in practice?

Let’s put it to the test. We’ll map out both processes step by step. When you line up the workflows side by side, something jumps out immediately: purchasing doesn't stand alone—it’s built right into the middle of procurement's longer journey.

Here's what this table actually proves: Purchasing takes up exactly three steps in procurement’s nine-step cycle. Look at steps 5, 6, and 7 of procurement. That’s your entire purchasing process. Everything before and after those steps? That’s where procurement adds its strategic value.

Let’s talk about what happens outside the purchasing bubble. Before any purchase order gets created, procurement teams do the heavy lifting. They dig into what the organization really needs, scout suppliers for quality and value, and negotiate terms that protect the business.

After the transaction closes, the work continues. Procurement measures supplier performance. They address issues and build relationships that create value on future purchases. This work doesn’t happen in purchasing. It can’t, as purchasing is focused on execution.

This is why companies that only focus on purchasing leave money on the table. They’re optimizing three steps out of nine. However, the other six steps are where the real value lives:

- Better payment terms get negotiated there.

- Quality issues get caught before they become expensive problems.

- Cost-saving opportunities show up through spend analysis.

- Supplier partnerships that drive innovation get built in those steps.

When businesses treat purchasing and procurement as the same thing, they usually end up with a team that’s great at processing orders. But that team doesn’t have the time or mandate to do strategic work. As a result, companies deal with higher costs, more risk, weaker supplier relationships, and missed opportunities.

The processes aren’t interchangeable. Now you can see exactly why.

Procurement vs. purchasing vs. sourcing: What’s the difference?

You’ll often hear another term mixed in with procurement and purchasing: sourcing. Where does it fit? Let’s clear that up.

Think of sourcing as a subset of procurement. It’s the phase where you identify, evaluate, and select suppliers. The research and decision-making happens here, before any contracts get negotiated or orders placed.

The breakdown works like this: Sourcing answers who to buy from. Procurement handles how you acquire goods and services strategically. Purchasing takes care of actually buying what you need.

What does sourcing involve? Market research, supplier identification, and capability assessments. Teams issue RFQs or RFPs, compare what suppliers offer, and recommend which vendors make sense for the business. After sourcing picks the right suppliers, procurement steps in to negotiate terms and lock down contracts. Purchasing then executes orders based on those agreements.

Different companies structure these processes differently. Some have dedicated sourcing teams that only do this work. Others roll it into procurement roles. The flow stays the same either way: sourcing feeds procurement, procurement enables purchasing.

Tactical purchasing vs. strategic procurement: Key distinctions

What really separates purchasing from procurement? It comes down to tactical versus strategic focus.

Purchasing lives in the tactical world of short-term focus and transactional work. You need to process requisitions, issue purchase orders, receive goods, match invoices, and pay suppliers. These tasks are essential. They keep operations running smoothly every single day. But they don’t build competitive advantage.

Procurement operates strategically. It’s about long-term value and relationship building. You analyze spending patterns, research supply markets, negotiate multi-year contracts, and cultivate supplier partnerships that reduce risk and drive innovation collaboratively. This work positions your organization for sustained success.

Consider the questions each function asks. Purchasing wants to know: “How do we buy this item quickly and correctly?” Procurement asks something bigger: “How do we structure our supply base to maximize value and minimize risk over time?”

You need both. Tactical execution keeps the wheels turning. Without it, nothing gets delivered and invoices pile up. But operate only tactically and you’re missing opportunities. Strategic procurement builds the framework that makes tactical purchasing actually work better. Procurement does the upfront work—vetting suppliers, negotiating favorable terms—so purchasing can execute efficiently without starting from scratch each time.

What happens when organizations blur this distinction? Procurement teams get buried in tactical work and strategic initiatives never materialize. You end up with higher costs, more risk, weaker supplier relationships, and opportunities that slip right past you.

Roles & responsibilities: Who does what?

Now that we know what procurement and purchasing include, let’s discuss the people who do this work. Of course, understanding the difference between these functions in general is important. But at the same time it matters even more when you’re structuring teams or just trying to figure out who can handle a specific task.

The roles look similar on paper. Both deal with buying things for the company. Both work with suppliers. Both care about getting good value.

But dig a little deeper and you’ll see the day-to-day responsibilities are quite different, as well as the skills required, the decisions each role makes, and the impact on the business.

Here’s how the roles actually break down and where they fit in your organization.

What procurement managers do

Procurement managers are responsible for the overall strategy. Their job is to create and maintain various systems that keep your supply chain running effectively in the long term. Individual purchase orders are not even on their radar, as they focus on bigger questions: Does your company have the right suppliers? The right contracts? The right processes in place?

Their key responsibilities include:

- Supplier evaluation and selection: Research the market and vet potential vendors, analyzing various risk factors, such as financial stability and capacity to scale.

- Contract negotiation: Figure out pricing structures, payment terms, and SLAs (Service Level Agreements) that protect the company.

- Supplier relationship management: Conduct regular check-ins with key suppliers. Handle performance reviews and resolve problems as they appear.

- Spend analysis and category management: Analyze spending patterns to figure out various opportunities for consolidation or better deals.

- Risk management and compliance: Keep an eye on current and future regulatory changes. Make sure that suppliers meet the necessary environmental and ethical standards.

What purchasing agents do

Purchasing agents are responsible for the execution. Their job is to make sure that orders get placed correctly, deliveries arrive on time, and invoices are paid without issues. Agents work strictly within the frameworks that procurement managers build.

Key responsibilities of a purchasing agent include:

- Process purchase requisitions: Review employee requests and confirm they fit within budget and policy.

- Create and issue purchase orders: Pick the right supplier from pre-negotiated contracts. Enter order details and fire off the PO.

- Track orders and manage deliveries: Chase down suppliers on delayed shipments. Work with receiving teams and handle returns when things go wrong.

- Process invoices and perform three-way matching: Line up purchase orders, delivery receipts, and supplier invoices. Hunt down discrepancies before payment goes out.

- Escalate supplier issues: Flag consistent supplier problems to procurement managers.

Here’s what purchasing agents don’t do: negotiate contracts or evaluate new suppliers. They stick with existing relationships and keep things moving.

How these roles fit in organizations

Bigger companies often contain procurement and purchasing within the same department but separate the roles. Procurement managers form overall strategy; purchasing agents handle execution. It makes sense, right?

Smaller organizations often mash these roles together into one position. This approach works fine when purchase volumes are manageable. But here’s what happens as companies grow: trying to do both becomes a bottleneck. Strategic work gets shoved aside because transactional work is urgent and never stops coming.

Why this distinction matters

Once the lines between these roles become more blurred, problems appear. Purchasing agents don’t have the skills or time for contract negotiations. Procurement managers stuck processing purchase orders can’t tackle strategic initiatives.

Clear role definition helps with hiring, performance measurement, and accountability. You can’t measure a procurement manager by order cycle time. That’s not their job. You can’t measure a purchasing agent by negotiated cost savings. They’re executing contracts, not creating them. The metrics need to match the role.

Why the distinction between purchasing vs. procurement is important

Understanding the differences between procurement vs. purchasing is essential for businesses aiming to save money, improve efficiency, and stay competitive. Here’s why it matters:

Avoiding missed opportunities

When businesses blur the lines in the purchasing vs. procurement distinction, they often focus only on meeting short-term needs, missing out on the broader strategic advantages procurement offers. These benefits include optimizing supply chains, minimizing risks, and reducing costs.

For example, procurement teams can analyze spending patterns to identify trends and consolidate purchases, which may qualify their companies for volume discounts and better contract terms. Procurement managers can also explore emerging suppliers offering innovative solutions that improve quality or reduce costs over time.

Streamlined operations

By clearly separating procurement vs. purchasing, businesses can ensure that each function operates at its highest potential. Moreover, this approach ensures clear accountability — procurement managers are accountable for securing the best suppliers and terms, while purchasing agents are responsible for the smooth execution of those agreements. This division minimizes confusion, optimizes resource allocation, and leads to faster, more accurate order fulfillment.

Cost savings beyond price tags

By recognizing the distinction between purchasing vs. procurement, businesses can avoid the trap of focusing solely on price and make more informed decisions that save money in the long run.

Purchasing typically focuses on the upfront price of a product or service — how much it costs right now and whether it fits within the budget. However, procurement goes further and considers the total cost of ownership (TCO). TCO is a complete assessment of all costs tied to a product or service, such as delivery fees, installation costs, maintenance, training, repair, and potential disposal or replacement costs.

By taking these factors into account, procurement managers can identify cost-effective solutions that offer better long-term value, even if their upfront cost is higher. For example, a slightly more expensive product may have lower maintenance costs or offer a longer lifespan, ultimately reducing the total cost over time.

Improved risk management

By understanding the distinction between procurement vs. purchasing, businesses can rely on procurement to mitigate risks before they become costly problems, including factors like:

- Supplier disruptions (like delays, bankruptcies, or geopolitical instability)

- Price volatility (like fluctuations in raw material costs or changes in currency exchange rates)

- Compliance issues (like regulatory changes or failure to meet environmental standards)

By considering these risks upfront, procurement teams can devise strategies to mitigate them — whether that means securing backup suppliers, locking in prices through long-term contracts, or ensuring compliance with international regulations.

Driving innovation and sustainability

If a company treats procurement and purchasing as the same, it risks focusing solely on the transactional aspects of purchasing. While this approach has its place, strategic procurement goes further — it drives innovation and fosters sustainability by partnering with forward-thinking suppliers.

Such suppliers can not only deliver high-quality products but also provide solutions that align with long-term sustainability goals. These include sourcing eco-friendly materials, adopting energy-efficient technologies, and collaborating with vendors committed to strong corporate social responsibility (CSR) practices.

The bottom line: Business impact and competitive advantage

When you get the distinction between procurement and purchasing right, the benefits show up in measurable ways across your business. Let’s take a look at them below.

Return on investment (ROI)

Strategic procurement improves ROI directly. It reduces total cost without sacrificing quality for it. Whenever procurement teams negotiate volume discounts, lock in favorable payment terms, or consolidate suppliers, these savings directly affect the bottom line.

Purchasing executes these agreements efficiently, but procurement creates them. Companies that invest in reliable procurement functions tend to see substantial cost reductions within one year.

Supply chain resilience

Procurement creates resilience for your supply chain before problems appear. Teams create safety nets by qualifying backup suppliers, diversifying the vendor base, or monitoring overall supplier health.

When disruptions happen—whether it’s a natural disaster, geopolitical tension, or a supplier going bankrupt—companies with strong procurement bounce back faster. Purchasing can’t do this work, as it’s reactive by nature.

Compliance and risk mitigation

Regulatory compliance isn’t optional, and procurement also owns it. From environmental standards to labor practices to data security requirements, procurement ensures that your suppliers meet all kinds of legal and ethical obligations.

This way, your company is protected from fines, lawsuits, and reputational damage. Even though purchasing verifies that orders are matched with pre-existing contracts, procurement actually writes those contracts with compliance built-in.

Strategic advantage

Here’s where it all comes together. Companies that treat procurement strategically gain advantages their competitors can’t easily copy. Better supplier relationships mean priority access during shortages. Stronger contracts mean protection when markets get volatile. Innovation partnerships mean better products faster.

These advantages compound over time, setting your company apart from others in your industry. Purchasing keeps operations running smoothly today. Procurement positions your company to win tomorrow.

Common challenges in procurement and purchasing

Even when organizations see the difference between procurement vs. purchasing, putting that knowledge to the test is not easy in most cases. Most companies run into similar obstacles. Luckily, these challenges are predictable, which means the solutions are too.

Most common pitfalls

Let’s look at the most common pitfalls and what you can do about them.

- Siloed processes

Procurement and purchasing work in isolation from each other and from other departments. Decisions get made in a vacuum and data doesn’t flow between teams. Finance, operations, and procurement rarely talk to each other.

- Reactive purchasing

Everything becomes urgent. Someone needs something now, so purchasing scrambles to find a supplier and rush the order. As a result, you lose money and negotiating power every single time.

- Lack of supplier strategy

Companies treat all suppliers the same, with a strictly transactional mindset. There’s no formal way to evaluate performance and relationships stay shallow, so you get no loyalty when markets tighten.

- Poor spending visibility

Purchase data lives in scattered spreadsheets and different systems. It’s difficult to see patterns. As a result, you miss savings opportunities and can’t negotiate volume discounts.

- Inadequate skills and resources

Purchasing teams get asked to negotiate complex contracts without training, while procurement managers drown in transactional work. Nobody can do their actual job well.

- Resistance to change

People like what they know. That’s why new processes meet pushback: nobody sees the value in change initiatives.

How to overcome them

The fixes aren’t complicated, but they do require commitment. Here’s what actually works:

- Break down silos: Create regular cross-functional meetings and include end-users in supplier selection. Additionally, share data using integrated systems to help everyone work with the same information.

- Plan proactively: Analyze historical spending data to anticipate common needs. Forge supplier partnerships before problems force your hand. Create approved vendor lists and framework agreements beforehand.

- Segment suppliers strategically: Identify which suppliers are critical to your business. Create scorecards to track performance and hold quarterly reviews with key partners.

- Centralize your data: Implement a procurement platform that captures all activity. Run regular spend analyses. Use visibility to consolidate suppliers and negotiate better terms.

- Invest in training: Teach procurement teams negotiation and strategic thinking. Train purchasing staff on efficiency and systems. Hire enough people so roles don’t blur.

- Start with quick wins: Show cost savings from small changes and communicate benefits clearly. Involve stakeholders in designing new processes to build ownership and momentum.

Best practices for long-term success

Overcoming challenges is one thing—building excellence is another. Here are the practices that set high-performing procurement and purchasing functions apart.

- Implement supplier relationship management (SRM): Don’t just manage transactions. Build real partnerships with your top suppliers. Regular business reviews, joint improvement initiatives, and open communication channels turn vendors into strategic allies.

- Adopt category management: Group similar spending into categories and assign ownership. A category manager for IT equipment thinks strategically about that entire spend area rather than treating each purchase as isolated.

- Leverage spend analytics: Use data to drive decisions. Regular spend analysis reveals consolidation opportunities, identifies maverick spending, and shows where you have negotiating leverage.

- Standardize specifications: When departments buy different versions of essentially the same thing, you lose volume discounts and complicate inventory. Standardization drives efficiency.

- Build cross-functional teams: Include finance, operations, legal, and end-users in procurement decisions. Better input leads to better outcomes.

- Invest in technology: Manual processes don't scale, while modern procurement platforms automate workflows, provide visibility, and free up time for strategic work.

- Create feedback loops: Regularly review what’s working and what isn’t. Continuous improvement should be built into your culture, not treated as a one-time project.

- Develop your people: Strong procurement requires specific skills. Invest in training for negotiation, market analysis, risk assessment, and relationship management.

Great procurement and purchasing don’t happen by accident. They’re the result of intentional practices applied consistently over time.

How to improve your procurement and purchasing processes

When you’re navigating the nuances of procurement vs. purchasing, there are always opportunities to streamline your processes, improve efficiency, and reduce costs. Here are some actionable steps to level up both functions:

Standardize your processes

Well-defined workflows ensure that both purchasing and procurement processes are predictable, efficient, and error-free. They help teams work cohesively, improve compliance, and build a foundation for scalability as the organization grows.

Clearly outline and document the steps in purchasing and procurement processes so team members know exactly what to do and when, minimizing the need for ongoing guidance. For procurement, this might include defining how to evaluate suppliers, manage negotiations, and draft contracts. For purchasing, it could outline tasks like placing orders, tracking deliveries, and processing payments.

Then, standardize templates for documents like contracts, purchase requisitions, and purchase orders. These templates ensure that all necessary information is included, from payment terms to delivery conditions, leaving no room for misinterpretation. Consistency also simplifies training new team members, enhances collaboration across departments, and facilitates compliance with company policies or legal requirements.

Last but not least, establishing clear approval hierarchies is crucial for maintaining control over spending. For procurement, this might involve requiring senior management approval for high-value contracts or vendor agreements. For purchasing, it could mean ensuring department heads review purchase requisitions. By defining who needs to sign off on each step, organizations can streamline decision-making and ensure accountability, especially for high-stakes purchases.

Collaborate across departments

Procurement and purchasing don’t exist in a vacuum. Effective collaboration with other departments ensures smooth operations and better decision-making, but it doesn’t have to mean endless meetings or shared KPIs. The key is to establish clear communication frameworks and well-defined roles that enable alignment without overwhelming anyone.

Outline clear responsibilities to avoid overlap between procurement vs. purchasing. Purchasing agents should focus on executing orders and managing short-term buying needs, while procurement managers handle long-term supplier relationships, strategic sourcing, and risk management. At the same time, finance should focus on budget approval and cash flow management, and operations can outline logistical needs. Knowing who does what prevents bottlenecks and confusion.

Having a feedback loop between teams is also highly beneficial. Procurement can collaborate with operations to evaluate supplier performance and delivery quality, while finance can guide procurement on budget constraints and cost-saving opportunities. This information exchange fosters better strategies and minimizes reactive decision-making.

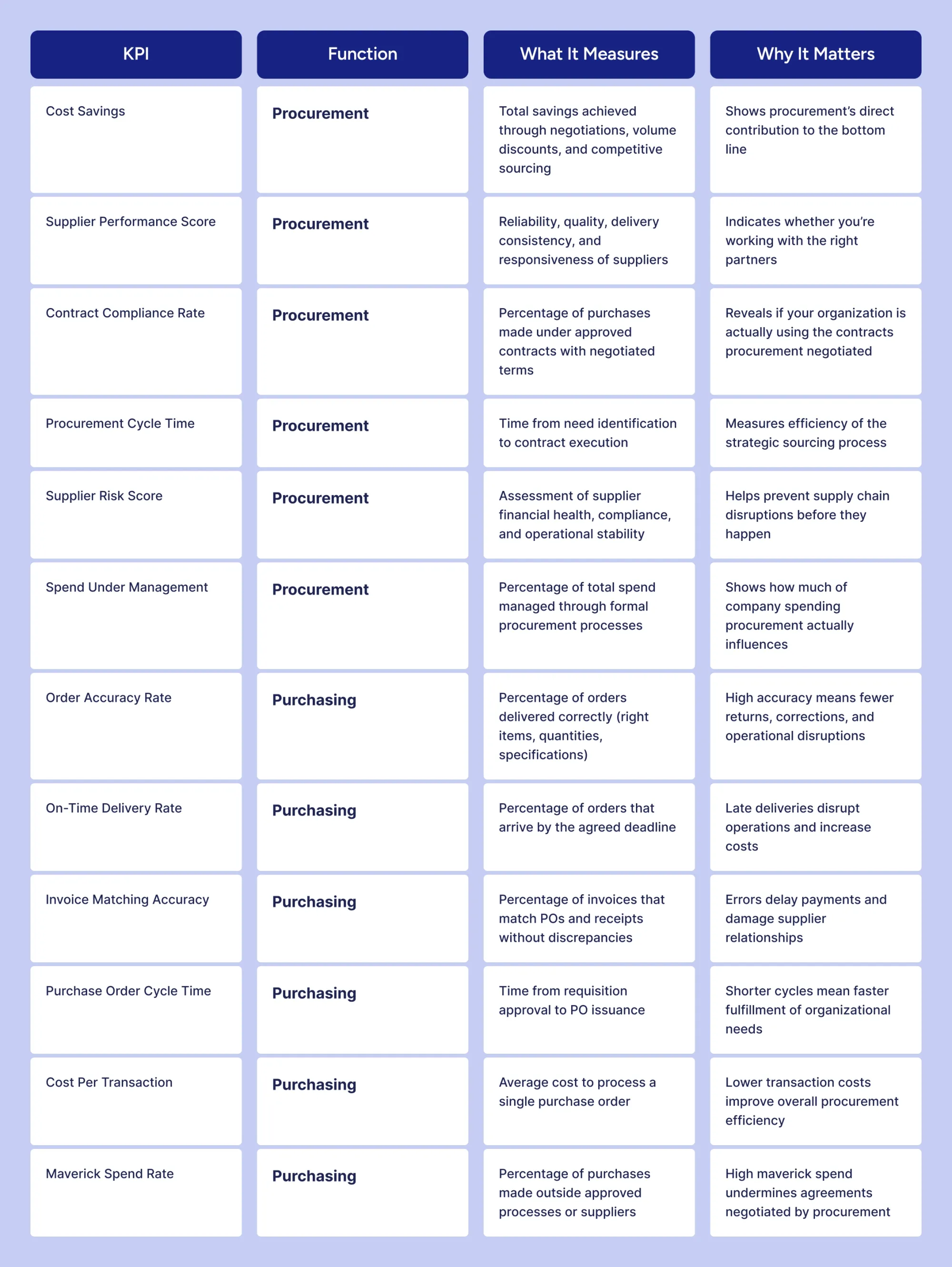

Track key metrics

Measure what matters for procurement vs. purchasing. Metrics show how well each function is performing and highlight areas for improvement.

Key procurement metrics:

- Cost savings

Track the savings achieved through strategic negotiations, volume discounts, or competitive sourcing. This metric demonstrates how procurement contributes to the company’s bottom line.

- Supplier performance

Evaluate suppliers based on reliability, quality, and delivery consistency. Key indicators include on-time delivery rates, defect rates, and responsiveness to issues.

- Contract compliance

Monitor adherence to the terms outlined in procurement contracts to ensure suppliers meet agreed-upon standards and pricing. Non-compliance can lead to unexpected costs, delays, or quality issues.

Key purchasing metrics:

- Order accuracy

Measure the percentage of orders delivered correctly, matching the purchase order in terms of quantity, specifications, and condition. High order accuracy reduces the need for returns and additional follow-up.

- Delivery timelines

Track how often deliveries arrive on or before the agreed deadlines. Late deliveries can easily disrupt operations and increase costs, so this is a critical metric for evaluating purchasing efficiency.

- Invoice matching accuracy

Assess how frequently invoices match purchase orders and delivery receipts. Errors in matching result in delayed payments, damaged supplier relationships, and administrative bottlenecks.

The table below gives you a comprehensive view of the most important metrics for each function. Use it as a starting point when building your performance dashboards.

There are different metrics for different goals. Procurement metrics focus on long-term value and strategic outcomes. Purchasing metrics focus on execution quality and transactional efficiency. Track both sets to get the full picture of how your organization acquires goods and services.

Adopt a platform for centralized procurement

In 2023, 62% of procurement decision-makers used analytics and reporting tools, while 54% automated previously manual processes. This demonstrates a clear shift toward digital solutions, which lead to greater efficiency and data-driven decision-making in procurement. The question is, what procurement software should you invest in?

Precoro is a procurement centralization and automation platform that simplifies how businesses manage both purchasing and procurement processes. Instead of juggling spreadsheets, emails, and disconnected tools, companies can bring everything — supplier info, purchase requests, approvals, orders, and invoices — into a single platform that works seamlessly across departments and entities.

1000+ companies use Precoro to automate and standardize procurement and purchasing workflows. The platform can enforce consistent approval workflows and ensures documents like purchase requisitions, orders, invoices, and receipts include all required fields and comply with company policies. In addition, built-in workflows eliminate the need for manual follow-ups, saving time and reducing errors.

Moreover, centralizing procurement and purchasing activities fosters better collaboration across departments. Finance teams can access real-time insights into spending and budgets, operations can monitor order statuses to plan inventory and logistics, and other teams can use supplier catalogs to create requests more quickly and easily track their orders. This shared visibility eliminates silos and ensures smoother communication without constant back-and-forth messages.

With everything in one platform, it becomes increasingly easy to enhance compliance. Automated approval workflows help companies ensure spending aligns with company policies, while detailed audit trails provide accountability by recording who approved what and when. This reduces risks like unauthorized purchases or compliance failures, making both procurement and purchasing more efficient and reliable.

Frequently asked questions about procurement vs. purchasing

No, procurement and purchasing are not the same. While they’re related, procurement is a strategic process focused on planning, sourcing, and managing supplier relationships to create long-term value. Purchasing, on the other hand, is a tactical function within procurement, which is focused on executing orders, processing payments, and ensuring goods or services are delivered on time. Essentially, procurement sets the strategy, and purchasing executes it.

In the discussion of procurement vs. purchasing, it’s important to note that purchasing is a subset of procurement, so some overlap exists between the two. Both involve activities such as placing orders and processing payments. However, while purchasing focuses on execution, procurement takes a broader, strategic approach that includes additional steps like supplier selection, negotiation, and contract management.

Yes, procurement is a broader term that encompasses purchasing as well as several other critical steps before and after making a purchase (such as identifying needs, researching and selecting suppliers, negotiating contracts, and managing supplier relationships).

Nowadays, these two professions are practically identical, as many organizations use these terms interchangeably. However, if your organization differentiates between purchasing vs. procurement managers, purchasing managers typically focus on placing purchase orders and monitoring their fulfillment. In contrast, procurement managers tend to have a more strategic role, which includes activities like market research, supplier selection, contract negotiation, and risk management.

Both are important, but procurement is more critical for long-term business success. While purchasing focuses on immediate transactions, procurement takes a strategic approach, optimizing costs, reducing risks, and improving supplier relationships to support broader business goals.

In most mid-sized and large enterprises, procurement is its own department, which has both procurement and purchasing specialists. However, in some businesses, it may report to either operations (to ensure smooth logistics and supply chain management) or finance (to focus on cost management), depending on the structure.

Procurement vs. purchasing: Key insights

Although often used interchangeably, procurement vs. purchasing refers to distinct functions. Procurement is a broad concept that includes need identification, sourcing, purchasing, and supplier and contract management.

Therefore, procurement is a strategic process that aims to establish long-lasting relationships with the most suitable suppliers and enhance the competitive advantage. That’s why it focuses on maximizing contractual value, risk mitigation, and supplier management.

On the other hand, purchasing is more tactical and focuses on short-term goals, such as making efficient transactions and ensuring the timely supply of necessary goods at the lowest price.

In short, in the context of procurement vs. purchasing, while procurement is about planning for both today and tomorrow — purchasing is about getting what you need today. Harmonizing and optimizing both of them allows companies to avoid uncontrolled spending and unforeseen complications.