15 min read

Procurement Compliance Explained: Examples, Challenges, and Best Practices

Follow procurement compliance best practices and tackle non-compliant instances with proven methods.

Companies often push aside procurement compliance to focus on more pressing issues. No wonder—procurement often gets tedious and burdened with time-consuming processes. However, ignoring procurement compliance is like ignoring a ticking time bomb. It’s only a matter of time before it explodes.

Eventually, you have to face far bigger issues than if you’d followed the protocols in the first place. Instead of developing procurement strategies to keep spend management and purchasing compliant, companies end up with multiple instances of maverick spend or unsustainable vendor behavior.

As authorities crack down on corporate non-compliance with the CSRD and ESG regulations, companies face pressure to adopt strong procurement compliance policies. These rules often seem restrictive, forcing procurement teams to choose compliance over flexibility and innovation. This article will go over the procurement compliance definition, the types of compliance, and the best practices to keep procurement both compliant and agile.

Scroll down to find out:

What is procurement compliance?

Examples of non-compliant procurement

Types of procurement compliance

Procurement compliance KPIs

Purchasing compliance roadblocks

Procurement compliance: Best practices checklist

Frequently asked questions about procurement compliance

What is procurement compliance?

Procurement compliance means ensuring all purchasing activities adhere to applicable regulations, laws, internal policies, and external guidelines. Its purpose is to avoid unethical and harmful behavior that can lead to fines, supplier issues, and reputational damage. The underlying goal, on the other hand, is to make the purchasing process consistent across the organization.

Procurement governance and compliance don’t just involve legal regulations. Recent policies cover sustainable and ethical efforts, such as sustainable sourcing, diversity initiatives, and environmental impact. Such regulations depend on various criteria, from industry-specific requirements to national and local laws.

For example, if your company is ordering raw materials from a supplier abroad, it must comply with customs regulations and chemical and safety standards. No matter the type of regulation, the goal is the same—to ensure that each step of the procurement process meets legal, ethical, financial, and environmental standards.

Examples of non-compliant procurement

No company is perfect—even the most stringent operations have one or two instances of non-compliant purchasing. Whether they were caused by lackluster regulations or improper cost control protocols, these slip-ups highlight the vulnerabilities in the procurement system. Let’s take a look at some ways in which these failures manifest:

- Maverick spend. Employees make purchases outside approved vendors, often due to convenience or lack of knowledge. Although one-off purchases from Amazon seem harmless, repeated instances might cost the company volume discounts, valuable contracts, and even its reputation.

- Inadequate record-keeping. Consistent documentation is your main proof of purchasing compliance. With scattered receipts, missing RFPs, and incomplete approval logs, records become a liability. Auditors aren’t the only ones affected—the entire procurement team is set to spend hours piecing together an audit trail.

- Conflict of interest. Employees might accept gifts or monetary compensation (kickbacks, commissions) for contract steering—deliberately directing an order to a specific supplier.

- Non-compliant contract execution. Although in theory contracts bind every procurement interaction, the reality often falls short. Contracts lose up to 40% of their value post-signature. Delayed payments and not following through with purchase volumes all lead to strained supplier relationships and possible legal disputes.

- Unsustainable sourcing. When choosing suppliers, companies need to consider not only cost and business interests, but also environmental impact. Nowadays, regulations like ESG and CSRD exist to promote responsible resource use and control carbon emissions. Non-compliance with sustainable procurement practices has severe consequences: fines, reputational damage, and in some cases, even legal disputes.

- Expired supplier certifications. If a supplier fails to update their certification, it puts them and your company at risk. This oversight opens the door to legal consequences and increases the risk of substandard materials ending up in your finished product.

Types of procurement compliance

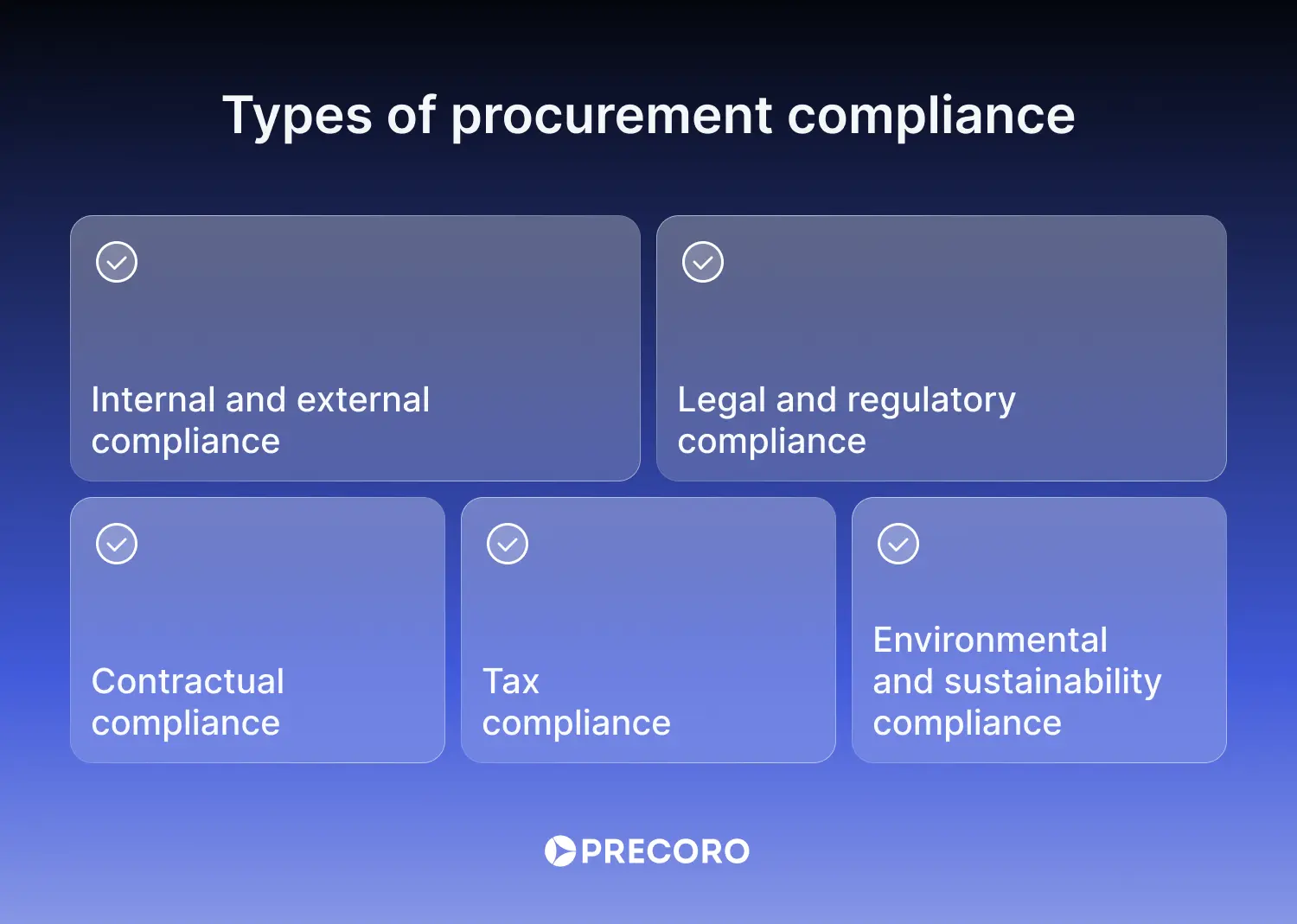

Not all purchasing compliance is created equal, and knowing which type of regulation you’re dealing with can make or break your purchasing decision. Regulations largely depend on the industry in which your company operates, the country, market reach, and various other criteria. Here are the most common types of procurement compliance, each with its own set of risks and rules.

Internal and external compliance

Both internal organizational policies and external regulations shape procurement compliance. Internal compliance consists of the purchasing guidelines and standards set by your own organization to keep procurement in check. These so-called guardrails help keep spending under control and structure the entire procurement process.

Companies that bid in public contracts—to deliver goods or services to state-owned or governmental organizations—are often required to enforce stringent internal procurement policies. For example, if the city hired a private firm to construct a bridge, the company would have to provide documented proof of how the procurement process is safeguarded.

Internal compliance rules aren’t optional, and failure to comply with them can have tangible consequences. Depending on the severity of the violation, it can lead to suspension, termination, financial penalties, fines, and even legal repercussions. Everyone who’s the slightest bit involved in procurement should know the internal workings of the process to avoid costly mistakes and slip-ups.

Examples of internal procurement regulations include:

- Procurement approval thresholds

- A catalog of preferred suppliers

- Purchasing card rules

- Contract management protocols

- Conflict of interest disclosure

- Audit and review protocols

External compliance, on the other hand, is imposed outside the organization. These regulations can be industry- or tax-related and enforced by local, national, and international law or regulatory bodies. If your company bids on public contracts, sources materials from overseas, or sells products across the country, your procurement process has to meet applicable requirements.

These rules aren’t just a box to check off your list. They’re designed to prevent fraud and unethical practices and make procurement a safe process for employees, suppliers, and end customers.

External procurement governance and compliance also raise the stakes. Although internal non-compliance can cost you your job and legal disputes, the price tag is heavier here: financial fines, blacklisting, legal battles, reputational damage, and even criminal charges. Between 2022 and 2024, around 19% of organizations faced legal action from the government and regulatory bodies because of compliance issues.

External compliance examples include, but are not limited to:

- Trade sanctions and embargoes

- Labor and human rights laws

- Environmental compliance standards

- Tax compliance

- Industry-related certifications

- Supplier contracts

- Intellectual property

Legal and regulatory compliance

Procurement teams often have to navigate multiple legal frameworks under which their company operates. Legal procurement regulations essentially enforce a structure for a corporate procurement process. It’s there to protect the markets from corruption, prevent monopolization of opportunities, and stop any form of discrimination or exploitation at the root.

Legal regulations vary in requirements depending on the industry and the locale of your company. For example, food production companies need to ensure their sourcing practices meet food safety standards, such as the Food Safety Modernization Act in the U.S. or EU Regulation 178/2002. Such laws require businesses to provide a traceable overview of the end product’s origin, starting from the initial supplier of raw materials.

Companies importing goods must comply with international trade laws, such as customs regulations, tariffs, and sanctions. Some laws, such as the California Transparency in Supply Chains Act, also regulate sourcing practices and require large businesses to vet the supply chain for suppliers who engage in exploitative or unsustainable practices.

Legal compliance ensures fair supplier competition, complete transparency in public or shareholder funds spending, and adherence to labor laws in supply chains. Following these regulations isn’t optional; they’re not just recommendations but rules set in stone.

Contractual compliance

Signing the contract is only one part of the deal—actually sticking to it is an entirely different story. Contractual compliance is a vital part of contract management and a crucial step of the vendor lifecycle, overseen directly by the procurement and compliance teams. Here, you focus not only on whether the supplier performs their due diligence but also whether you are able to meet the negotiated purchase volume and payment terms.

Tax compliance

Six Sigma Research estimates that businesses can lose $6 million per $1 billion in procurement costs due to mishandling taxes. Tax obligations are notoriously complex: when businesses buy goods or services, taxes need to be calculated correctly, based on who the vendor is, where the product is sent, and how it's used.

Lines blur when you’re dealing with different countries, since each jurisdiction has its own set of regulations. What counts as a business expense, how sales tax applies, or systems like VAT in the EU, can vary from place to place. If any step of the process goes wrong, it can lead to overpaying taxes, delays in payment approvals, or even penalties during audits.

A key part of tax compliance in procurement interactions is verifying if the supplier has any history of tax debts or disputes with tax authorities. If a supplier doesn’t pay taxes or submit proper documentation on time, it could be a sign of potential issues down the road.

Environmental and sustainability compliance

Meeting Environmental, Social, and Governance (ESG) goals is a priority for many organizations. Companies now more than ever understand the impact their decisions have on the environment and society as a whole. With frameworks like ISO 20400 and the Corporate Sustainability Reporting Directive (CSRD) imposed on procurement, companies are more careful about choosing new suppliers and sourcing manufacturing processes.

Are the suppliers using ethically sourced materials? Are their safety and security certifications up to date? Are their workers paid fairly? These are just some questions that plague the minds of procurement leaders, who want to make sure the company’s sourcing meets sustainability standards.

Procurement compliance KPIs

To make sure you’re aware of the pitfalls and potential shortcomings in the company’s procurement compliance, choose appropriate key performance indicators (KPIs). Define what compliance regulations your company needs to focus on and select metrics based on those.

Let’s examine some KPIs you can use to understand how compliant your procurement process really is.

Spend under management

Spend under management tracks how much of your total spend is actually managed by the procurement team. When you know the percentage of your spend that went through the procurement process and approval framework, it’s much easier to identify spend leakages and non-compliant spending.

Tracking spend under management also helps prevent maverick spend and potential budget overruns. For example, the company determined that 80% of the total spend was properly approved and handled by the procurement team. That means 20% was spent outside the procurement cycle—probably through unapproved suppliers or maverick purchases. With this knowledge, the team can focus on the 20%, identify the gaps, and develop solutions to reduce this number.

Supplier diversity

Supplier diversity refers to involving suppliers from underrepresented groups in your supply chain. Nowadays, 97% of Fortune 500 companies have dedicated supplier diversity programs, where minority-owned businesses can compete for a place in the procurement process. Some governmental mandates require a certain number of contracts to be allocated to vendors from minority groups. Most of them set an established quota of diverse suppliers that the governmental agency needs to work with to stay compliant.

On a more profound level, businesses can focus on supplier diversity as part of their corporate social responsibility efforts and ESG goals. By choosing suppliers from different geographical regions, minority groups, and small businesses, your company demonstrates that it cares about inclusivity.

Audit finding resolution rate

How quickly your company resolves issues found during audits can provide a clearer picture of the state of procurement compliance inside the organization. Procurement audits must be carried out regularly to ensure all employees follow the best practice procurement policy.

Audit finding resolution rate tracks the percentage of audit findings resolved within a certain timeframe. This metric is especially important in public procurement among government agencies.

A high resolution rate points to efficient processes and a proactive approach to procurement—employees take accountability for missteps and quickly work on a solution. On the other hand, a low resolution rate is a sign of a lack of ownership, unclear communication, and resistance to change. Tracking the time spent fixing issues found during audits can help structure the resolution process and assign responsible employees to the case.

Contract compliance rate

Compliance rate in contract management measures how many contracts adhere to the established requirements—delivery times, purchase volume, and quality standards. This metric is especially useful when you’re experiencing issues with vendors and want to figure out whether your sourcing processes are more trouble than they’re worth. You can calculate contract compliance with the following formula:

(Total Contract - Non-Compliant Contracts) / Total Contracts x 100% = Contract Compliance Rate

Example: (73 - 11) / 73 x 100% = 84%

The calculation above shows that 11 of the 74 contracts didn’t comply with the policies, which makes the compliance rate 84%. From this point forward, the procurement team can analyze which departments experienced contract issues and implement new controls, such as a supplier performance review or a more stringent contract handover process.

Procurement cycle time

Procurement cycle time tracks how long the entire procurement interaction lasts, from the initial purchase order to final delivery. This metric helps your company identify inefficiencies in the procurement process.

If the transaction spans longer than planned (for example, the order had to be delivered by July but was shipped out only by mid-August), it might be a sign of an overcomplicated procurement structure, riddled with unnecessary approvals or negligent suppliers.

Non-compliance incidents

The simplest way to determine if your procurement is actually compliant is to calculate how many violations occurred over the course of a month or a quarter. A yearly figure can also help track the general dynamic of procurement compliance in your company. Examples of such incidents include an employee skipping an approval step or purchasing from an unapproved supplier.

Cost of compliance

Procurement governance and compliance require money and resources, which is exactly what compliance cost measures. These costs have been steadily rising, with nearly two-thirds of companies expected to increase their compliance budgets in the coming years.

All expenses a company takes on to meet regulatory requirements count toward this metric. If any resource is used to stay compliant, it adds to the compliance cost. Common examples include employee wages, software costs, and time spent on reporting and audit resolution.

Reporting rate

The reporting rate measures how often the required documents, such as incident logs, supplier certifications, and compliance records, are submitted on time. With a well-developed reporting routine, the procurement team can be ready for audits or reviews and spot issues as soon as reports come in.

Purchasing compliance roadblocks

Staying compliant is important, but it’s not always easy. In an attempt to stick to regulations, procurement teams run into issues that delay the process or prevent any progress altogether. Here are the key challenges your company may face on its way to full compliance.

Rapidly changing regulations

Laws and regulations—no matter if they’re industry-specific or set by the government—can change at any time. The timeframe varies, with things like anti-corruption laws updating irregularly, often after a scandal or a major incident. Other regulations, such as the EU Corporate Sustainability Reporting Directive (CSRD), are subject to review every three years. This means companies have to keep all the internal processes and procedures aligned with the updated regulations to avoid trouble later on.

Location-specific policies

Does your company plan to sell its products on an international scale or open a branch overseas? While ambitious, these initiatives open the door to a whole new gamut of regulations.

Working with foreign suppliers? If the vendor is from the U.S. and your company is from the EU, make sure to check whether the supplier has an export license, if they need one. New tariff policies are also a concern. With the introduction of US tariffs on foreign goods in 2025, companies have to bear rising freight costs, which increased to 18-30%, depending on the industry sector.

Manual processes

Procurement governance and compliance are often riddled with paperwork—certifications, contracts, reports, invoices, all scattered across multiple desks or devices. Without a centralized platform, it’s difficult to track procurement non-compliance and quickly react to audit findings.

Compliance and reporting software like Precoro provides specific methodologies for data collection, procurement intelligence, and filling out ESG questionnaires. Thanks to a custom report builder, you can use Precoro to create a customizable CSRD report without wasting time gathering data.

Supplier transparency

Even if the company has complete control over its internal processes, some things still may slip through the cracks externally. If your company doesn’t use a vendor management system, supplier information is scattered across different platforms, leaving procurement teams to manually track and update the data.

In some cases, supplier communication leaves much to be desired, with some suppliers not sharing crucial details. This exposes your company to numerous risks, such as unethical supplier practices, non-compliance instances, and supply chain delays.

Cybersecurity concerns

Digital procurement and compliance solutions make purchasing that much easier and faster, but they also come with new risks. Since sensitive financial data is stored there, data breaches and cyber threats might be fatal to the entire company if the software doesn’t have a secure data protection system.

It’s also important to ensure that the platform you wish to use complies with the required regulations. For example, Precoro upholds the data protection standards set by GDPR, HIPAA, SOC 2 Type II, UK GDPR, and CCPA.

Procurement compliance: Best practices checklist

Once you've established just how important procurement compliance is to protecting your business, it’s time to take action. While every company has a different set of compliance regulations, most of them can be addressed with seven straightforward steps:

- Prioritize risks. Start by identifying high-risk areas that require immediate attention. If the issue can seriously damage the company and leave it vulnerable to other threats, it should be addressed immediately. Low-risk problems can wait, but set a clear timeframe to resolve them.

- Implement regular audits and reviews. Internal audits shouldn’t be just a formality. In the hands of a skillful procurement team, they become a powerful tool that keeps your purchasing compliant and structured. Besides spotting gaps and violations, procurement teams can use audits to highlight what’s working well and implement these practices in the problem areas.

- Build a selection of vetted suppliers. Contracts with reliable, pre-approved suppliers help reduce maverick spend, quality issues, and non-compliance incidents. Before adding the vendor to the approved list, verify their credentials and certifications and conduct background checks. A supplier management system keeps all your supplier information in one place, ready for regular review and updates.

- Establish clear procurement policies. Consistent purchasing guidelines define who can buy what, from which supplier, and under which contract. They also outline approval workflows that each purchase needs to go through before final delivery.

- Train dedicated teams. Even the most effective policies are useless if the team isn’t aware of them. The procurement team needs to have complete access to procurement guidelines and receive regular training on any compliance rules and regulations.

- Monitor regulatory updates. Laws and regulations are subject to regular review. Monitor any industry or regional updates and notify the dedicated teams of any changes. The established policies also must be reviewed as the regulations change.

- Develop contingency plans. Force majeure situations, such as natural disasters, power outages, and geopolitical events, can disrupt supply chain and procurement operations. Create a detailed backup plan that outlines steps of action, alternative suppliers, and a clear stakeholder escalation procedure. This way, the procurement team can act immediately and prevent as much damage to the company as possible.

Frequently asked questions about procurement compliance

Procurement compliance means making sure all procurement activities comply with legal, regulatory, ethical, internal, and external policies. Examples of these policies include CSRD, HIPAA, trade sanctions, vendor certifications, and contract agreements.

Any company can measure procurement compliance with the following metrics:

- Spend under management

- Contract compliance

- Audit findings

- Non-compliant incidents

- Contract compliance rate

- Supplier diversity

- Cost of compliance

- Reporting rate

Procurement compliance isn’t just a formality. While some rules might seem strict and limiting, they help protect organizations from major legal, financial, and ethical risks that can damage the company in the long term. Compliance regulations make procurement fair and transparent for everyone involved—suppliers, employees, and end customers.

Non-compliance can affect your company both legally and financially. Failure to comply with regulations can lead to legal disputes, fines, fraud, and contract cancellations. It also opens the door for unethical practices that don’t align with the company’s sustainability and environmental goals.

Procurement compliance and reporting software helps you stay in control. Such tools automate CSDR reporting by collecting data and creating customizable reports. As the platform locates data gaps, it offers potential fixes and gives the procurement team complete control over who manages what in each disclosure.

Procurement compliance in a nutshell

It’s easy to mistake purchasing compliance for a simple formality. But it’s much more than that—compliance regulations shield your company’s purchasing from costly risks. Regulations act as a guideline to keep procurement ethical, sustainable, and, most importantly, proactive in meeting corporate social responsibility goals.

Compliance laws and rules are complex and always changing. But with the right tools and structured purchasing policies, your company can easily adapt to updated regulations and keep the business compliant.