10 min read

Procurement KPIs & Metrics: What To Focus on and How To Measure

Check out our list of the top 13 procurement KPIs, learn how to track them, and what to focus on to drive the most value for your company.

As the old saying goes, "If you cannot measure it, you cannot improve it." It is especially true in today's competitive and ever-changing business world. In 2024, procurement success is not about cost savings as much as it used to be. The understanding of the "successful procurement operations" has shifted towards the general value that the procurement function generates for the business.

So, how can companies in 2024 track procurement performance and align it with the business goals and objectives?

The answer is simple: through Procurement Key Performance Indicators (KPIs).

In this article, we'll go through the top 13 procurement metrics crucial for business success. We'll discuss how to track them and what to focus on while using the KPIs for driving the most value from procurement for your company.

- What are procurement KPIs?

- Categories of procurement KPIs

- Cost-saving KPIs

- Quality KPIs

- Delivery KPIs

- Inventory KPIs

- What to focus on while analyzing KPIs

- Boost your procurement performance with the right software

What Are Procurement KPIs, and Why Use Them?

Procurement KPIs (Key Performance Indicators) are measurable metrics that help organizations assess how well their purchasing and sourcing activities perform. These indicators offer valuable insights into key areas such as cost control, efficiency, quality, and supplier reliability.

By tracking procurement KPIs, businesses can pinpoint opportunities for improvement, streamline processes, and ensure their procurement efforts support broader strategic objectives. In general, procurement KPIs play an important role in understanding whether the business is growing or stagnating.

As a result, by tacking the right KPIs, company stakeholders can significantly improve their decision-making process by backing it up with the actionable data.

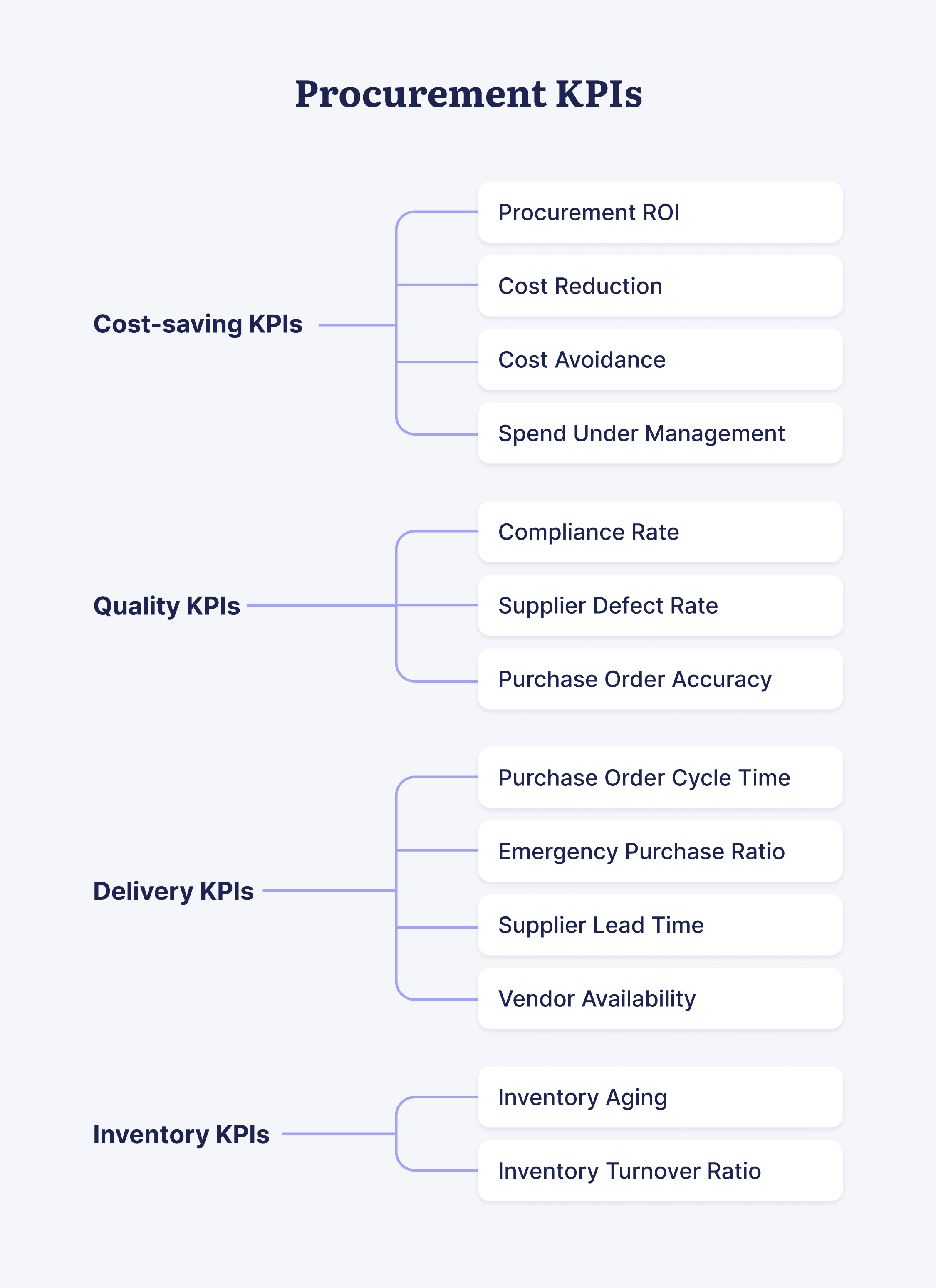

Procurement KPI Categories

When it comes to procurement KPIs, there are many to choose from. And even then, it's not uncommon for the companies to come up with their own custom metrics.

In this article, we are going to look at some of the key procurement KPIs that are generally used by companies of all sizes across different industries. Depending on their purpose, there are the following procurement KPIs categories:

- Cost-saving KPIs: Procurement ROI, Cost Reduction, Cost Avoidance, Spend Under Management (SUM).

- Quality KPIs: Compliance Rate, Supplier Defect Rate, Purchase Order Accuracy.

- Delivery KPIs: Purchase Order Cycle Time, Emergency Purchase Ratio, Supplier Lead Time, Vendor Availability.

- Inventory KPIs: Inventory Aging, Inventory Turnover Ratio.

All of these KPIs are importnat for the company that wants to take a comprehensive approach to maximizing the value of the procurement function. That can definitely be a long-term goal for ensuring that the business flourishes.

At the same time, a business that is currently facing difficulties in the source-to-pay cycle, might need to focus on the previously overlooked KPIs as a short-term goal.

Let's go over specific procurement KPIs and discuss how to make the most ouf of tracking them.

Cost-saving KPIs

Procurement ROI

Procurement ROI is used to determine the overall profitability and cost-saving benefits of a procurement function.

How to measure: Calculate the ratio of your annual cost savings to your internal yearly costs of procurement.

It is important to keep in mind that procurement ROI measures only the hard savings and does not consider cost avoidance. Therefore, it works best when correlated with other KPIs for a complete picture of the procurement team's performance.

Cost Reduction

Cost reduction helps measure the tangible hard savings achieved over a certain period using cost management practices.

How to measure: Compare the old costs with the new costs for the same goods or services. Then group the purchases by the suppliers and track the ones with the highest savings.

Cost reduction KPI tells you how competent your procurement team is at driving savings and how effective their cost management techniques are. This metric can also be integrated in the supply chain analytics and help the procurement department to optimize costs by prioritizing the most efficient vendors and suppliers.

Cost Avoidance

This procurement KPI helps the procurement department reduce future costs and prevent price increases that are usually caused by inflation or other economic factors.

How to measure: Subtract the total amount of the the awarded bid from the average cost of the product.

Cost avoidance KPI measures how effective are preventive actions undertaken by the procurement team. Such actions can include, for instance, negotiating better contracts with the suppliers, initiating replacement of the faulty equipment, or investing in the purchasing process improvement.

Unlike cost reduction, cost avoidance targets strategic spend and soft savings that don’t explicitly appear in the company's bottom line. This is why for the full picture, it should be assessed together with the cost reduction KPI that tracks hard savings.

Spend Under Management

Spend under management or SUM is the percentage of procurement spending that happens under the control of procurement managers, with their knowledge, and in accordance with the established operational workflows.

How to measure: Calculate the difference between the total approved spend (direct and indirect costs) and maverick spend.

While complete elimination of maverick spend is quite unrealistic, organizations can track the SUM to ensure that unmanaged spending is kept to the minimum. Ultimately, the higher the percentage of strategically managed costs is, the more potential there is for recognizing cost-optimization opportunities.

Quality KPIs

Compliance Rate

Measuring compliance rate helps companies understand how well their suppliers meet the business requirements.

How to measure: Compliance rate can be measured in several ways by calculating:

- The ratio of disputed to total invoices.

- The difference between the paid and quoted prices.

- Accuracy of the quantity of delivered goods.

Compliance rate follows how well the company's suppliers are aligned with contracted terms, such as delivery time, prices, maximum response time in case of any issues, payment method, etc. If this KPI rate drops, it may result in the company having to purchase from suppliers outside of the contracted scope and, therefore, in a higher risk of indirect or maverick spending.

Supplier Defect Rate

This KPI is used to evaluate the quality of each supplier by measuring the total number of substandard products to the total number of units inspected.

How to measure: Divide the total number of defective products by the total number of units tested.

The procurement department can calculate the supplier defect rate based on defect types and generate valuable insights into supplier performance and reliability. This is especially important for industries like automotive and aerospace, where supplier bases are multi-tiered and the cost of each mistake is high.

Purchase Order Accuracy

This metric is used to assess whether the suppliers deliver the correct goods at the right time according to the purchase orders.

How to measure: Calculate the percentage of purchase orders which were not fulfilled as issued (compare items, prices, quantities, and delivery date/address errors) to the total number of issued purchase orders, typically over a certain period of time.

A low purchase order accuracy can substantially increase the company's operating costs. That's why it's critical to track this KPI to ensure that the ratio of inaccurate product or service deliveries remains low.

Delivery KPIs

Purchase Order Cycle Time

This KPI indicates the total time spent on fulfilling a purchase order, from its creation to payment completion.

How to measure: Calculate the total time spent on fulfilling the purchase orders and categorize the suppliers according to the order completion time:

- less than 4 days — short cycle time;

- from 4 to 8 days — medium cycle time;

- more than 8 — long cycle time.

The purchase order cycle time metric doesn't take into account how long it takes to produce and deliver the goods and is typically measured in hours or days. This KPI is especially valuable when it comes to selecting the right supplier to fulfill the urgent orders.

Emergency Purchase Ratio

This metric indicates how often the organization has to make emergency purchases and ultimately, how well the procurement department executes plans.

How to measure: Calculate the ratio of emergency purchases to the total number of purchases made over a fixed period of time.

While emergency purchases are sometimes a necessary last resort due to unexpected product shortages, a high rate of ad hoc orders can easily result in high procurement costs, missed discounts opportunities, and maverick spending. It's also a sign of poor procurement planning.

Tracking emergency purchases and taking consistent actions to minimize them helps businesses save money, improve procurement strategies, and ensure the continuity of the goods supplies.

Supplier Lead Time

This KPI reveals how long it typically takes for a supplier to ship an order after receiving it.

How to measure: Subtract the PO acceptance time from the delivery time (goods and receipts delivery).

Supplier lead time is typically measured in days from the goods availability confirmation till the delivery and three- (or two-) way matching. If particular suppliers consistently fall short of projected lead times, it can affect the purchasing company’s ability to fulfill its own obligations. Procurement leadership might need to reconsider cooperating with such suppliers.

Vendor Availability

As stated earlier, a high ratio of emergency purchases isn't something a business should strive for. Still, if the push comes to shove, it's good to know that you have vendors that can respond to emergency orders.

How to measure: Fot the specific vendor, calculate the ratio of the number of times when items were available immediately to the total number of orders placed.

When measuring supplier availability, you always know whom you can rely on in case of a critical situation.

Inventory KPIs

Inventory Aging

An inventory aging KPI indicates how quickly your inventory moves. By inventory, this KPI means all available items that are grouped based on the time kept in inventory.

How to measure: To calculate inventory age, follow the formula: average inventory age = [average inventory cost ÷ cost of goods sold] x 365.

The inventroy aging KPI is used to determine which inventory items are moving too slow or even are obsolete and the costs associated with storing and maintaining these items. A good inventory age is usually somewhere between 60 and 90 days from the date of receipt. Inventory over 180 days is generally considered dead stock and should be prioritized for utilization before ordering new products.

Inventory Turnover Ratio

This metric shows how often a company sells and replaces inventory during a given period of time, typically a year.

How to measure: Divide the inventory days by 365 and flip it. For example, if inventory has been in stock for 55 days, then the formula will be the following = 1 / (55/365) = 6.7. This means you can sell and replace the stock of goods about 6 to 7 times a year.

Inventory turnover ratio helps businesses evaluate effectiveness of inventory management and make better decisions on purchasing materials, manufacturing goods, and pricing them for sale.

A low inventory turnover ratio may indicate weak sales or excess inventory, while a higher ratio indicates strong sales but may also mean inadequate inventory stocking.

What to Focus on While Analyzing KPIs

As you can see, there are many procurement key performance indicators to follow. Tracking them all at once may not be a good option, as it can easily lead to losing the focus, data confusion, and poor measurements.

At any given moment, it's better to narrow the list down to the most critical KPIs. That will help procurement management identify and improve poorly optimized supply chain processes and ultimately, drive the company's strategic procurement.

Let's discuss how to select the most relevant procurement KPIs for your business.

Prioritize

Choose one or several metrics that will directly contribute to your organization's specific procurement goals for the next period of time. Consider how time-consuming tracking specific KPI may be and how many individuals you have available for this task.

Check if the selected KPI meets the following criteria:

- Is it easy to measure the KPI promptly and accurately?

- Does this KPI align with the overall company objectives and strategy?

- Does the KPI cover a wide array of procurement goals?

- Do we have enough people to measure it properly?

- Will the KPI have the potential to help us solve the current procurement challenges?

If most of these questions are a “yes,” the KPI is one to track.

Allocate Responsibilities

KPIs serve as valuable tools for measuring progress and it's important to get them right. The results of procurement analysis are better if there is a responsible team dedicated to tracking and reporting on the given KPIs. Allocate the KPI responsibilities to specific teams or individuals and establish appropriate deadlines for preparing reports.

Make It Systematic

Don't forget to check your KPIs regularly, e.g., monthly, quarterly, or by other predefined reporting frequencies. Regular monitoring is crucial for recognizing if the business is under- or over-performing, if any preventive measures need to be taken, or if more resources can be allocated to the procurement team.

Considering that many goals of different departments within organization are interconnected, it's important to share the findings abour the relevant procuremet KPIs across organization. This ensures that all stakeholders are on the same page.

Boost Your Procurement Performance with the Right Software

Key performance indicators are valuable tools when it comes to measuring the performance of the procurement function and identifying the opportunities for boosting general business value.

To ensure availability of the reliable procurement data, progressive companies implement dedicated procurement automation software. Without proper technology in place, it can be quite challenging to collect data, keep track of the procurement KPIs, and drive improvements. And that's relevant for various industries, whether it's a construction business, renewable energy sector, hospitality, healthcare or other industries.

Let's see how a procurement solution can help:

- Have all the necessary data easily accessible anytime and anywhere.

- Streamline requests, purchase orders, invoices, and vendor management.

- Track all procurement KPIs from a centralized dashboard.

- Eliminate redundant and repetitive tasks with the process automation.

- Decrease HR’s workload by reducing the need to hire and train more staff.

- Sync documents, vendors, and all the information you need within accounting or ERP systems.

These are just a few benefits that over 1000+ Precoro customers enjoy daily. Our procurement software is one of the best solutions available the USA, the UK, Australia, and South Africa.

Want to experience these benefits yourself? Book a demo to have a personalized product overview and get all your questions answered.

Conclusion

Procurement KPIs are metrics for tracking and evaluating the efficiency of procurement processes within an organization. These metrics help companies gain actionable insights into both internal and external source-to-pay operations and better align procurement strategy with the business objectives.

While a company can track many key performance indicators, it is crucial to set priorities correctly in order to achieve the best results. Procurement leaders should take the time to define their business current needs and select KPIs that help meet those needs. Progressive companies also chose to implement dedicated software for procurement data consolidation and analysis.