28 min read

How Supplier Onboarding Can Make or Break Your Procurement Process

Supplier onboarding sets the tone for every vendor relationship. Learn the steps, best practices, and useful tools to get it right.

Paying on time is no longer enough for a successful partnership. Sustainable long-term cooperation comes first, and transactions go second: 60% of businesses say working with supply chain partners is crucial to solving logistics and supply chain challenges. In a world that’s getting desensitized to disruptions, lasting partnerships now take precedence over the transactional nature these relations once had.

A productive supplier relationship begins long before the first invoice arrives in your inbox. The first seeds are planted when a vendor grows familiar with how your organization works and is formally introduced into its systems—during supplier onboarding. It’s the foundation of the entire relationship, which establishes expectations, rules, and points of communication for both parties.

This article will explore the advantages of a structured system for this process, its key stages, challenges, proven methods, and best tools for managing supplier onboarding in 2026.

Keep reading to find out:

What is supplier onboarding?

A step-by-step breakdown of supplier onboarding

Where the supplier onboarding process breaks down

Benefits of supplier onboarding

Supplier onboarding best practices

What to look for in vendor onboarding software

Best tools for managing supplier onboarding in 2026

Case in point: Supplier onboarding with Precoro

Frequently asked questions about supplier onboarding

Key insights

What is supplier onboarding?

Supplier onboarding is a critical process that companies follow to gather information about the vendor, verify their legitimacy, and make sure they’re ready to cooperate. The goal of onboarding is to prepare the supplier for collaboration within the company’s purchasing environment and systems. The procurement team collects the data, confirms capabilities and compliance, aligns vendors with organizational policies and expectations, and sets them up in the supplier onboarding software.

The entire vendor onboarding meaning lies in identifying trustworthy and reliable suppliers for long-term cooperation and guiding them through the company's tools and workflows. If done correctly, this step is likely to save your company multiple headaches, as it establishes open communication and clear expectations early on, rather than putting them off for later.

A step-by-step breakdown of supplier onboarding

Supplier onboarding might be systematic, but it’s rarely linear. Just like you wouldn’t use a sledgehammer to crack a nut, you wouldn’t do a complete background check on a vendor who provides printer paper. Some suppliers need a quick setup, while others warrant a thorough due diligence check.

The steps in onboarding depend on how critical or risky the supplier is to the supply chain and the impact they have on the company’s operations, both financially and product-wise. Sometimes, you just need the basics, but in rare cases, skipping crucial steps can cause the entire workflow to fall apart. Use this breakdown of core stages as a supplier onboarding process template for future use:

1. Assess your needs and select a supplier

Like almost everything in the procurement process, vendor onboarding begins with a need and the request to fulfill it. Maybe no one currently supplies what your team’s looking for, or maybe your go-to vendor isn’t cutting it anymore. Either way, someone puts in a request, and the search for a new supplier begins.

The procurement team goes through the entire vendor management lifecycle: they research suppliers, select one through either competitive bidding or direct selection, and initiate the onboarding process.

This step is a preamble for what supplier onboarding is. It’s a consistent starting point, regardless of whether you’re buying corporate merchandise for an event or critical materials for production. The team always checks whether the supplier aligns with company goals, meets the needs, and complies with company policies.

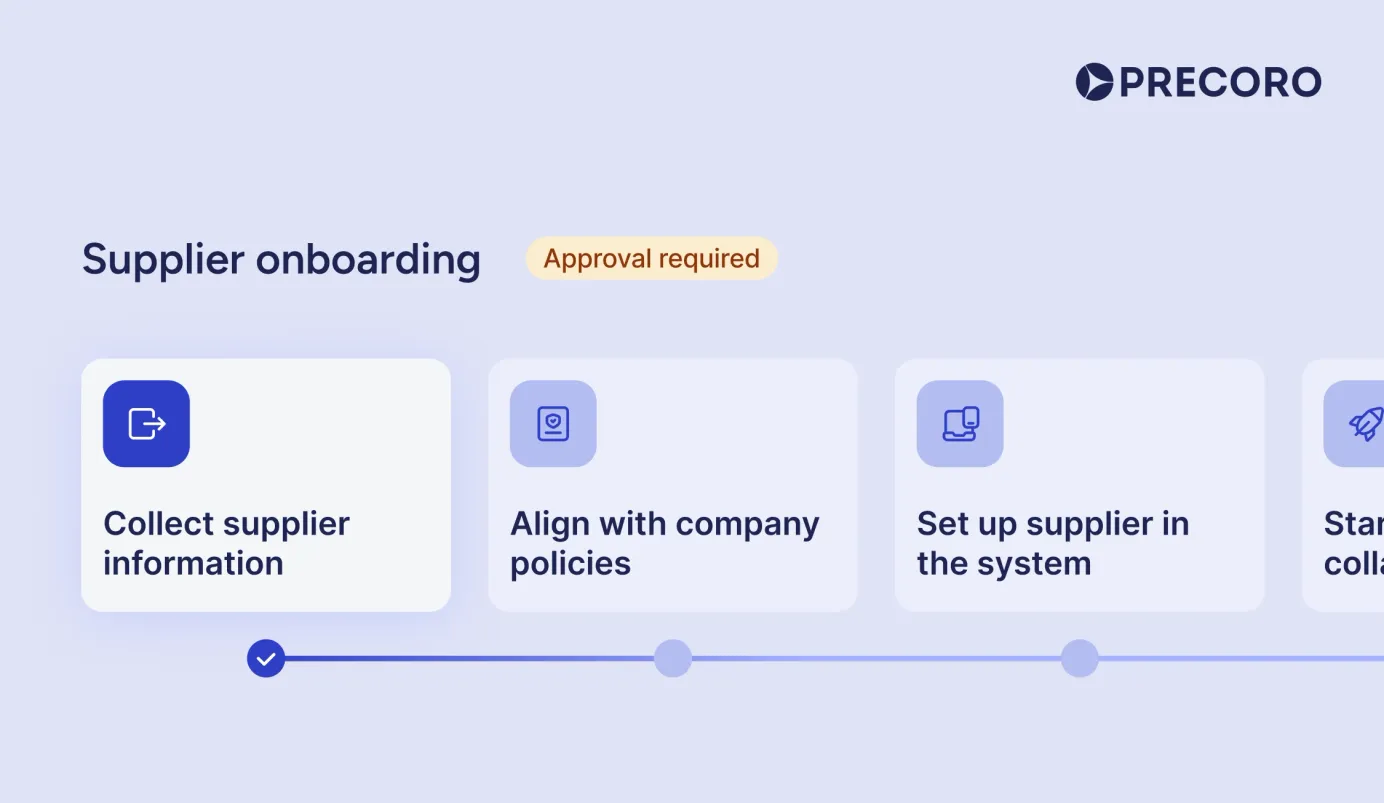

2. Collect supplier information

After the supplier is selected, it’s time to gather all the necessary data on their business. All of it comes in handy later on, during due diligence, contracting, and further collaboration. The information isn’t just necessary for security and safety purposes. Without it, the company won’t be able to pay the supplier correctly or meet its own regulatory obligations.

Supplier onboarding best practices recommend using a standardized form to collect core data, which most companies typically do. They then follow up for specific documents based on supplier type, industry, or internal policies.

What you ask for depends on your priorities. For example, if your organization emphasizes sustainable sourcing, you may request third-party environmental or social impact certifications (e.g., ISO, ENERGY STAR, and others).

Here’s a non-exhaustive list of the most common information to include in your supplier onboarding process template:

- Legal and business identity: Legal name, business address, registration number.

- Tax information: Tax classification, TIN, VAT number, tax forms (e.g., W-9), country of tax residence, tax exemption status (if applicable).

- Banking and payment details: Account number, account holder name, routing or SWIFT codes, and default currency.

- Primary contacts: Points of contact for various purposes, including operational, financial, or legal matters.

- Licenses and certifications: Industry- or region-dependent documentation to prove the supplier can legally provide goods or services.

- Security and compliance documentation: Data protection policies and NDAs.

- Insurance: Proof of required insurance coverage.

- Sustainability and diversity: Certifications for supplier diversity or sustainable practices, ESG reports.

- Product details: Product or service specifications, pricing model, and delivery terms.

- Customer references: Case studies, testimonials, or reference calls.

To verify the data, companies often conduct independent research. They check public records, business registries, and government databases. For critical suppliers, this step may also involve site visits, product testing, and reference calls with customers in the same region or a similar industry.

3. Conduct a supplier onboarding risk assessment

Before any contract is signed, but after prospective suppliers have been selected, companies need to review all collected information and conduct a due diligence check. At this stage, you need to confirm that the supplier can operate safely within the company’s purchasing environment. Due diligence is non-negotiable: in 2025, poor vetting led 41% of companies to one failed vendor relationship, with 66% losing money and 48% suffering from product launch delays.

The degree of supplier onboarding risk assessment will vary depending on the supplier. Low-risk vendors for less critical purchases won’t require a thorough verification. With critical suppliers, however, you need to be cautious and thoroughly vet them. During due diligence, companies verify:

- Company background and structure:

Confirm the supplier’s legal identity, ownership structure, and business registration details. Review how long the company has operated, where it’s based, and who is responsible for management and decision-making. Location matters, especially when suppliers operate in high-risk countries or across borders (unless you’re prioritizing global sourcing).

- Financial stability:

Assess whether the supplier can financially handle the expected scope of work without issues down the line. Review tax records to make sure they comply with local regulations. The supplier’s sales, assets, and liabilities are good indicators of how they’ll perform in the long term. Finally, any investment in R&D is a clear sign that the vendor isn’t staying stagnant but is actively planning to grow.

- Legal and regulatory alignment:

Only 43% of companies review supplier licenses and registrations to confirm they can operate legally. However, the impact of such negligence will fall on you, the buyer, not on them, the vendor. Verify that the supplier meets industry- and region-specific requirements for the goods or services they provide. Check any licenses and certifications in public records. For high-risk vendors, use third-party services to see if the supplier is on any sanction lists or involved with PEPs to steer clear of legal and reputational trouble.

- Corporate responsibility and business conduct:

Whether or not you have formal ESG policies, it’s important to ensure that the supplier meets baseline expectations for ethical and fair labor practices. A brief ethics questionnaire or a signed code of conduct can demonstrate alignment without overloading the process with paperwork.

- Reputation and market standing:

Don’t take everything at face value. Instead of purely relying on submitted information, get a second opinion, either through a reference interview or independent research. Any information on customer feedback or industry awards can help spot red flags before you officially commit to the supplier. Plus, it can be the deciding factor between one supplier and another.

- Information security and data protection:

If the vendor handles sensitive data, you’ll need to assess how they protect and manage it. Ask for ISO 27001 or SOC 2 audits, review their incident response plan, and understand how they manage user access.

More questions don’t mean better or more elaborate answers. Long, exhaustive questionnaires are difficult to review and even harder to fill out. In fact, companies using integrated, simplified vendor onboarding forms were found to catch potential risks 54% sooner.

You might think you’re covering all the bases by asking everything from the vendor’s legal structure to last quarter’s revenue, but this approach easily backfires. Instead, you get rushed, careless responses and skipped fields.

4. Get internal buy-in and approval

During a supplier onboarding risk assessment, involve relevant stakeholders to ensure the supplier is fully approved to enter the company’s purchasing workflows. Procurement should confirm the vendor actually meets the business requirements, while finance needs to verify that they have enough information for future payments.

Legal gives the green light once the supplier checks all the boxes—licenses, certifications, and compliance with the regulations that matter to your business. Meanwhile, IT weighs in on access to the company’s software for supplier onboarding and compliance: what data can be shared, how securely, and whether the supplier can be added to your tech stack.

5. Draft and sign a contract

Once a company approves a new supplier, it should sign a contract outlining the terms and conditions of the working relationship. This step fluctuates throughout the onboarding process. Some companies require signing an agreement before the supplier can be officially onboarded, while others are more lax and consider it a final step.

At this point, all the discussions and negotiations turn from simple words to a firm commitment. The supplier contract typically outlines:

- Delivery schedules and fulfillment expectations

- Points of contact on both sides to keep communication clear and consistent

- Intellectual property rights, especially for services or custom work

- Confidentiality and data security requirements, particularly when systems or sensitive data are involved

- Deliverables, which define the specific goods, services, or outcomes the supplier must provide

- KPIs to measure performance over the course of a partnership

- SLAs, which set response times, uptime, or quality standards

- Penalties, applied when deadlines, quality standards, or compliance requirements are missed

- Escalation clauses, which define how issues are raised and resolved

- Exit and termination clauses, which explain how either side can end the agreement without disputes

Regardless of when you sign the contract, this agreement establishes expectations and responsibilities before any purchase orders or invoices are issued. Using specialized supplier onboarding software proves beneficial at this stage as well. Tools like Precoro help teams store, manage, and track contracts in one place as part of the process.

6. Add the vendor to internal systems

Integration into the internal systems is the crux of supplier onboarding. During the contracting phase, the supplier is assigned a point of contact person, usually from the vendor management or procurement team. Together with the IT specialist, they help set up the vendor in ERP or the company’s software for supplier onboarding and compliance.

Without a dedicated tool, communication with the supplier typically occurs via email or messaging platforms, while performance is recorded in spreadsheets. Such a setup makes it nearly impossible to track what was approved, what’s still pending, and which document belongs to which vendor. The best supplier onboarding software provides visibility into the entire trail of purchase, from the first request until final receipt, which is a much better and structured approach.

At this stage, your team creates the supplier record in the purchasing and accounting systems, using approved information such as the legal name, tax details, payment method, currency, and categories. Teams also define how the vendor works with the new supplier onboarding process:

- Are purchase orders required?

- Who approves PRs, POs, and invoices?

- How will the supplier submit invoices?

- Where is the key communication happening?

With Precoro’s Supplier Portal, suppliers can self-register, enter their own details, and communicate with the team in one place. No need for email back-and-forth; only a clear, up-to-date record is required.

7. Instruct the supplier

The onboarding doesn’t end with the supplier entering the system. You can’t just let them free-fall into the new purchasing environment, especially if they haven’t previously worked with supplier onboarding software.

Before the first transaction, guide the vendor through the entire procurement process. Tell them exactly how requests are made, when they turn into purchase orders, and which details from POs must be included in the invoices.

Go through invoicing as well: if you’re in the EU, many countries have already adopted a mandatory e-invoicing B2B mandate. If you’re using supplier onboarding software, set up a separate meeting or send detailed instructions to guide them through the system.

Where the supplier onboarding process breaks down

Once onboarding is established and has been proven effective in practice, there isn’t much that can go wrong. But before you have any supplier onboarding process or flow, even a missed message can skew the entire system. These bottlenecks might cause it to last up to six months—an egregious amount of time during which you could’ve already bought the supplies from a different vendor. Look out for these gaps when onboarding suppliers:

- Too many people are involved

Procurement or the dedicated vendor management team will likely handle the majority of the process, while finance, legal, and IT each focus on their own part. What matters is having a single place where all teams can see progress, share updates, and stay aligned throughout the project.

Fragmented onboarding might seem efficient at first, as each team handles its own responsibilities, but in practice, progress happens simultaneously but doesn’t line up. To make matters worse, if multiple teams contact the supplier separately, the supplier might get a skewed interpretation of their expectations or not know which instructions to prioritize.

- Onboarding is manual and reactive

Vendor onboarding often remains reactive and manual in its initial stages. Employees track their progress in spreadsheets and collect data haphazardly via multiple emails, texts, or even phone calls, without any audit trail to speak of. Some companies don’t initiate the onboarding process until after the invoice is issued, which means the supplier hasn’t undergone even the basic due diligence checks.

- Data is incomplete from the start

A staggering 82% of companies aren’t confident in the accuracy of their vendor data. Even with supplier onboarding software in place, a lot of the information still relies on manual entry, which makes outdated details or a field left blank almost inevitable. With incomplete or inaccurate data, supplier onboarding will either stall or continue to encounter issues down the line. Smart forms with required fields and conditional logic reduce the risks, but won’t help long-term if the rules aren’t consistently enforced.

- Requirements aren’t clear or consistent

You can count supplier onboarding as a success if the vendors understand what’s expected of them. If those expectations are vague or inconsistent, suppliers walk away with the wrong impression: that working with your company will be just as unclear and disjointed.

This issue concerns both onboarding and future cooperation. One team requests tax forms, another banking details, while a third follows up later for certifications, often through different channels. Internally, there’s no unified supplier onboarding process template, and requirements vary by requester, region, or business unit.

- Suppliers don’t engage

Some suppliers simply don’t prioritize onboarding. Exhaustive, time-consuming questionnaires, lengthy instructions, or complicated setups can all deter vendors from onboarding. If you’re getting one-word answers or no reply at all, it's time to reconsider a different supplier or a more structured approach.

- Overcommitment to low-impact suppliers

Not all suppliers need the same level of onboarding. Excessive focus on a one-time vendor simply wastes time and resources better spent on strategic partners. 57% of companies use the same supplier assessment criteria across all vendors, which does make the process objective and consistent.

However, the downside outweighs the benefits: the onboarding process takes more time. Use a tiered approach by streamlining supplier onboarding for low-impact vendors and giving a deeper, more strategic treatment to suppliers that matter.

Benefits of supplier onboarding

Vendor onboarding is a reflection of your future partnership. You can even think of it as a test drive: you’re not purchasing from them (yet), but you’re learning how each company works and what common ground you have. Besides this, onboarding suppliers comes with several strategic advantages, namely:

Minimizes risks

A simple act of due diligence performed early on, before any invoice lands in your inbox, already mitigates the potential risks that companies without proper onboarding face regularly. Moreover, 86% of organizations that deploy technological vendor onboarding software surface potential risks early. When the company skips onboarding, it’s exposing itself to:

- Dishonest suppliers who turn out to have compliance issues or lack the required expertise once work has already started.

- Legal and financial penalties caused by missing tax details, incorrect supplier data, or documentation that doesn’t hold up during audits.

- Reputational damage when supplier misconduct becomes public after you sign the contract.

- Operational disruptions because suppliers lack the capacity, financial stability, or approvals needed to deliver on time.

- Data security leaks when suppliers gain access to software for supplier onboarding and compliance without meeting security or privacy requirements.

Boosts a company's bottom line

An established evaluation process in supplier onboarding means you’re not only verifying suppliers; you’re also comparing them. You can shortlist suppliers, spot who offers better pricing, reliable terms, and consistent quality, all before you even sign a contract. Of course, you need a structured approach to take advantage of this—an RFI provides all the required structure.

Plus, with a smooth onboarding process, both the buyer and the seller waste less time, resources, and expenses. In the long run, your administrative costs decrease, and employees can focus on creating a product that satisfies customers and boosts sales.

Reduces maverick spending

Maverick spend refers to off-contract purchases from non-preferred suppliers. Employees often bypass the standard procurement process to make unauthorized purchases, which can result in higher costs and reduced visibility into spending. The reasons are often understandable. The team might not know how to purchase correctly, find the current procurement procedure difficult, or believe that using a different supplier is more cost-effective.

Regardless of the reasoning, rogue buying opens an entire can of worms you’d rather leave closed, including higher expenses and exposure to unforeseen risks. Established vendor onboarding clearly defines the requirements for suppliers, what can be purchased from them, under what terms, and through which channels.

Businesses know supplier management is key to preventing off-contract purchases: 56% of leading companies implement pre-approved supplier lists to combat maverick spend. When suppliers are already approved and set up in the company’s purchasing environment, employees are far less likely to go rogue.

Provides transparency in supplier relationships

A well-designed vendor onboarding process helps establish mutual trust with suppliers and sets clear expectations early on. Vendors are aware of the documents required from them, the workflow for orders and invoices, and what specific information they need to provide. Internal teams, on the other hand, receive a clear audit-ready record of suppliers' data and also know precisely what to expect.

After a thorough due diligence and training sessions, there won’t be any surprises down the line. And if something does change, both sides have open communication channels that are there to continue building trust and strengthening collaboration between the two parties.

Reduces time to activate future suppliers

Developing a systematic vendor onboarding process takes time and effort. The documentation you have to design, including questionnaires, terms of cooperation, and a set of requirements, requires a lot of attention to detail and critical thinking. The good news is that once you establish a process, it can be used as a frame of reference each time you onboard a new supplier.

Instead of starting from scratch every time, a sequence of defined steps already saves time and reduces the workload of procurement and other departments, so they are free for other crucial tasks. For example, they can focus on how to automate supplier onboarding processes and make them even more efficient.

Supplier onboarding best practices

Good onboarding doesn’t just add more steps—it optimizes and builds on the ones the company already has. Simple but straightforward rules around documentation, approvals, and digital setup already lay the groundwork for a trustworthy collaboration. Below are supplier onboarding best practices that make sure you get the basics right before adding anything new.

Define the approval process

Companies should designate a person within their organization to be responsible for evaluating and approving new suppliers. Assigning roles helps avoid confusion and reduce redundancy, ultimately leading to a smoother vendor onboarding process.

The number of people or teams involved depends on the size of the organization and the complexity of its supply chain. In small organizations with only a few suppliers, one person or a small team may be sufficient to manage the relationship. However, in larger companies with a more extensive supply chain, you’ll benefit from multiple teams or departments involved in vendor onboarding, such as:

- Procurement to ensure that a potential supplier has competitive pricing and high-quality goods

- Finance to assess the supplier's financial stability and payment terms

- Legal to ensure that the supplier meets legal or regulatory requirements and that the company's intellectual property is protected

- IT to set up the supplier within the company's systems and provide access to the necessary tools and resources

Develop the approval workflow itself: who approves what, at what time, and in what order. For example, procurement may screen suppliers first, followed by finance and legal, with IT setup happening only after final approval.

Implement tiered supplier onboarding

A one-size-fits-all approach might cause more harm than good, both to the supplier and your company. Match the onboarding steps to the supplier’s impact on the company: the more critical they are, the deeper your assessment should go.

Don’t rely on subjective opinions to determine which suppliers carry the most impact: after all, different teams have entirely different priorities. Instead, use segmentation tools that help structure the findings and categorize suppliers.

For example, a Kraljic Matrix categorizes suppliers based on business impact and risk, while the supplier preferencing matrix helps determine how important your company is to the supplier in the early stages of the partnership.

Consider other factors, such as regulatory compliance, data access requirements, and spend threshold. For example, if the supplier needs to comply with additional regulations due to their industry, you might focus due diligence on verifying their licenses. If the purchases are high-spend but low-risk, the company might do a shorter due diligence check than for high-risk vendors.

If you’re using a Kraljic Matrix, the level of onboarding will essentially depend on what the suppliers provide and the degree of risk they introduce. For instance:

- Critical suppliers (high risk, high impact): Strategic vendors whose goods or services are essential to daily operations. These suppliers should go through the most thorough onboarding, including full due diligence, legal review, clear SLAs, and defined escalation paths.

- Leverage suppliers (low risk, high impact): Suppliers operating in competitive markets where pricing and contract terms matter most. Onboarding should focus on terms, pricing, and contract alignment rather than extensive risk assessments.

- Bottleneck suppliers (high risk, low impact): Suppliers that don’t drive profit but are hard to replace and can disrupt operations if something goes wrong. They require risk-focused onboarding, supplier backups, and close monitoring.

- Non-critical suppliers (low risk, low impact): Vendors for non-essential goods, such as office supplies or consumables. Onboarding should be fast and lightweight, with standardized forms, minimal approvals, and catalog-based purchasing to avoid unnecessary overhead.

Make requirements clear and specific

Employees involved must clearly understand what vendor onboarding is, together with the criteria that matter most during supplier selection. That’s the first step, which prevents you from working with suppliers that can't really satisfy the company's needs. By clearly defining your expectations, you’re being transparent with your vendors and setting the standard for future partnerships.

The set of requirements will depend on the company's goals, policies, the industry, and the type of products or services they’re purchasing. They may prioritize:

- Quality standards (such as ISO certifications or industry-specific standards)

- Compliance with regulations

- Specific ethical and social responsibility standards (for example, fair labor practices and environmental sustainability)

- Delivery and lead time

- Pricing and payment terms

- Confidentiality and data security

Undoubtedly, it’ll take some time to consider all the criteria, write them down, and create a clear-cut policy to share on the company's website, as well as a supplier onboarding guide for those responsible. The good news is that once a company establishes a standardized set of requirements and evaluation processes, it won't need to reinvent the wheel with each new onboarding.

Establish an open channel of communication

Vendor onboarding involves sending and receiving a wide range of information, including policies, documents, questionnaires, and messages (such as emails and phone calls). A single communication channel with potential suppliers allows companies to centralize information and quickly resolve any issues. For this purpose, look for a tool that provides a written record of the communication.

Many companies default to using email, which makes complete sense: it’s easy to use, lets you add attachments, and can be accessed anywhere. However, users can't organize the documentation and other data over email, not to mention the effort it’d take to find the needed information later. The same problem also applies to instant messaging platforms like Slack or Microsoft Teams. They’re convenient for straight-to-the-point communication, but aren’t designed for documentation storage.

Specialized tools, such as procurement software with a supplier portal like Precoro, are the ideal option for these scenarios. On such a platform, suppliers can enter their own business details and attach the necessary documents, which will be stored and easily accessible in the system.

Such procurement tools also let companies add new vendors through the supplier onboarding platform, where they can communicate directly with the team. Creation and approval of POs, requests for proposals, receipts, invoices, and other relevant documents can all be done in a single system.

The best supplier onboarding software will also allow you to message suppliers directly from within the tool. For example, in Precoro, companies can share their policies and lists of supplier requirements via a customizable email sent with the initial invite or via the supplier registration form.

Provide training sessions (if needed)

A final piece of supplier onboarding best practices is to establish a successful working relationship between the supplier and the company. That's why you should include training sessions about the company's operations, workflows, and technology stack.

Training might not be necessary if processes are already simple, if there’s no complicated vendor management or supplier onboarding software, or if the supplier already uses and understands the required platform. In these cases, clear documentation and guidelines may be all the supplier needs to work effectively with the company.

For big organizations or businesses with unique workflows or demanding tools, it’s recommended to conduct training or orientation sessions for new vendors. Neglecting this step may result in miscommunication, errors, and a breakdown in the supply chain. The guidance can take many forms, such as walkthroughs, videos, one-on-one conversations, webinars, and more. Usually, the company suggests the preferred format to the supplier.

What to look for in vendor onboarding software

Simply implementing a new tool isn’t enough. The best supplier onboarding software must have substance, features that can be actively used by teams and yield measurable results. Squeaky-clean demos that promise “AI-everything” aren’t enough. In 2026, procurement teams are shifting away from jumping on every automation bandwagon and towards tools that show consistent ROI and stable performance. Here’s what to prioritize when looking for a new supplier onboarding tool:

Centralized supplier profiles

All supplier data, including legal info, tax forms, and banking details, should be stored in one place, with configurable access for everyone who needs it. Leave desktop folders, scattered inboxes, and spreadsheets with confusing names in the past. Prioritize vendor onboarding software that provides a single, up-to-date record of the supplier in your system.

Supplier self-service

Instead of putting more work on your team’s shoulders, let suppliers handle it. Look for systems with a dedicated module that allows vendors to register themselves and submit required information through a secure supplier onboarding portal. Information should flow directly into the system, without manual re-entry or email back-and-forth. At a minimum, the supplier onboarding software should allow teams to:

- Invite an unlimited number of suppliers.

- Create an approval workflow for suppliers.

- Send customized registration forms and adjust mandatory fields such as a legal address, account number, and more.

- Review completed forms, attachments, and notes from suppliers.

- Approve, reject, or send suppliers' forms for revision.

- Automated addition of new vendors and their information to avoid human error and save valuable time.

Built-in approvals and status tracking

You need to see precisely where each vendor is in the supplier onboarding process flow. Tools with built-in, configurable approvals, comments, and real-time status tracking help you identify delays before they become bottlenecks.

Integration with accounting and ERP systems

If you’re using any type of accounting or ERP software, narrow the list down to tools that support seamless integration with it. Without integrations, you’ll have to reenter or edit data multiple times, which is usually where errors and gaps appear. A good supplier onboarding software offers a two-way sync between your favorite tools.

Alerts and reminders

Supplier onboarding often stalls simply because someone misses a step. Built-in alerts and reminders notify both internal teams and suppliers when action is required, whether it’s to review a submission, renew the contract, or approve a purchase order. For example, in Precoro, teams receive an alert when the contract needs to be renewed.

Easy setup and usability

If the tool is difficult to use, suppliers won’t complete onboarding, and your team won’t adopt it. More features don’t mean better visibility. The best supplier onboarding software offers fewer features that are intuitive, quick to configure, and don’t require months of training to adopt.

Best tools for managing supplier onboarding in 2026

Make your investment deliberate. Skip the experiments and choose supplier onboarding software that delivers on its promises and gives you absolute control over procurement and vendor management. Below are the tools that could completely change your approach to vendor partnerships in 2026.

Precoro

Precoro is a procurement centralization and automation software that approaches supplier onboarding as part of the whole procure-to-pay process, not a standalone task. Suppliers can self-register, upload documents, receive POs, and submit invoices through a dedicated Supplier Portal.

Your teams review and approve suppliers through configurable workflows, and approved supplier data can be reused across purchase requests, POs, and invoices. For suppliers that support it, Precoro also offers PunchOut catalogs, so employees buy directly from approved vendors while purchases remain compliant and traceable.

Best for: Mid-sized and growing companies with decentralized purchasing teams that need consistent supplier data, enforceable approvals, and control across the entire procure-to-pay cycle.

Not ideal for: Organizations that only need supplier due diligence or compliance checks without purchasing, invoicing, or spend management workflows.

Coupa

Coupa is a cloud-based spend management platform that supports supplier onboarding through the Coupa Supplier Portal (CSP). Suppliers receive an invitation, register in CSP, and complete the required forms. In some cases, buyers also need a Financial and Legal Assessment questionnaire before approval.

CSP allows suppliers to receive and manage purchase orders in one place, create and submit invoices, and view invoice statuses. The onboarding flow follows formal, standardized steps defined by the organization.

Best for: Large organizations that want standardized supplier data collection, formal approvals, and integrated questionnaires.

Not ideal for: Teams that need lightweight supplier setup or minimal steps for supplier participation.

SAP Ariba

SAP Ariba is a procurement and supplier management platform that handles vendor onboarding through SAP Business Network. Suppliers typically create or link their Business Network account and fill in the required company, tax, banking, and compliance information specified by the buyer.

Suppliers submit their details through structured questionnaires and profiles, which are reviewed by internal teams before approval. Once approved, suppliers can access and update their own information through SAP Business Network and begin receiving POs, submitting invoices, and tracking document status.

Best for: Large organizations that require standardized supplier data and supplier self-service through SAP Business Network.

Not ideal for: Teams that want lightweight supplier setup with minimal onboarding steps for low-risk or occasional suppliers.

Tipalti

Tipalti is an accounts payable and global payments platform designed to help finance teams pay suppliers accurately and on time. Supplier onboarding primarily focuses on the needs of accounts payable, specifically collecting the correct tax and payment details before committing any funds. The platform, unfortunately, doesn’t offer the same depth of procurement workflows as other similar tools.

Suppliers complete onboarding through a self-service portal, where they enter their banking and tax information. The system adjusts required fields based on the supplier’s location and payment method. Built-in reminders keep onboarding moving, and internal teams can step in when a supplier needs help updating details.

Best for: Finance and AP teams that manage high payment volumes, international suppliers, and complex tax or payment requirements.

Not ideal for: Organizations that require supplier onboarding to be closely integrated with broader procurement workflows.

Trust Your Supplier (TYS)

Trust Your Supplier is a risk management and supplier onboarding platform that centers onboarding around a single supplier profile that suppliers maintain and share with connected buyers. Suppliers use TYS Connect to manage their so-called “digital wallet” (a collection of their information), upload documents, respond to requests, and track onboarding status from one dashboard.

Blockchain-based TYS supports standardized questionnaires and due diligence data with added risk context (for example, ESG, financial, compliance, and cybersecurity insights) through integrated third-party data. Although this supplier onboarding platform offers rich functionality for this step, it often requires integration with separate procurement systems to support day-to-day purchasing.

Best for: Large organizations that need audit-ready supplier data, standardized due diligence, and a reusable supplier profile that suppliers keep up to date.

Not ideal for: Businesses that need supplier onboarding to be embedded into procure-to-pay processes with minimal additional tools.

Case in point: Supplier onboarding with Precoro

Take a look at how one of the best supplier onboarding software helped companies manage vendors across different industries and locations.

Serial 1 Cycle

Industry: Micromobility

Location: United States

Company size: 51-200 employees

Serial 1 is a premium e-bike company that originated as a Harley-Davidson skunkworks project and later evolved into a standalone business. They now sell e-bikes in the USA and more than 20 European countries. As the company continued to grow, purchasing became increasingly challenging to manage. Procurement was entirely manual and email-based, while communication with suppliers relied on phone calls and follow-ups.

What Precoro helped with:

- Supplier onboarding became easy and centralized within Precoro.

- Suppliers were added to a Supplier Portal, moving all POs, invoicing, and communication to one place.

- Automated workflows replaced emails.

- Customized approval workflows that are easy to monitor.

Redbud Brands

Industry: Venture Capital and Private Equity Principals

Location: United States

Company size: 51-200 employees

Redbud Brands is a venture capital fund that helps innovative companies discover and establish their identity on the market. As part of their work, the team supports multiple businesses at different stages of growth. They needed to manage procurement processes across 10 companies, in addition to their own. Redbud Brands had no visibility into their documentation flow, no automated workflows, and a completely manual, Excel-based process.

What Precoro helped with:

- Unified templates for purchase orders.

- Ability to export and import supplier lists when onboarding suppliers for new companies.

- POs are sent directly to suppliers from Precoro with status tracking.

- 100% of payments are made on time.

Remilk

Industry: Biotechnology

Location: United States, Israel

Company size: 51-200 employees

Remilk is an Israeli biotechnology startup that produces animal-free dairy proteins. By early 2023, the team had grown to around 100 members, with industrial-scale production underway. Initially, Remilk had no process in place before Precoro, and purchases were made through CEO approvals, direct supplier calls, and accounting entries after invoices arrived.

What Precoro helped with:

- Centralized supplier management and P2P process.

- Implementation of the Supplier Portal: vendors can upload invoices directly and self-register with the supplier registration forms.

- Vendor onboarding through a centralized platform instead of back-and-forth emails and questionnaires.

Frequently asked questions about supplier onboarding

Secure storage begins with consolidating all supplier data in a single, controlled supplier onboarding software, rather than relying on emails or spreadsheets. Teams should restrict who can view or edit sensitive fields such as bank details, tax IDs, and legal documents. Any change to payment or legal information should require verification and include a timestamp indicating who made the change, what was updated, and when. Such vendor onboarding best practices reduce fraud risk, prevent silent data changes, and give a clear audit trail.

To integrate vendor onboarding software with your ERP, select a tool that offers a native integration or an API connector. This way, once suppliers submit their information, the approved records are automatically updated in the ERP. Make sure the integration covers the basics you actually need: supplier name, address, tax ID, banking details, and approval status. Conduct a quick test with one or two suppliers to confirm that the ERP correctly processes the data without requiring manual fixes.

Vendor onboarding can take anywhere from a few hours to several weeks, or even up to six months. It all depends on the supplier’s risk level and the company’s internal processes. Low-risk suppliers with complete information and no contractual or regulatory requirements typically complete onboarding within a few days. High-risk or strategic suppliers take longer because they require deeper checks, legal review, and system configuration.

Procurement usually owns supplier onboarding, but success in this process requires coordination across teams. Procurement manages supplier requests, requirements, and approvals, while finance validates payment and tax details. Legal steps in when contracts or regulatory obligations apply, and IT may support system access or integrations. When ownership is unclear in vendor onboarding, the best practice is to designate procurement as the process owner with input from other teams.

Key insights

Vendor onboarding sets the tone for every supplier relationship that follows. When companies take the time to approve suppliers properly, collect the correct data upfront, and define how collaboration works, they avoid many of the issues that later slow down procurement.

A structured onboarding process brings clear, practical benefits. It reduces exposure to high-risk or non-compliant suppliers, limits off-contract purchases, and shortens the time it takes to approve and activate new vendors. It also provides teams with a reliable way to compare suppliers, maintain accurate data, and ensure visibility across purchasing.

Instead of adding more steps, focus on the basics. Supplier onboarding best practices don’t add more bureaucracy—they improve what you already have. Set clear internal ownership, define requirements, open a communication channel, verify supplier data, provide guidance where needed, and formalize agreements.

Technology plays a key role in making this step sustainable. The best tools for managing supplier onboarding in 2026 include procurement software with a dedicated supplier module and portal, which allows vendors to submit information themselves and keep documentation and communication in one place. If you want to see how this looks in practice, a tool like Precoro is a good starting point.