13 min read

Procurement Optimization: How to Build a Framework for Consistent Purchasing

Your purchasing can be more effective. See how procurement optimization can build on the strengths of your process and address its weaknesses.

Even a quick look at your procurement process is enough to see the gaps. Your AP team might search through inboxes for invoices instead of opening one system with every PO, invoice, and receipt already in place. Then consider how employees request purchases. Do they follow a straightforward, one-way process, or do they have to ping multiple people? Or, even worse, do they simply buy on their own and leave the procurement team out of the loop?

No matter how perfect your purchasing may seem, it’s bound to hit a wall if left at the mercy of outdated methods, tight deadlines, and scattered systems. That wall is a clear sign that something about the current process requires procurement optimization. With the ever-expanding procurement software market and digital transformation on the tip of everyone’s tongues, the question isn’t “Should we optimize?”, but “How soon can we do it?”

Below, we’ll explore what procurement optimization is, how to approach it, and the strategies that you can apply to various stages of the purchasing process.

Read on to find out:

What is procurement optimization?

Why procurement optimization matters now (and why it’s getting harder)

How to approach procurement optimization without breaking your process

Procurement process optimization strategies you can rely on

Frequently asked questions about procurement optimization

Why Precoro is the go-to AI platform for procurement optimization in 2025

What is procurement optimization?

Procurement optimization is a structured approach to improving how a company buys and processes its purchases. The key focus depends on what the company wants to achieve, but generally, the goal is to make procurement smooth for the employees, more cost-effective in the long run, and more resilient.

Procurement process optimization isn’t a complete redesign of the entire workflow. That’s the job of procurement transformation, during which companies often change their entire purchasing structure or shift their strategy (e.g., move from bargain-hunting to a Total Cost of Ownership mindset).

Optimization, on the other hand, improves on things that already exist and adds on or subtracts certain parts of the process, methods, or tools to make it efficient and simply better.

Why procurement optimization matters now (and why it’s getting harder)

Improving is always good, but with the turbulent political climate and US tariffs impacting the supply chain, there’s little to no room for error. Below are both internal and external factors that make procurement process optimization a priority:

Disruptions keep rising

Supply chains are still shaky: 76% of companies suffered delays from disruptions in 2024, while 22% reported more than 20 incidents in a single year. It’s a downward spiral: the number of disruptions increased by 40% in 2024.

To combat this, companies either diversify their supply chain and adopt new sourcing strategies or rely on procurement optimization to strengthen what they already have. While optimization is crucial, it’s also more difficult to achieve with constant disruptions because you have to account for multiple external factors you can’t control.

More spend managed per FTE

Along with disruptions (and largely because of them), the workload has doubled, too. A single employee has to manage 50% more spend than they did five years ago. Procurement is expected to handle more with less: you have to optimize more volume, more categories, more suppliers with the same people and time.

Without a properly carried out procurement process optimization, employees face burnout and unsatisfactory performance, while companies have to deal with the fallout when the procurement function inevitably fails.

Leakages in tail spend

Tail spend is one of the most vulnerable areas of spend. Even though these small transactions make up the majority of organizational expenses, they’re easy to miss if an employee orders something off-contract or at a higher price than negotiated. Plus, direct procurement is, most likely, the first area you’d address during procurement optimization, since it carries the highest priority.

Implementing simple intake steps, like standardized guided forms, and clear approval steps with SLA that set response times and accountability, helps prevent tail spend leakages, if not completely fixes them.

Compliance and cost pressure mount

ESG, CSRD, and global regulations shift the focus from procurement cost optimization (“Can we find this cheaper and quicker?”) to sustainability, resilience, and risk. Companies won’t get away with simple spreadsheets of numbers with no matching documents—they now need a clear audit-ready trail for all purchases.

E-invoicing mandates add another layer of complexity. Several EU countries, like Belgium, plan B2B mandates from 2026 onward, with Italy being one of the first to roll it out in 2019. Most already require e-invoices for public-sector transactions.

On top of that, inflation is one of the most pressing concerns for 62% of companies from the CIPS survey. So procurement optimization has to account for regular policies, e-invoicing requirements, and company goals, all of which are hard to juggle when combined.

Talent gap widens

Procurement now requires a certain skillset that it didn’t require before. Employees have to think strategically, analyze data, have an understanding of the procurement landscape, and be adept at technology. Many companies still can’t bridge the growing talent gap, with 65% relying on outsourcing for tech expertise.

Any tool, no matter how innovative, won’t work if the team doesn’t understand how to use it or what to do with the insights it provides. Procurement process optimization and automation rely on the people behind it. And if there isn't enough talent to make it happen, the only way forward is through training.

AI raises the stakes

Even if the above challenges haven’t reached your company yet, there’s still a reason to optimize. AI sets a much higher bar for what procurement professionals can achieve. It’s the new normal—40% of procurement teams have already adopted AI. You’re not getting a competitive edge with AI procurement optimization, but simply leveling the playing field.

That’s all the more reason to replace outdated spreadsheets and legacy systems with AI-powered tools. Yes, you’re getting on the same level as your competitors, but you also benefit from automation that frees up your team’s time for more meaningful tasks and quick insights. AI procurement optimization gives you instant access to the information you’d normally spend hours looking for.

How to approach procurement optimization without breaking your process

Rushed optimization does more harm than good. Any so-called “improvements” that aren’t backed up by purchase optimization research can quickly drive the processes into the ground. A slower but more precise approach, where you target specific areas you clearly know require improvement, is your safest bet.

1. Diagnose before you change anything.

Find out what’s actually wrong before taking any action. Despite what your policy says, you have to outline how purchases actually happen. Note down the biggest offenders: any delayed approvals, budget overruns, issues with intake can be signs of much bigger problems.

2. Fix high-impact steps first.

Quick fixes that require little to no resources can be shown as proof of the results to stakeholders. But when it comes to procurement optimization, you need to fix the gaps that drain the most value. Focus on the steps employees go through every day, like intake, PO creation, and 3-way matching.

3. Don’t redesign the whole process.

There’s no need to tear down the entire workflow. You’re not transforming it, after all, you’re optimizing. Introduce any improvements in phases and focus on fully fixing one area before moving on to another.

4. Don’t add steps.

How to improve procurement efficiency? The answer is easy: optimize. Optimization is there to simplify. If any changes add steps but don’t address the actual issue (e.g., add an approval step that doesn’t fix the delays), then it’s just extra work.

5. Get feedback from the end users.

The golden rule of purchasing best practices is that the people who actually deal with procurement daily will have more insight into where the process breaks down than any consultants. Running changes by them also means they understand what’s coming and are prepared ahead of time.

6. Build a foundation before adding AI.

AI procurement optimization depends entirely on the quality of the data you feed it. If the workflow is inconsistent, the system relies on incorrect information and produces unreliable results. First, establish a basic process, centralize your data in a single system, and then introduce automation.

Procurement process optimization strategies you can rely on

Here are some of the procurement best practices you can use to fix the core issues in your purchasing and build a process that holds up even in the face of disruptions.

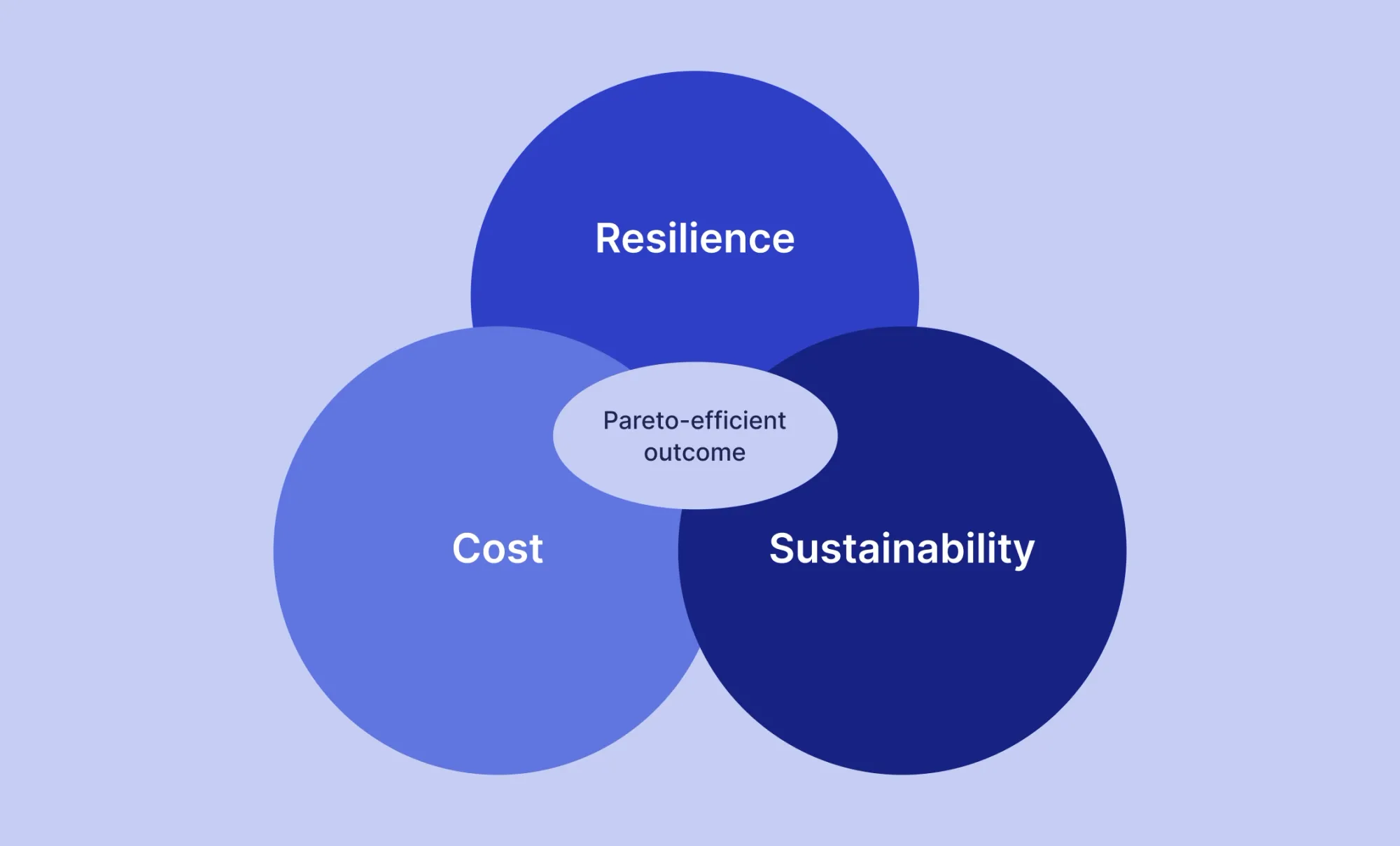

Apply a multi-objective optimization model

A multi-objective optimization model is a decision-making framework that evaluates several goals at the same time and identifies the option that achieves the best possible trade-offs. No single “perfect” solution exists because improving one objective often worsens another. The final solution is known as a Pareto-efficient outcome, the best overall option where no objective overshadows the other.

This mathematical principle can be easily applied to the decades-long debate in procurement: Cost vs. Resilience vs. Sustainability. A one-track focus on cost optimization in procurement can overshadow other objectives: the cheapest option is often the least sustainable, and the least sustainable option can carry the highest long-term risk.

Choose the option that balances all three, rather than optimizing for just one. Score suppliers across these objectives and pick the one that performs well overall, not just the one with the lowest price.

Automate the routine with P2P software

For 83% of companies that are considering procurement optimization, automation comes first. High-priority strategic work is difficult to implement if the entire workflow is hindered by manual steps that could’ve been easily done by software. Approval routing, 3-way matching, and data entry are just some of the tasks your team likely dreads but still spends a large amount of time on.

Ask yourself the following questions when looking for an AI platform for procurement optimization in 2025:

- Does the system create a guided intake channel, so every request includes all the required information?

- Can it route approvals automatically without manual follow-ups?

- Is 3-way matching built in, and does it link the PO, invoice, and receipt?

- Is invoice capture automated and supported by AI?

- Can it enforce supplier rules, such as preferred vendors or approved catalog items?

- Can it sync directly with your accounting or ERP system?

If the answer to most of these is “no,” your process will still be carrying the work that AI procurement optimization software can handle in a fraction of the time.

Consolidate and rationalize suppliers

SMBs were found to have nine times more suppliers than employees and only use about 25% of them, with an average of 800 suppliers. What happens with the rest? Several things can go wrong:

- Different teams order from different vendors without realizing it. As a result, they pay inconsistent prices and end up with double delivery fees for identical items.

- Suppliers go through onboarding and then fall off the radar after teams spend hours setting them up.

- Spend is spread across too many suppliers, which makes price comparisons and procurement cost optimization difficult.

- Negotiation power drops, since no single supplier receives enough volume to offer stronger terms.

If any of these seem familiar, your supplier list might be bloated. Time to employ some supplier optimization techniques, specifically consolidation and rationalization. Supplier consolidation means narrowing down your supplier base to a smaller group of trusted suppliers to ensure consistent pricing and better terms.

Rationalization involves evaluating your supplier network and removing those that the company no longer needs. Vendor scorecards and the Kraljic matrix are both great tools to use during the sourcing optimization process.

Build a procurement Center of Excellence (CoE)

With the talent gap growing, companies need a clear way to help employees develop strategic procurement skills. That’s where a procurement Center of Excellence (CoE) comes in: a small team, often just two or three experts, that guides purchasing decisions across the entire organization. Their role is to make sure everyone follows proven procurement best practices and has access to support and knowledge. Procurement CoE can increase strategic headcount by 20%.

The CoE is essentially a centralized hub that provides consistent guidance on policies, sourcing standards, and supplier management. Teams can go there for answers, templates, knowledge sharing, and expertise, which helps less experienced employees learn new skills.

Enforce category strategies

Category management is a strategy in itself. By managing each spend category with its own terms, approvers, and specifics, you improve company-wide spend as a whole and strengthen sourcing optimization. Spend management then becomes targeted and more precise: for example, equipment and printer paper can’t go through the same procurement path.

Look at the entire picture of spending and group it into categories, such as office supplies, IT, marketing services, and manufacturing. Together with the team of stakeholders, assign category managers and develop a playbook for how each type of spend should be handled. Include:

- Who should be involved

- Which supplier(s) to use

- Who approves the purchase

- What terms apply

- What information must appear on every request

Even these basics make the entire process more transparent and easier to control. Category strategies also help prevent maverick spend and duplicate invoices. With clearly defined steps and purchasing best practices, employees stop sourcing on their own, and approvals move faster because the expectations are already set.

Frequently asked questions about procurement optimization

To facilitate procurement cost optimization, fix the steps that slow people down. Set one clear way to submit requests so no one depends on emails or conversations. When every request is processed the same way, approvals move faster and follow the right rules. Once POs, invoices, and requests sit in one system, the data becomes reliable, supplier choices improve, and budget owners see the real impact of each purchase.

First, fix parts of the workflow that fail most often during the day-to-day: missing details at intake, stalled approvals, inconsistent suppliers, or invoice mismatches. Each technique you choose must solve one of those issues. Supplier optimization with consolidation helps negotiate better terms, structured intake improves data quality, and automation takes over manual work. Optimization works when each change fixes a clear issue.

Not quite. Optimization improves the current workflow. Transformation changes the entire operating model. Optimization fixes existing issues in the procurement process. Transformation introduces new structures, new priorities, or new ways of working across the function.

You optimize a decentralized process by using one system and one set of rules across all locations. Each site submits requests the same way, follows the same approval thresholds, and uses a shared supplier list, with flexibility to engage local vendors when necessary. This sourcing optimization approach gives procurement and finance full visibility without restricting how local teams operate.

Why Precoro is the go-to AI platform for procurement optimization in 2025

Procurement optimization succeeds only when the basics are solid: a clear process for requesting purchases, one place to track documents, a single source of truth for suppliers and budgets, and workflows that teams actually follow. Precoro gives companies the necessary structure from day one. It centralizes the entire P2P process, applies clear rules across categories, and removes the manual work that slows teams down.

Precoro supports AI procurement optimization of your entire process with a robust set of features, including:

- Centralized system with one intake path for all requests.

- Advanced approval routing with custom rules, roles, thresholds, and SLA reminders.

- AI Assistant that answers procurement questions using real company data.

- AI-powered OCR that extracts data from invoices and receipts for expense reimbursements.

- 3-way and 2-way matching to prevent inconsistencies and double payments.

- Supplier management with catalogs, PunchOuts, and vendor records in one place.

- Contract management with alerts for renewals and expirations.

- Custom reports and intuitive dashboards with 150+ data points.

- Integrations with Xero, QuickBooks, NetSuite, Slack, and other core finance tools.

- Role-based access and audit trails to support compliance and internal controls.

- Mobile approvals so you can review and approve purchases on the go.

It’s important to remember that new software won’t guarantee successful procurement optimization. It’s a tool, first and foremost, that gets you the most results when guided by thorough research, clear needs, and an understanding of strategic objectives. Precoro helps enforce these improvements and put them into action, so you can clearly see the measurable results.

Want to see Precoro’s AI features in action?