10 min read

Crafting a Procurement Management Plan to Mitigate the Impacts of Inflation

In the ever-evolving landscape of business, inflation is something every stakeholder should care about. Learn how a procurement management plan can improve a company’s durability and mitigate the effects of inflation.

Inflation is an unavoidable fact of the globalized economy, and it impacts organizational spending across various sectors. Whether on a smaller or larger scale, inflation is a reality for every country. The inflation rate can vary greatly by location — for instance, in 2023 it was 3.4% for the US yet 10.7% in the Czech Republic.

Escalating expenses associated with rising prices of raw materials, finished goods, third-party services, and labor along the entire supply chain expose businesses to a heightened threat of margin reduction. As the department overseeing an organization's external expenditure, procurement is responsible for softening the impact of inflation.

That’s why developing an exhaustive procurement management plan is not just a strategic move to keep spending under control and mitigate financial risks; it's also a necessity for navigating the complexity of changing markets and ensuring the uninterrupted flow of business operations.

In this article, we will discuss how a robust procurement management plan can help address and mitigate the effects of inflation. Keep reading more about the following:

- Defining a procurement management plan

- Understanding the impact of inflation on procurement

- Pillars of a winning procurement management plan

- 5 steps to create a procurement management plan to mitigate inflation

- Frequently asked questions

Defining a Procurement Management Plan

A procurement management plan outlines the approach and processes an organization should follow to acquire goods, services, or works necessary for business operations. It also serves as a roadmap for how the organization will conduct its purchasing activities for both direct and indirect spending.

This strategic document contains key principles of procurement management and is designed to ensure that the entire procurement process is aligned with the organization's goals and objectives, project requirements, and budget constraints. A typical procurement management plan includes:

- Identification of needs. A detailed analysis of the goods, services, or works required, including specifications and any specific demands.

- Objectives and scope. Clearly defined project management goals, procurement objectives, and an outline of what the organization intends to achieve through its procurement activities.

- Budget and funding. Details about available funds and what they’ll be spent on, to ensure that financial constraints are considered and adhered to throughout the process.

- Market analysis. Examination of the market conditions, including supplier capabilities, pricing trends, and overall market dynamics, to make informed procurement decisions.

- Risk assessment. Identification of potential risks associated with the procurement, such as market fluctuations, supplier reliability, or other external and internal factors that may impact the process.

- Procurement methodology. Selection of the appropriate procurement method, whether it be competitive bidding, direct negotiations, or other procurement approaches based on the nature of the goods or services being acquired.

- Procurement schedule. A timeline outlining key milestones and deadlines for each stage of the procurement process, ensuring that the purchases align with organizational timelines and project schedule.

- Supplier selection criteria. Criteria for evaluating and selecting suppliers, which may include considerations such as pricing, quality, experience, and sustainability. It’s also good to mention approval processes that differ for particular suppliers based on the type of goods or services purchased.

- Contract management practices. Details on how procurement contracts will be managed, including the contract approval process, performance monitoring, and mechanisms for addressing issues that may arise during the contract period.

- Compliance and regulations. Guidelines ensuring the procurement management plan aligns with relevant laws, regulations, and organizational policies to maintain legal and ethical compliance.

- Communication and engagement. Plans for communication, both with internal stakeholders and external suppliers, throughout the procurement process to maintain transparency and address concerns.

- Monitoring and evaluation practices. Mechanisms for monitoring the progress of the procurement management plan and evaluating its effectiveness, with the flexibility to make adjustments as needed.

A thorough procurement management plan helps organizations make informed decisions, mitigate risks, and achieve the best value for money in their procurement activities. It is also an essential tool for promoting transparency and accountability in the purchasing process.

Understanding the Impact of Inflation on Procurement

The first step in preparing an effective mitigation plan is to understand the various ways in which inflation can affect procurement processes. The most obvious outcome of inflation is the rising cost of goods, services, and work the company needs for production and daily operations. That, in turn, can cause a price jump for the final goods and services and might lead to customer loss.

To maintain the stability of company operations, final product quality, and customer satisfaction, procurement professionals must not only react to the challenges but also proactively prepare to tackle them. Let’s take a look at some areas where procurement professionals should prepare to deal with inflation impact.

Cost Increases

Inflation often leads to an increase in the overall cost of goods and services. Procurement costs may rise as suppliers adjust prices to account for increased production, transportation, or labor costs.

Contract Conditions

Suppliers may adjust their pricing strategies in response to inflation. That can lead to buying organizations not being able to renew the contracts or having to renegotiate the deals.

Supply Chain Disruptions

Inflation can contribute to supply chain disruptions, affecting the availability and delivery of raw materials, components, and finished goods.

Impact on Budgets

Inflation can disrupt the forecasted budgets of organizations, causing them to spend time and human resource to recalculate the budgets, make alternative plans, and possibly make some last-minute cuts.

Shifts in Procurement Strategies

Inflation may cause companies to have to change their procurement strategy, which could involve shifting priorities (for instance, from sustainability to cost-reduction,) changing types and amounts of purchased items, and switching to other suppliers.

Technology Adoption

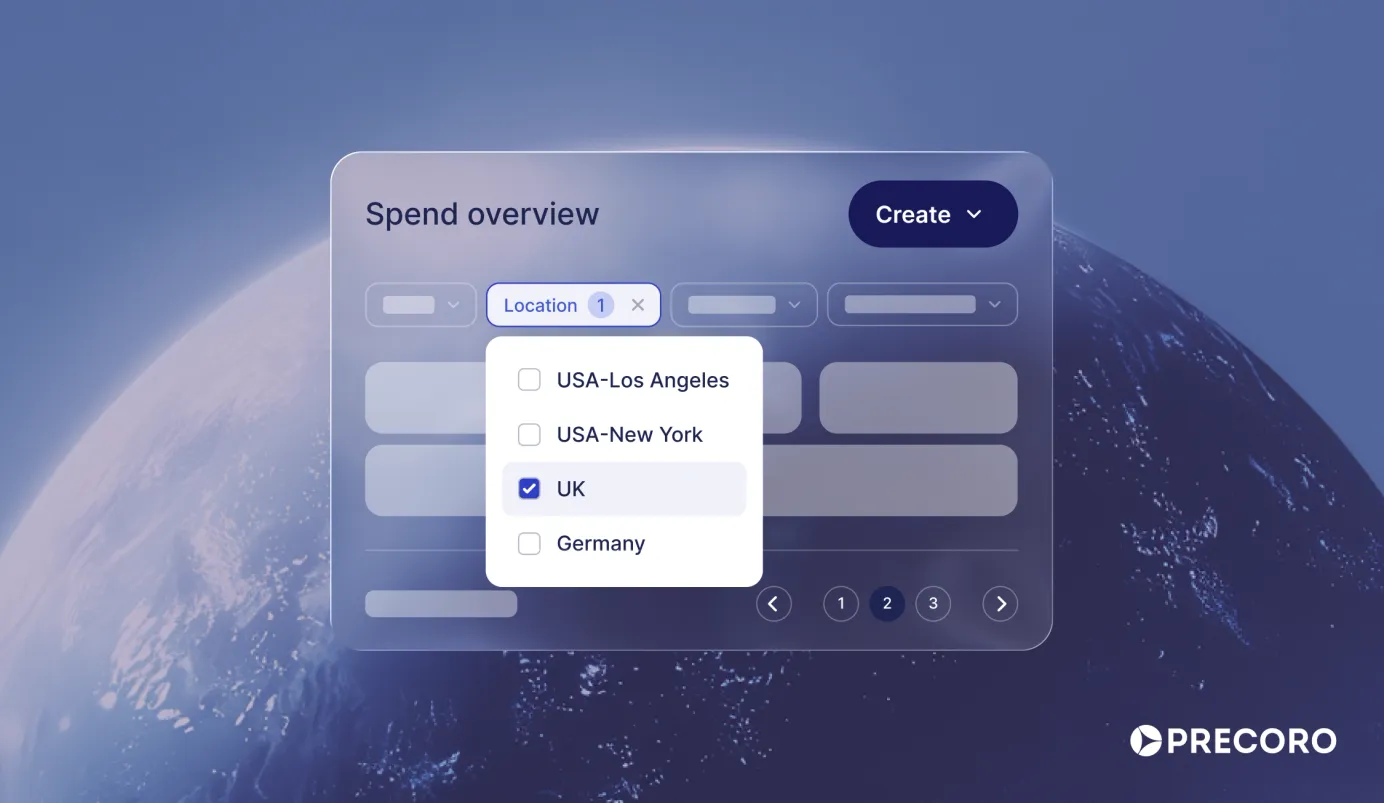

Organizations may discover that they need to implement software to get real-time market insights and make informed decisions. The effects of inflation can also cause companies to seek software that will help them optimize procurement operations in order to reduce potential financial losses. It's best to choose a system suited to your region, whether in the USA, the UK, Australia, or South Africa.

Pillars of a Winning Procurement Management Plan

To prepare a robust strategy in the face of inflation, it’s important to keep in mind several pillars of a successful procurement management plan. Let’s look at the key factors the procurement management should consider while preparing an action plan.

Vendor Management

Vendors and suppliers are any business’s core partners when it comes to navigating changes in the financial landscape. Proactive engagement with suppliers builds a foundation for collaboration and, as a result, fosters a resilient supply chain.

Establishing and nurturing strong relationships with suppliers is critical for battling inflation. Developing trustful and open communication lets your organization stay abreast of market fluctuations and anticipate price changes. With this knowledge, procurement professionals can negotiate more favorable terms.

Strategic Sourcing

Diversifying the sourcing channels is a crucial tactic for mitigating the impact of inflation. Procurement professionals should explore alternative sourcing options, both domestically and, if feasible, internationally. Diversifying suppliers and vendors helps to shield the company from inflation by reducing dependence on one or few suppliers.

Having a diverse supplier base means that if one of a company’s typical suppliers have to increase their prices or delivery cost due to inflation significantly, the company will have other, already approved vendor options to choose from. This allows the purchasing company to be more flexible and less likely to face delays or disruptions.

For companies who can expand their sourcing network to include suppliers from different countries, they can avoid region-specific inflation by purchasing from elsewhere.

Contract Management

Conducting a comprehensive review of existing contracts can help identify opportunities for renegotiation in the face of changing economic circumstances. Proactive companies also implement designated contract management software to keep track of active contracts and get timely notifications when it’s time to renew.

With such a system in place, the procurement team has a clear overview of contract statuses and won’t miss key moments – like renewal dates – to adjust for impending inflation and other market developments. One of the things to do when expecting or facing inflation is to negotiate long-term agreement with fixed pricing. Parties can also choose to include a detailed escalation clause tied to specific economic indicators that provides a way to ensure cost predictability amidst the uncertainty of inflation.

The renegotiation process should be approached collaboratively, ensuring that both parties benefit from a fair and sustainable arrangement. While the purchasing company benefits from the price predictability, the selling partner ensures that sales happen even if the market conditions change.

Cost-Benefit Analysis

Companies should incorporate thorough cost-benefit analyses into the process of preparing a procurement management plan. This involves assessing the total cost of ownership of the planned purchases, which includes looking at the projected inflation rates. Procurement professionals should consider available alternative products or services available on the market and analyze their strengths and weaknesses through the whole source-to-pay cycle.

Such analysis provides valuable insights, guiding strategic decision-making by the procurement team. This way, procurement professionals can make informed choices that align with the organization's overarching financial goals.

Technology Integration

An efficient procurement management plan should include an understanding of how the power of technology can help mitigate instabilities likely to arise from unexpected inflation. Implementing procurement management software and tools that offer real-time market insights, analytics, and automation can skyrocket the efficiency of a company’s procurement processes and ensure its operational stability.

Procurement software also enables better monitoring of supplier performance and internal operational efficiency. High-quality insights help identify cost-saving opportunities, which in turn contribute to a more agile and adaptive procurement strategy. Pro tip: choose procurement software that best suits the needs of the region you're operating in: for example, Precoro serves customers worldwide, from the Czech Republic and Ireland to Japan.

Collaboration Across Departments

Ensure clear communication and foster collaboration between procurement, finance, production, and other relevant departments within your company. Cross-departmental cooperation ensures a holistic understanding of the organization's needs and financial landscape.

If the organization is involved in project-based planning, it's also a good idea to consult project team members. For instance, project managers can contribute with unique production process knowledge and R&D engineers can offer their know-how to find alternative, possibly more cost-efficient procurement options.

By working collaboratively, departments can collectively contribute to a more resilient and responsive organization. Procurement strategies can be adjusted to the current market situation while staying aligned with overall business objectives. Such an organization will be prepared to continue its operations and ensure the final product quality despite the rising costs of purchased materials, goods, or services.

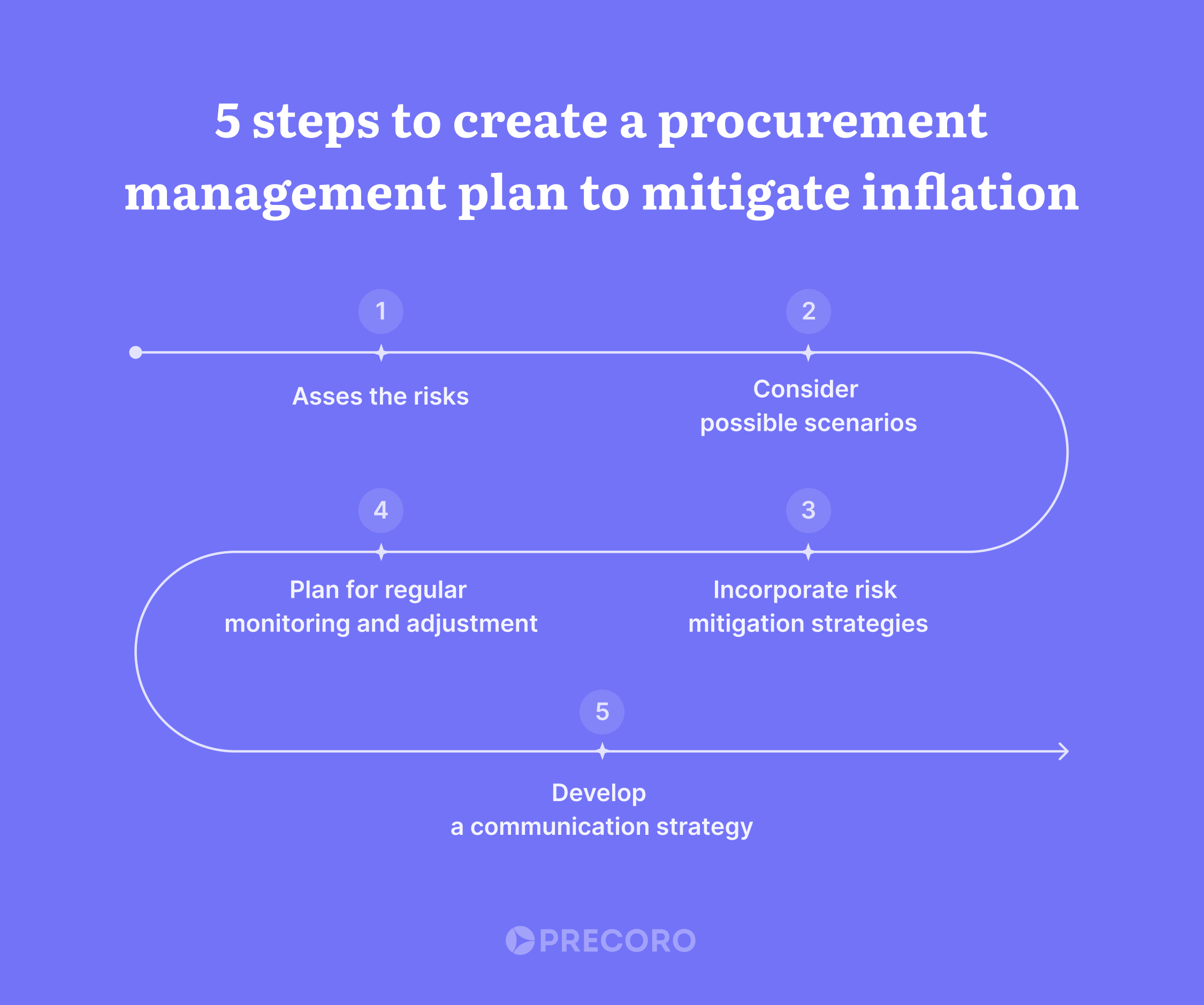

5 Steps to Create a Procurement Management Plan to Mitigate Inflation

Let’s see how the procurement department can proceed in preparation of a durable plan for mitigating inflation’s impact on the company. The following five-step process can be referred to as a basis and adjusted for the specific structure and timing of the business.

- Assess the Risks

Planning for possible future inflationary cost rises should start with financial professionals conducting a thorough risk assessment. They should identify potential causes for inflation, such as economic indicators, geopolitical events, and supply chain vulnerabilities. These risks are then prioritized according to their probability and potential impact on procurement costs.

- Consider Possible Scenarios

In the next step, the financial and procurement teams should cooperate to outline potential inflationary scenarios and their impacts on procurement. It’s important to define the possible range for how severe and sudden the cost rises might be and which supply chain component will be affected the most. By planning out possible inflation scenarios, the procurement team can move on to prepare risk mitigation strategies for the changes of various intensities.

- Incorporate Risk Mitigation Strategies

The procurement team proceeds with integrating risk mitigation strategies into the purchasing plan. There are several typical strategies that may be used:

- Alternative sourcing strategies

- Dynamic pricing models

- Contingency contracts

These strategies can help achieve stability and flexibility in the face of inflationary pressures. It’s a good practice to include several possible risk mitigation strategies in the procurement management plan designed for different scenarios, even if that might seem like an overreaction at the beginning of the planning process.

- Plan for Regular Monitoring and Adjustment

As a part of creating a resilient procurement management plan, companies should prepare to introduce necessary tracking practices. This includes tracking external events — such as economic trends, disruptive events, and inflation indicators — and internal procedures that react to external events.

As a part of procurement plan preparation, the responsible team chooses a robust monitoring system to track and regularly assess the effectiveness of the procurement process. This proactive approach allows for timely adjustments to the plan, ensuring its relevance in the dynamic economic landscape.

- Develop a Communication Strategy

A communication strategy is an integral part of the procurement plan. Clear communication fosters transparency and ensures that all relevant parties are aligned with the organization's strategies to navigate inflation challenges. The procurement team should plan and establish communication channels with the suppliers and the business stakeholders to keep them informed about the procurement progress.

As a part of planning for noise reduction and clear communication, the procurement team should choose a dedicated software that allows everyone involved in the source-to-pay process to stay in sync. Procurement software serves as a powerful consolidation tool for everyone involved.

Both stakeholders and suppliers can have direct access to the system and see relevant documents, order updates, reports, and other information in real time. Being able to collaborate and communicate in the shared environment takes the risks of misunderstanding close to zero and allows supplier relationships to stay solid even in the face of instability.

A Good Plan Is Half the Battle

Preparing a robust procurement management plan that addresses the possible impacts of inflation is a must-do for organizations seeking sustainable growth. With proactive supplier relationship management, strategic sourcing, contract management, cost-benefit analysis, technology integration, and cross-departmental collaboration, procurement professionals can navigate the challenges posed by inflation and contribute to the overall resilience of the business. Remaining flexible and agile in response to market dynamics will position your organization for long-term success in the face of economic uncertainties.

Frequently Asked Questions

A procurement management plan is a strategic document that outlines the approach and processes an organization should follow to acquire goods, services, or works necessary for business operations.

A procurement management plan should contain information about the conditions in which procurement will be happening, and the details of the expected procurement process, including market analysis, description of the company’s needs, available budget, supplier and contract management practices, monitoring and communication practices, and information about legal compliances.

Inflation can affect a company’s procurement in many ways. The key outcomes include cost increases, changed contract conditions, supply chain disruptions, budget impact, a shift in procurement strategies, and necessity for technology adoption.

To prepare a procurement management plan that will help the company mitigate inflation, procurement professionals should take the following five steps. Start with assessing the inflation risks, then consider specific possible scenarios and incorporate risk mitigation strategies in case of them. After that, it’s necessary to conduct regular monitoring and adjustments. Finally, it’s also important to develop a supplier communication strategy to coordinate the efforts while adjusting to new market conditions.

Get in touch with us and let’s see how Precoro can help you to manage procurement well: