9 min read

Vendor vs. Supplier: How to Distinguish and Manage

In 2020, the global Supply Chain Management market was valued at $15.85 bln.

And it's expected to double by 2026. Efficient SCM starts with a well-managed network of suppliers and vendors.

Although “supplier” and “vendor” are often used interchangeably, they play different roles in the supply chain. A supplier delivers raw materials, components, or specialized goods to businesses for use in their production processes. On the contrary, a vendor sells finished products or services directly to consumers or other businesses. Suppliers usually operate earlier in the supply chain and often handle bulk orders, whereas vendors are the final step before the customer, offering complete, ready-to-use products.

We'll dive into specifics:

- Vendor and supplier definition

- What are the main differences between them

- Tips for managing relationships with vendor and supplier

- Risks involved in both cases

- When to work with suppliers

- When to work with vendors

- Tips for building quality relationships with vendors and suppliers

- FAQ

Vendor vs. Supplier – basics

The terms "vendor" and "supplier" are often used interchangeably, but that is not entirely correct. Vendors and suppliers are two different distribution channels used in the supply chain process.

Let's see how they differ.

Supplier

A supplier is a strictly B2B (business to business) entity that makes large quantities of a specific product, material, or service available to other companies.

Suppliers are placed at the supply chain's beginning and provide goods or services to the companies for further processing.

Suppliers can provide raw materials for manufacturing products or act as an intermediary between the manufacturer and the buying company. In this case, the supplier receives a commission from both the customer and the manufacturer.

Vendor

The vendor, however, is at the other end of the supply chain.

Acting as the last link selling products or services directly to the end customers – companies or individuals – the vendor receives a fee from the customer for sourcing the product tailored to his needs.

Vendors, therefore, participate both in B2B (business to business) and B2C (business to consumer) relationships.

Some vendors supply goods or services on behalf of another company and are defined as the "third-party vendors." For example, software vendors often sell software and support services to the end-user on behalf of large IT corporations.

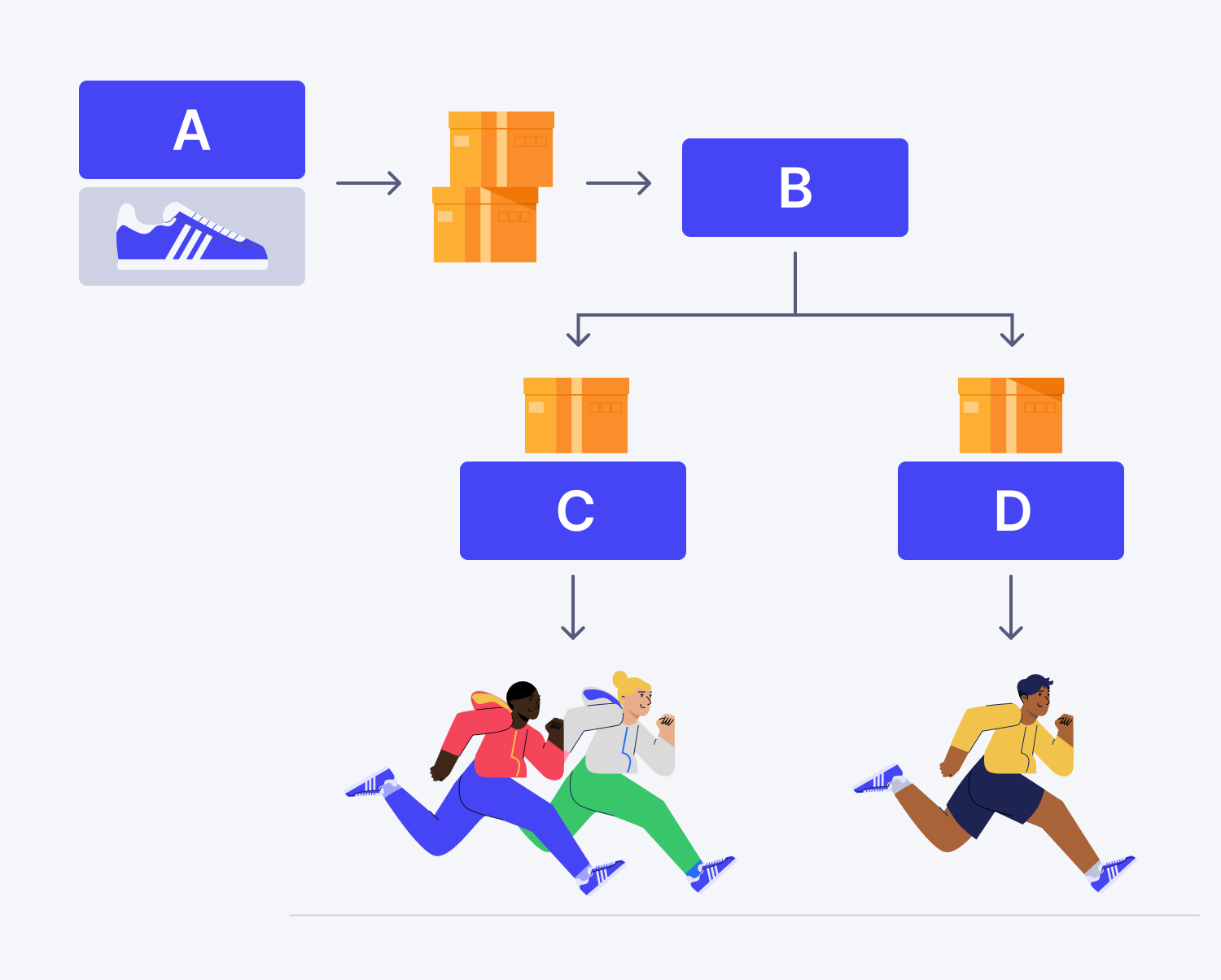

The vendor is quite a "flexible" term. Let's imagine a company A, that manufactures a finished product – sneakers.

Sneakers are then sold to the wholesaler B and later distributed to the retailers C and D. In this case, manufacturer A is a vendor for B, and wholesaler B is a vendor for retailers C and D. Retail shops are vendors for each individual customer buying sneakers.

A supplier delivers raw materials or components used in production and serves as an upstream partner in a long-term B2B supply chain relationship. In contrast, a vendor provides finished goods or services, typically functioning as the downstream link in a shorter-term B2B or B2C relationship. The main difference lies in their position within the supply chain, the type of relationship, and the nature of what they provide—suppliers focus on inputs, while vendors focus on final products.

Blurred lines

Sometimes lines between manufacturer, supplier, and vendor roles are not clear.

Some vendors are also manufacturers and produce their goods in-house. For example, one company can act as a vendor at the market but at the same time have production capacities and manufacture its own goods to supply itself and other vendors.

Check-list for Distinguishing Vendor from Supplier

To understand whether a company acts as a vendor or as a supplier in particular settings, run the check of the following criteria.

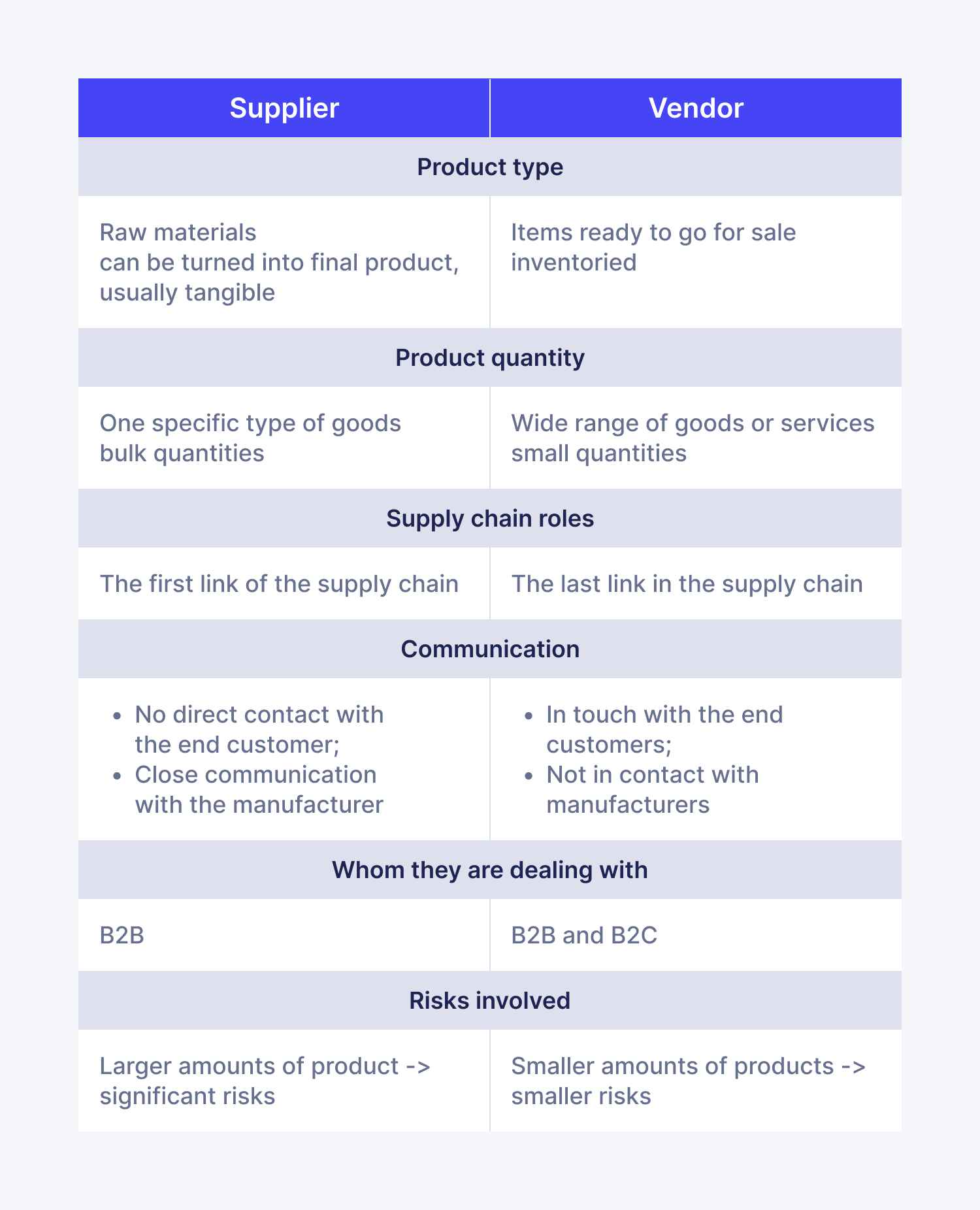

Product type

Suppliers usually work with raw materials that can be turned into the final, primarily tangible, product. Vendors typically provide items ready to go for sale and can be inventoried. That is probably the main difference.

Product quantity

Suppliers usually offer one specific type of goods in bulk quantities, while vendors provide a wide range of goods or services in small quantities each.

Supply chain roles: business to business or business to consumer

The typical supply chain is:

- Supplier

- Manufacturer

- Distributor

- Vendor

- Customer

The supplier comes into play as the first link of the supply chain. Suppliers do not have direct contact with the end customer but communicate closely with the manufacturer.

The vendor is the last link in the supply chain, directly before the end customer. Vendors are in touch with the end customers, but usually not with manufacturers.

Whom do they get goods/services for

A supplier gets materials for companies to process and turn into the final product, dealing strictly with B2B. Vendors source avail goods and services to sell them to the end customers – companies or individuals.

Risks involved with the supplier and the vendor

Supplier-related risks are more significant as suppliers deal with larger amounts of products. Halting products from the supplier can cause a chain reaction throughout the supply chain, causing an outage of the product meant for the final consumer.

On the opposite, vendor-related risks are more minor, as they work with smaller quantities of products. If the vendor faces difficulties delivering the product, it is significantly more accessible for the customer to find a substitute.

When to Work With Suppliers

A company that needs materials in bulks should use suppliers. Suppliers sell products in larger quantities for lower prices, so manufacturers and other companies using their services can stay profitable after reselling produced goods.

Suppliers are your go-to for finding raw materials if you are procuring supplies for production. Let's say you are a business that makes fermented lemonades – then you would need to find suppliers who'd sell ingredients for the drinks.

When to Work With Vendors

However, if you are a bar that sells fermented lemonades, among other drinks, to the guests, you don't need to produce them. It would make more sense to buy lemonades rather than produce them in-house.

If your business resells finished products to the customers, you can source smaller amounts of various articles from vendors.

You'd also use vendors as individual consumer who needs to use the finished product right away. When you buy products for immediate use, it would rather be several products in smaller amounts – a request for the vendor.

How to Manage Vendor and Supplier Relationships Well

In today's competitive and fast-paced world, it’s essential to build good relationships with your partners to stay flexible and meet the market’s requirements.

Suppliers and vendors are important players throughout the whole supply chain – each on an appropriate stage.

Therefore, every organization pursuing business goals should work on productive partnerships.

Suppliers' Insights

Suppliers are the significant source of the inputs into the manufacturing process: both physically and informationally.

The essence of the supplier relationship lies in finding the best option for raw materials in the saturated market. Finding good material helps ensure manufacturing the best product to offer down the supply chain to distributors, vendors, and end customers.

In addition to this, suppliers can often provide you with relevant insider information about the material's market and trends, which will help evaluate the new product's potential and identify potential opportunities.

Businesses that build excellent and productive relationships with their suppliers achieve long-term competitive advantage. Having established trusting relationships with the suppliers, companies can plan long-term and scale up efficiently.

Manufacturer–supplier relationships should be partnerships built not only on financial transactions but also on mutual trust and shared goals of bringing the top product on the market.

Vendors' Insights

Vendors are irreplaceable when it comes to an understanding the end customer. As the last supply chain link, the vendor can offer a unique first-hand insight into the customers' needs and preferences.

Vendors sell goods and services directly to the consumers and can provide manufacturers with trustworthy feedback on the product quality. Frequent interaction with the final customer makes vendors especially valuable for market surveys.

Trustworthy partnerships with vendors help understand the end customer better, improve product design, and possibly cooperate in funding new marketing opportunities.

Tips for Building Quality Relationships with Vendors and Suppliers

Managing relationships with both vendors and suppliers is a continuously evolving process. Relationships should be trusting and developed as partnerships, but at the same time follow clearly defined principles and rules.

Vendor management is focused on getting the most value from acceptable costs. Regular price comparisons and fees evaluations allow finding vendors who offer the best quality to price ratio while staying fit for the end consumers' requirements.

Suppliers management is about selecting suppliers who can offer finest materials in the saturated market. The company should collaborate with the suppliers to achieve relevant market share with the qualitative product.

Managers follow different objectives and focal points with vendors and suppliers, but our tips will help make the most of both.

Be open

Talk to your suppliers and vendors, cooperate on strategizing sessions and retrospective meetings, and invite them to participate in planning actively. Strive for a direct and close relationship.

Be honest

Practice transparency in your day-to-day communication with vendors and suppliers, bring any issues to their attention, and be honest about your needs and wants. Offer honest feedback and ask for the same.

Be clear

Create specific performance criteria that everyone involved will understand, accept and follow. Introduce metrics for evaluating whether KPIs are met and standards achieved.

Take care of formalities

As in any business relationship, it's a good idea to write all or at least the critical principles of your cooperation. Signing a contract helps ensure accountability and avoid unfortunate misunderstandings.

Automate communication

Taking some organizational load off the shoulders of your managers, procurement team, and accountants will streamline processing information and communication. That's why some companies start using supplier management software.

Introducing a supplier relationship management system allows automation of everyday planning, tracking, and reporting tasks, minimizes errors and informational noise, and helps communicate more clearly.

Treat each vendor and supplier as a partner

You do well when your vendors and suppliers do well, and vice versa. Make sure they feel to be a part of your business. Build a good relationship by informing them about changes in processes and new releases and asking their opinions.

Maintain quality and price balance

Remember that you are paying not only for the goods but also for the services. Let your vendors and suppliers understand that you value professional handling and are willing to pay for it.

Keep consumers in mind

When introducing any changes or adjusting workflows, make sure that it benefits the end consumers. Any materials from the suppliers and any vendor practices should be well-received by your consumers to result in meeting business objectives.

You Might Have Wondered

Yes, for sure. One company might need to purchase a specific type of commodity in large quantities (via supplier) and, at the same time, buy other goods or services in smaller amounts (via vendor).

Not necessarily. A vendor can be sourcing and selling goods directly from the manufacturer to the end customer. Or go through the distributor who acts as a middleman housing goods in warehouses and selling to smaller vendors.

Finally

Although "supplier" and "vendor" are often used interchangeably, they refer to distinct roles in the supply chain. A supplier delivers raw materials, components, or services to other businesses for use in production, while a vendor sells finished products or services directly to end customers.

Suppliers work upstream in the supply chain and focus on business-to-business relationships that support manufacturing. On the contrary, vendors operate downstream and focus on business-to-consumer sales, which bring the product to the ultimate user.

To purchase efficiently and meet your end customers' expectations, it is essential to build honest business relationships with vendors and suppliers. Vendor management software like Precoro can help with that.