19 min read

Procurement Challenges and Solutions: From Strategy to Execution

Address procurement challenges head-on, from supply chain issues to vendor control, with cost-saving solutions.

Inflation is now the top concern for 62% of procurement pros, up from 37% last year. It's driving up budgets and supplier costs. As old contracts end, costs are rising fast, and extreme weather — such as floods, droughts, wildfires — is hitting suppliers, transport, and materials, adding serious supply chain risk.

AI sounds great for automation and predictions, but it's hard to roll out due to high prices, data security concerns, and the need for new IT skills. At the same time, companies are expected to cut spending and meet tougher sustainability goals, which often cost more. New regulations, such as the EU's CSDDD and the U.S. forced labor laws, require teams to delve much deeper into their supply chains than before.

And to top it off, many teams are still stuck with manual processes and scattered systems — so they spend most of their time on paperwork instead of strategy.

Below, we've outlined the most common procurement challenges and solutions for you to explore, divided into sectors and locations.

Top 11 challenges in procurement

Early warning signs of poor procurement management

Sector-focused challenges in procurement

Top procurement challenges in Australia in 2025

Challenges in South Africa’s procurement in 2025

Wrapping up

Frequently asked questions about procurement challenges

Top 11 challenges in procurement

1. When suppliers don’t deliver

There’s always that one supplier who ships late, sends poor-quality materials, or disappears when trouble arises. A single bad delivery might seem minor, yet supplier unreliability can snowball into missed deadlines, rising costs, and supply chain disruptions that cascade throughout the entire operation.

Solutions:

- Use performance dashboards to automate data tracking.

- Conduct regular reviews and use scorecards frequently to address gaps.

- Investigate performance lapses to identify underlying procurement issues and apply corrective actions.

- Develop contingency plans or dual sourcing to reduce dependency.

- Set clear KPIs, such as in-time delivery percentages or quality expectations, and regularly conduct performance reviews to keep suppliers on track.

Note!

At this stage, intuition isn’t enough — let technology guide you. With digital procurement systems, leaders gain real-time insights into supplier performance and can identify potential risks early.

2. PO and invoice mismatch

A PO says “ten units at $12,” but the invoice says “ten at $21.” Sound familiar? Minor errors, often caused by manual entry or last-minute changes, can create confusion, lead to extra administrative work, and result in payment delays. Left unchecked, they frustrate suppliers and can even halt supply lines.

Solutions:

- Automate and standardize PO workflows to reduce manual errors.

- Define variance thresholds so only significant mismatches require action, reducing unnecessary delays.

- Automate alerts to flag and route discrepancies in real time.

- Resolve procurement issues fast — review, approve, and communicate directly with vendors.

- Hold mismatched payments until everything’s aligned.

- Document actions and analyze trends to identify and tackle challenges in the procurement process.

3. Cybersecurity goes weak

Digital procurement brings speed — and risk. Cyber threats, such as invoice fraud and data breaches, have doubled to 26 attacks per month in 2025, since April. Invoice scams, phishing attacks, or even grand-scale data breaches can occur more quickly than anyone anticipates. And the results are rapid financial loss, data breaches, operational disruptions, and reputational damage across supply chains. These procurement challenges and solutions highlight how technology can both empower and endanger supply chains.

Solutions:

- Conduct regular supplier security assessments.

- Use AI-driven monitoring to detect security risks or anomalies in supplier data and transactions.

- Implement strict access controls and zero-trust models.

- Standardize incident response and vulnerability management.

- Foster transparency and collaboration across ecosystems for rapid threat identification.

4. Vendor management inefficiency hits hard

It often starts small: a missed email, an unclear order, a forgotten update. Soon, deliveries run late, product quality slips, and blame circles between teams and suppliers. That’s what happens when vendor management lacks structure. But when communication flows, processes align, and performance is tracked, everything clicks: costs drop, timelines hold, and suppliers become trusted partners, not just vendors. These are classic challenges in the procurement process, where poor coordination turns minor oversights into costly setbacks.

Solutions:

- Centralize all vendor data across teams and locations in the vendor management system for a single source of truth.

- Use approval workflows to onboard vendors efficiently, collecting necessary compliance documents and approvals upfront.

- Set up the Supplier Portal so vendors can update their catalogs, submit invoices, and track payment status, reducing communication delays.

- Store contracts and set automatic reminders for renewals and expirations to ensure compliance.

- Use AI-powered invoice processing and three-way matching to verify invoices for faster and more accurate payments.

5. The moment compliance fails

Procurement processes look neat on paper, but real life is messier. People approve things over calls, buy outside the system, or forget to upload records. It’s all fine — until an audit, dispute, or review comes up. Then the missing trail turns into a major headache, highlighting some of the challenges in the procurement process that even seasoned teams overlook.

Solutions:

- Use procurement software to embed policy rules and approval workflows, ensuring all purchases follow defined processes automatically.

- Centralize supplier data, purchase requests, approvals, and communications in one system for audit trails and transparency.

- Perform internal audits regularly to identify compliance gaps and validate adherence to policies.

- Provide regular training on compliance policies, workflows, and regulatory changes to all procurement staff.

- Prepare backup plans for supply disruptions, including alternative suppliers and escalation protocols.

- Deploy AI and rule-based systems to detect policy violations, flag risks, and escalate issues in real time for corrective action.

6. Demand forecasting and inventory management downfall

Order too much, and warehouses overflow with products that tie up funds and gather dust. Order too little, and production grinds to a halt while customers grow impatient. Too often, such challenges of procurement are shaped by fluctuating markets, evolving consumer needs, and uncertain global conditions, which go far beyond just numbers on a spreadsheet.

Solutions:

- Use AI to analyze market trends, competitor data, and social media sentiment for superior accuracy over historical models.

- Apply ABC analysis to prioritize key items.

- Set optimal reorder points and safety stock based on demand and lead times.

- Use integrated ERP systems for real-time inventory visibility.

- Run what-if analyses to prepare for demand fluctuations.

- Track performance using KPIs like forecast accuracy and inventory turnover.

7. The pain of managing global supply chains

Global supply chains can shift rapidly due to sanctions, border conflicts, or shifts in trade policy.

Coordinating with suppliers across different time zones, cultures, and languages can lead to communication breakdowns and misunderstandings, or even worse, delays and increased costs.

Solutions:

- Use advanced supply chain management systems for real-time visibility and analytics.

- Maintain regular communication and collaboration with key suppliers to foster strong relationships and mitigate potential risks.

- Diversify your supplier base and resilience by reducing reliance on any single region or supplier, thereby protecting against geopolitical disruptions.

8. Technological barriers to procurement automation

Procurement technology has much to offer, but implementation isn't always easy. Some procurement organizations still struggle with old ERP systems that can’t easily integrate with modern e-sourcing, CLM, or SRM platforms. The result is fragmented data, redundant manual entry, and limited automation capabilities, which are typical digital challenges facing procurement professionals.

Solutions:

- Prioritize cloud-based (SaaS) solutions for better scalability and easier interoperability.

- Use OCR and NLP (Intelligent Content Extraction) tools to automatically extract and structure data from invoices, contracts, and other unstructured documents.

- Select low-code or no-code platforms that let you easily configure complex business rules and approval hierarchies.

- Require automation vendors to hold key security certifications, such as ISO 27001 and SOC 2.

- Implement a strict Role-Based Access Control (RBAC) system to limit access to sensitive data within the platform.

- Configure the system to automatically flag or block non-compliant transactions (e.g., maverick spend, use of unapproved vendors).

- Maintain ongoing IT training for your team, so they know what to do when challenges in the procurement process arise.**

9. Supply chain disruptions

A single crisis — a typhoon, a tariff, or a new outbreak — can send shockwaves through global trade. Containers pile up, prices spike, and production stalls. Supply chain disruptions expose procurement’s vulnerabilities in cost control, supplier reliability, and logistics coordination, leading to price volatility and delivery interruptions. They also highlight weak visibility beyond Tier 1 suppliers.

Solutions:

Managing supply chain disruptions demands constant vigilance and quick responses to unforeseen events. Procurement teams need contingency plans to mitigate the impact of these challenges in the procurement process.

- Keep extra stock on hand, and have flexible agreements that can adapt to changing circumstances, to avoid overreliance on a single source or region.

- Build strategic inventory buffers for critical materials to cushion short-term disruptions without impacting production.

- Adopt agile procurement practices — implement flexible contracting, expedited approvals, and rapid sourcing mechanisms to respond swiftly to changing conditions.

- Apply AI and automation for predictive analytics, demand forecasting, and automatic reorder triggers to maintain supply continuity.

- Continuously review and update policies based on lessons learned from past disruptions to improve resilience.

10. Slow procurement processes

Manual processes and fragmented data systems slow procurement at every step. Requisitions sit idle in approval chains, vendor onboarding is slow, and missing contract details stall negotiations. The purchase-to-pay process is particularly prone to delays and errors, as information must move through multiple departments and disconnected platforms.

Solutions:

- Map the entire procurement process to identify and remove steps that don’t add value.

- Standardize workflows and procedures to minimize variation, errors, and confusion across teams.

- Enable self-service purchasing tools for routine, low-risk transactions to improve efficiency and user experience.

- Automate approval workflows with defined escalation paths and service-level agreements (SLAs) to ensure speed and accountability.

11. Talent shortages and skills gaps

You can have the best procurement tech in the world with sleek dashboards and AI, but it's useless if no one knows how to use it. Reports stall, budgets drift, and opportunities slip away. That’s what talent shortages look like.

Procurement today needs people who can turn data into decisions, but those skills are in short supply. Without the right talent, even the smartest tools can’t drive results — it’s like having a race car with no driver. It's hard to recruit and retain procurement professionals with modern skills in areas like data analytics, digital tools, and strategic sourcing. Still, it's not an impossible mission.

Solutions:

- Build an early talent pipeline through internships and campus programs.

- Use social media and employer branding to showcase company culture and ESG initiatives.

- Prioritize inclusive and diverse hiring practices for innovation and stronger teams.

- Activate employee referral programs with incentives to leverage networks.

- Develop clear, up-to-date job descriptions focusing on skills over formal degrees.

- Invest in continuous upskilling and reskilling around digital tools and analytics.

- Offer competitive compensation, career progression, and mentoring/learning opportunities.

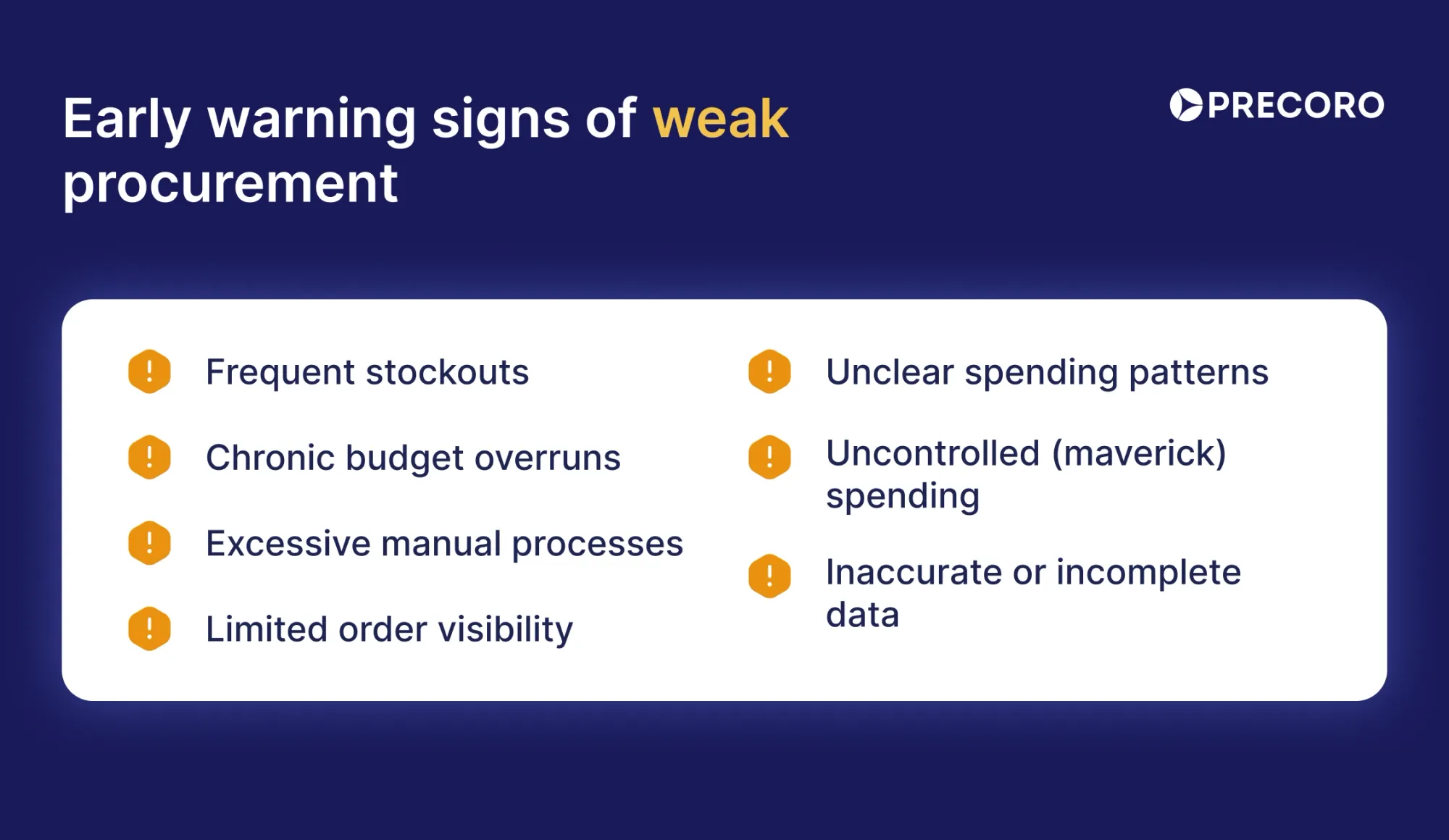

Early warning signs of poor procurement management

Procurement problems often start small — a late order here, an overrun there — but add up fast. Watch for these early signs that your procurement process may be losing control or efficiency.

- Frequent stockouts: Recurring shortages of essential materials that disrupt production schedules or customer deliveries.

- Chronic budget overruns: Persistent overspending on goods and services beyond approved procurement budgets.

- Excessive manual processes: Heavy reliance on paper-based purchase orders, approvals, and data entry that slow down operations.

- Limited order visibility: Inability to easily track purchase order status, supplier performance, or delivery timelines.

- Unclear spending patterns: Poor visibility into where and how money is spent across departments or categories.

- Uncontrolled (maverick) spending: Regular instances of employees making purchases outside approved procurement channels or contracts.

- Inaccurate or incomplete data: Unreliable procurement information that hinders reporting, forecasting, and supplier negotiations.

- Frequent rush orders: A pattern of last-minute purchases that leads to high pricing and additional freight costs.

Quiz: How much is your procurement in challenge right now?

Rate each statement by selecting one number (1 = Strongly Disagree, 5 = Strongly Agree). Then click Calculate Score.

Total Score: 0 / 50

Your result will appear here.

Sector-focused challenges in procurement

Procurement is not a one-size-fits-all discipline. Different sectors, such as healthcare, construction, manufacturing, and public services, face distinct procurement hurdles shaped by industry regulations, supply chain complexity, and market trends. Let's determine what hurdles each industry must navigate:

Education procurement challenges

Behind every classroom and campus operation lies a complex set of challenges in the procurement process, and many institutions struggle to get the right goods and services efficiently while keeping costs under control.

- Inefficient processes: Many educational institutions still use manual, paper-based workflows with multiple approvals that slow down resource procurement and reduce efficiency.

- Budget pressures: Tight budgets driven by limited funding and rising costs force procurement teams to balance quality with affordability.

- Regulatory complexity: Schools and universities face numerous compliance requirements across different levels of government. Non-compliance risks penalties, making staff training, standardized processes, and audit-ready systems essential.

- Vendor management issues: Failing to manage a wide range of suppliers effectively, often due to weak systems or inadequate partnerships, results in poor performance visibility and communication gaps.

- Disconnected systems: Fragmented tools for budgets, spend, and supplier data reduce transparency and make it hard to monitor procurement holistically.

- Budget and capacity limits: Deferred maintenance and rising operational costs require smarter collaboration, such as regional procurement consortia, to pool resources and cut expenses.

Solution:

When it comes to education procurement, Precoro gives schools, universities, and districts complete visibility and control over every dollar spent — with compliance built right into the process.

With real-time budget control, finance and administrative teams always know exactly how much funding remains, down to the department or project level. The Supplier Portal centralizes vendor collaboration and onboarding, and helps handle procurement contract management challenges with automated alerts.

Compliance no longer depends on manual checks or paperwork. Precoro automates approval flows to match institutional policies, ensuring every purchase is reviewed by the right person at the right stage. Detailed audit trails record every decision for transparent reporting, audits, and accreditation reviews.

By combining proactive budget visibility with automated compliance, Precoro helps educational institutions protect public funds, simplify accountability, and focus resources where they matter most — on teaching, learning, and student success.

Aerospace procurement challenges

With strict regulations, long lead times, and zero room for error, procurement in aerospace hits different. Below, read more about challenges and solutions:

- Material shortages: Aerospace manufacturers face delays of over 60 days in obtaining materials such as titanium, aluminum, composites, and rare earths, which drive up costs and can halt production.

- Demand uncertainty: Narrowbody aircraft demand is rebounding, but widebody and defense procurement remain uneven, making production planning and budgeting difficult.

- Financial pressure: Limited financing constrains efforts to scale production despite operational improvements.

- Regulatory complexity: Tight aerospace standards and geopolitical sanctions complicate procurement and supply chain compliance.

- Global supply chain risk: Complex, interdependent networks require flexible planning, multi-sourcing, supplier risk management, and digital forecasting.

- Sustainability focus: Growing emphasis on ethical sourcing and sustainability in procurement strategies.

Solutions:

In aerospace procurement operations, Precoro centralizes procurement across plants and projects, aligning purchases with budgets to save time and reduce errors. It gives real-time spend visibility, automatically updates remaining budget, and prevents uncontrolled overspending through customizable approval workflows. Smart contract management and integrated supplier portals streamline orders, invoices, and supplier interactions, cutting lead times.

The platform ensures compliance with SOC 2 Type II, GDPR, and CCPA while maintaining full audit trails and Power BI reporting. AI tools detect duplicate invoices and pricing errors to reduce fraud. Precoro integrates seamlessly with ERPs like NetSuite, QuickBooks, and Xero, offers mobile access for on-the-go approvals, and can be implemented in weeks. Additionally, role-based access and two-factor authentication enable secure and controlled collaboration.

Automotive procurement challenges

Procurement in the automotive sector is uniquely challenging due to its intricate supply chains, high demand for innovation, and constant pressure to optimize costs and ensure quality. Among the main challenges are:

- Supply chain disruptions: Shortages of key materials (steel, aluminum) cause long lead times and higher costs, worsened by geopolitical and economic instability.

- Rising costs: Inflation, labor shortage, and fuel volatility drive up manufacturing and shipping expenses.

- Sourcing shifts: Automakers move from global to regional sourcing to reduce tariffs and adapt to trade barriers.

- Inventory issues: JIT systems struggle amid border delays, leading to higher buffer stock needs.

- Operational hurdles: Transport delays, customs issues, capacity swings, and cultural barriers increase complexity.

Solutions:

One supplier delay or incorrect part can disrupt production, raise costs, and damage delivery timelines. In procurement for the automotive field, Precoro helps maintain control and transparency at every stage of the purchasing cycle by combining strong supplier management with real-time process visibility.

Through centralized supplier databases, buyers can track approved vendors, performance history, and negotiated pricing across all plants. Precoro ensures teams always purchase from qualified suppliers using up-to-date catalogs, which prevent duplicate or off-contract orders. This transparency reduces risks in multi-tier supply chains and builds stronger, more accountable supplier relationships.

With real-time visibility, managers see exactly where each request, purchase order, and invoice stands — from requisition to payment. Automatic budget updates, price variance alerts, and detailed spend reports give finance and operations teams the data they need to act fast and avoid delays.

Challenges in hospitality procurement

Behind every warm welcome and flawless service is a supply chain under constant pressure to deliver consistency. Here are some hospitality procurement challenges to explore:

- Supplier dependency poses a threat to operations and brand reputation.

- Lack of centralized procurement management hinders optimization.

- Manual procurement steps create delays and errors, reducing operational efficiency.

- Weak cost control and tight margins require strict cost management without compromising quality.

- Compliance and regulations, ongoing adherence to health, safety, and sustainability standards.

- Disconnected systems slow procurement processes and reduce data accuracy.

- Demand forecasting for guests and seasonal patterns.

- Increasing demand for environmental responsibility prompts suppliers to strive for ethical sourcing.

- Supply chain disruptions, shipping delays, shortages, and regional disruptions affect supply continuity.

- Balancing adequate stock levels with unpredictable demand.

- Remote location challenges, shortage of suppliers, rising logistics costs, and difficulty maintaining supplier standards in remote properties.

Solutions:

In hospitality, every location runs at its own pace — a hotel may need linens while a restaurant orders produce — but all those costs must stay aligned under one budget. Precoro solves this with multi-location spend control and real-time budget visibility, two features that make a measurable difference in day-to-day operations.

With Precoro, each property can manage its own suppliers, taxes, and currencies while still following company-wide purchasing policies and approval limits. Headquarters gains full visibility across locations, instantly seeing who buys what, from whom, and at what price. Real-time budget tracking updates with every request and invoice, so managers can spot overspending before it happens (no surprises at month-end).

This balance of centralized control and local flexibility keeps procurement fast, compliant, and cost-effective. From hotels and restaurants to entire resort chains, Precoro gives hospitality teams the transparency and control they need to run operations smoothly, protect margins, and deliver a consistently high-quality guest experience, with SOC 2, GDPR, and UK GDPR.

Manufacturing procurement challenges

Every delay, price hike, or quality slip in procurement hits the factory floor first. Yet, beyond cost, manufacturing procurement has more challenges and solutions to explore:

- Global sourcing: Managing suppliers across countries and time zones is tough, with language barriers, cultural differences, and ongoing geopolitical or shipping disruptions.

- Quality control: Ensuring consistent material quality requires strong audits, inspections, and supplier checks to prevent defects.

- Price volatility: Fluctuating raw material prices prompt companies to employ hedging, long-term contracts, and more strategic cost management.

- Supplier risk: Unreliable or unstable suppliers can disrupt production, so monitoring and backup plans are key.

- Resilience: Companies need agile and flexible supply chains to handle labor shortages, political tensions, and material delays.

- Slow processes: Manual procurement slows response times and limits visibility, calling for digital upgrades.

- Low tech adoption: Many firms still struggle to fully use AI and digital tools for better visibility and collaboration.

Solutions:

Manufacturing doesn’t stop at the office — and neither does Precoro. Its mobile app lets teams approve requests, review invoices, and submit expenses from anywhere, even on the factory floor. That means faster approvals, fewer delays, and production that stays on schedule. Whether you’re managing suppliers or checking budget status, everything you need is in your pocket, supported by a platform that’s as mobile and fast as your operations.

On top of that, Precoro keeps data connected through direct integrations with ERP systems like NetSuite, SAP, and Microsoft Dynamics 365 Business Central. AI-based invoice automation matches and verifies documents instantly to reduce errors and shorten approval cycles. Custom fields for work orders and BOMs, role-based access, and detailed spend reports give manufacturers full control without extra effort.

Top procurement challenges in Australia in 2025

Nearly 60% of Australian manufacturers are still dealing with serious material delays caused by global shipping bottlenecks, shortages of raw materials, and political tensions like China’s trade sanctions. To manage that risk, many are adopting diversification strategies, such as the “China-plus-one” model.

At the same time, public sector procurement teams are struggling to modernize. Legacy systems, cybersecurity worries, and poor data quality make it hard to bring in automation or AI — and even harder to stay compliant with the Commonwealth Procurement Rules. Furthermore, workforce productivity growth remains weak at 0.8%, intensifying pressure on procurement teams to automate and innovate for improved efficiency.

Organizations can tackle these challenges through supplier diversification, better digital tools with strong data governance, integration of ESG across procurement, agile cost and risk control, and more government support, especially for SMEs.

Challenges in South Africa’s procurement in 2025

South Africa has huge potential in sectors such as mining, agriculture, automotive, and textiles, but real-world challenges often limit it. In South Africa, only about 18% of firms take part in public procurement, lower than the Sub-Saharan Africa average of 22%. These points highlight real barriers, such as complex regulations like B-BBEE and the PFMA, along with strict compliance requirements, which make procurement more complicated than it needs to be.

There’s a big push to build supplier diversity, but many local suppliers still struggle with capacity and resources. Logistics and infrastructure gaps, along with port delays and currency volatility, add even more pressure.

At the same time, there’s growing momentum around digitalization — primarily through e-procurement platforms — to simplify and speed up processes. However, procurement issues such as supplier reliability, quality control, and labor disruptions continue to cause setbacks. That’s why more organizations are turning to multi-sourcing and stronger local partnerships to build resilience.

Wrapping up

Complexity undermines all types of procurement. And it often starts with a lack of standardized intake. If even one team bypasses the rules, management loses the full picture, which leads to last-minute purchases, supplier chaos, and overspending. As a result, poor forecasting, missed opportunities for negotiation, fragmented reporting, and other challenges in the procurement process arise.

Procurement transformation clicks better with Precoro:

- Guided intake workflows: Every requester follows the same intuitive, step-by-step process. No rogue emails or unclear requests — everything starts and stays inside Precoro.

- Centralized requests: All purchase requests are logged in one platform, instantly categorized by department, project, or cost center for clear oversight.

- Pre-approved catalogs and vendors: Teams can only select from approved products and suppliers, drastically reducing off-contract spend and compliance risk.

- Automated approvals: Dynamic workflows route requests to the right approvers instantly — no bottlenecks, no confusion, full audit trail.

- Real-time spend tracking: Procurement and finance gain visibility into committed spend before it hits the budget. You can forecast accurately and prevent overspending.

- ERP and accounting sync: Only approved data flows into your ERP, with no duplicates, errors, or unapproved invoices.

- Dashboards & reports: Precoro gives live insights into who’s buying what, when, and for how much, enabling true spend control and informed decision-making.

Frequently asked questions about procurement challenges

Suppliers may fail to deliver on time or meet quality needs, which hurts production. Cost control is hard when raw material prices change. Too many suppliers and outdated tools make the procurement process slow and unclear, so even seasoned procurement teams struggle with how to overcome procurement challenges.

Dark purchasing refers to unauthorized purchases outside formal procurement processes. It leads to cost overruns, compliance risks, and a lack of spending visibility, undermining procurement goals.

Procurement is hard because there’s a lot to manage all at once. Supply market limits from global risks, natural disasters, or regulatory shifts. It also has to align different internal needs and priorities across departments. Fragmented systems, poor visibility, and managing supplier performance in changing markets make the process even harder.

E-procurement offers many benefits, but it also comes with risks. It faces cyber and data privacy threats, supplier dependency, and tech integration issues. User resistance and weak compliance also slow adoption. Strong security and clear rules reduce these risks.

Managing suppliers isn’t easy — their reliability can vary in terms of quality, delivery, or finances, which can disrupt operations. Overreliance on one supplier or region adds risk, so it’s important to diversify. Plus, keeping up good communication, monitoring performance, and making sure contracts are followed takes a lot of time and effort.

“Dark purchasing” or “maverick spend” refers to purchases made outside of approved procurement processes (unauthorized suppliers, ad-hoc orders). Problems: lack of visibility, weaker negotiation leverage, higher prices or lower quality, and increased compliance risk. Solutions: implement centralized procurement platforms, enforce approval workflows, monitor spend patterns, and set clear policies.

If you already know the problems… what’s stopping you from fixing them?