10 min read

Sourcing and Procurement: One but Not the Same

A complete exploration of two closely related but different processes. In-depth comparison, recent trends, and best practices included.

This month, we continue our Procurement Basics series and would like to introduce our readers to yet another set of often misused business terminology.

As both sourcing and procurement are related to obtaining supplies for the organization, confusing these two terms is easy. But they are different, although closely related, processes.

Understanding their distinction can help you ensure the coordination between the responsible teams and adopt the right strategies for improving both sourcing and procurement.

Read on to find:

- Sourcing vs. procurement: key differences

- Procurement process overview

- Sourcing process overview

- How strategic sourcing influences your business

- Sourcing and procurement: a detailed comparison

- How to coordinate sourcing and procurement processes

- Recent trends in sourcing and procurement

Sourcing and Procurement Compared

In the following comparison table, you'll discover the main differences between these two essential processes:

| Sourcing | Procurement |

|---|---|

| Tasked with choosing suitable suppliers and negotiating the most favorable contract terms |

Tasked with acquiring the high-quality goods at the right time to meet company needs |

| Contains fewer steps | Involves multiple processes and numerous steps |

| Involves defining the need, researching the market, running sourcing events, vetting suppliers, and negotiating contracts |

Comprises sourcing, requisitioning, purchase ordering, making a payment, examining data, and managing contracts |

| Focuses on who provides the supplies | Focuses on what and how is supplied |

| Takes a strategic approach | Includes both strategic and tactical components |

| Aims at minimizing costs and building a robust supply chain | Aims at fulfilling internal needs and gaining a competitive advantage |

| Creates vendor and supplier relations | Manages supplier relationships to procure goods |

| Builds supply channels and systems | Uses supply systems developed by sourcing |

| Makes the flow of supplies possible | Emphasizes streamlining the flow of supplies |

What Is Procurement Process?

Procurement is a set of processes related to acquiring goods and services to satisfy a company’s needs.

For instance, if your company requires raw materials to manufacture its products, you first choose where to procure these materials, send a purchase order to the selected supplier, and pay for delivered items.

And all these activities are parts of the broader procurement process in your organization.

The typical procurement process involves the following steps:

- Spotting internal needs and creating a purchase requisition;

- Evaluating the market;

- Shortlisting suppliers and issuing RFQ or RFP;

- Reviewing quotations and selecting vendors;

- Negotiating with suppliers;

- Creating a purchase order;

- Expediting and receiving the ordered items;

- Auditing the delivered order to ensure supplier compliance;

- Receiving a goods receipt and an invoice;

- Performing a 3-way-match;

- Making a payment;

- Keeping record;

- Assessing the supplier performance and establishing a vendor relationship.

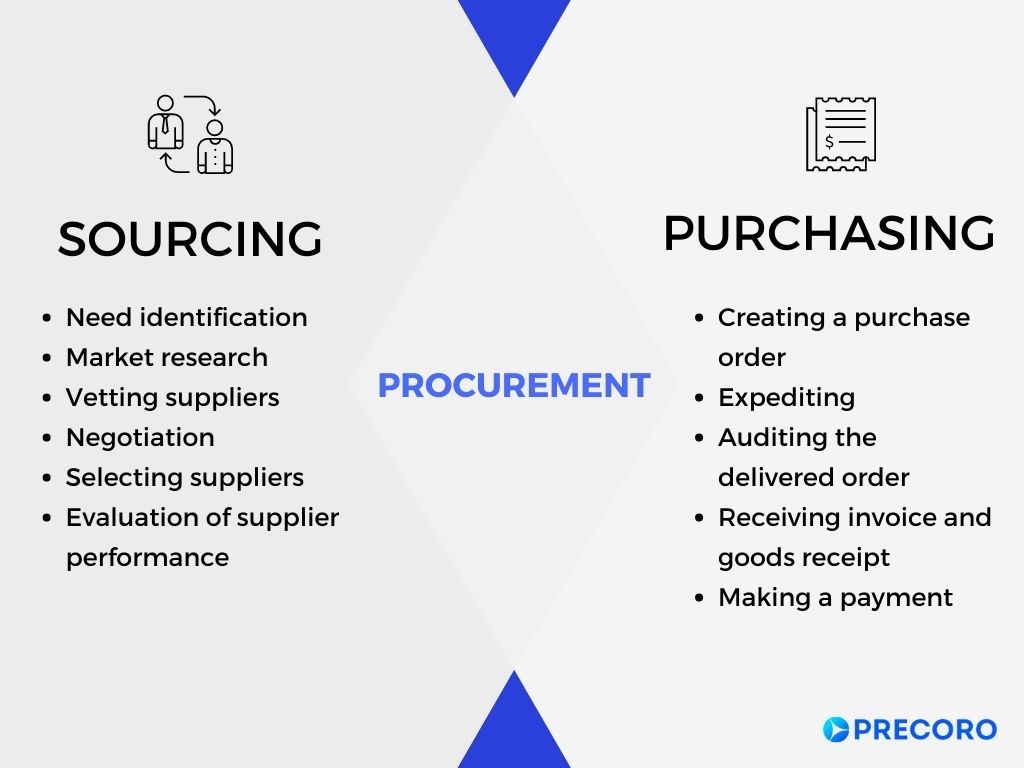

Simply put, procurement steps combine sourcing (selecting and negotiating with suppliers) and purchasing (placing a purchase order and paying) processes.

However, it is crucial to understand that procurement is a multi-stage complex process, which in addition to sourcing and purchasing, involves supplier management, contract management, and data analysis.

With sourcing as its subset, procurement directly impacts a company’s bottom line performance and competitiveness.

Effective procurement strategy allows negotiating the most favorable payment terms and establishing solid relationships with reliable and affordable suppliers.

In addition, procurement aims to guarantee that internal needs are satisfied on time with high-quality products.

What Is Sourcing Process?

Sourcing in procurement is a process of assessing, selecting, and managing suppliers to acquire the desired goods and services from them.

As the name suggests, sourcing focuses on creating sources through which an organization can obtain its supplies. Thus, it enables procurement and helps ensure the availability of necessary goods and services for a company. This step heavily relies on the vendor management lifecycle to support partnerships.

Another term that you will hear a lot when purchasing products from vendors or suppliers is strategic sourcing.

Strategic sourcing refers to adopting various sourcing strategies and models to minimize the risks and costs while increasing the purchase value.

The Role of Strategic Sourcing in Business

Strategic sourcing is crucial to a company's development. It allows to negotiate the best price and quality of the purchase and thus directly influences the company’s profit margin and net income.

Besides, the sourcing team helps ensure that chosen suppliers maintain a high level of performance.

Since potential vendors undergo an extensive vetting process, the sourcing team can choose the most reliable and qualified providers.

Selecting suitable suppliers is essential, as the further you go down the supply chain, the harder it will be to detect and correct mistakes.

Moreover, sourcing specialists ensure that if the primary suppliers face problems and cannot fulfill the contract requirements, alternative providers can replace the main ones.

This, in turn, helps mitigate supplier risk and prevent supply chain disruption. So, sourcing starts the supply chain and guarantees its stability and resilience in the long run.

Sourcing Process Steps

Typically, strategic sourcing contains the seven following steps, developed by A. T. Kearney in 2001 and widely used since.

Step 1. Analyzing internal needs and understanding the spend category

First, the sourcing team has to identify the company’s needs — what goods or services must be purchased — and define specifications for these products.

Employees also have to analyze the spend and define the spend category: are you buying food and beverages for the office or computer software or maintenance services?

Who uses these goods or services? How much is used? Who’s involved in the supply chain?

Step 2. Researching the market

Upon determining internal needs, the sourcing specialists search for suppliers, review the market offerings, and evaluate the market for risks and opportunities.

They also break down the cost components of the product and assess them along with raw materials, transportation, and labor costs.

Step 3. Developing a sourcing strategy

The third step is choosing the right strategy — deciding where to buy necessary goods to minimize costs and ensure the stability of the supply chain. In this step, a company also devises the set of criteria for potential suppliers.

Step 4. Issuing RFQs or RFPs and vetting suppliers

Next, employees start the process of soliciting bids and evaluating vendors. An organization can send potential suppliers a request for quote (RFQ) or a request for proposal (RFP).

Both are business documents that announce a project and ask for bids to assess each vendor’s ability to complete this project.

A request for proposal is usually more complex than a request for quote and contains project details, pricing analysis, product specifications, and delivery terms.

Step 5. Negotiating and selecting suppliers

Upon receiving quotations from vendors, a sourcing team evaluates responses, asks for clarifications if needed, and begins negotiating with shortlisted suppliers for lower prices, better payment terms, benefits, etc.

At the end of the negotiation process, a responsible person chooses the most suitable suppliers based on quality and pricing, reputation, recognition on the market, and possible risks.

Step 6. Arranging supplier integration process

Once the selected vendor was notified, the implementation process begins. A buyer and a supplier sign a contract.

The sourcing team also has to develop a communication plan and a system for measuring supplier performance.

Step 7. Benchmarking and assessing results

The final step takes place after the purchase is made. The sourcing team benchmarks the status of the spend category and analyzes the suppliers’ performance based on established KPIs.

Sourcing vs. Procurement: How are They Different?

Now that we broke down procurement and sourcing processes let’s look closely at the differences between these two.

Process Components

Since sourcing is a subset of procurement, sourcing is a less complex process with fewer components. It comprises defining internal requirements, searching for vendors, arranging sourcing events, and assessing suppliers.

On the other hand, procurement encompasses the sourcing process itself, purchasing (placing of purchase orders, receiving of the order, and making payments), data analysis, contract and supplier relationship management

Timing

Sourcing takes place mainly before the purchase is made. However, the sourcing team can also step in during the purchasing process if suppliers can’t fulfill their responsibilities in compliance with a contract.

Besides, at the end of the procurement process, it is a sourcing task to judge the suppliers’ performance and decide whether to continue the relationship.

Unlike sourcing, procurement is an end-to-end process covering all the activities before, during, and after the purchase.

Goals and Focus

Sourcing is a strategic process with long-term goals such as creating relationships with the most suitable suppliers and building and maintaining a resilient supply chain.

The procurement process, on the contrary, combines strategic (sourcing and supplier relationship management) and tactical (purchasing) components.

It mainly concerns itself with buying high-quality goods and services for the lowest price and satisfying internal requirements.

Simply put, sourcing focuses on who provides the commodities, while procurement — on what and how has to be purchased.

Function

- Sourcing supports procurement by building supply chains and systems for procurement professionals to use.

- Procurement provides information for sourcing.

Sourcing specialists develop vendor relations, while the procurement team leverages these relationships to obtain desired products.

Thus, sourcing makes the flow of supplies possible, whereas procurement aims at streamlining and optimizing this flow.

Besides, the sourcing team agrees on the pricing and quantity of the product with suppliers.

Then, the procurement department uses that information to forecast the spend and determine how much budget to allocate for buying a certain quantity of goods.

To sum up, sourcing develops a foundation for procurement to fulfill its aim.

Just as procurement is impossible without sourcing, sourcing can’t function correctly without data from procurement specialists.

Procurement managers gather information on supplier performance during the purchasing process, and the sourcing team uses it to evaluate vendors and either continue working with them or terminate the contract.

How to Coordinate Sourcing and Procurement?

As you can see, communication between procurement and sourcing teams is crucial for organization operations to run smoothly.

Sourcing requires data from procurement to ensure that an organization works only with effective suppliers.

And procurement needs statistics obtained by sourcing to make an accurate spend forecast and increase cost savings.

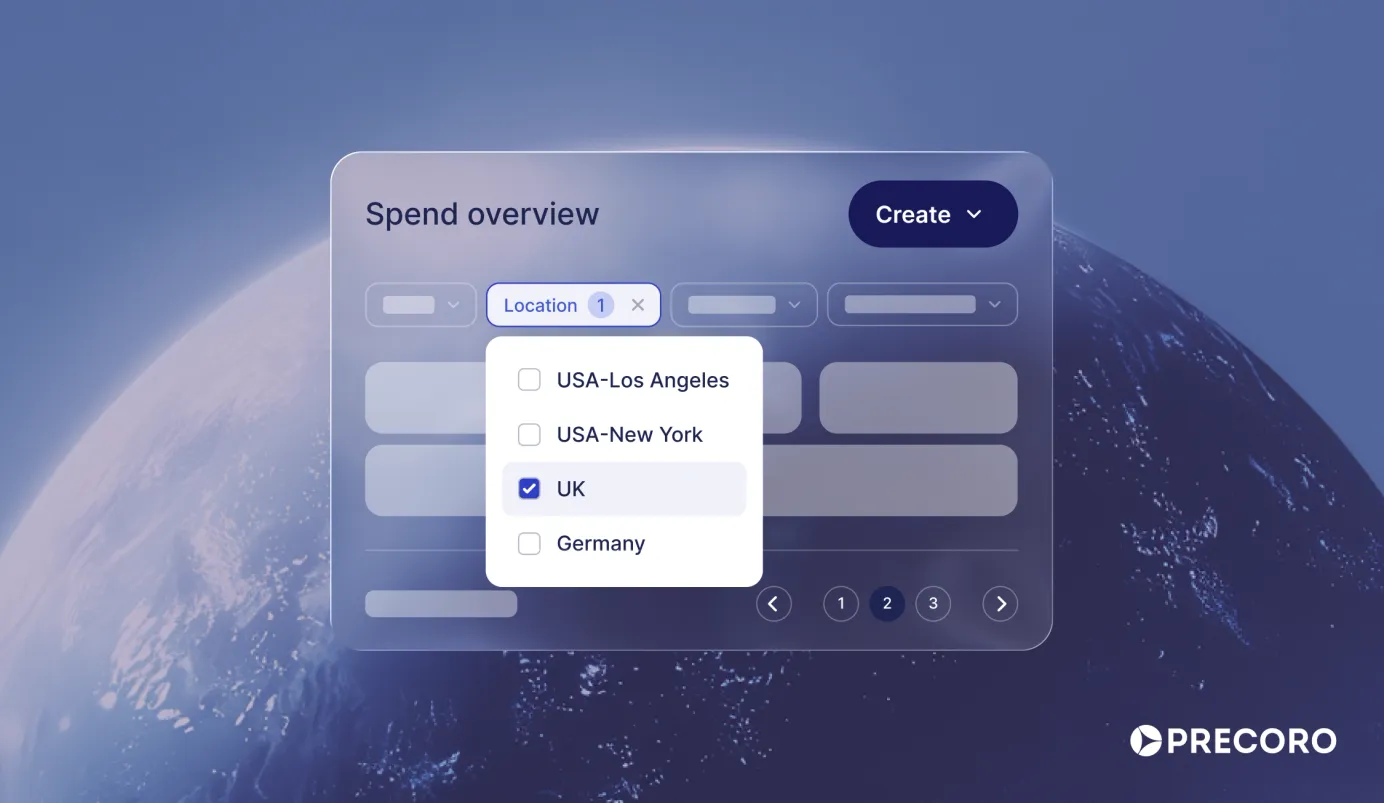

The right procurement technology can help you store all the sourcing and procurement data in one place and improve the collaboration between procurement and sourcing teams.

Benefits of installing a comprehensive procurement software include, but are not limited to:

- Enhancing communication between procurement and sourcing teams in a centralized system

- Streamlining the purchasing process by eliminating manual, error-prone work

- Improving supplier relationship management, featuring reports on vendor performance

- Automating purchase ordering process and approval workflow

Precoro software allows you to do everything mentioned above and more. In addition, Precoro can help you enhance purchasing operations, increase transparency, and get insights into budget management.

Featuring real-time reporting and integration to your favorite accounting systems and ERP software, Precoro is a one-stop solution for businesses of all sizes.

Sourcing and Procurement Trends

Now that procurement and sourcing play an even more important role in business, it’s useful to understand what tendencies they recently display.

Emphasis on Risk Management and Flexibility

The COVID-19 pandemic showed how important it is for a business to adapt quickly to unpredictable circumstances and mitigate risks.

As a result, resilience and adaptability of supply chains became one of the top priorities for organizations.

Procurement specialists aim to thoughtfully evaluate and manage supply chain risks and design better contingency plans, such as establishing relations with backup suppliers and optimizing inventory.

Digital procurement transformation and adoption of cloud-based software solutions allow an organization to improve supply chain management, become more agile and mitigate risks more effectively.

Sustainable Procurement

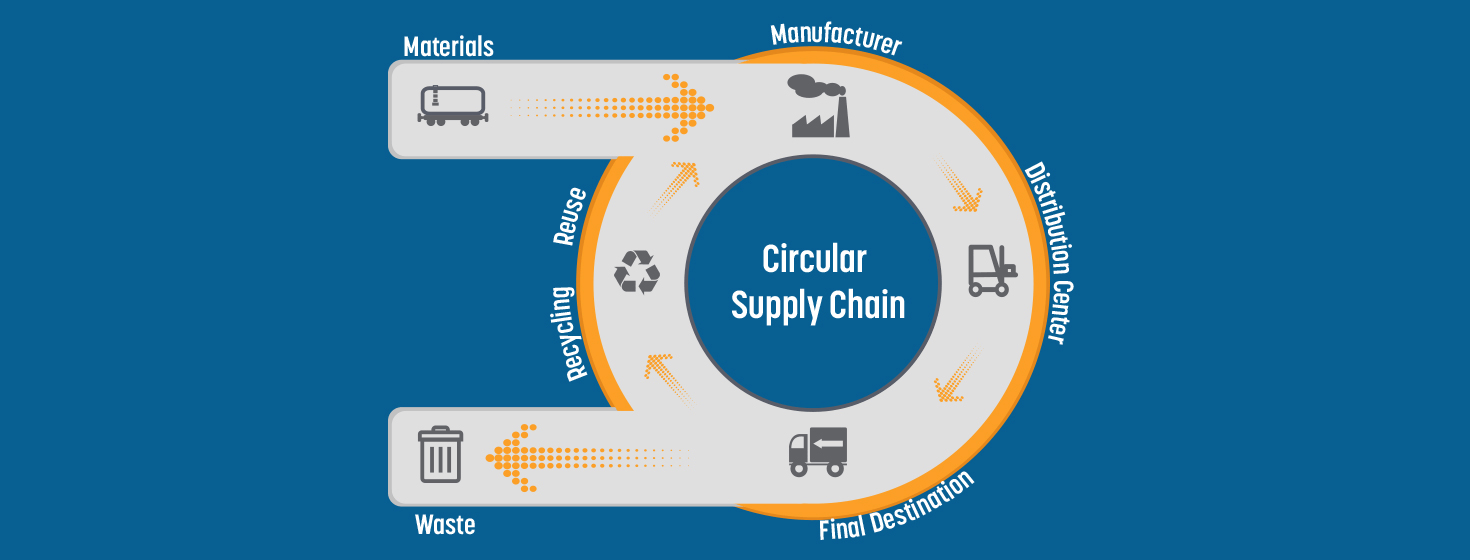

Now, when the consequences of pollution and global warming become impossible to ignore, more and more organizations begin to take a sustainable procurement approach.

Its practices include, for example, consideration of local sourcing, selection of suppliers who also align with sustainability values, and switching from linear to circular supply chains. The latter allows to reduce waste and adds up to cost savings.

Prioritizing Corporate Social Responsibility

Aside from sustainability, businesses are also expected to become more socially conscious and positively impact the community.

One example of corporate social responsibility initiatives includes switching to ethical sourcing — procuring goods from organizations that offer safe and fair working conditions to their employees and minimize their negative impact on the environment.

Focus on Increasing Collaboration with Suppliers

Nowadays, organizations focus on strengthening collaboration with suppliers by ensuring transparency and better communication.

Supplier collaboration can help you improve stability, manage risks more effectively, negotiate more favorable terms, and boost the company’s competitiveness.

Spend Optimization

In these uncertain times, cost reduction became one of the key practices companies turn to. It helps increase revenue and contributes to the sustainable growth of an organization.

Modern expense management practices increase transparency and spend visibility, control the maverick spend, and manage contracts more effectively.

FAQ

Sourcing is a subset of procurement, which focuses on supplier selection and negotiation. On the other hand, procurement concerns itself with purchasing goods and services and ensuring the availability of necessary commodities. Besides, sourcing is tasked with creating supply systems and vendor relationships, while procurement leverages those to procure goods.

It is a process of applying various sourcing strategies to selecting and negotiating with suppliers to ensure the best pricing and purchase value and lower supply chain risks.

Both sourcing and purchasing are the components of the broader procurement function. Sourcing focuses on the relational part of the buying process (who to buy from?), while purchasing — on the transactional one (what to buy and how much to pay for the products?). Procurement combines these two while also including data analysis, vendor and contract management.

Summing Up

Sourcing and procurement are two closely related but different processes.

Sourcing is a subset of procurement. It focuses on evaluating the market, selecting the most favorable suppliers, and negotiating with them.

Strategic sourcing ensures that the lowest possible pricing and the highest value are locked in the contracts.

Procurement is a broader process than sourcing. It involves all the activities related to procuring goods: from purchase requisitioning to record keeping.

Sourcing has long-term goals like establishing relationships with reliable suppliers. Procurement also has short-term purchasing objectives.

The sourcing team creates relations with vendors and oversees how procurement specialists leverage these relations to purchase necessary commodities.

Sourcing aims to set up and plan supply chains while the procurement function is running and improving these supply chains.

Going digital and installing cloud-based procurement tools can help improve collaboration between sourcing and procurement teams, reduce spending, and optimize the buying process.