16 min read

Vendor Scorecard: Definition, Benefits, and Examples

Discover vendor scorecards, learn about their benefits, and explore practical examples to enhance your supplier management process.

Read on to learn:

What is a vendor scorecard?

Vendor evaluation vs. vendor scorecard

When to use a supplier scorecard

Key metrics to track on your vendor scorecard

Example of a vendor scorecard

How to create a vendor scorecard

Types of vendor scorecards

Benefits of the vendor scorecard

Why vendor scorecards are hard to make

How to integrate vendor scorecards into vendor management

How to approach a vendor about a scorecard

Frequently asked questions about vendor scorecards

What is a vendor scorecard?

A vendor scorecard or a supplier scorecard is a tool businesses use to measure supplier performance. They rate product quality, delivery time, communication, errors, and delivery accuracy. Typically, companies display these KPIs in graphical vendor scorecard templates, such as radar or bar graphs, and update them every three or six months, depending on the type of vendor.

Vendor evaluation vs. vendor scorecard: What's the difference?

The key difference between a vendor evaluation and a vendor scorecard lies in their purpose and timing:

Vendor evaluation is a structured process that happens primarily during the selection phase. Companies size up vendors based on criteria such as price, features, and support to identify the best fit for the organization.

In contrast, vendor scorecards are ongoing tools that take place after selection. They help procurement managers track and measure performance metrics, such as quality, delivery, cost, and compliance, to guide contract renewals and drive continuous improvement.

In short, vendor evaluation helps you pick the right vendor upfront, while vendor scorecards track and improve vendor performance over time. Below in our guide, you’ll find a vendor scorecard example with detailed data.

When to use a supplier scorecard (+free template from Precoro)

Typically, organizations turn to a vendor selection scorecard during vendor onboarding, regular performance reviews (quarterly or biannually), and strategic sourcing initiatives. Starting with a focused set of KPIs tailored to your business goals ensures the scorecard remains relevant and actionable. Over time, you can expand and refine the vendor selection scorecard to capture more nuanced insights and drive greater supplier value.

At the very beginning, many companies use a vendor scorecard template in Excel when they need to:

- Evaluate existing suppliers

- Select new vendors

- Monitor performance

- Improve supplier output

- Make sourcing decisions

- Negotiate contracts

- Manage risk

- Communicate expectations

With the key metrics we've listed below, you can build your own custom vendor scorecard template, which will help you take a structured, objective, and transparent approach to supplier performance evaluation. Or use our free vendor scorecard template to see which vendor works best for you.

After all, regular use of scorecards helps maintain high standards, optimize costs, and align your supply chain with your organization’s evolving priorities.

Key metrics to track on your vendor evaluation scorecard

Measure only what counts most. Here are the top vendor scorecard metrics to include:

Price and cost

Price is not everything, but unpredictability is a problem. Fluctuations in pricing, hidden fees, or sudden surcharges can destabilize your budgeting and pricing models.

What to track:

- Unit cost changes over time.

- Freight and surcharge history.

- Comparison to alternate suppliers (benchmarking).

- Total cost of ownership (TCO), including service and defect costs.

Tip: Monitor cost changes in context. A simple vendor scorecard example: if a vendor’s costs are rising but their delivery and quality remain excellent, that might still be acceptable. But unexplained or frequent price shifts warrant closer scrutiny. Create alerts for unusual cost jumps that aren’t aligned with industry benchmarks or previous agreements.

On-time delivery rate (OTD)

On-time delivery keeps your supply chain steady—without it, delays or errors cause costly disruptions and chargebacks.

What to track:

- Percentage of shipments arriving as scheduled.

- Average lead time vs. promised lead time.

- Frequency and causes of late or expedited shipments.

- Delivery accuracy (correct items, quantities, and undamaged goods).

Tip: Use a vendor assessment scorecard to monitor delivery consistency and trends. Identify persistent delays or frequent rush orders as signs of reliability issues. You should address them or consider alternative sourcing options. Set clear delivery performance standards and automate vendor reporting. Then, analyze order frequency and seasonality data to understand how delays impact your operations.

Quality

Quality drives customer trust and cuts costs by reducing defects, returns, and warranty claims. It’s the frontline defense for your brand’s reputation.

What to track:

- Defect and rejection rates.

- Frequency and impact of quality issues.

- Compliance with industry standards and certifications (like ISO).

- Speed and success of corrective actions.

Tip: Use quality metrics to separate reliable vendors from the rest in your vendor evaluation scorecard. Feed this data into supplier development and risk management strategies. Link quality performance to vendor rewards and improvement plans to maintain high standards and clear accountability.

Efficiency

Efficiency measures how well your vendors use resources and time to deliver products or services. Poor efficiency leads to higher costs, delays, and wasted resources that impact your bottom line.

What to track:

- Cycle time from order to delivery.

- Resource utilization rates (e.g., labor, materials).

- Percentage of orders completed without rework or errors.

- Vendor responsiveness to changes or issues.

- Cost per unit relative to industry benchmarks.

Tip: Analyze trends in vendor efficiency to identify bottlenecks or waste in your vendor evaluation scorecard. Vendors with consistently low efficiency may require process improvements or reconsideration in your supply chain. Combine efficiency metrics with quality and delivery procurement intelligence to get a holistic view of the vendor performance scorecard and prioritize improvement efforts.

Compliance

Compliance protects your business from legal risks and reputational damage. Vendors who don’t follow the rules put you in hot water.

What to track:

- Adherence to contracts and service agreements.

- Compliance with industry regulations and standards.

- Frequency and severity of violations or audit issues.

- Timeliness and accuracy of required documentation.

- How quickly vendors fix compliance issues.

Tip: Track compliance to avoid penalties and disruptions. Vendors with repeated issues need closer monitoring or replacement. Automate compliance tracking to catch problems early and reduce risk.

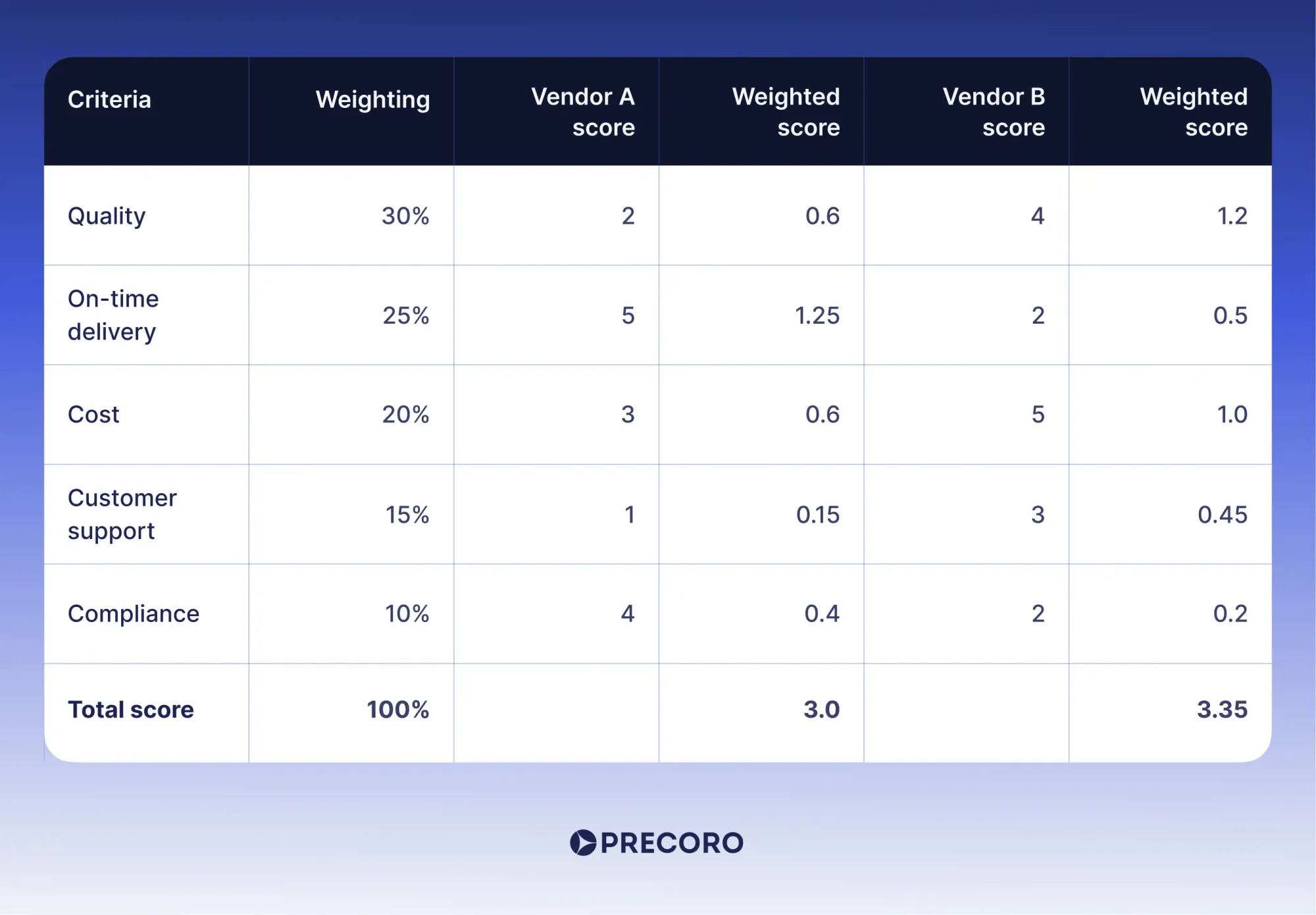

Example of a vendor scorecard

Here is an example of a basic vendor scorecard used to assess vendor performance. It gives you a sharp, structured way to measure KPIs across key areas—each rated from 1 to 5, with 5 reflecting peak performance. In this context, "weight" shows how important each score is to your company’s goals. First, you assign higher weights to key criteria, then multiply them by vendor scores to reflect their priority in the final evaluation.

Note!

This format is adaptable to your business context. You can find other vendor scorecard examples for inspiration and add new evaluation factors or modify weightings to better reflect internal priorities.

- Quality (30%): Evaluates the vendor’s ability to meet quality requirements. Vendor A scored 2, suggesting issues with quality, while Vendor B scored 4, indicating better performance.

- On-time delivery (25%): Measures the punctuality of delivery. Vendor A scored 5, indicating strong reliability; Vendor B scored 2, showing recurring delays.

- Cost (20%): Reflects pricing efficiency. Vendor A scored 3, suggesting average cost performance, while Vendor B scored 5, indicating excellent pricing competitiveness.

- Customer support (15%): Assesses service quality and responsiveness. Vendor A scored a low 1, suggesting poor support, while Vendor B scored 3, reflecting average service.

- Compliance (10%): Checks adherence to contractual and regulatory standards. Vendor A scored 4, while Vendor B scored 2, highlighting potential compliance concerns.

Total Scores:

- Vendor A: Final weighted score is 3.0

- Vendor B: Final weighted score is 3.35

These two vendor scorecard examples clearly show that vendor B slightly outperforms vendor A and suggest a stronger overall performance.

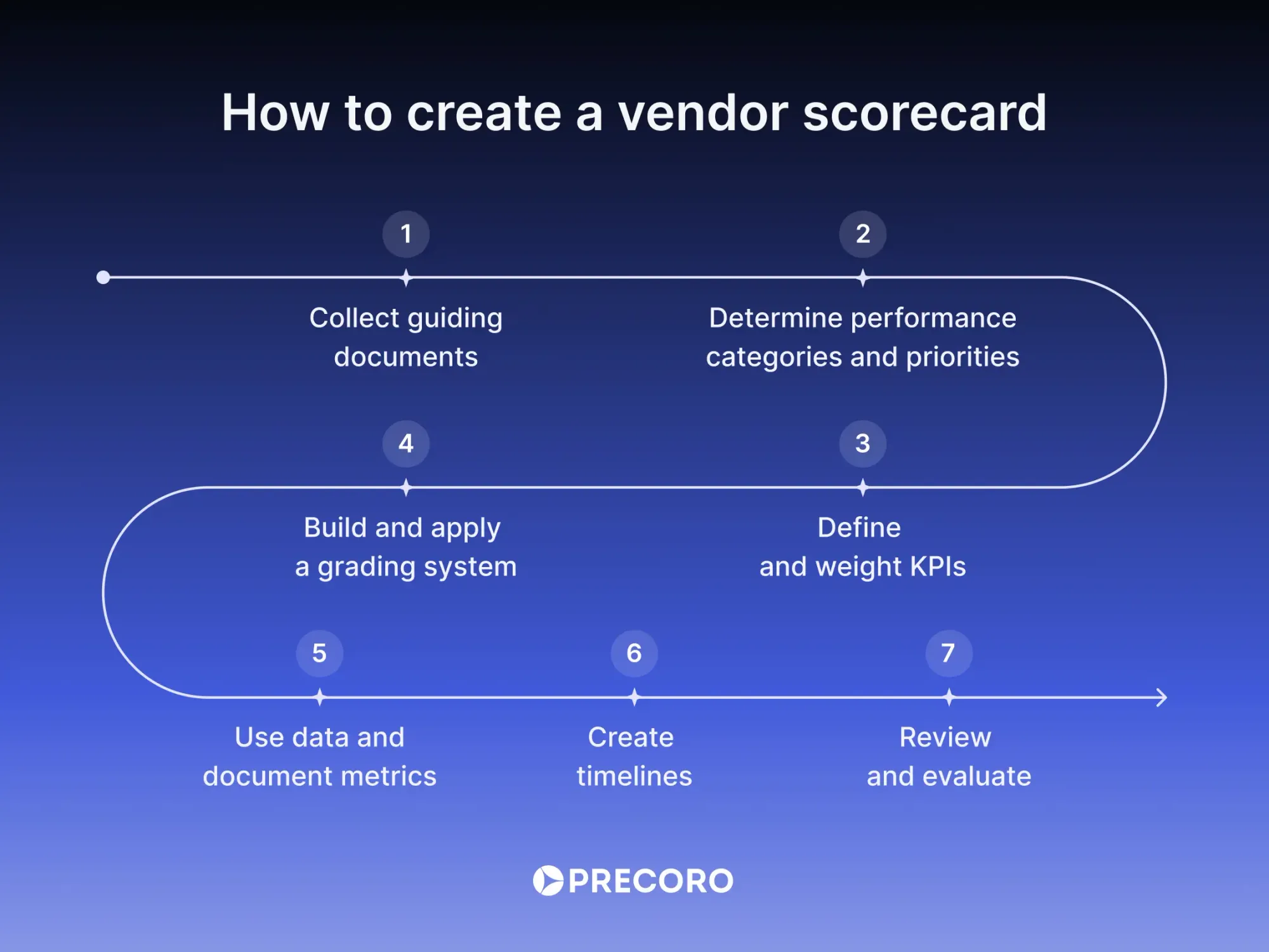

How to create a vendor scorecard

Don’t guess which vendors are doing well. Build a scorecard and let the numbers speak. Here’s a detailed guide on how to create a vendor assessment scorecard hassle-free:

Step 1. Collect guiding documents

Gather your Request for Proposal (RFP), vendor responses, and contracts. Review these documents to identify critical factors and service level agreements (SLAs).

Step 2. Determine performance categories and priorities

Identify the factors that most significantly impact project success and categorize them into three key areas: quality, delivery, and service. Limit each category to about three measurable KPIs. Prioritize these based on their impact on your business and risk mitigation.

Step 3. Define and weight metrics

Specify clear, measurable KPIs within each category (e.g., on-time delivery rate, defect rate, responsiveness). Assign weights to each KPI to reflect their relative importance to overall vendor performance.

Step 4. Build and apply a grading system

Develop a vendor scoring scale, such as 1 to 5 or Yes/No, depending on the complexity of the vendor scorecard metrics. Define what constitutes a good or poor score to ensure consistent evaluation. Apply this grading scale to vendor data to calculate scores for each KPI and category.

Step 5. Use data and document metrics

Gather quantitative and qualitative data from vendor performance records, audits, and feedback. Document all metrics, vendor scoring rationales, and data sources to maintain transparency and repeatability.

Step 6. Create timelines

Establish a schedule for when you will perform vendor evaluations (e.g., quarterly or annually). Define deadlines for data collection and vendor scoring to ensure timely and consistent assessments.

Step 7. Review and evaluate

Regularly review vendor scores with stakeholders and vendors themselves. Use the scorecard results to identify areas for improvement, inform decision-making, and adjust KPIs or weights as needed to reflect changing priorities.

Types of vendor scorecards

Different vendors, different needs—explore the scorecard types that keep your supplier game sharp and your decisions smarter.

Basic vs. advanced scorecards

Basic scorecards track a few simple vendor scorecard metrics for quick checks. In contrast, advanced scorecards combine multiple data points and complex calculations to deliver a complete, strategic view of business health.

Basic vendor assessment scorecard example:

A small retail outlet uses a spreadsheet to track daily sales and compares them to a fixed daily target. The scorecard shows total sales, the percent to goal, and simple bar charts updated weekly by the store manager.

Advanced vendor scorecard example:

A global telecom company uses an advanced scorecard integrating KPIs such as Average Revenue Per User (ARPU), customer churn rate, network uptime, and customer satisfaction scores. These KPIs are weighted according to strategic priorities, updated daily from multiple data sources, and visualized in an interactive dashboard for executives.

Manual vs. automated scorecards

Manual scorecards require people to enter and update data by hand. They offer a simple way to track performance but are often prone to delays and errors. Automated scorecards use technology to collect and check data in real time. They provide fast and accurate information that helps teams manage vendors more effectively.

Manual vendor assessment scorecard example:

A medium-sized store uses spreadsheets to track delivery times and order accuracy every week. The store manager types in the data every Monday and reviews simple metrics, such as average delay and error rate, to assess the vendor's performance.

Automated vendor scorecard example:

A big manufacturing company connects data from buying, shipping, and quality systems into an automated scorecard. The system monitors key metrics, including on-time delivery, defect rates, and cost changes. It updates the dashboard right away, so managers can make quick and smart decisions.

Сollaborative scorecards

Collaborative scorecards bring together multiple teams, departments, or external partners. They share data and align efforts toward common goals, increasing transparency and joint accountability.

Collaborative vendor scorecard example:

A company and its key suppliers share a collaborative scorecard to monitor delivery times, quality metrics, and sustainability goals. Both parties access a shared dashboard that updates in real time. They use it to coordinate improvements and strengthen their partnership.

Industry-specific scorecards

Industry-specific scorecards customize KPIs and strategic goals to fit the unique demands of different sectors. They help organizations focus on the most relevant vendor scorecard metrics and initiatives that drive success in their field.

Industry-specific vendor assessment scorecard example:

A mining company tracks cost reduction, product quality, extraction efficiency, and innovation. It measures KPIs such as cost savings percentage, quality ratings, extraction rates, and the number of new ideas generated. The company adopts advanced mining technologies and creates innovation labs to reach these goals.

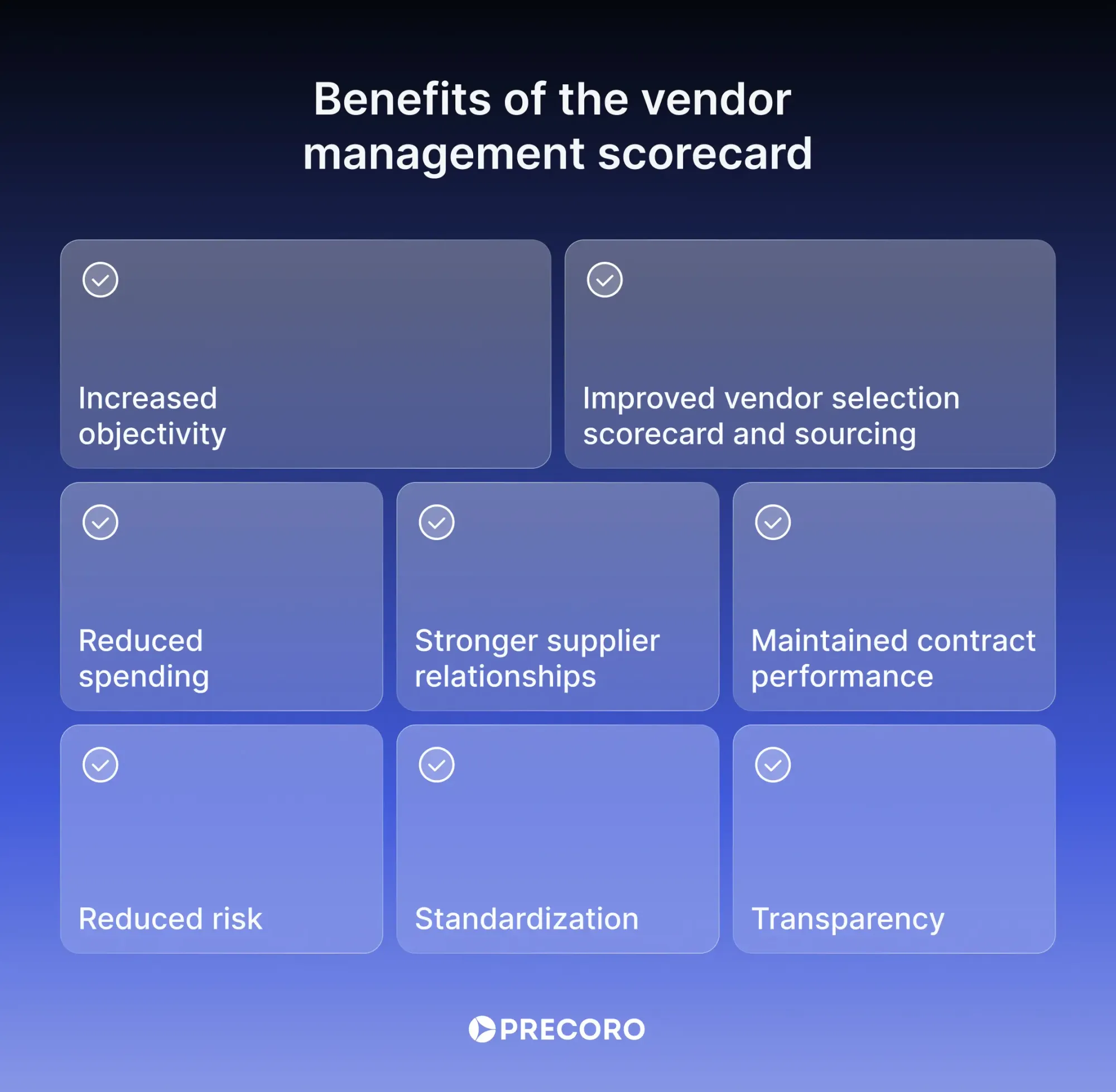

Benefits of the vendor management scorecard

Vendor scorecards bring a much-needed layer of clarity and control to vendor relationships. They cut through the noise with objective, data-driven insights. And numbers speak louder—vendor scorecards boost on-time deliveries by 15% in just six months.

Here’s a detailed overview of the advantages of vendor scorecards for companies:

1. Increased objectivity

Subjective opinions and bias often plague vendor management lifecycle. Scorecards flip the script by using hard data, such as delivery times, quality metrics, compliance rates, cost performance, and more. This objectivity helps to follow internal politics and ensure vendors are evaluated purely on performance. The result? Fairer decisions and less friction.

2. Reduced spending

Keep a sharp eye on vendor performance, and inefficiencies become impossible to ignore. Scorecards catch vendors who miss goals or hike costs. With this insight, companies renegotiate, focus spend on the best, or cut ties with the rest, and, as a result, unlock major savings.

3. Improved vendor selection scorecard and sourcing

Companies often choose vendors by reputation or instinct, but that approach falls short. With detailed vendor scorecard metrics, you can measure quality, delivery, innovation, and price. The result: smarter sourcing and more resilient supply chains.

4. Stronger supplier relationships

Trust grows from transparency. Scorecards define clear expectations and a common language between buyers and vendors. Regular performance reviews using scorecard data encourage open dialogue, deepen collaboration, and drive ongoing improvement and, as a result, turn deals into lasting partnerships.

5. Maintained contract performance

Contracts don’t just sit in a file—they hold vendors accountable. Scorecards track how well vendors meet SLAs, delivery deadlines, and quality benchmarks. Thus, with real-time oversight, companies can spot issues fast and fix contract breaches before they spiral.

6. Reduced risk

Vendor risk runs deeper than cost. It covers compliance gaps, quality issues, delivery hiccups, and reputational hits. Scorecards catch these red flags early, helping companies stay ahead and avoid costly surprises.

7. Standardization

Vendor management gets messy without a standardized evaluation. Scorecards bring uniform criteria and vendor scoring to every supplier. That consistency helps you compare performance, track trends, and scale your vendor strategy smoothly.

8. Transparency

Scorecards reveal vendor performance to all stakeholders. Thus, procurement and executives gain full visibility into vendor rankings. With such transparency, all the stakeholders are on the same page.

Why vendor scorecards are hard to make

Basically, vendor management scorecards are hard to build because the data you need is scattered across multiple systems and teams, which makes it tough to identify reliable sources. Beyond that, there are many other challenges of vendor scorecards, including:

Automating data collection

Manual data gathering is both time-consuming and prone to errors. Automation through system integration is essential, but it is also technically challenging and requires ongoing audits to maintain data quality.

Synthesizing data

Combining diverse data points into a clear, actionable scorecard demands thoughtful analysis and a focused methodology.

Clarity and relevance of metrics

Using too many or vague KPIs creates confusion and misaligned expectations. Scorecards must focus on a few key, agreed-upon vendor scorecard metrics that align with business priorities.

Limited supplier visibility

Without continuous communication and modern monitoring tools, the understanding of supplier performance is incomplete, which reduces the effectiveness of the scorecard.

Best practices for using vendor scorecards

Start simple and build your vendor management scorecard gradually. Focus first on a few key metrics, such as quality, delivery, and service. This approach helps your team and vendors understand the process clearly. As you gather more data and experience, add more detailed criteria to capture a complete view of vendor performance.

Use external benchmarks to compare your vendors against industry standards or similar suppliers. This comparison helps you set realistic performance goals and identify areas where your vendors excel or need improvement.

Opt for decision matrices to evaluate vendors objectively. Assign weights to each criterion based on its importance to your business. Then, score vendors on these criteria and calculate a weighted total. This method ensures you balance factors like cost, quality, and responsiveness fairly.

Apply the Kraljic matrix to categorize your procurement items and tailor your vendor management strategies:

- Bottleneck items: These have high supply risk but low business impact. Manage them by mitigating risks and identifying alternative suppliers.

- Routine items: These have low supply risk and low impact. Optimize procurement for efficiency and cost control.

- Strategic items: These have high supply risk and high business impact. Build strong, collaborative partnerships with vendors supplying these items.

Use a weighted decision matrix to prioritize evaluation criteria clearly. This tool helps you make balanced decisions that reflect your business priorities.

Tie vendor performance to incentives. Link scorecard results to contract terms, bonuses, or penalties. This connection motivates vendors to improve and maintain high standards. Additionally, share scorecard results openly to encourage transparency and collaboration.

How to integrate vendor scorecards into vendor management

Vendor scorecards don’t work in isolation. Plug them into your vendor management system (VMS) to get real results. Here’s the playbook:

Data collection: Automate data capture with tools like Precoro or NetSuite to track vendor performance in real time. Procurement automation cuts errors and frees your procurement team to focus on what matters.

Performance monitoring: Use live data to make smarter decisions about your suppliers. Embed scorecards into your procurement workflows for nonstop tracking and continuous improvement.

Regular audits: Run audits regularly to verify vendor data, check compliance, and spot areas that need attention.

Corrective actions: Spot underperformers fast. If a vendor misses deadlines, act quickly—renegotiate terms or find a better partner.

Integrate, automate, audit, and act. That’s how you turn a vendor management scorecard from a checkbox into a competitive edge.

How to approach a vendor about a scorecard

If your company is new to vendor selection scorecards, bring your suppliers into the process early and position the change as a true partnership. Discuss the idea of scorecards casually with your vendors before implementation.

Send a formal notice that explains the initiative, including key performance indicators (KPIs) and metrics. Schedule vendor meetings to answer questions and address concerns upfront. Roll out the vendor management scorecards with a soft launch to catch and fix any issues early.

Check in frequently with your suppliers to understand how the new standards work for them and how they feel about their scores.

Ultimately, it’s all about engaging with suppliers. Collaborate, measure progress, and maintain regular communication—quarterly, monthly, or weekly, depending on the relationship.

Frequently asked questions about vendor scorecards

Vendor scorecards rate suppliers based on key factors such as quality, cost, and delivery. They use clear metrics to score performance, which helps companies spot issues and choose the best vendors. As a result, vendor management is simple, fair, and data-driven.

Vendor scorecards help spot trends and issues early on to improve accountability for both vendors and internal teams. Thus, vendor selection improves and leads to better cost control, risk reduction, and stronger supplier relationships.

Typically, vendor scorecards kick off after the RFP, when the vendor is being onboarded. At this time, the procurement team looks over the evaluation rules and decides on the KPIs. These KPIs will be used to check how well the vendor performs during the contract period.

Stick to quarterly reviews for general vendors, but prioritize monthly updates for key players. Additionally, update immediately after disruptions, major delays, or contract changes. Letting old data sit kills your ability to negotiate or pivot.

Procurement teams use scorecards to assess supplier quality and delivery. Department heads provide feedback on the impact of vendors, while executives track risk, value, and alignment with company goals.

Gatekeeper and SirionLabs are packed with AI-driven vendor and contract lifecycle management. While SAP Ariba and Coupa deliver enterprise-grade analytics, Precoro stands out for its clean and intuitive approach to procurement and vendor evaluation.

Take control of vendor performance with Precoro

Why wrestle with numbers when Precoro’s vendor management features do the heavy lifting? Though it doesn’t label it a "vendor scorecard," Precoro’s customizable reporting helps you keep supplier performance front and center.

Key features Precoro has to keep an eye on vendor performance:

- Onboard, evaluate, and track vendors with custom approval workflows and supplier registration forms, ensuring suppliers meet your company’s quality, delivery, and performance standards.

- Generate real-time reports on vendor spending, contract compliance, and performance metrics, enabling you to analyze and score vendors systematically.

- Track key metrics such as defect rate, lead time, and on-time delivery to evaluate suppliers objectively. This approach supports the vendor scorecard concept using Precoro’s reporting and supplier management modules.

- Collaborate through Precoro’s Supplier Portal to maintain accurate, up-to-date vendor information and performance data.