14 min read

Unlocking Success: Why Strategic Sourcing Matters

Would you like to improve your procurement process, develop supply channels, and gain a competitive advantage? Let's see how strategic sourcing can be helpful with the task.

The dynamic landscape of modern business comes with increasing product variety and volatile prices, making it more important than ever to stay competitive on the market. To enhance their competitive edge, companies across industries are adopting a key tactic: strategic sourcing.

Strategic sourcing is a holistic approach to supply chain management that includes tactics for optimizing the total cost of ownership, improving supplier relationships, and ensuring long-term value creation. In this blog post, we explore what constitutes the strategic sourcing process, how to design and execute such a process, and how it can help your organization thrive.

In this article, read about the following:

- What strategic sourcing is

- The difference between strategic and typical sourcing

- What the strategic sourcing process looks like

- Qualities of effective sourcing professionals

- How companies can achieve a competitive edge through strategic sourcing

- The role of technologies in strategic sourcing

Defining Strategic Sourcing

Before getting into strategic sourcing, let’s first define the more simpler activity: sourcing. As part of the larger procurement process, sourcing involves finding and evaluating suppliers for goods or services that need to be purchased. Sourcing tasks include sending out requests for proposals (RFPs), evaluating supplier bids, selecting vendor partners, negotiating contracts, and then managing supplier relationships.

Often, the purpose of sourcing is simply for companies to find the supplier or vendor that offers the best price for the required item. Goals beyond the best purchasing price fall into strategic sourcing.

Strategic sourcing is a systematic and disciplined approach to developing, structuring, and optimizing the company's supply chain. It prioritizes not just the lowest purchase price, but the lowest total cost of ownership — meaning the total cost of a product or a service during its lifecycle, including purchase, maintenance, repair, staff training, support, security, and other costs.

Strategic sourcing involves the meticulous evaluation of suppliers and the overall procurement process to extract maximum value from both. With strategic sourcing, historical and current data are collected in order to analyze established processes, predict market requirements, maximize purchasing power, and align purchasing strategy with organizational objectives. The goal of strategic sourcing is to streamline supply chain management, increase efficiency in acquisition, reduce risk, and improve price financial forecasting visibility — all of which result in boosted profitability.

The Difference between Strategic and Typical Sourcing

The main difference between strategic and regular sourcing is that strategic sourcing is a dynamic, comprehensive process focused on the total cost of ownership; regular sourcing, on the other hand, keeps it simple by primarily focusing on the purchasing price. Simple sourcing takes less time to execute and requires fewer resources to plan, but can cost more down the road. Strategic sourcing is more complicated, but it considers all the expenses and savings that might arise over the lifecycle of a purchased product or service.

In many cases, new companies start with simple sourcing to get the procurement process rolling. As the business grows, sourcing evolves to become more strategic. Businesses, especially those working internationally, have to deal with complex international compliance requirements, supply chain disruptions, and ever-evolving consumer behaviors that require them to replace simple sourcing with its strategic variant. Companies often need to establish a new vendor management lifecycle that ensures each supplier decision is made carefully.

Sourcing teams work as strategic advisors who can offer their market knowledge and leverage negotiation power to find the best offer and build strong supplier relationships. It's not about the lowest price anymore, but rather about security in the established partnerships, minimized risks, and continuous supply availability.

In the strategic sourcing process, the price is just one component of the big picture. Company priorities extend far beyond just the purchasing price, so strategic sourcing also considers the following factors:

- Delivery price

- Delivery speed

- Quality and durability

- Servicing requirements

- Regulatory compliance

- Innovation

These factors should be weighed against each other, as well as against the purchasing price.

How the Strategic Sourcing Process Works

Strategic sourcing is done through identifying the best suppliers, negotiating favorable contracts with them, and maintaining long-term relationships, as well as through continuous improvements to the purchasing workflows.

Strategic sourcing requires a teamwork-oriented work environment, as sourcing professionals have to collaborate with the top management to prioritize the company's needs and develop sourcing plans. Collaboration with finance teams is critical, too, as it leads to a more comprehensive understanding of a business’s back-office operations, thereby allowing for better strategic planning and response to changes.

Let's see how the typical strategic sourcing process would look. This is applicable to organizations purchasing different types of goods (both raw materials and finished goods) or services.

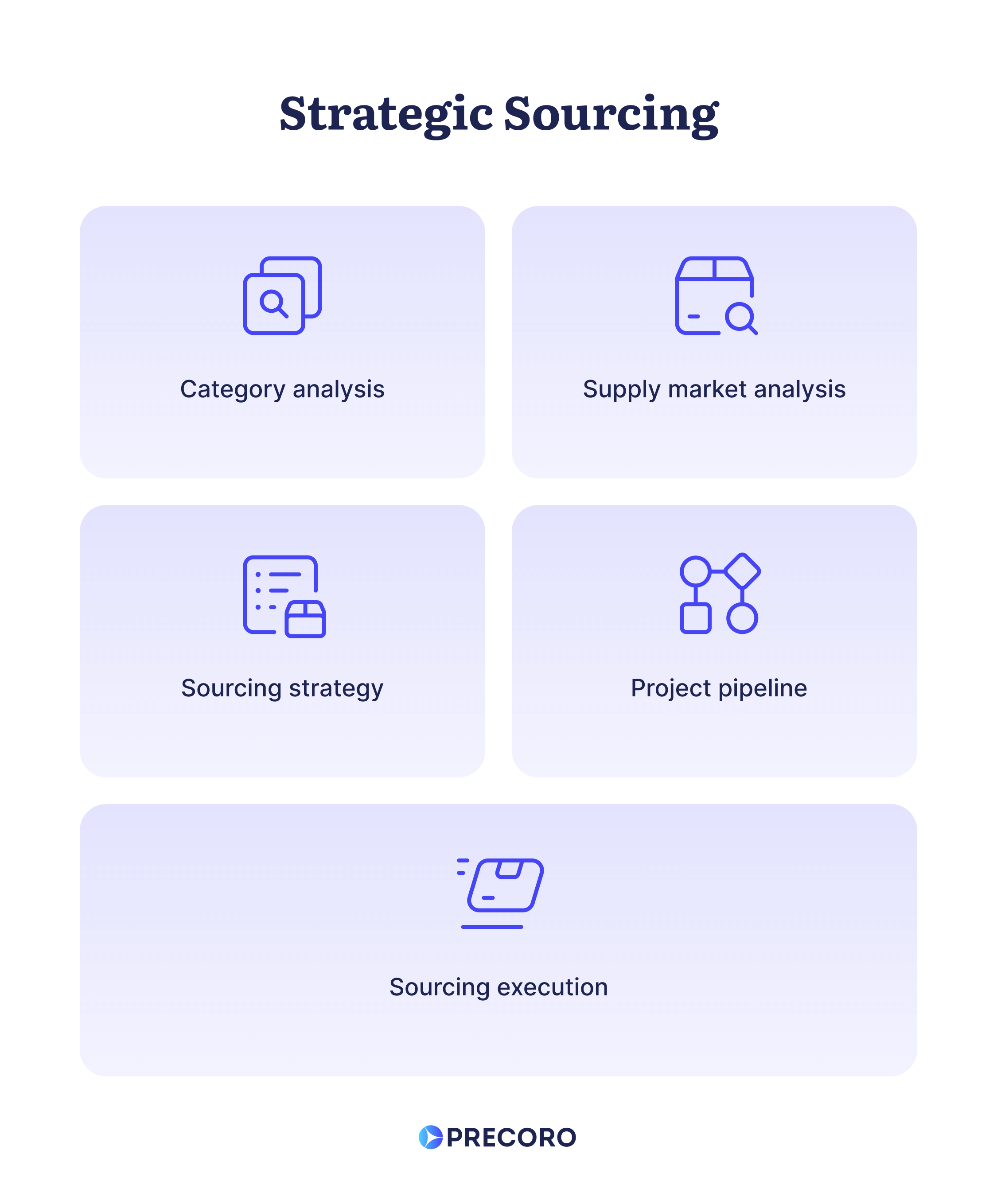

Step 1. Category analysis

The sourcing team together with the stakeholders (typically top management) analyzes the business needs and requirements of specific departments, identifies current spending patterns, and categorizes the typical purchases according to purpose, quantity, and purchase frequency. Such analysis is essential for understanding procurement requirements.

Step 2. Supply market analysis

The sourcing team researches the supply market and gets a qualified overview of what it has to offer. Such research helps them to better understand the vendors and suppliers operating on the market, as well as the competition, available prices and price development trends, and potential risks. It's important to understand the market in order to negotiate for better bargains.

Step 3. Sourcing strategy

Next, the sourcing team creates an actual sourcing strategy. There are several aspects to cover when preparing the sourcing strategy. The final outcome depends on the type of business and the final product. Let’s look at some of the decisions that sourcing managers need to make.

- Whether to make or to buy. The sourcing team decides whether they can and should produce some of the required products in-house, or whether to purchase them.

- Building risk strategy. The sourcing team anticipates which risks the company could encounter while conducting business. This concerns different stages of business operations: from purchasing necessary goods or services and all the way to distributing the final product.

- Building sustainability strategy. The company needs to define where they stand on sourcing and production sustainability. By establishing requirements and formalizing them in a corporate sustainability strategy document, teams can significantly limit the number of potential suppliers.

- Target cost. Another thing that the sourcing team determines within the sourcing strategy is the desired product’s life-cycle cost. In a way, it’s an answer to the following question: how much can we spend on the materials to then generate desired profit from the final product?

- Create a purchasing process. The procurement team establishes the purchasing process in order to get a clear understanding of what’s expected from the suppliers or vendors and everyone else involved.

- Build a supplier portfolio. Finally, the sourcing team creates a portfolio of potential suppliers and vendors that have the potential to meet the company needs.

Step 4. Project pipeline

The sourcing team then defines criteria for narrowing down the supplier portfolio, with the goal of eventually arriving at a “winner.” As part of this, they analyze whether or not the business priorities and governance styles of potential suppliers align with the purchasing company’s principles. The sourcing professionals also evaluate how the suppliers operate and mitigate risks, and whether they can meet the purchasing company’s requirements in terms of product quality, accessibility, and price.

Step 5. Sourcing execution

Building the supplier selection process. The sourcing team comes up with a repeatable process for selecting the right suppliers. It usually incorporates a bidding process, during which the purchasing company sends out a request for proposal (RFP) and the potential supplier responds with their proposal. The sourcing team then creates the RFP criteria and template. The criteria should include a description of the issue and requirements for the anticipated product or service, price per unit, total budget, delivery terms, and other relevant terms and conditions. If needed, the purchasing company can also follow up with a request for information (RFI) to gather any additional information for final comparison and decision.

Negotiating contract terms. After shortlisting potential suppliers or vendors, the purchasing company representatives (typically the sourcing manager together with the legal team professional) initiate contract negotiations. At this step, both parties are looking to negotiate the most beneficial offer for themselves, so it might take several rounds to achieve compromise and arrive at the best possible contract terms. Key information present in the finalized contract should include the product or service description, pricing per item and tax information, delivery and payment timeframes, and payment methods. If requested, any additional terms and conditions can be included.

Integration and implementation. Once the contract is signed by both parties, the company onboards new vendors and suppliers, establishes clear communication channels, and integrates them into the existing procurement processes. At this point, both parties are ready to carry out the contract terms.

Benchmarks, analysis, and improvements. The sourcing team, in cooperation with procurement specialists and management, establishes performance metrics (KPIs, key performance metrics) and monitors sourcing success. That includes tracking how well the suppliers perform and if the company's needs are met. Establishing benchmarks for successful performance and analyzing them continuously allows the company to identify potential issues as soon as possible and take measures to improve the process.

The Impact of Market Analysis on Sourcing Decisions

Market analysis plays a significant role in making strategic sourcing decisions. Sourcing professionals analyze the market to understand global trends and preferences of consumers, estimate the likelihood of risks, and evaluate supply chain conditions. This allows the sourcing team to understand supply and demand dynamics and the competitive landscape and, as a result, the pricing trends.

Market analysis also helps organizations pinpoint areas of improvement and identify possible cost-saving opportunities and alternative sourcing options. Market data plays a pivotal role in establishing contracts and renegotiating existing contracts in order to secure the best value for the organization.

The Art of Negotiating Contracts

Contract negotiation is an integral part of strategic sourcing, as contracts help organizations secure favorable terms and conditions, mitigate risks, and build long-lasting partnerships with suppliers. To prepare for contract negotiation in strategic sourcing, it is important for the sourcing team to accomplish the following steps:

- Defining procurement goals for different kinds of suppliers

- Recognizing the negotiation styles of both parties

- Understanding supplier perspective on potential deals

- Practicing active listening

- Preparing contract terms

- Assembling a competent negotiation team

- Being ready to communicate and iterate by moving forward step by step

Thorough contract negotiation helps businesses secure the best possible deals. In addition, by setting non-negotiables, the buying company representatives can make sure their organization's interests are well looked after and their key principles are considered.

Unlocking the Power of Supplier Relationships

Strong supplier relationships are beneficial when it comes to strategic sourcing, as they increase the likelihood of supplier accountability, reliability, and flexibility. Building strong supplier relationships in strategic sourcing involves focusing on continuous and strategic supplier relationship management (SRM). That means engaging in open communication, setting clear expectations, establishing supplier performance metrics and milestones, and promoting mutual success.

A good practice is to evaluate suppliers according to key performance indicators, such as:

- Quality of goods or services

- Cost of goods or services

- Delivery time and quality

- Responsiveness of supplier representatives

Tracking KPIs enables procurement professionals to objectively evaluate current suppliers and identify areas for improvement. The metrics also serve as guidelines for evaluating potential partners to purchase from.

Strong supplier relationships can lead to long-term beneficial partnerships that help secure better offers. They also tend to lower price volatility, transaction costs, and chances of availability problems, delays, or quality issues. These benefits can ultimately lead to a competitive advantage in strategic sourcing.

What Makes Sourcing Professionals Effective?

Sourcing professionals are typically responsible for strategic sourcing. They collaborate with stakeholders, lead negotiations, and use their extensive product knowledge and problem-solving skills. The main responsibilities of sourcing professionals include:

- Analyzing products and services from suppliers

- Conveying the advantages of strategic sourcing and procurement to relevant stakeholders

- Engaging in negotiations with suppliers

- Formulating and optimizing procurement strategies consistent with business objectives

- Conducting supplier performance assessments

Sourcing professionals should be skillful negotiators and effective collaborators. They should not only align with the stakeholders to identify the business needs but also partner with the suppliers to ensure their needs are met and the partnership can flourish. Generally, sourcing professionals have a few skills that help them accomplish all of this.

Emotional Intelligence. Sourcing professionals should have the interpersonal and communication skills to expertly navigate negotiations, tough conversations, and the emotions of others. High EQ helps these employees "read the room" and stay empathetic to suppliers and stakeholders while remaining focused on the deal.

Creativity. Since strategic sourcing involves cooperation with several internal departments and external partners, it requires sourcing professionals to come up with solutions for cross-departmental and even cross-company challenges. In addition to this, the sourcing team has to react to market shifts and disruptions while minimizing the impact on the final product — and that's a challenge that often requires "out of the box" thinking.

Extensive Product Knowledge. In order to find the best suppliers and vendors for the company, the sourcing professional needs to understand the details of their company's production cycle and the final product or service. In addition to this, thorough product knowledge helps the sourcing team predict potential risks better and mitigate them by contracting suppliers who are flexible enough to adjust to the changes. Finally, sourcing professionals with good product knowledge can recognize the suppliers who are fit to help drive innovation.

Understanding of Market. The most efficient strategic sourcing leaders aspire to not only meet the current business needs, but also think forward, anticipate how market shifts might affect the business needs over time, and consider how to meet them. By staying one step ahead, the sourcing team can close favorable deals that will remain that way even amidst change.

Data-Driven Approach. Strategic sourcing has to rely on data. When sourcing professionals prioritize data and metrics in the decision-making process, it's easier for them to win over the stakeholders and negotiate good deals with suppliers. Sourcing professionals can leverage data to identify saving opportunities and better demonstrate the impact of sourcing on overall business success.

Achieving a Competitive Edge Through Strategic Sourcing

Sourcing and procurement teams often operate behind the scenes, but they are both vital to the success of the business. When both teams cooperate, the organization gets a comprehensive understanding of their back office operations and budgeting principles and can select the most appropriate supplier to cover the operational needs within the allocated budget.

Strategic sourcing allows organizations to gain a competitive advantage by lowering costs, mitigating risks, and promoting innovation through robust supplier partnerships. It also contributes to supply chain resilience by helping to build strong supplier relationships and optimize procurement decisions.

In addition to this, organizations that approach the sourcing process strategically can ensure the synergy between the company procurement and general business goals. When sourcing practices are aligned with general business goals, procurement activities contribute to the overall success of the organization, rather than hinder it with bad deals or maverick spend.

By staying abreast of changing priorities and clearly articulating sourcing objectives at any given moment, organizations can continuously drive business growth and build enduring value. Let's delve into some of the specific benefits of strategic sourcing and how they’re achieved.

Cost Efficiency and Savings

In the realm of business, where every penny counts, cost savings and efficiency are crucial. Strategic sourcing is a potent tool that lets organizations streamline their procurement processes, negotiate better deals, and ultimately reduce costs.

By identifying the most cost-effective suppliers through detailed market analysis and negotiating favorable terms with them, an organization can significantly improve its bottom line. Such favorable terms can include, for example, various discounts such as volume-based and early-bird discounts. Strategic sourcing professionals can also assist the procurement department in identifying suppliers who can offer better deals and conditions.

Risk Mitigation

Strategic sourcing can help identify and assess potential risks in supplier markets and devise sourcing plans to enhance risk management. Some of these practices include diversifying suppliers, implementing a system to monitor supply chain visibility, and regularly evaluating suppliers.

In an interconnected global economy, businesses are exposed to various risks ranging from geopolitical uncertainties to supply chain disruptions. Strategic sourcing takes a holistic approach to risk management and involves developing strategies to not only deal with the consequences but also introduce preventive measures and so-called “plans B and C.”

Innovation and Collaboration

Strategic sourcing leads to better supplier partnerships, which in turn leads to better opportunities for fostering innovation. Organizations who establish long-term, trusted relationships with suppliers are more likely to engage in idea-sharing and joint problem-solving.

This ultimately creates an environment where innovation thrives and both parties can mutually benefit. For instance, suppliers are more likely to offer innovative opportunities to their regular customers, who in turn are more likely to cooperate on potentially groundbreaking product developments.

Quality Assurance

Part of strategic sourcing involves establishing internal quality benchmarks and criteria to make sure goods are up to standard. Then, quality assessments and rigorous supplier evaluation are conducted prior to signing contracts. By doing this companies can enhance product quality, customer satisfaction, and brand reputation. All of that, in turn, has a positive long-term impact on customer loyalty.

Better Compliance and Ethical Sourcing

In an era where corporate social responsibility (CSR) is gaining prominence, strategic sourcing plays a pivotal role in ensuring practices that are ethical and compliant with the law. By verifying suppliers' adherence to social and environmental standards, companies can commit to higher ethical and quality standards for the materials, goods, and services they use.

In line with the strategic sourcing practices, companies also follow the evolving landscape of regulatory compliance and discuss how sourcing practices can be adapted to meet changing legal requirements. Beyond the adherence to legal requirements, ethical sourcing can also have a great long-term positive impact on brand image and customer perception.

Improved Adaptability

Markets evolve, and so should a company’s procurement strategy. Strategic sourcing is inherently flexible, allowing companies to adapt to changing market conditions seamlessly. When sourcing practices are guided by data analytics, businesses can stay ahead of the curve in a rapidly evolving business environment and respond to market trends, economic shifts, emerging technologies, and potential risks.

Operational Efficiency

Efficiency is the backbone of successful businesses. Through strategic sourcing, organizations can optimize supplier evaluation and contracting processes, streamline communication, and ensure a higher level of accountability. All of that results in reducing lead times, enhancing overall operational efficiency, minimizing supply waste, and improving resource utilization.

To centralize the data, automate the sourcing process, minimize human errors, and ensure maximum accountability (both on the purchasing company’s and the supplier’s sides), more and more organizations are introducing specialized software solutions.

The Role of Technologies in Modern Strategic Sourcing

Technologies like procurement software are revolutionizing strategic sourcing by automating tasks, offering in-depth data insights, and improving collaboration among stakeholders. Procurement automation tools can enhance operational efficiency and lower risks by automating tasks, minimizing human intervention, validating supplier data, and guiding employee activities.

Sourcing and procurement teams can also manage supplier databases and inventory more easily, automate requesting and approving, track the movement of goods, monitor documentation flow, and control budgets. This provides transparency that is invaluable in ensuring sourcing success and supplier compliance.

Vendor management software like Precoro not only helps to boost operational efficiency and transparency, but also offers analytic capabilities like custom report generation to help companies understand their data better and predict trends. Contact us to discuss how Precoro can enhance sourcing and procurement processes for your company. You strategize — we help to execute.

Key Takeaways

Strategic sourcing is a necessity for companies that hope to thrive in a competitive landscape, and it comes with a lot of benefits. It’s a powerful approach to improving procurement processes and supply chain management market adaptability.

By focusing on the total cost of ownership, supplier relationships, and long-term value creation, strategic sourcing can help organizations reduce costs, mitigate risks, and foster innovation. As your company explores the realms of strategic sourcing, it embarks on a transformative journey toward sustained growth and resilience in the ever-evolving business landscape.