15 min read

Single Source vs. Sole Source: What Is the Difference?

Find out the differences between single source vs. sole source, along with their benefits, challenges, and examples.

The difference between sole source vs. single source is on the surface. In single sourcing, your company selects a single supplier exclusively, even though there are other capable suppliers on the market. For example, you might choose one electronics manufacturer to supply all your circuit boards, even if five others could do it too. The reason? You want bulk discounts, faster delivery from a familiar partner, or better coordination across orders, which are usually formalized through single-source contracts that lock in these benefits.

In sole sourcing, you don’t have a choice—only one supplier can provide what you need. When a product or service is sole-sourced, for instance, a patented chemical made exclusively by one company, you’re locked in. It means that the sole-source supplier controls the price and terms, which is often called a monopolistic supplier.

While both procurement strategies have their uses, don’t spend precious time debating single source vs. sole source. We’ve created a helpful guide that explains the sole sourcing definition and the meaning of single sourcing, packed with benefits, challenges, and examples of each. So, in the end, you’ll be 100% clear on the difference between single vs. sole source.

Find out more about:

What is single sourcing?

Examples of single-source procurement

What is sole sourcing?

Examples of sole-source procurement

Key differences between single sourcing and sole sourcing

Advantages and disadvantages of single sourcing vs. sole sourcing

Challenges of single source and sole source

Single source vs. sole source: What to choose?

Frequently asked questions about single and sole sourcing

What is single sourcing?

Single sourcing is a strategy in which a company decides to purchase all its products or services from a single supplier, even though many other qualified suppliers offer the same goods and services.

At its core, single sourcing is about nurturing a close partnership that delivers benefits such as better pricing, steady quality, and improved communication flow.

Examples of single-source procurement

Witness single sourcing in action. Below, we’ve showcased a few scenarios where businesses rely on one supplier to simplify operations, reduce risks, and build stronger partnerships.

Scenario 1: Reliable surgical gloves from a single certified supplier

A hospital network needed surgical gloves that met strict safety and hygiene standards to protect patients and staff. They had been working with multiple suppliers but faced inconsistent quality and delayed deliveries, which disrupted operations. To address this issue, the procurement team decided to single-source from a certified supplier who could consistently meet all their requirements, offer competitive pricing, and maintain reliable delivery schedules.

Scenario 2: High-performance EV batteries from one supplier

An automotive company is designing a new electric vehicle that requires a specialized battery pack. The company’s current battery supplier can’t meet the higher quality standards the company needs. So, the procurement team evaluates several battery manufacturers.

After checking out who meets all the technical specs and environmental requirements, they pick one supplier that not only fits the bill but also offers better delivery terms—faster and at a better price. They made a single-source contract with that supplier to keep the project on track without lowering quality.

What is sole sourcing?

Sole sourcing is a strategy where a company selects the supplier because there is no other option available on the market, or nobody can fulfill the order for the required product or service.

This procurement strategy comes into play when the vendor owns exclusive rights, patented technology, or unique expertise that no other vendor can possess. It’s basically the core of the overall sole source meaning.

Examples of sole-source procurement

The following examples show how businesses face unique challenges that leave them no choice but to rely on a single trusted supplier.

Scenario 1. Unique coffee beans from one roaster

A local coffee shop wanted to offer a unique espresso blend that gave them a competitive edge. They sourced beans from several roasters but never quite achieved the flavor they wanted. After extensive searching, they discovered a small nearby roaster who produced a rare bean grown in a microclimate and delivered exactly the taste profile they needed. Since no other roaster could provide this specific bean, the coffee shop sole-sourced its beans from this roaster to maintain consistency and keep its signature flavor exclusive.

Scenario 2. Exclusive software plugin for a game

An independent game development studio needed a specialized software plugin that added unique graphics capabilities to their project. The plugin was patented and developed by a single company with exclusive rights to distribute it. Without any alternative products available, the studio had to source the plugin to complete the game on schedule and deliver the intended user experience.

Key differences between single sourcing and sole sourcing

Here are the primary differences between the two procurement approaches:

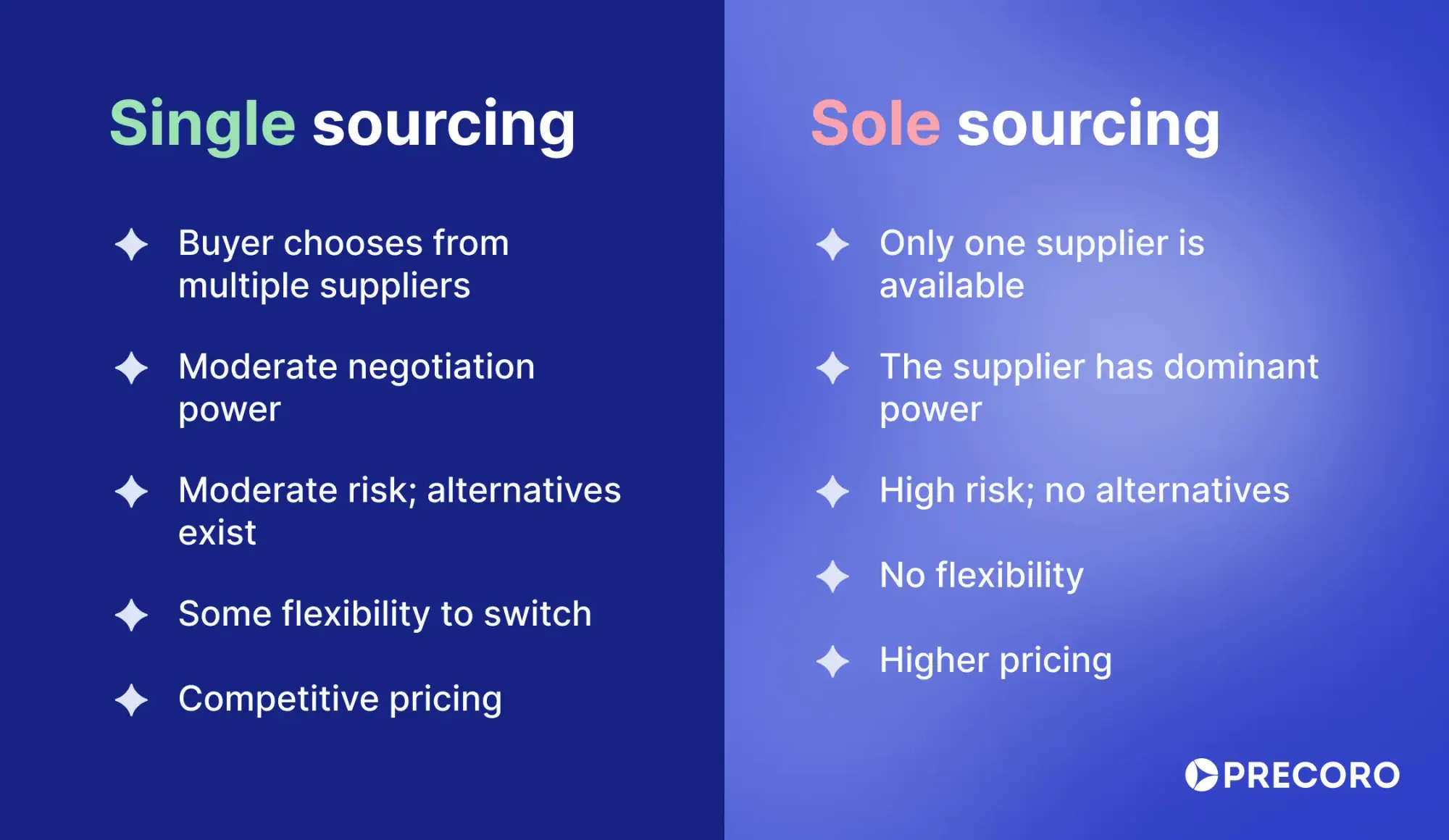

Supplier choice

In single-source procurement, there are many other vendors, yet you choose one exclusively. The reason for the choice may be performance, cost, or convenience. If any problem arises, you can switch to another single-source supplier, but it takes time and effort.

In sole sourcing, there is only one supplier, and the company has no other option. The single-source provider has a patent, certification, or exclusive capability. If problems arise, you have no place to go; you’re locked in, and that’s it.

Dependency

In single sourcing, you depend on one supplier. However, you’ve got a backup plan (or at least the option to create one). Switching will incur costs, delays, and approvals, but it’s possible.

In sole sourcing, you’re 100% dependent. If the sole-source supplier has issues—factory fire, bankruptcy, labor strike—you’re in trouble. No second option, no safety net.

Negotiation power

With single sourcing, you can negotiate more effectively. The single-source provider knows that the buyer can turn to any other vendor if the costs become too high or the process becomes too complicated. That factor keeps prices, delivery terms, and service more reasonable.

Sole sourcing gives the buyer no power. Since there are no other suppliers to turn to, the buyer must accept whatever price or terms the supplier sets, even if they’re not fair or reasonable.

Risk

With single-source procurement, you can explore other establishments if your primary choice cannot meet your requirements. Thus, this approach allows some room for risk diversification, which decreases the chance of incurring a great loss.

On the other hand, sole sourcing can increase risks, as you have no alternative if your supplier fails to meet your requirements.

Flexibility

Single sourcing leaves room for flexibility as companies can choose to switch suppliers if necessary. However, changing a single-source supplier takes effort: contracts, quality checks, and training. It’s not fast, but it’s doable.

Sole sourcing leaves no room to maneuver. Want to scale faster? Only if the supplier can. You don’t control the pace.

Pricing

With single sourcing, you get competitive pricing. The supplier knows they’re being compared to others, even if you’re not actively shopping. Such competition keeps things honest.

If you opt for sole sourcing, expect higher costs. With no competition, the supplier sets the price. You’re not negotiating—you just have to accept their terms.

Quality

When comparing sole source vs. single source, it’s important to understand how supplier behavior changes. In a sole-source situation, suppliers know they must stand out to be chosen by you. So they work harder to give you good options. They want to impress you.

But when you sole-source, the supplier knows they’re the only option. So they might not feel the need to come up with new ideas or improve solutions. You might get the same thing over and over with no changes.

Advantages and disadvantages of single sourcing vs. sole sourcing

Before locking in a supplier, know the trade-offs. Weigh the advantages and disadvantages of single vs. sole source, so you’re not caught off guard later.

Single sourcing advantages

- Better pricing through volume discounts with one supplier.

- One supplier means steady quality and prices.

- Orders come faster with single sourcing.

- Easier to build trust with one supplier.

- Less admin work with just one supplier.

- Simple system integration with one supplier.

Single sourcing disadvantages

When you’re tied to one supplier, they hold the upper hand. Without competition, there’s little incentive for them to lower prices or improve terms. This highlights a key difference in single-source vs. sole-source strategies: both limit options, but the lack of competition can lock you out of better deals or new technologies. For instance, if a competitor’s supplier develops a faster, cheaper component, you’re stuck with whatever your single supplier offers.

Sole sourcing advantages

- The management of a sole-source supplier cuts down on coordination and paperwork.

- You get access to the supplier’s unique skills and services.

- You avoid time-consuming supplier searches.

- The supplier understands their products inside and out.

Sole sourcing disadvantages

Sole sourcing often results in weaker cooperation and higher dependence, which can lead to lower supplier quality. This situation reflects the sole sourced meaning, where a company relies entirely on one supplier without alternatives. With no other options available, procurement costs tend to be higher because there’s less room to negotiate better prices. Additionally, since the supplier focuses solely on your product, if they become overwhelmed with orders, it can cause delays that disrupt your supply chain and operations.

Challenges of single source and sole source

Both single-source and sole-source procurement strategies come with their own set of challenges. Limitations can impact cost, supply reliability, and operational flexibility. Understanding these issues and their solutions will help you make a clearer choice in the sole-source vs. single-source decision.

Single sourcing challenges

There are clear benefits to single sourcing, but it can also create problems that hit both your operations and your future strategy.

Supply chain disruptions

A single supplier’s issues—such as natural disasters, labor strikes, or financial instability—can halt production and skew the entire supply chain plan. For example, the 2011 Japan earthquake disrupted Toyota’s supply chain due to reliance on single suppliers for specific parts.

Limited bargaining power

With only one supplier, negotiation leverage is reduced, potentially leading to higher costs or unfavorable terms. Suppliers may exploit this dependency, especially if switching costs are high.These challenges are common in both single-source vs. sole-source procurement.

Quality risks

If the supplier’s quality falters and there’s no immediate alternative, you risk defective products or delays. For instance, Boeing’s reliance on a single supplier for 737 MAX components caused issues when quality problems arose. This case highlights a core risk shared in single-source vs. sole-source strategies.

Capacity constraints

A single supplier may struggle to meet demand spikes, causing delays or lost sales. This was evident during COVID-19 when medical supply chains, reliant on single sources, faced shortages.

Innovation stagnation

A sole supplier may lack the incentive to innovate or improve, limiting access to new technologies or efficiencies compared to multi-sourcing. This tendency highlights a key difference in single-source vs. sole-source approaches—while single sourcing may encourage some competition, sole sourcing can lead to complacency and slower progress.

How to manage the risk of single sourcing

Relying on one supplier means fewer headaches—until something goes wrong. Here’s how to stay prepared and keep your supply chain and finances secure.

- Build backup plans before things go wrong

Don’t wait until a supplier messes up to react. Have a solid backup plan ready so your business keeps running no matter what. - Keep an eye on your suppliers all the time

Just because a supplier was solid last year doesn’t mean they still are. What was a stable supplier last year may not be today. Regularly check their financial health and risks so you’re not caught off guard. - Make your single-source contracts tougher

Contracts shouldn’t just cover prices—they need to hold suppliers responsible and protect you if things go south. - Hold your long-term suppliers to high standards

Even trusted partners can slack off. Keep reviewing their performance and push for improvements to keep things running smoothly.

Sole sourcing challenges

Supplier dependency

Having only one supplier increases the risk of supply chain breakdowns. If that supplier has financial problems, production delays, or quality issues, the whole operation can be severely impacted.

Higher costs

With no competition, the supplier dictates the price, which means higher procurement costs. This is a typical downside in the debate of sole source vs. single source, where sole sourcing tends to limit negotiating power.

Quality control concerns

With no other options, the buyer may be stuck with lower-quality goods or services if the sole supplier fails to meet standards.

Limited innovation

When buyers are locked into a sole source, they risk missing out on industry trends, technologies, or approaches that other potential suppliers can offer.

Reduced negotiation power

Negotiation power is often weaker in the sole-source vs. single-source scenario when sole sourcing is involved. Basically, in sole-sourcing deals, power shifts to the supplier. This dynamic can reduce the organization's ability to negotiate favorable terms and conditions, as the sole-source supplier can dictate pricing and delivery schedules.

Compliance risks

If the sole supplier fails to meet regulatory requirements, the buyer may face legal penalties and damage to stakeholder confidence.

How to mitigate sole sourcing challenges

- Strengthen supplier relationships

Keep open and clear communication with suppliers. Use contracts that clearly outline expectations, include penalties for non-compliance, and offer rewards for good performance. Build long-term, trust-based partnerships, no matter whether you choose sole-source vs. single-source strategies. - Modify or redesign the product

Look for alternatives to modify or redesign the product to get rid of sole source dependencies. Even if a redesign isn't possible right now, simply considering it might open up the market to other suppliers. - Automate and centralize

Use digital tools to centralize and control spend and improve communication. Automate to reduce manual work and improve efficiency. Purchasing automation and centralization help manage the complexities that come with both sole-source vs. single-source procurement.

How to choose between single source vs. sole source

When weighing single-source vs. sole-source procurement, remember that sole sourcing is often not a choice but a necessity driven by constraints or lack of alternatives. Your procurement requirements and needs will determine which approach applies.

First, check your budget; then, assess the supplier costs, risks, and capabilities. Here are additional factors to help clarify which approach—single source vs. sole source—fits your situation best.

- Supplier availability: In the single-source vs. sole-source debate, if multiple suppliers can deliver, sole sourcing isn't possible. Single sourcing then becomes the practical option as it provides competitive pricing and alternatives in case the current supplier fails to deliver.

- Risk management: The risks differ greatly in single-source vs. sole-source decisions. With a sole source, you have no fallback if the supplier fails, which necessitates a contingency plan. Meanwhile, a single source offers more flexibility if problems arise.

- Cost: A single source usually means better pricing, as you have alternatives; a sole source usually costs more, as there is no competition.

- Industry regulations: Some industries require sole-source procurement by law, which means the single-source vs. sole-source choice may be dictated by compliance rather than preference.

Note!

From time to time, take a step back and ask yourself if your sole source is still valid. Many teams fall into the trap of “we’ve always done it this way” and ignore changing supply landscapes, putting the company at risk.

When to use single sourcing

Single sourcing works best when your procurement goal is to build long-term relationships and maximize the value from a trusted supplier. This model is widely used in the automotive, tech, and fashion sectors to maintain steady quality and control costs.

When to use sole sourcing

When only one supplier can meet specific technical or regulatory demands, sole sourcing is the only practical option. This model is frequently seen in healthcare, aerospace, and luxury sectors, where uniqueness and compliance are non-negotiable.

Frequently asked questions about single and sole sourcing

The key difference between single source vs. sole-source lies in supplier choice. Sole sourcing means there is just one supplier with no alternatives, whereas single sourcing means the buyer picks one supplier from several available. For example, a car manufacturer uses sole sourcing when only one supplier makes a unique engine part. However, he uses single sourcing to pick one preferred tire supplier from the list of qualified vendors. Knowing when to apply sole-source vs. single-source strategies can help balance risk and cost.

Review single-source vendors at least annually to ensure they meet your quality, cost, and delivery standards. If performance issues arise, review them more frequently—every six months or quarterly—before single-source contract renewal or after significant price increases. Thus, you’ll ensure compliance and keep your supply chain on track.

Instead of sole sourcing, organizations can issue limited RFPs to a small number of vendors, use a GSA schedule or a public framework contract, or competitively negotiate add-on services to increase supplier options and reduce risks. When deciding between sole source vs. single source, these options give you more control.

Not inherently. It becomes a red flag only when there is no apparent justification, a conflict of interest, the required documentation is missing, or there is a recurring pattern of awarding contracts without competition.

Examples include Oracle support renewals, SAP module upgrades, medical device parts tied to specific brands, and emergency repair contracts during outages. These cases require sole sourcing due to exclusivity, proprietary technology, or urgent needs.

Yes, a single source can eventually become a sole source. A single source can transition to sole source if, over time, other suppliers exit the market, technologies change, or contractual agreements create exclusivity. Understanding the differences in the single-source vs. sole-source dynamic helps companies prepare for this transition and manage related risks effectively.

Procurement costs often rise when a company relies on sole sourcing. Since there is no competition, as the sole supplier meaning implies, there is no other vendor available or chosen to provide a product or service. With no competition, the company loses negotiating power. Without other suppliers vying for the business, the sole supplier can increase prices or offer less favorable terms. When weighing single-source vs. sole-source options, remember that sole sourcing usually means higher costs because the supplier faces no competitive pressure.

To sum up

The key difference between single sourcing and sole sourcing is pretty simple but critical. Single sourcing means you’ve chosen to buy from one supplier even though others can supply the same product or service. This decision is often made to simplify management, get better pricing, or build a stronger partnership. Importantly, you still have options if things go wrong because other suppliers exist.

Sole sourcing, however, means there’s literally only one supplier who can provide what you need—no alternatives. This typically occurs when the product is unique, patented, or the supplier is the sole qualified source. That makes your supply chain more vulnerable because you depend entirely on that one supplier.

So, when deciding which path to take, consider your risk tolerance and the market. Single sourcing is a strategic choice to gain benefits, but with alternatives as a safety net. Sole sourcing is often a necessity that requires strong contracts and backup plans to handle supply disruptions.

After all, with a clear idea of single source vs. sole source in mind, you can manage risks properly, avoid costly interruptions, and keep your procurement aligned with business goals.